Mini EF-Series (EF030, EF040 & EF055 models)

Corporate Headquarters: 1080 North 11th Street, San Jose, CA 95112 Phone: (408) 292-2214 Fax: (408) 292-2733

www.mountztorque.com

Page 2

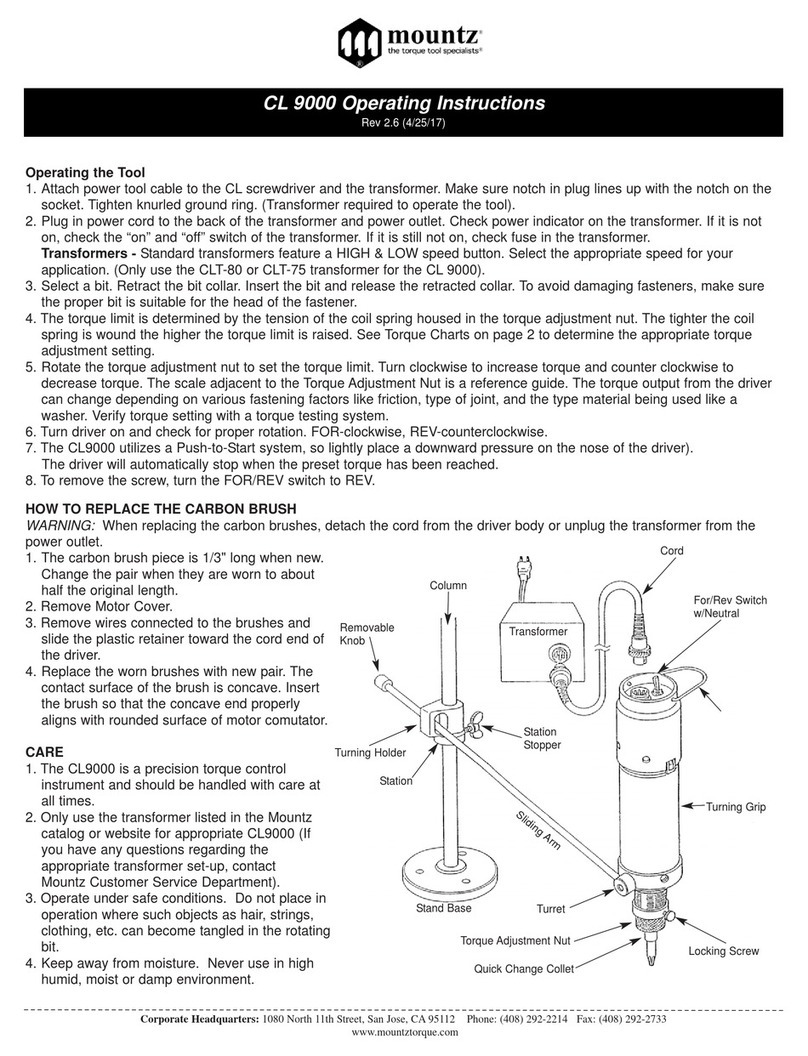

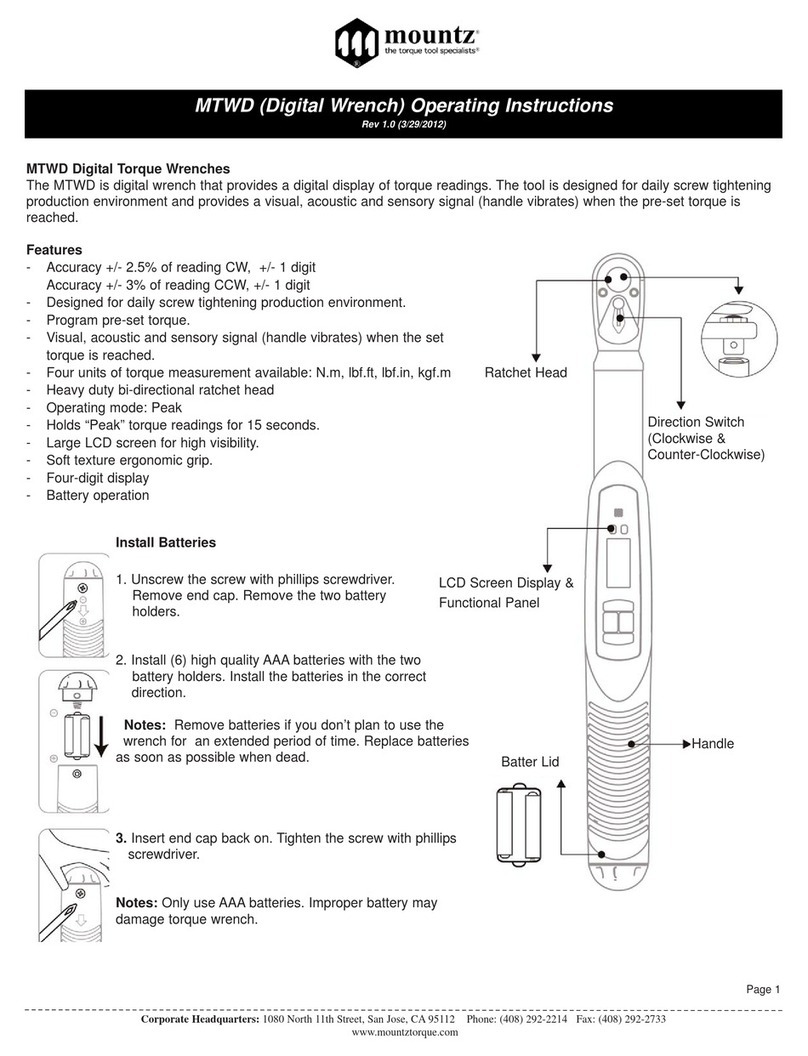

Plug for power

tool cable

Torque Adjustment Nut

Bit Collar Lever Torque Cover

(EF030, EF040 & EF055 models only)

Item # 145773

Protects from incidental or

operator tampering of torque

setting.

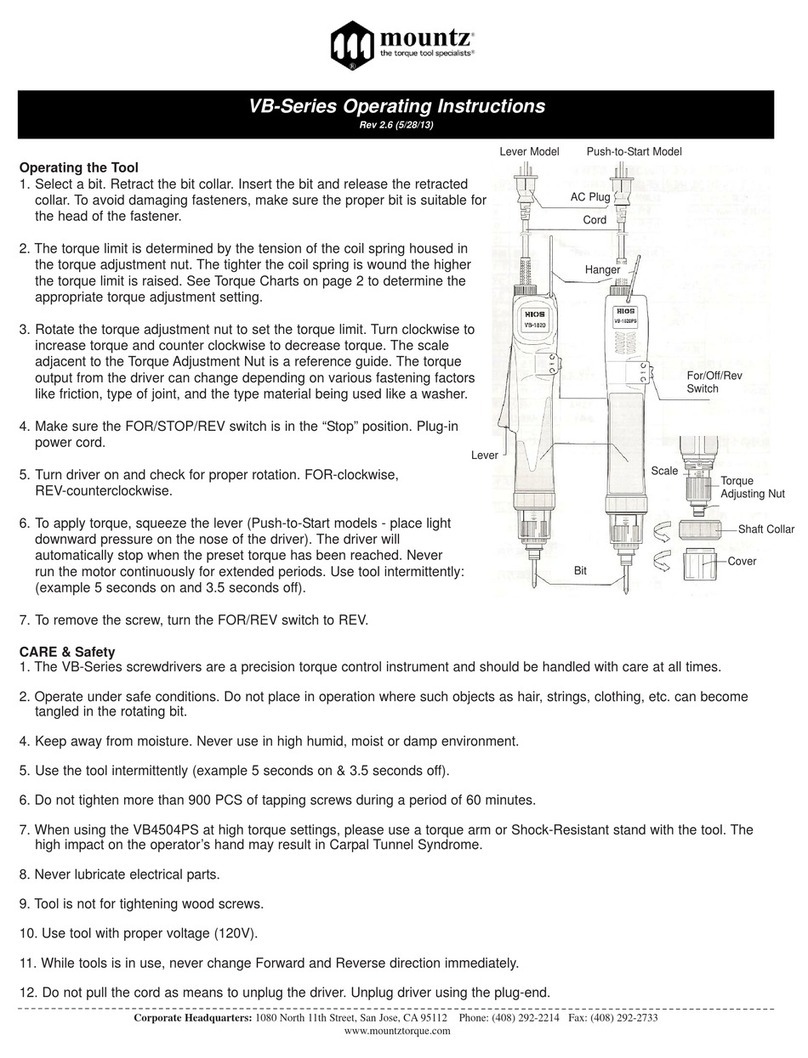

Operating the Tool

1. Attach power tool cable to the EF screwdriver and the transformer. Make sure notch in plug lines up with the notch on

the socket. Tighten knurled ground ring.

2. Plug in power cord to the back of the transformer and power outlet. Flip power switch to “ON” position located on the back

of transformer.

4. Select a bit. Retract the bit collar. Insert the bit and release the retracted collar. To avoid damaging fasteners, make sure

the proper bit is suitable for the head of the fastener.

5. The torque limit is determined by the tension of the coil spring housed in the torque adjustment nut. The tighter the

coil spring is wound the higher the torque limit is raised. See Torque Charts on page 3 to determine the appropriate

torque adjustment setting.

6. Rotate the torque adjustment nut to set the torque limit. Turn clockwise to increase torque and counter clockwise to

decrease torque. The scale adjacent to the Torque Adjustment Nut is a reference guide. The torque output from the

driver can change depending on various fastening factors like friction, type of joint, and the type material being used

like a washer. Verify torque setting with a torque testing system.

7. Turn driver on and check for proper rotation. FOR-clockwise, REV-counterclockwise.

8. To apply torque, squeeze the lever (Push-to-Start models - place light downward pressure on the nose of the driver).

The driver will automatically stop when the preset torque has been reached.

9. To remove the screw, turn the FOR/REV switch to REV position.

CARE

1. The EF-Series screwdrivers are a precision torque control instrument and should be handled with care at all times.

2. Only use the transformers listed in the Mountz catalog for appropriate EF driver model (If you have any questions

regarding the appropriate transformer set-up, contact Mountz Customer Service Department).

3. Operate under safe conditions. Do not place in operation where such objects as hair, strings, clothing, etc. can become

tangled in the rotating bit.

4. Keep away from moisture. Never use in high humid, moist or damp environment.

The Mini EF electric screwdrivers feature a motor with built-in

graphite brush (not replaceable brush)