U-Line H-4564 User manual

Other U-Line Truck manuals

U-Line

U-Line Magliner H-4938 User manual

U-Line

U-Line H-3200 User manual

U-Line

U-Line Magliner H-1382 User manual

U-Line

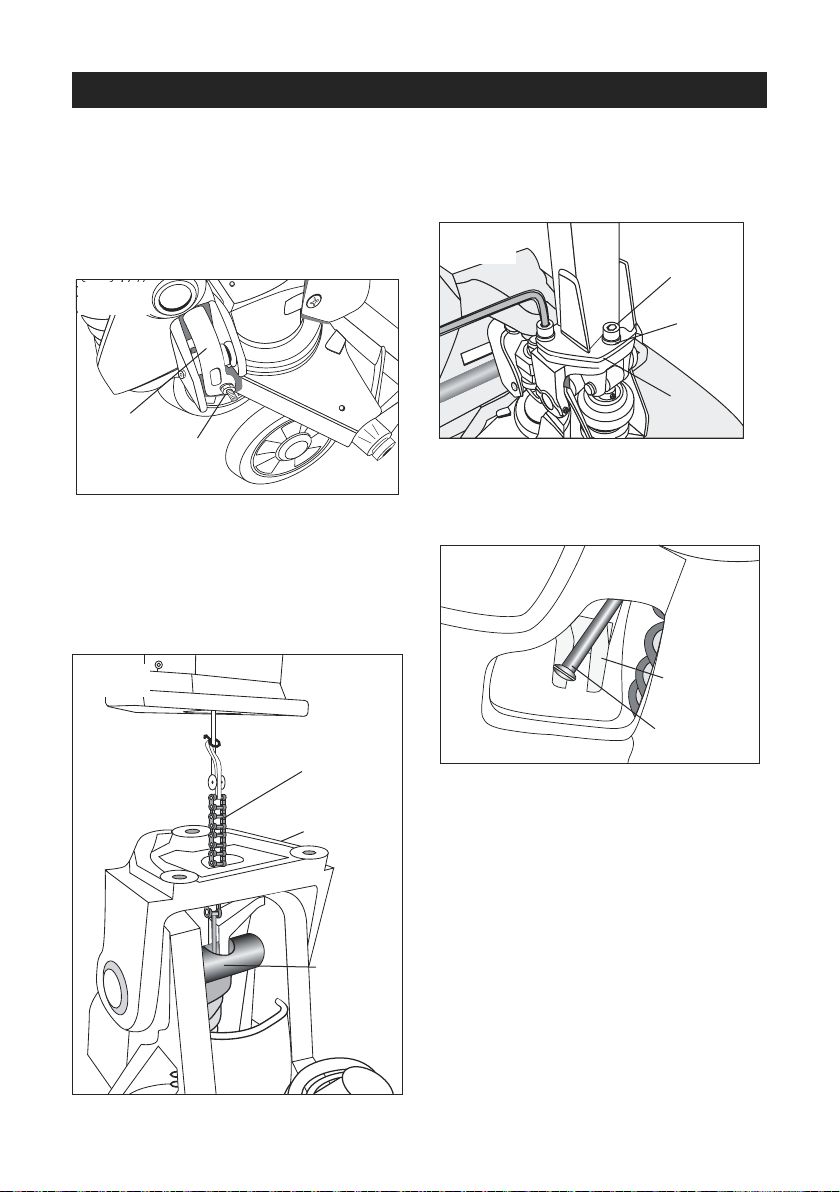

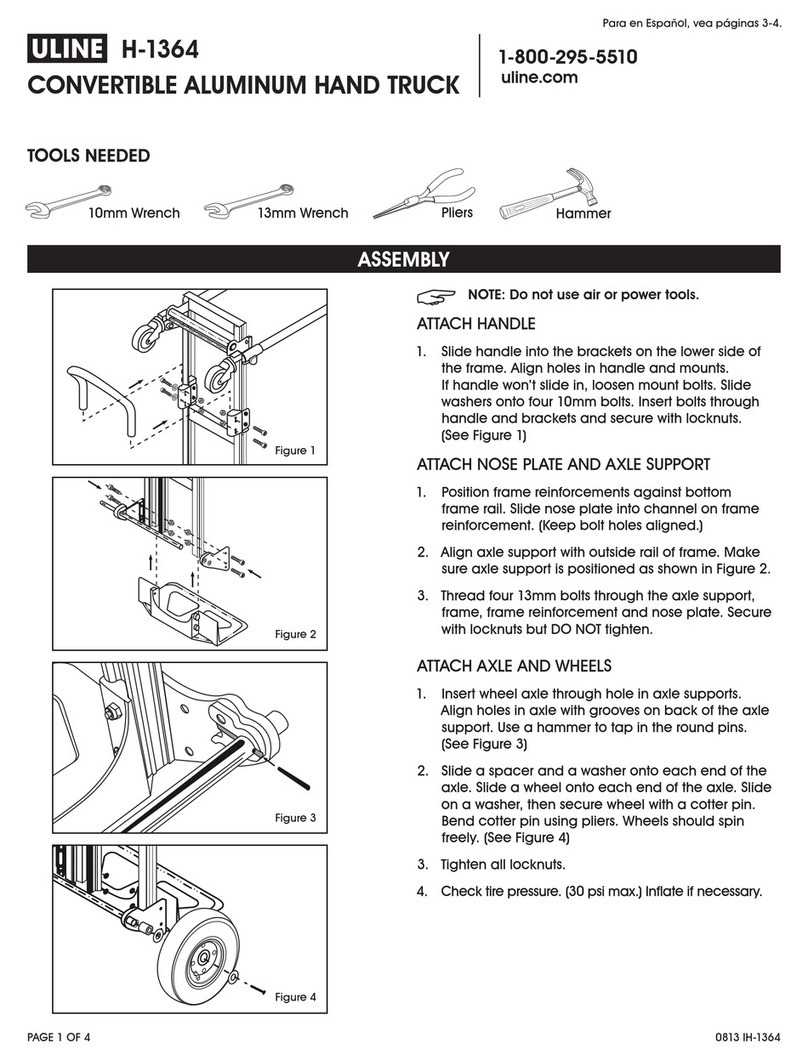

U-Line H-1364 User manual

U-Line

U-Line H-1787 User manual

U-Line

U-Line Big Joe H-4709 User manual

U-Line

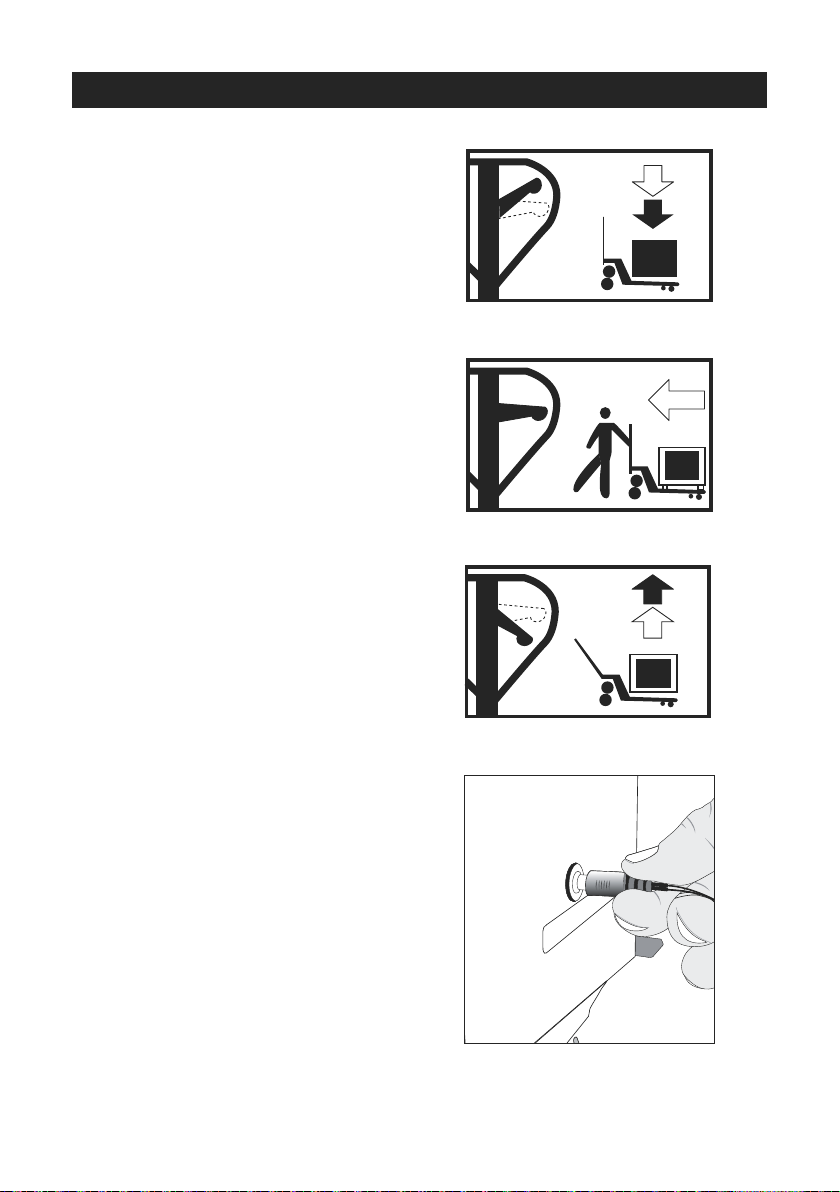

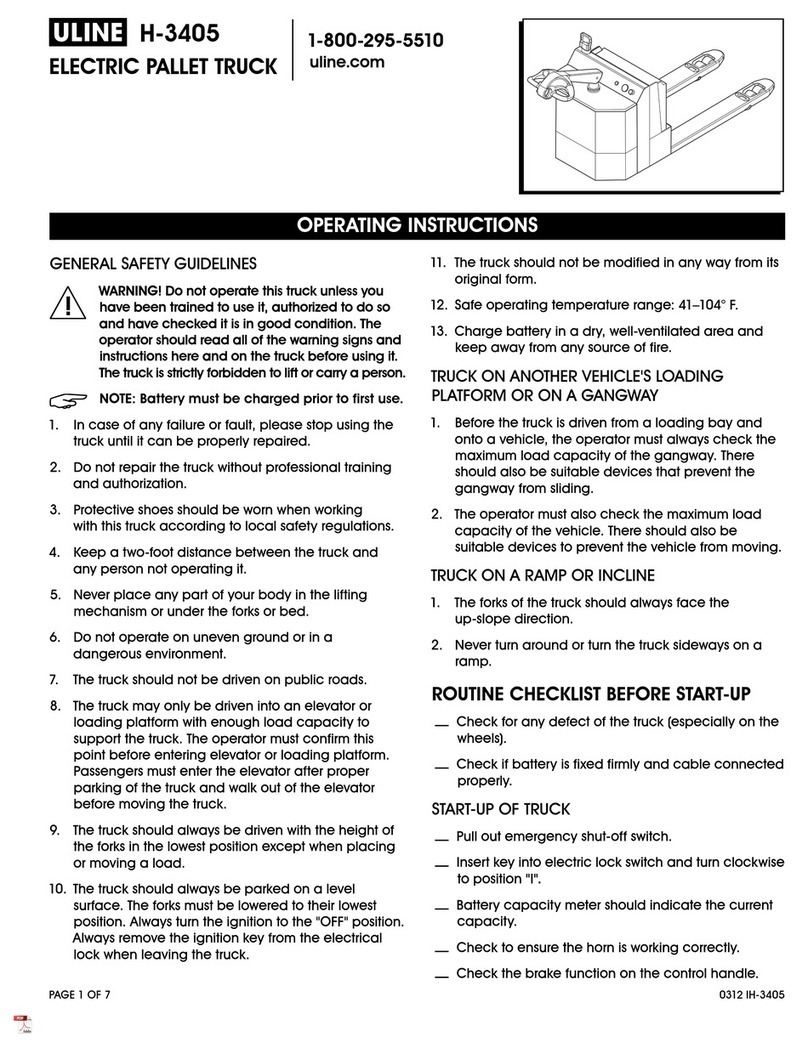

U-Line H-3405 User manual

U-Line

U-Line H-1201 User manual

U-Line

U-Line H-1480 User manual

U-Line

U-Line H-2638 User manual

U-Line

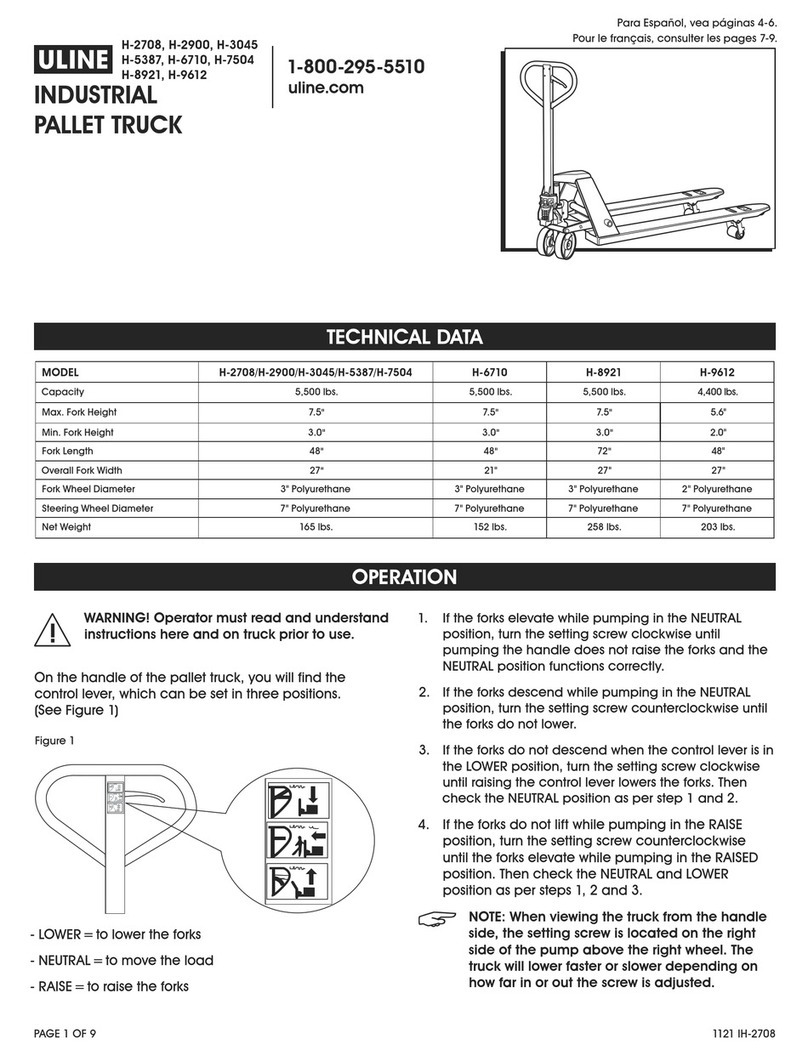

U-Line H-8921 User manual

U-Line

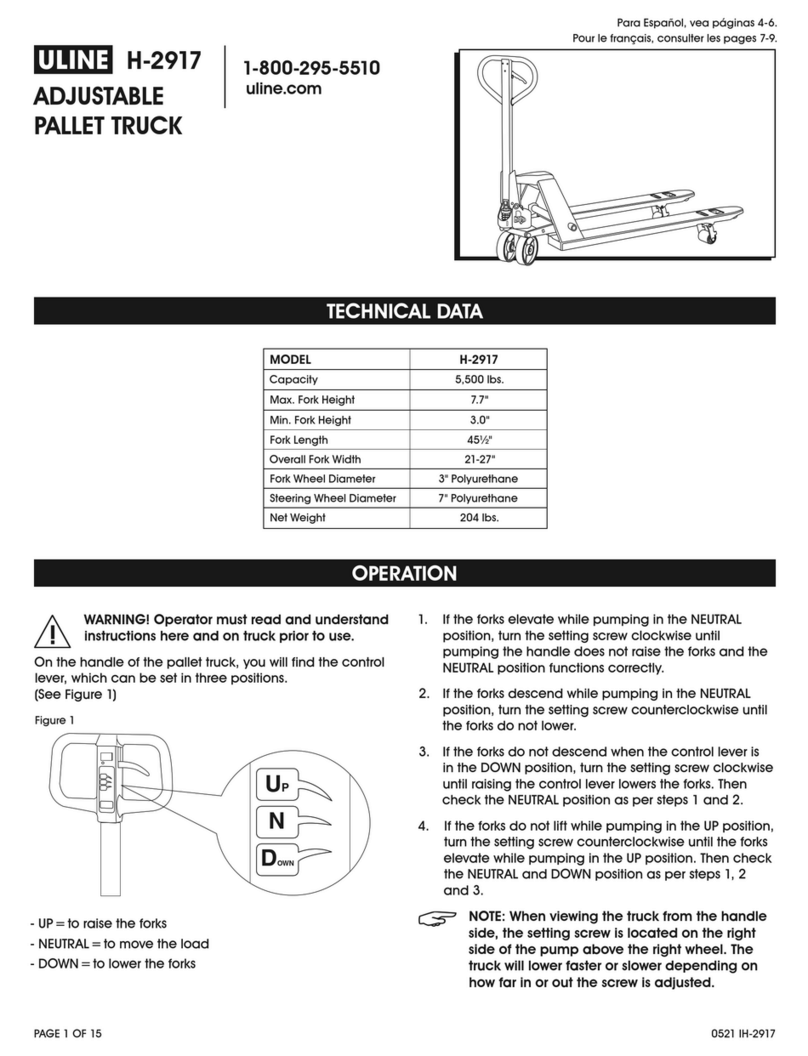

U-Line H-2917 User manual

U-Line

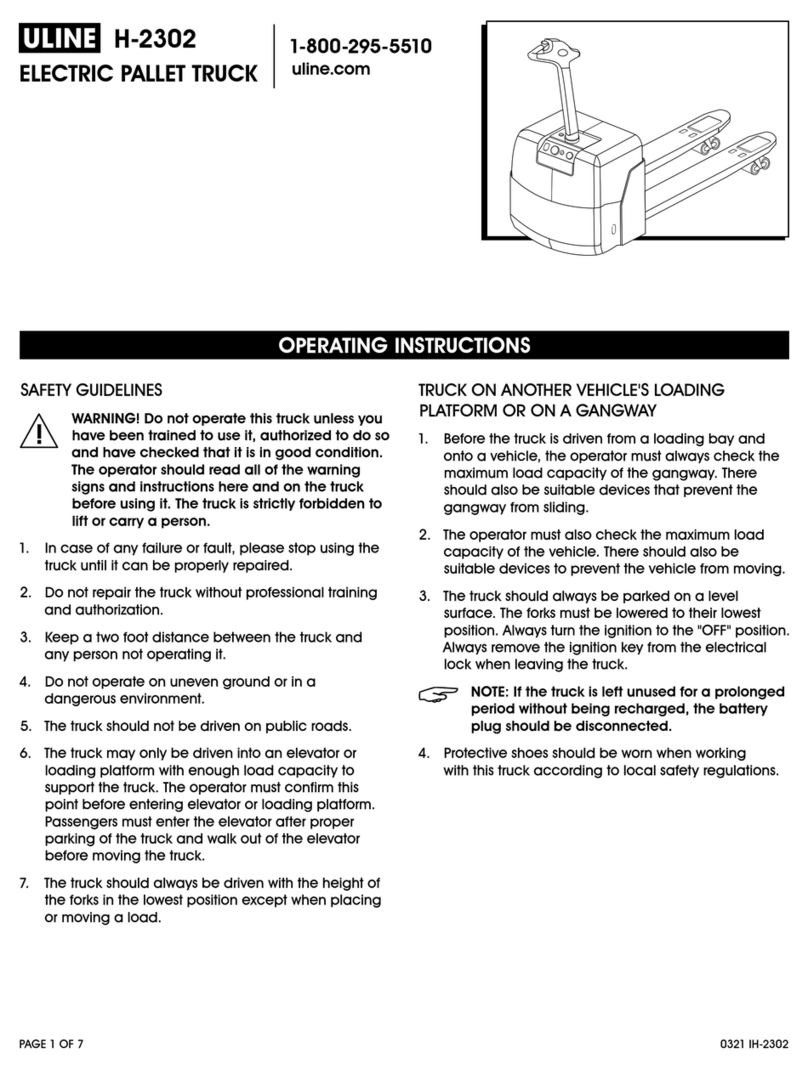

U-Line Н-2302 User manual

U-Line

U-Line H-7505 User manual

U-Line

U-Line H-1387 User manual

U-Line

U-Line H-1826 User manual

U-Line

U-Line MAGLINER H-4938 User manual

U-Line

U-Line H-2638 User manual

U-Line

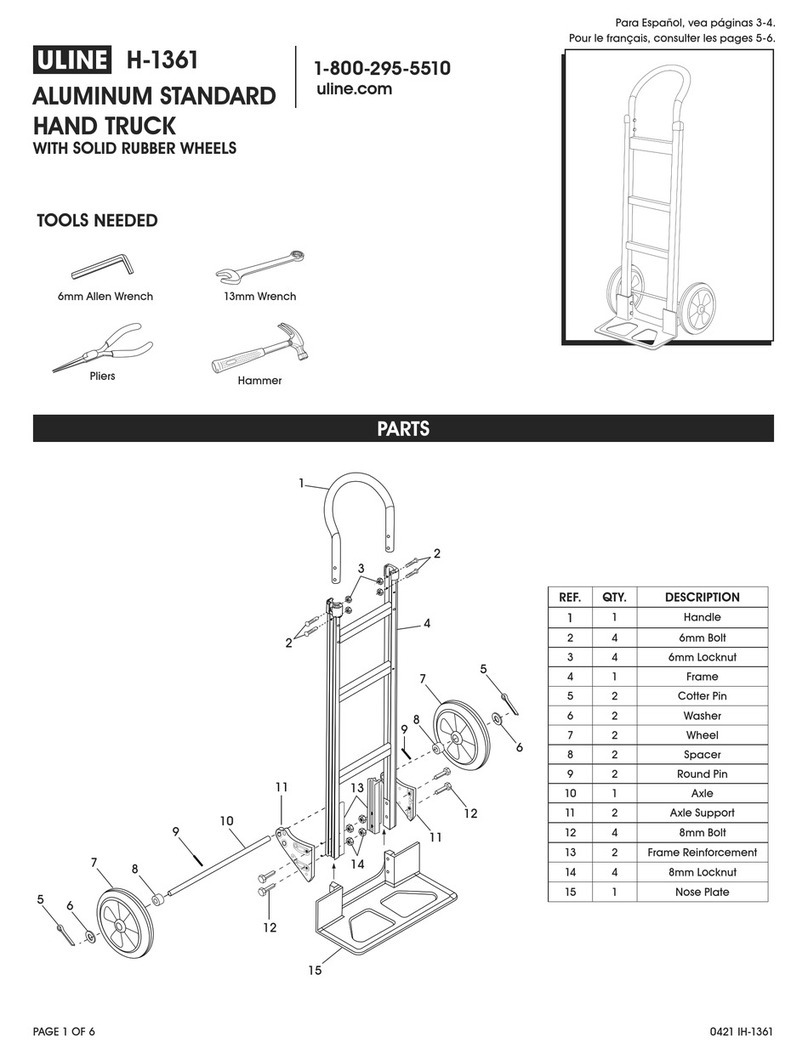

U-Line H-1361 User manual

U-Line

U-Line BT H-1003 User manual