Moxy MT 26 User manual

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 1

Chapter 1

Engine

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 2

Chapter 1

Engine

Index

Removal of engine assembly ................................................................ 5

Lifting the engine.........................................................................................................................11

Engine identification............................................................................ 12

Fuel system .......................................................................................... 13

Schematic diagram of the fuel system ........................................................................................13

Overflow valve.............................................................................................................................13

General .......................................................................................................................................14

FUEL...........................................................................................................................................14

Fuel filter .....................................................................................................................................15

Water separating prefilter............................................................................................................15

Feed pump ..................................................................................................................................17

Diagnostic prosedure .......................................................................... 18

Use of diagnostic kit, machine ....................................................................................................18

Measurement ..............................................................................................................................21

Ecom standard settings code......................................................................................................24

Engine control unit, ECU ..................................................................... 27

Wiring and cable duct..................................................................................................................28

Throttle position sensor...............................................................................................................28

Positions of sensors for ECU ......................................................................................................29

Diagnostic lamp and switch.........................................................................................................31

Fault codes..................................................................................................................................32

How to read fault codes from the ECU control unit .....................................................................33

Flash codes tables ......................................................................................................................35

Overview of flash codes for coordinator......................................................................................37

Renewing the control unit............................................................................................................39

Removing the ECU wiring ..........................................................................................................40

Cylinder head ....................................................................................... 44

Special tools................................................................................................................................44

Cylinder head, parts view............................................................................................................45

Valve mechanism ........................................................................................................................46

Dismantling ................................................................................................................................51

Renewing the valve stem seal.....................................................................................................51

Replacement of valve seats ........................................................................................................52

Machining the valve seats insert .................................................................................................53

Renewing the valve guides ........................................................................................................55

Renewing PDE unit injector sleeves ...........................................................................................56

Assembly ....................................................................................................................................57

Fitting ..........................................................................................................................................57

PDE Injectors........................................................................................ 58

Fitting the PDE injector ...............................................................................................................58

Adjusting unit injectors ................................................................................................................62

Adjusting the valve clearance and unit injectors .........................................................................64

Checking, adjusting the PDE32 injector rocker arms (I)..............................................................65

Turbocharger ........................................................................................ 67

General ......................................................................................................................................68

Special tools................................................................................................................................69

Measuring radial clearance and axial clearance ........................................................................70

Renewing the turbocharger.........................................................................................................72

Continuation next page

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 3

Pistons and cylinder liners.................................................................. 73

Special tools................................................................................................................................74

Connecting rods..........................................................................................................................75

Removing and dismantling connecting rods and pistons ............................................................76

Renewal of bearing bushing in connecting rod ...........................................................................78

Pistons ........................................................................................................................................80

Assembling piston and connecting rod .......................................................................................82

Cylinderblock........................................................................................ 83

Cylinder liner ...............................................................................................................................83

Removing the cylinder liners .......................................................................................................85

Measuring the cylinder liner height .............................................................................................86

Fitting the cylinder liners .............................................................................................................87

Fitting the piston and connecting rod ..........................................................................................88

Flywheel and flywheel housing........................................................... 90

Special tools................................................................................................................................91

Removing the flywheel................................................................................................................91

Renewing the rear crankshaft seal..............................................................................................93

Removing the flywheel housing ..................................................................................................93

Fitting flywheel housing...............................................................................................................94

Fitting the flywheel ......................................................................................................................96

Timing gears......................................................................................... 97

Gear drive ...................................................................................................................................97

Belt drive collant pump, generator and AC compressor..............................................................98

Renewing the seal in the front cover...........................................................................................99

Crankshaft damper....................................................................................................................100

Timing gear, view exploded.......................................................................................................101

Special tools ....................................................................................... 102

Crankshaft seal .........................................................................................................................103

Timing gear cover......................................................................................................................105

Intermediate gear......................................................................................................................107

Crankshaft gear ........................................................................................................................108

Camshaft gear ..........................................................................................................................109

Camshaft ............................................................................................ 110

Crankshaft .......................................................................................... 112

Lubrication system ............................................................................ 114

Oil pump....................................................................................................................................114

Lubrication oilways ..................................................................................................................115

Oil pressure...............................................................................................................................116

Oil cooler, engine .....................................................................................................................117

Oil cooler view...........................................................................................................................118

Renewing seals.........................................................................................................................119

Oil filter......................................................................................................................................120

Centrifugal oil cleaner ....................................................................... 121

Dismantling and assembly ........................................................................................................122

Cooling fan ......................................................................................... 126

Continuation next page

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 4

Cooling system .................................................................................. 127

View of the cooling system........................................................................................................127

Circulation .................................................................................................................................128

View of the radiator system.......................................................................................................128

Disassemble the cooling unit ....................................................................................................129

Thermostat and thermostat housing .........................................................................................131

Thermostat................................................................................................................................132

Coolant pump............................................................................................................................133

External cleaning ......................................................................................................................137

Internal cleaning........................................................................................................................137

Specifications..................................................................................... 138

General information...................................................................................................................138

Cylinder head............................................................................................................................140

Turbocharger ............................................................................................................................142

Pistons and cylinder liners ........................................................................................................142

Connecting rods........................................................................................................................143

Flywheel and flywheel housing .................................................................................................143

Timing gear ...............................................................................................................................144

Lubrication system ...................................................................................................................145

Troubleshooting tables ..................................................................... 146

White smoke .............................................................................................................................146

White smoke, water vapour.......................................................................................................146

Black smoke when running/under load .....................................................................................147

Black smoke on starting ............................................................................................................148

Blue smoke ...............................................................................................................................148

Fuel in the oil.............................................................................................................................148

Oil in coolant ............................................................................................................................149

Coolant/water in oil ...................................................................................................................150

Low oil pressure........................................................................................................................151

High oil pressure (Engine warmed up)......................................................................................153

Abnormal wear (liner, piston rings, etc.)....................................................................................153

Vibration, no driven components engaged................................................................................154

Delivery pipe fractures ..............................................................................................................155

External corrosion on cylinder liner ...........................................................................................155

Engine difficult to start...............................................................................................................155

Fluid stroke................................................................................................................................156

Knocking noise..........................................................................................................................156

High oil consumption.................................................................................................................158

High fuel consumption...............................................................................................................159

Low compression ......................................................................................................................159

Low engine output.....................................................................................................................159

Hot engine.................................................................................................................................161

Cold engine...............................................................................................................................162

Coolant loss ..............................................................................................................................162

Polluted coolant.........................................................................................................................162

Engine heater............................................................................................................................163

High oil temperature..................................................................................................................163

High exhaust temperature.........................................................................................................164

Low charge air pressure............................................................................................................164

Low fuel pressure......................................................................................................................165

Low system voltage...................................................................................................................165

High system voltage..................................................................................................................165

External oil leakage...................................................................................................................166

External fuel leakage ................................................................................................................166

External coolant leakage...........................................................................................................167

Oil pressed out via crankcase ventilation..................................................................................167

Turbocharger breakdown ..........................................................................................................167

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 5

Removal of engine assembly

NOTE!

Place the dump truck on level ground and apply parking brake

Apply articulation lock.

Turn off main switch in battery case.

Raise the dump body and lock it with the safety support.

Raise the tiltable cab and lock it with the safety support

Drain engine coolant

Look in OPERATION & MAINTENANCE MANUAL chapter 2 for instructions.

Take away the cab bolt, left and right hand side.

Nv 46 mm

Turn the direction valve on the pump in lifting up

position.

Place wheel chocks to the front wheel

With the handle, pump and raise the cab.

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 6

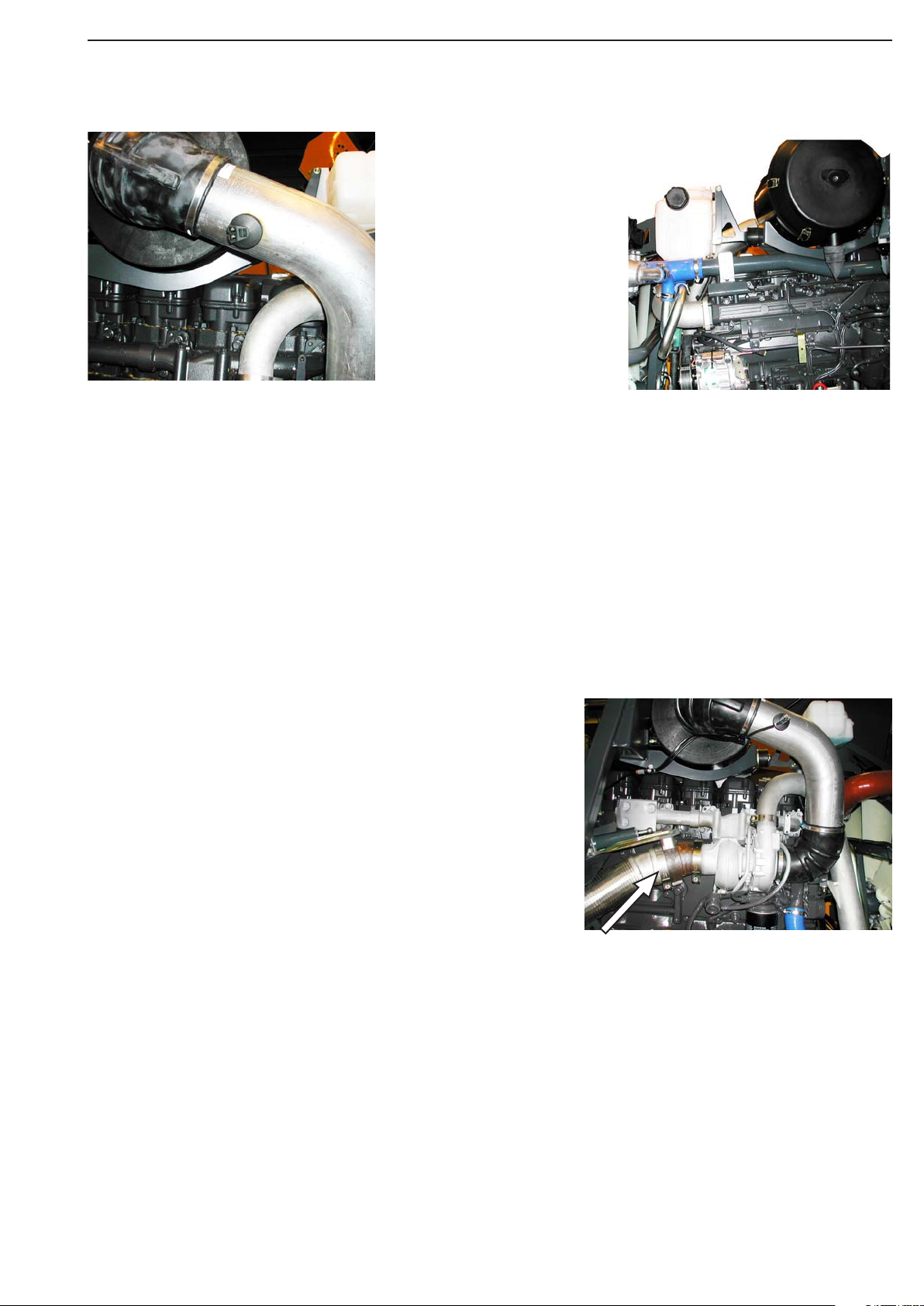

Left side:

1

Disassemble the cab pump unit from the air filter stand.

2

Remove the water hose from the pipe socket.

3

Remove the fuel hoses (3 pcs) and

4

Disassemble screws from filter stand bracket

Right side:

1

Unscrew the hose clamps and remove the pipe bend,

filter - turbo

2

Disconnect the oil hose from engine brake cylinder and bracket

disassemble the other end at left side on the magnetic valve

3

Hook up the filter stand in lifting device.

4

Screw off the fastening bolt for filter stand,

left and right hand side

2

1

1

4

3

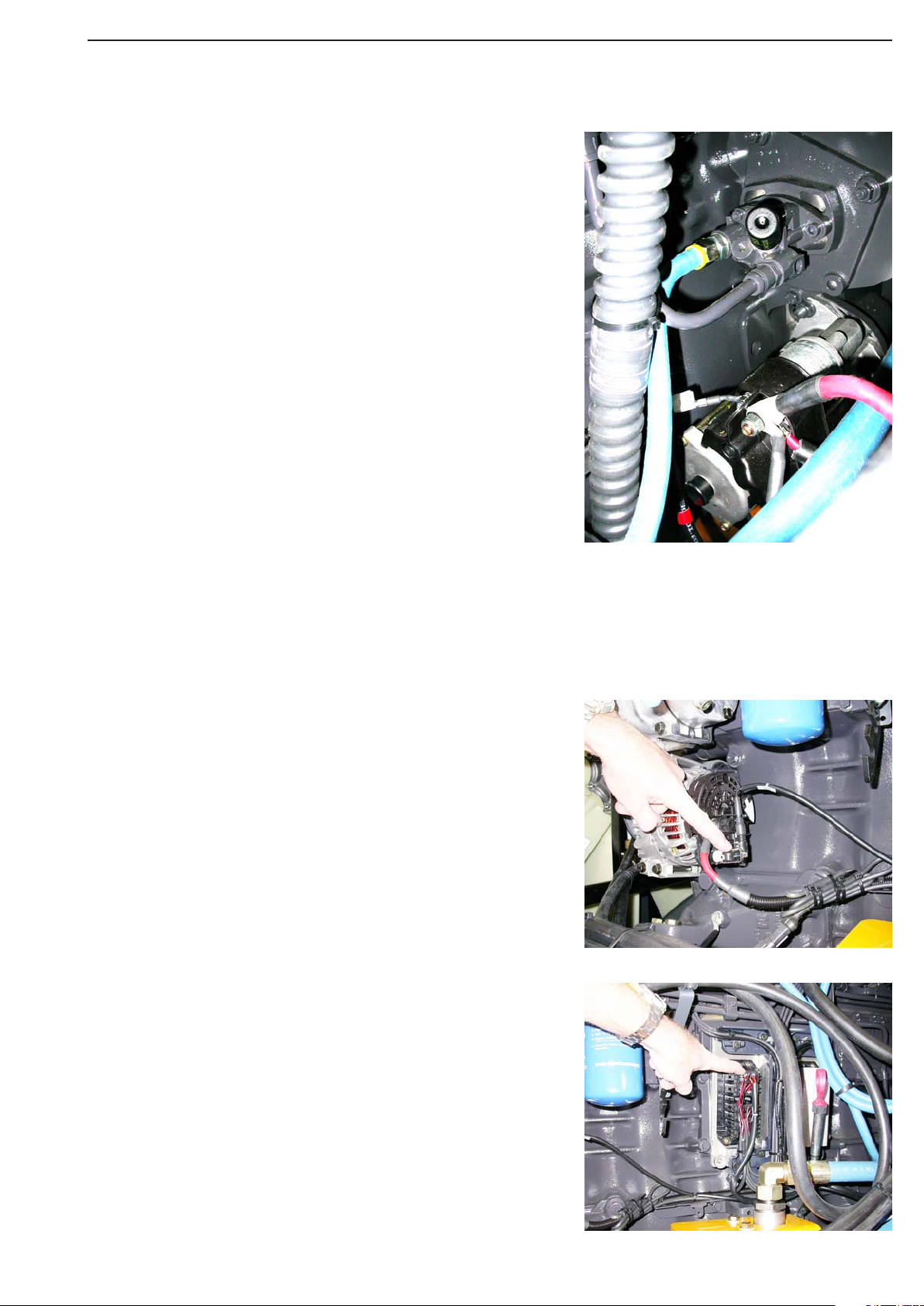

Disconnect the brake hose from the magnetic valve.

(Left side behind the cab bracket)

1

2

34

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 7

Disconnect the exhaust pipe from the turbo pipe bend.

Disasssemble the cable to the Air filter sensor.

Disassemble the clamps for the wiring on the filter stand

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 8

Slack the transmission belt.

Disassemble the ground wiring.

Detach the Air Cond. compressor with the hoses on, from the

engine. Check that all of the clamps are undone.

Place the Air condition compressor on the left while the engine is

dismount.

Disconnect the hose from the termostathousing,

the pipe between the air cooler and the engine air inlet.

Disconnect bracket for the air pipe and bracket between engine

and fan rack

Disconnect the outlet pipe bend from turbo, and the inlet water

hose from the transmission cooler.

Disconnect the retur hose. (Engine - ekspantionstank)

(Quick release coupling)

(Front of the engine, view from the right hand side)

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 9

Disconnect the contact on the dynamo.

Remove the cover and disconnect the electrical contact from the

engine ECU -S6 control unit

Disconnect the cables between starter motor and the frame

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 10

1

Disassemble screw for the ground cable (2 pcs)

2

Left and right hand side, disassemble 3 screws on the engine

mounting bracket.

2

1

1

2

1

Disassemble the hose clamp bracket.

2

Unscrew the engine bracket bolt left and right hand side.

1

2

Drive shaft

Remove safety atcher.

Remove driveshaft between transmission and engine coupling,

12

2

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 11

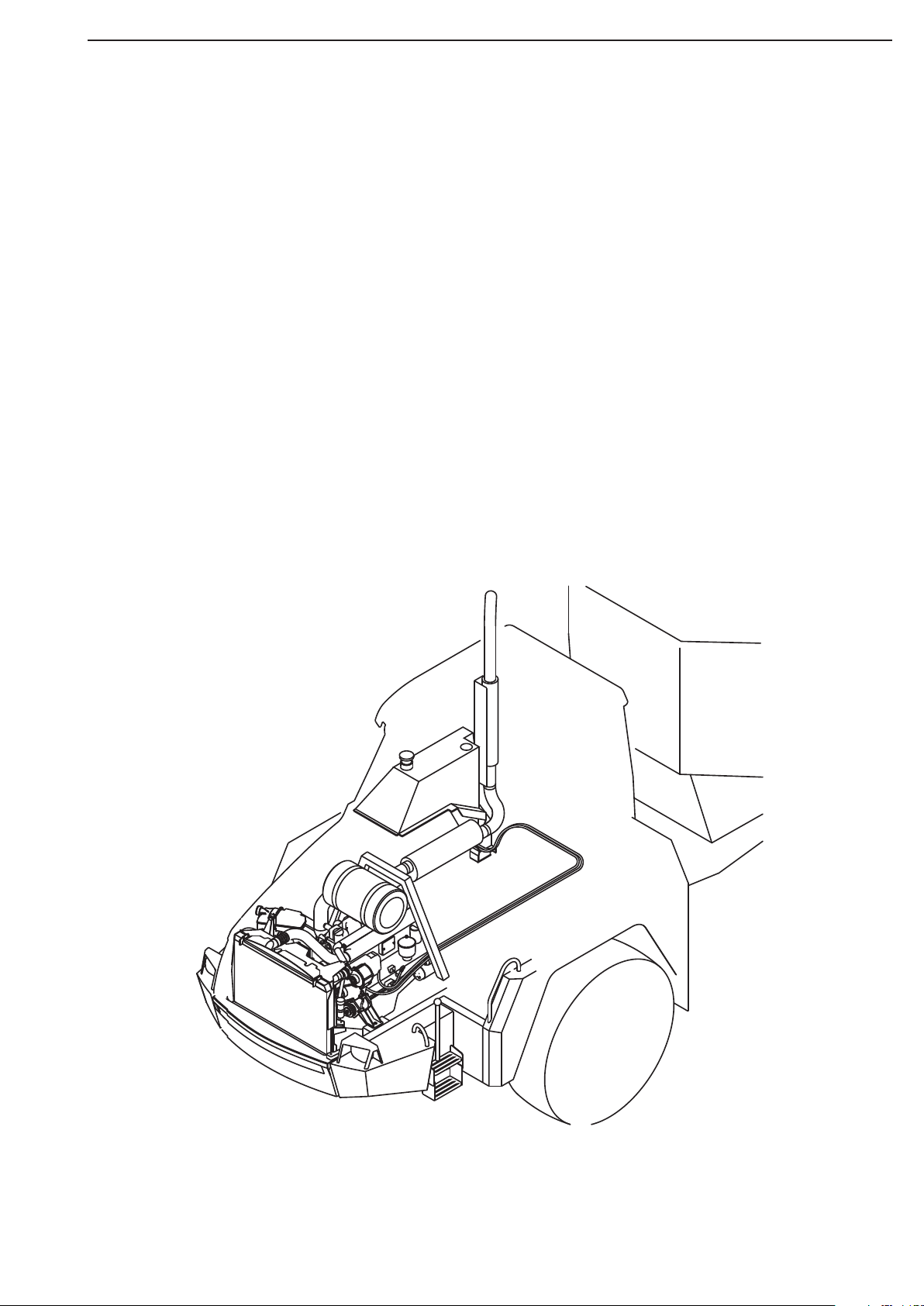

- Fasten the lifting chain 8373 to the rear

lifting eyes.

- Fasten the lever block 8394 to the front

lifting eye.

With attention, lift the engine out from the frame

Note:

The lifting eyes are sized to cope

with a maximum angle of 30°.

Lifting the engine

Note:

The engine lifting eyes are designed

for lifting the engine only, not the

engine together with its ancillary

equipment (alternator, gearbox etc.)

or fram

8394 8373

Lever block Lifting chain

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 12

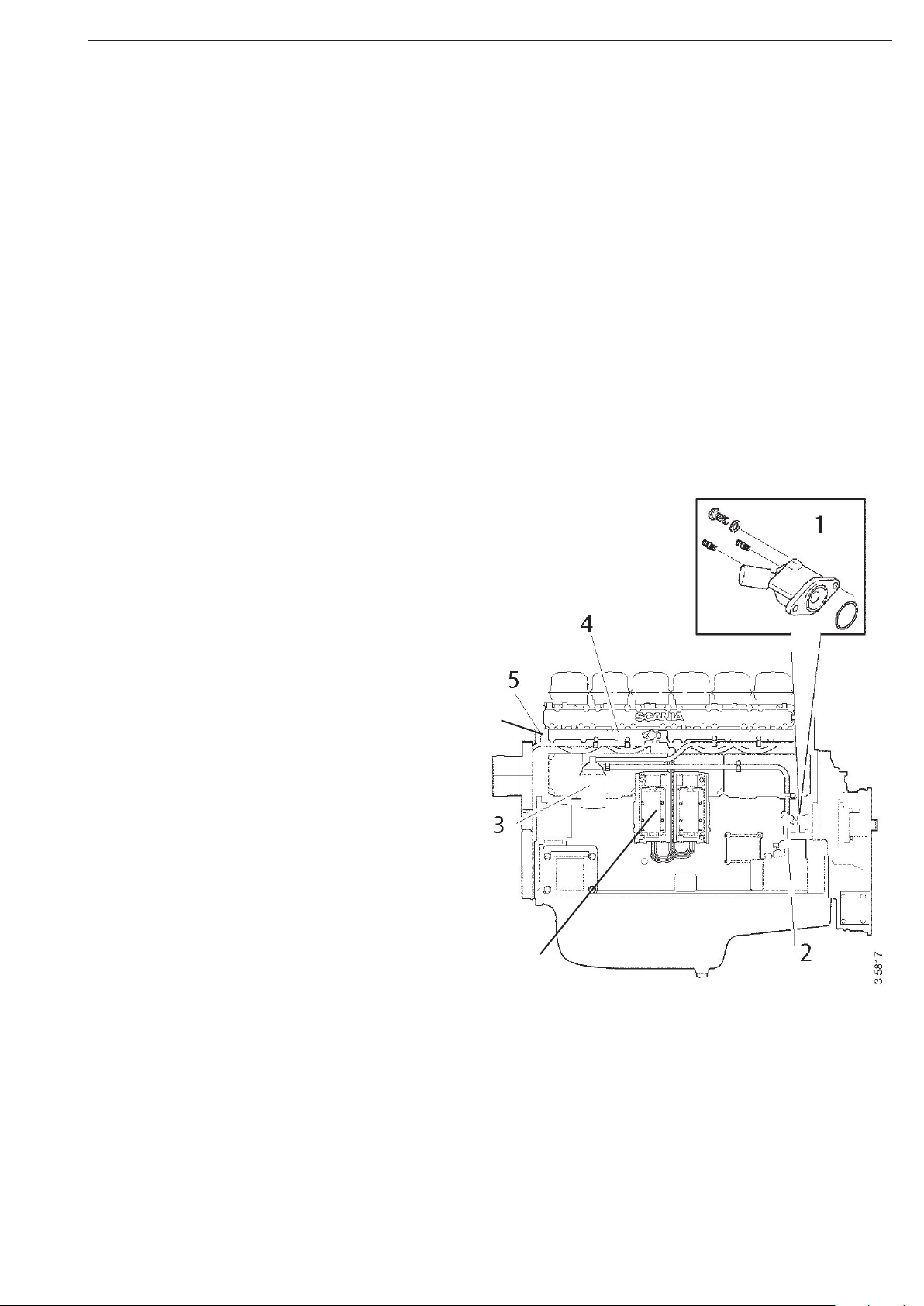

Engine identification

10 © Scania Industrial & Marine Engines 2005-11:1

TYPE DESIGNATIONS

The engine type designation indicates, in the form of a code, the type of

engine, its size and applications, etc.

The type designation and engine serial number are stamped on the right side

of the engine block. See illustration.

DC 9 63 A 02 P

Type

DC Supercharged diesel engine with air-cooled charge air cooler.

Displacement in whole dm3

Performance and certification code

Indicates, together with the application code, the normal gross engine

output.

The actual output setting of the engine is indicated on the engine card.

Application

A For general industrial use

Variant 01-99

Type of regulator

P EMS engine management system with PDE and S6

The engine designation indicates, in the form of a code, the type of

engine, its size and applications, etc.

The type designation and engine serial number are indicated on a

type plate affixed to the right-hand side of the engine.

The engine number is also stamped on the engine block immedi-

ately above the type plate.

Refer to the illustration.

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 13

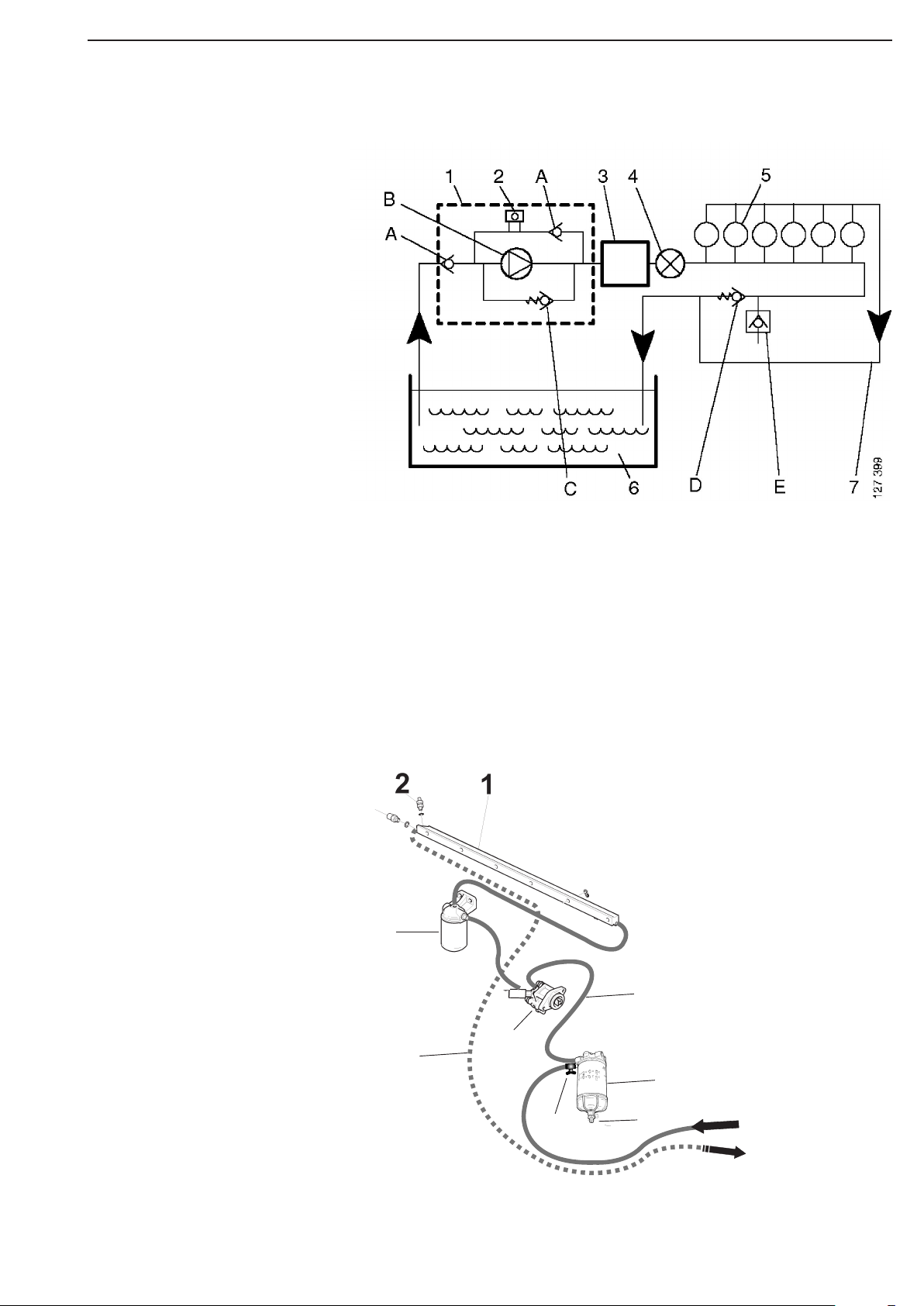

Fuel system

1 Feed pump

2 Hand pump

3 EMS control unit

4 Fuel filter

5 Cylinders

6 Fuel tank

7 Return line for excess fuel

A Check valve

B Gear pump (feed pump)

C Safety valve

D Pressure relief valve

E Drain nipple

Schematic diagram of the fuel system

Overflow valve

The purpose of the overflow valve is to limit the pressure in the

fuel system and continuously vent it. The overflow valve ensures

that the fuel circulates round the system and that there is always

fuel in the injection pump for cooling, lubrication and injection.

Opening pressure is 0.6 - 0.8 bar.

Working pressure is approx. 1 bar.

1 Fuel rail

2 Pressure relief valv

3 Fuel filter

4 Feed pump / hand pump

5 Shut-off cock

6 Oil hose water filter - feedpump

7 Water separating prefilter

8 Retur line

9 Drain valve

Supply from tank

Retur to tank

3

4

8

6

7

59

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 14

Apart from fuel lines and a fuel tank, a PDE

(Pumpe-Düse-Einheit) fuel system with unit

injectors consists of the following items:

• a feed pump

• a hand pump

• a fuel filter

• one fuel rail.

• a pressure relief valve

• One PDE type unit injector per cylinder.

The fuel system also includes an electronic

control system. The control system includes an

electronic control unit, the unit injector

solenoid valves and sensors.

General

PDE

Diesel fuel oil

The composition of the diesel fuel oil has a great influence on the functioning and

the service life of the engine and the injection system.

The engine output and exhaust emissions are also dependent on the fuel quality.

The diesel fuel must meet European standard EN 590.

The table below shows the requirements for some of the most important properties:

Environmentally favourable fuels (low sulphur fuels)

There are three classes of so called environmentally favourable fuels (SS15 54 35).

Class 1 is sulphur-free and class 2 is low in sulphur. Compared with class 3 (normal fuel), these fuels are less

dense and this reduces engine power output.

FUEL

Property Requirement

Viscosity at 40°C 2.0 - 4.5 mm2/s (cSt)

Density at 15°C 0.82 - 0.86 kg/dm3

Sulphur (concentration by mass) max. 0.3%

Ignitability (CET rating) min. 49

Flashpoint 56°C

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 15

Fuel filter

Design

Fuel filter are of single-mounted type. The filter screw on to a

retainer which is bolted to the engine.

The filter consists of a metal container with a folded paper ele-

ment. The filter cannot be dismantled but must be changed as a

complete unit.

The fuel filter has no bleed screw and is bled by undoing plug 4

in the free inlet passage.

Function

Fuel is pumped into the inlet by the fuel pump. It then continues

through passages in the filter retainer to the upper part of the fil-

ter, down through the filter or filters and on to the outlet passage.

From there, the fuel is piped to the injection pump.

1. Filter retainer

2. Filter

3. Gasket

4. Plug

Fuel filter, constituent parts

Note:

Close the shut-off cock when renewing

the filter.

The same intervals between changes apply as

for those for an ordinary fuel filter.

Water separating prefilter

1 Shut-off cock

2 Drain valve

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 16

Temperature dependence of diesel fuel

At temperatures lower than those specified for the diesel

fuel, paraffin wax may precipitate from the fuel and block

filters and pipes. The engine can then loose power or stop.

The diesel fuel is adapted for use in the specific climate of

each country. If a vehicle or an engine is to be operated in a

temperature zone with lower temperature than normal, first

identify the temperature properties of the fuel concerned.

The properties of the fuel when cold can be improved by

adopting one of the following measures before the tempera-

ture drops:

- If the fuel concerned cannot cope with the expected

temperatures, and diesel fuel is not available with the

correct temperature properties, we recommend that

an electric fuel heater is installed as a preventative

measure.

- The low temperature properties of diesel fuel may

be improved by adding kerosene as a preventative

measure. A maximum of 20% may be added. When

refuelling, the kerosene should be added first, so that

it mixes thoroughly with the diesel fuel.

Note:

It is prohibited to use kerosene in engine fuel

in some countries.

- To prevent water in the fuel from freezing and

forming ice, a maximum of 0.5-2% alcohol

(isopropanol) may be added.

Drain fuel tanks and drain or change fuel fil-

ters regularly.

Warning

It is not permitted to mix

kerosene with diesel fuel that is

already adapted for the climate

concerned. This can damage

the

PDE injectors. All use of

paraffin other than kerosene is

forbidden, as it causes engine

damage.

!

Important

It is not permissible to mix

petrol with diesel fuel. In the

long term, petrol may cause

wear to the PDE injectors and it

may also cause damage to the

engine.

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 17

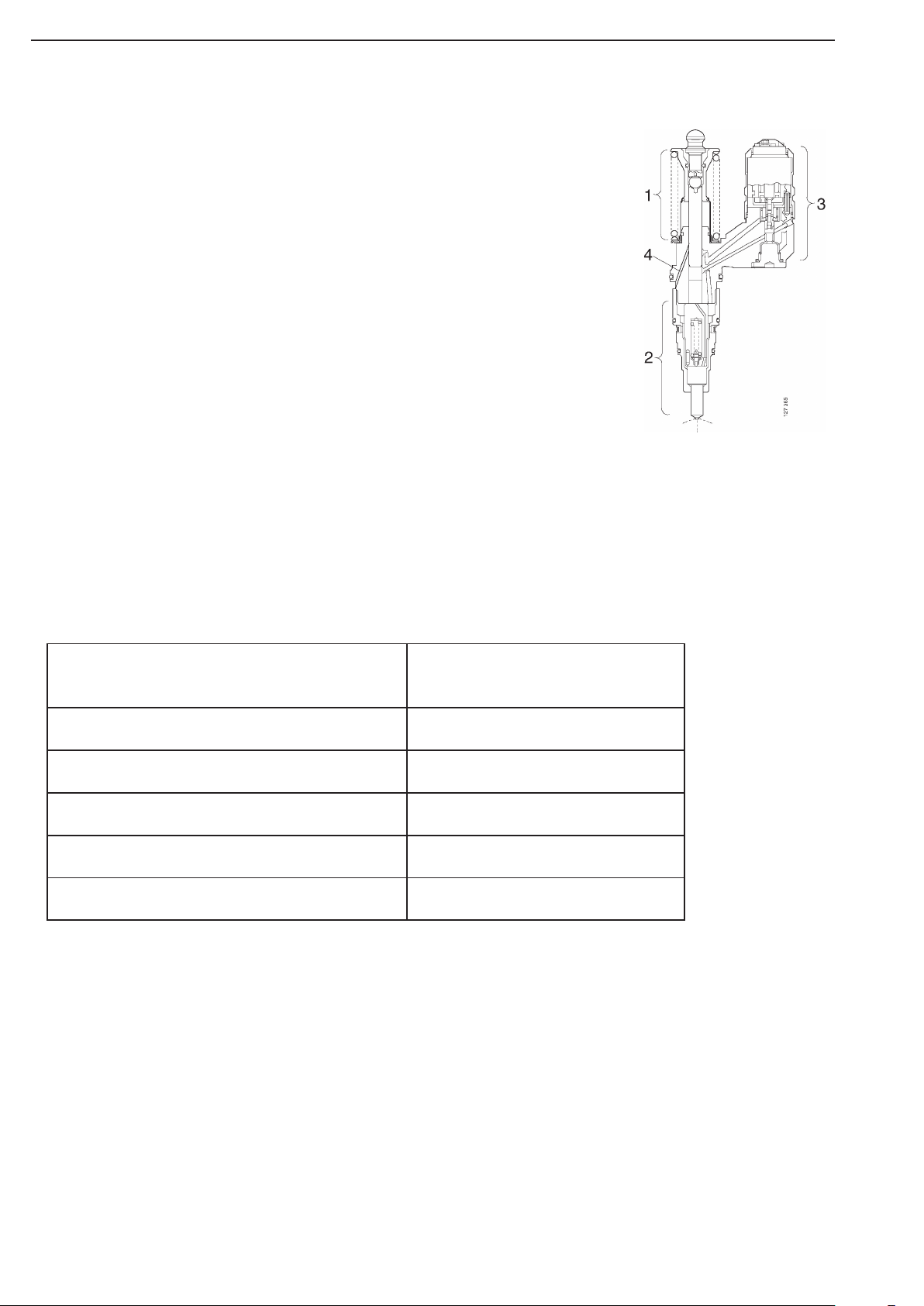

Feed pump

The feed pump 1 draws fuel from the fuel tank and forces it through the fuel filter 3

and into the fuel rail 4.

On the feed pump there is a hand pump 2.

The hand pump is used to vent air from the fuel system.

On the fuel rail there is a pressure relief valve 5.

The pressure relief valve constantly regulates the fuel pressure. When the pressure is too high,

the pressure relief valve opens, so that the excess fuel is returned to the fuel tank.

The fuel rail distributes the fuel to the unit injectors in each cylinder head.

The ECU control unit determines when the unit injectors must inject fuel into the cylinders.

Feed pump renewal

1

Clean the outside of the feed pump.

Remove the suction and pressure lines

from the feed pump.

Fit protective plugs.

2

Unscrew the bolts and remove the feed

pump.

3

Place a new O-ring onto the feed pump and

lubricate with O-ring grease.

4

Fit the feed pump.

5

Connect the suction and pressure pipes.

6

Bleed the fuel system; refer to Bleeding the

fuel system.

7

Start the engine and check for leaks.

1 Feed pump

2 Hand pump

3 Fuel filter

4 Fuel rail

5 Pressure relief valve

6 Bleeder nipple

7 ECU control unit

6

7

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 18

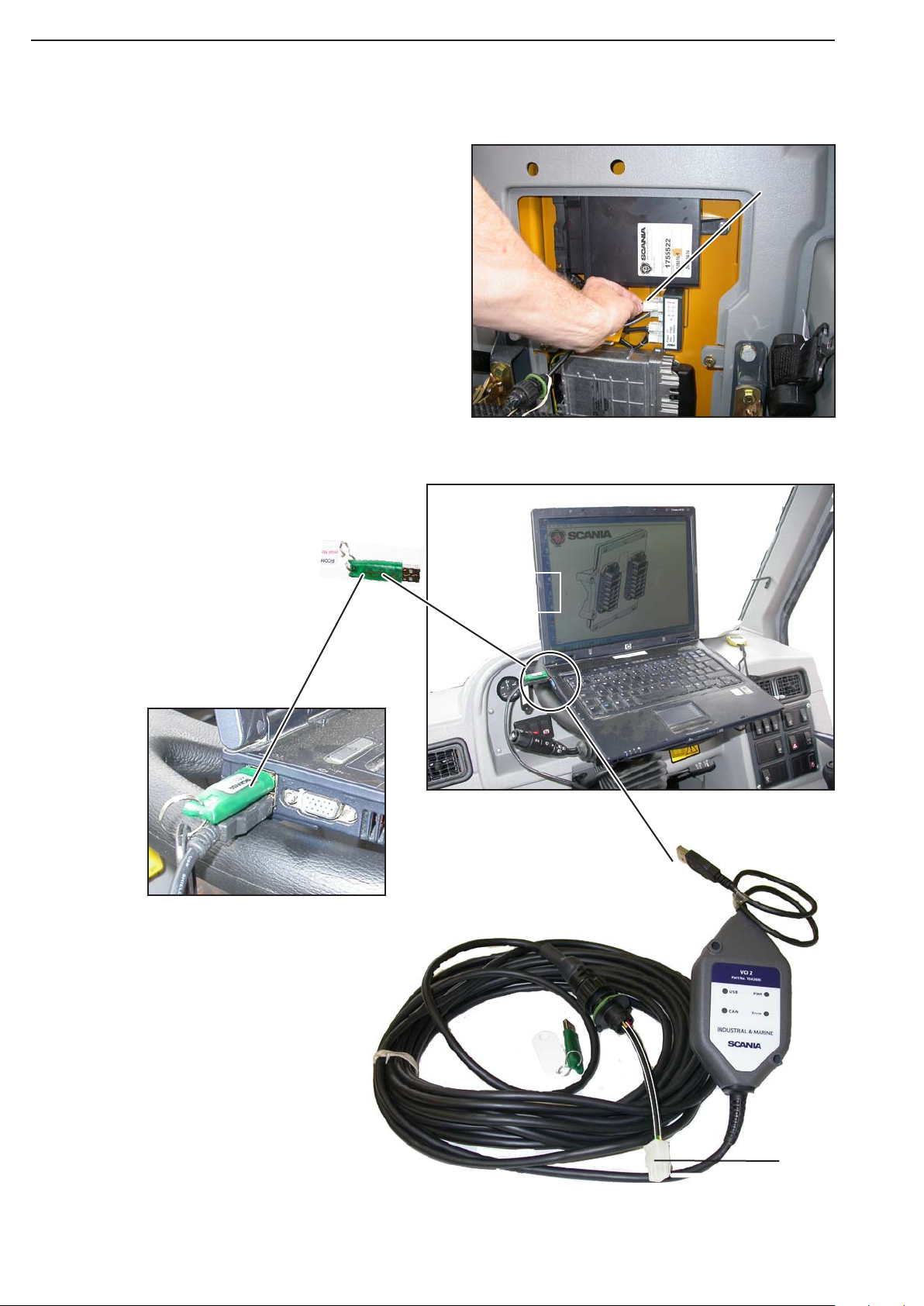

VCI

2

Use of diagnostic kit, machine

2

Install the VCI (ECOM programming unit)

Moxy No.513376

1. Switch on the laptop.

2. Connect the cabel end (1) to the CT1 unit

3. Connect the USB plug (2) to the Laptop

4. Put in the USB key

5. Switch on the ignition key (If read the setting

parameters)

6. Start the engine. (If controlling of the param-

eters)

7. Start on Laptop the engine ECOM program.

4

1

3

Diagnostic prosedure

Engine

SHOP MANUAL MT26-31 - 06.2005

Tier-3 710655- Ch 1 page 19

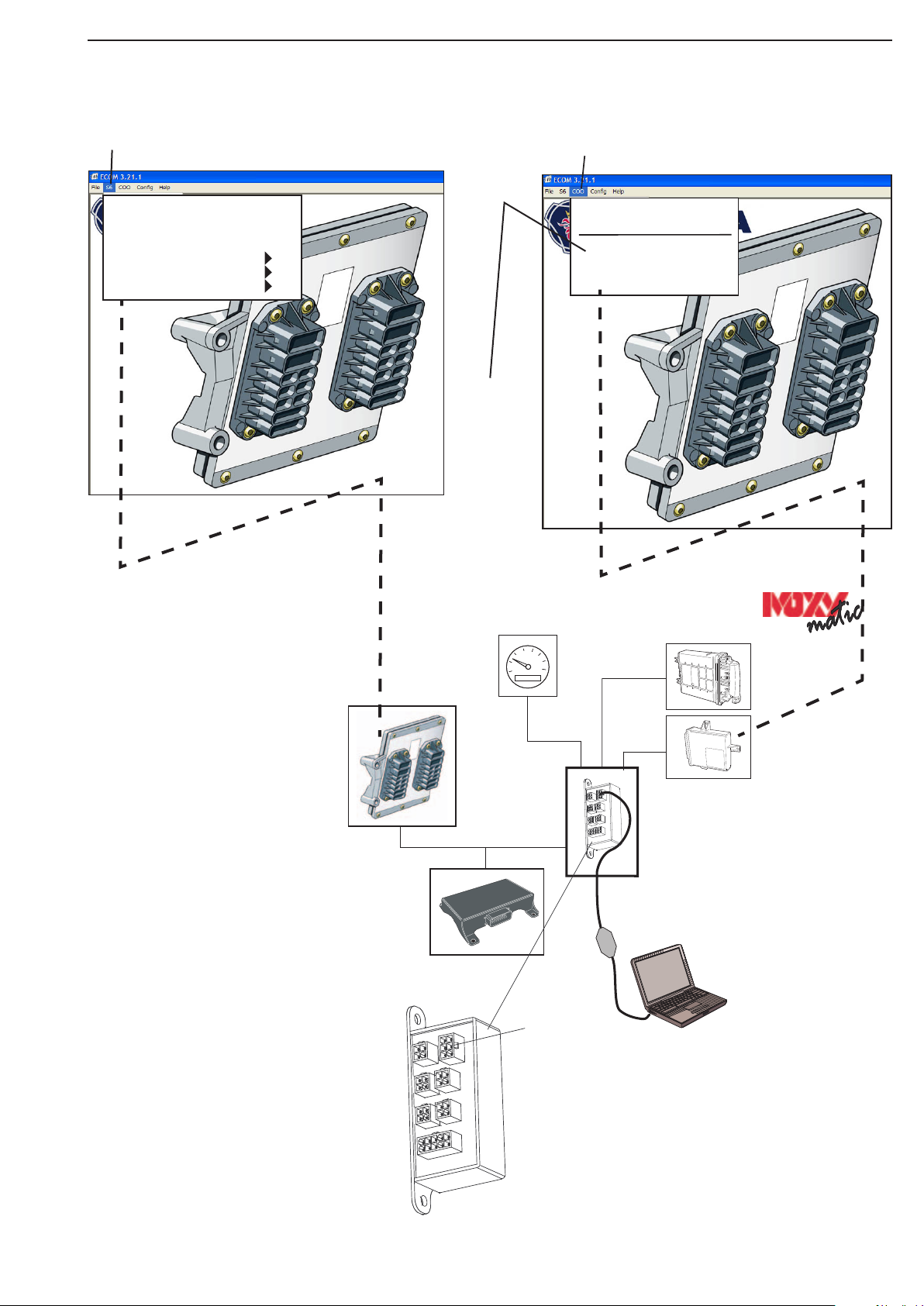

VDO

Tacho EST 37

EMS

COO

IVC4(B)

EMS

S6

Laptop

CT1

(CANbus

conne-

ction)

Test port

CT1

(CANbus connection)

The CT1 has following func-

tions:

Connection point for all CAN-

bus devices on the truck

Contains two independent

CANbus interfaces and han-

dles data transfers between

these buses

Connection point for engine

diagnosis

Handle WDB monitoring and

alarm

Handle histogram logging (In-

formation for service)

Master

Slave

Diagnostic Faul Codes

ECU Identification

Program EEPROM

COO

To read

the fault

codes

in the

coordina-

tor (EMS

COO.)

S6

Diagnostic Fault

Codes

Measurement

ECU Info/ID

Data Logs

SHOP MANUAL MT26-31 - 06.2005

Engine

Tier-3 710655-

Ch 1 page 20

S6

Diagnostic Fault Codes

Measurement

ECU Info/ID

Data Logs

E2

Engine Test

Read out fault codes

Measuring of valves

Adjusting of parameters

Other manuals for MT 26

1

This manual suits for next models

1

Table of contents

Other Moxy Truck manuals