Blades

and

inserts should be sharpened

with

a fine honing stone. When

the

bright

cylindrical

part

of

the blade has been

ground

away,

a

new

blade

must

be fitted.

The

edge

of

the

cutter

insert must also be

sharp

at

all rimes; resharpen

only

the

top

face.

From

time to

tim

e,

apply

a few drops

of

oil

to

the

slot

in

the

anvil

to

lubricate the blade guides. Also lubricate

the

cutting edge

by

apply-

ing a

little

oil

with

a brush along the scribed line

on

the·sheet. Slacken

screw (66), every day,

and

apply

a few drops

of

oil here, to lubricate

the slides

of

plunger (67), connecting linkage (72)

with

roller (73),

needle bearing (74)

and

ball bearing (46).

The

nibbler head being the

power

transmitting

element requires good

lubrication. The gear grease should be renewed

after

approx. 300

working

hours. Please,

only

use

our

special

FEIN

gear grease

Sst

1.

A mixing

of

this grease

with

other

greases endangers the greasing

capacities,

and

therefore

al

so

usc

Sst 1 grease for rhe roller bearings in

the gear head.

quantity

order

reference I contents

·rype I I

oz

g oz g

ISst 1 for gears 1 0.53 1

15

MZ

60-3/Sst

1 I 3.2 I

90

No

claims can be

entertained

for

damage

due

to

negligent maintenance

or

inadequate

lubrication.

After

900

working

hours

the machine s

hould

be cleaned thoroughly.

For

this purpose the machine

is

dismantled as described in

paragraph

5

and

the

individual

parts

are

then cleaned.

The

ball

be~rings

(33)

are rinsed

in

clean solvent

and,

when

dry,

packed

with

our

special

grease Sst 1.

In

orda

to

prevent

overheating

of

the

bearings

at

high

speeds

the

space between

inner

and

outer ring

of

the bearing should

be filled

only

about

1/a

with

grease.

5.

Dismantling

The

tool should

on

ly

be

taken

apart

by

an

expert,

wo

rking m the

following sequence:

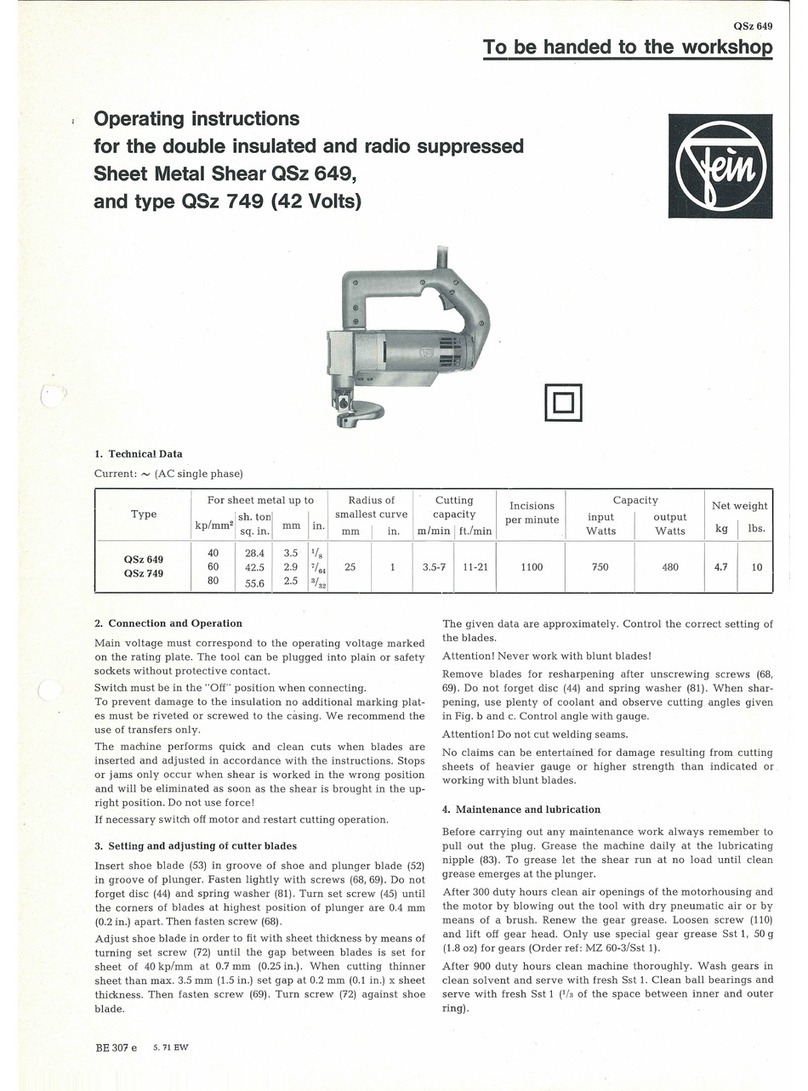

1. Unscrew screws (22, 23), then rake off handle cover (21).

2.

Loosen connection cable from switch (14)

and

draw

out

switch.

Clamp

off

motor

cable.

Unscrew screws (12),

take

out

carbon

holder

(10), remove screw

(16)

and

dr

aw

out

interference capacitor (15).

3.

Unscrew

two

hexagon socket screws (43)

and

remove

outer

bear-

ing (44), unscrew

four

cylindrical screws (57)

and

take

off

inter-

mediate bearing (40).

4.

Draw

out

armature

(26), unscrew three screws (31)

and

remove

armature

pinion (30).

5.

Draw

insulating ring (9)

out

of

motor housing (1), unscrew cylin-

drical screws (8)

and

tak

e

out

pole housing (6).

6.

Repair

and

Spare

Parts

We recommend

our

Fein Service Stations

to

carry

out

all

overh

aul

and

repair

work

quickly

and

expertly.

When

ordering

spare

parts,

please,

quote

model

and

serial

No

in

addition

to

order

reference

or

send

in

sample

part.

We

draw

your

attention

to

the need to

carry

out

a

high

voltage test

in accordance

with

your

local regulations (or

VDE

regulation 0740)

before

taking

a tool

into

service

after

any

repair

carried

out

by

y

our

own

staff.

(