Corporate Headquarters: 1080 North 11th Street, San Jose, CA 95112 Phone: (408) 292-2214 Fax: (408) 292-2733

www.mountztorque.com

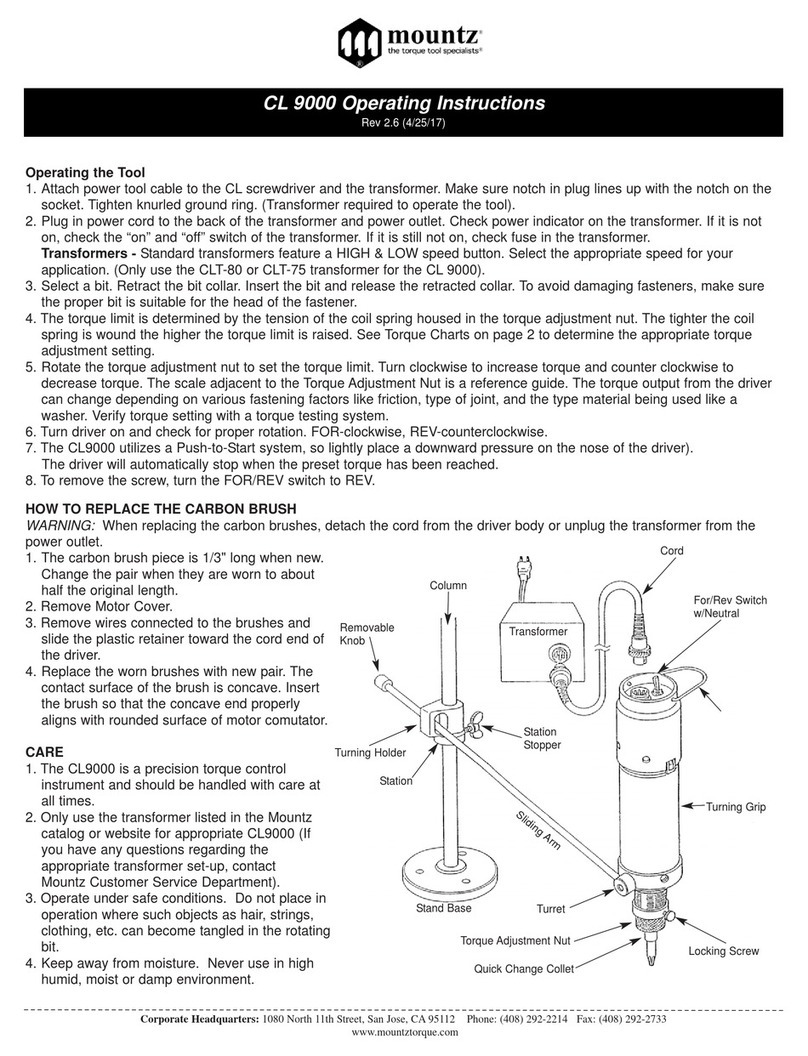

Maintenance Intervals:

The number of cycle shown on the table below should be used as a guideline for effective maintenance in order to reduce

unexpected down time. Maintenance intervals may be determined by the several approaches: number of cycles in use,

number of hours in use, type of joint, torque and calender time. All these factors should be considered for the best

preventative maintenance. The following inspection and replacement intervals will vary depending on tightening load and

cycle-on time.

Parts Descriptions Inspection Replacement

1. Carbon Brush 200,000 cycle 500,000 cycle

2. Motor 1,000,000 cycle 2,000,000 cycle

3. F/R Switch 1,000,000 cycle 2,000,000 cycle

4. Gear Case 1,000,000 cycle 3,000,000 cycle

5. Clutch 1,000,000 cycle 3,000,000 cycle

6. Cable 400,000 cycle 1,000,000 cycle

Testing Power Tools:

1. Application Method: Use a torque tester in “Peak Mode” with a rotary torque sensor between the power tool and the

actual fastening joint application. This is the best way to test since youare using the actual joint as the test station. You

will see the actual torque applied to the fastener. Caution: Variances in tool performance may occur do to the addition of

the rotary torque sensor.

2. Simulated Method: Always use a quality joint rate simulator (run down adapter) with a torque tester when testing power

tools in a simulated application. Use Joint rate and Breakaway methods

to obtain most accurate torque readings in a simulated rundown.

Service

Mountz Inc. features an experienced calibration and repair staff. Our trained

technicians can calibrate and repair most any tool. Mountz provides rapid

service with quality that you can trust as we offer three state-of-the-art cali-

bration lab and repair facilities that can calibrate up to 20,000 lbf.ft.

With over 45 years of experience, Mountz’s in-depth knowledge of torque is

reflected in our tool’s craftsmanship and our ability to provide solutions to

both common and uncommon torque applications. We perform calibrations in

accordance with ANSI/NCSL-Z540. Mountz is dedicated solely to the manu-

facturing, marketing and servicing of high quality torque tools.

Tool Service & Repair Capability

Torque Wrenches: Click, Dial, Beam, Cam-Over & Break-Over

Torque Screwdrivers: Dial, Micrometer, Preset & Adjustable

Torque Analyzers/Sensors: All brands

Electric Screwdrivers: All brands

Air Tools: All brands

Impact Wrenches, Drills, Pulse Tools, Grinders, Percussive Tools,

Air Screwdrivers, Nutrunners, DC Controlled Nutrunners

Torque Multipliers: All brands

EF-Series (EF080, EF120 & EF180) Operating Instructions

Mountz Service Locations

Eastern Service Center

19051 Underwood Rd.

Foley, AL 36535

Phone: (251) 943-4125

Fax: (251) 943-4979

Western Service Center

1080 N.11th Street

San Jose, CA 95112

Phone: (408) 292-2214

Fax: (408) 292-2733

www.mountztorque.com

Twitter: @mountztorque

Download a “Service Form” and include a copy

when you send the tools in to be serviced.

Looking for fasteners?

www.mrmetric.com