D

Group 177 General

Program Structure

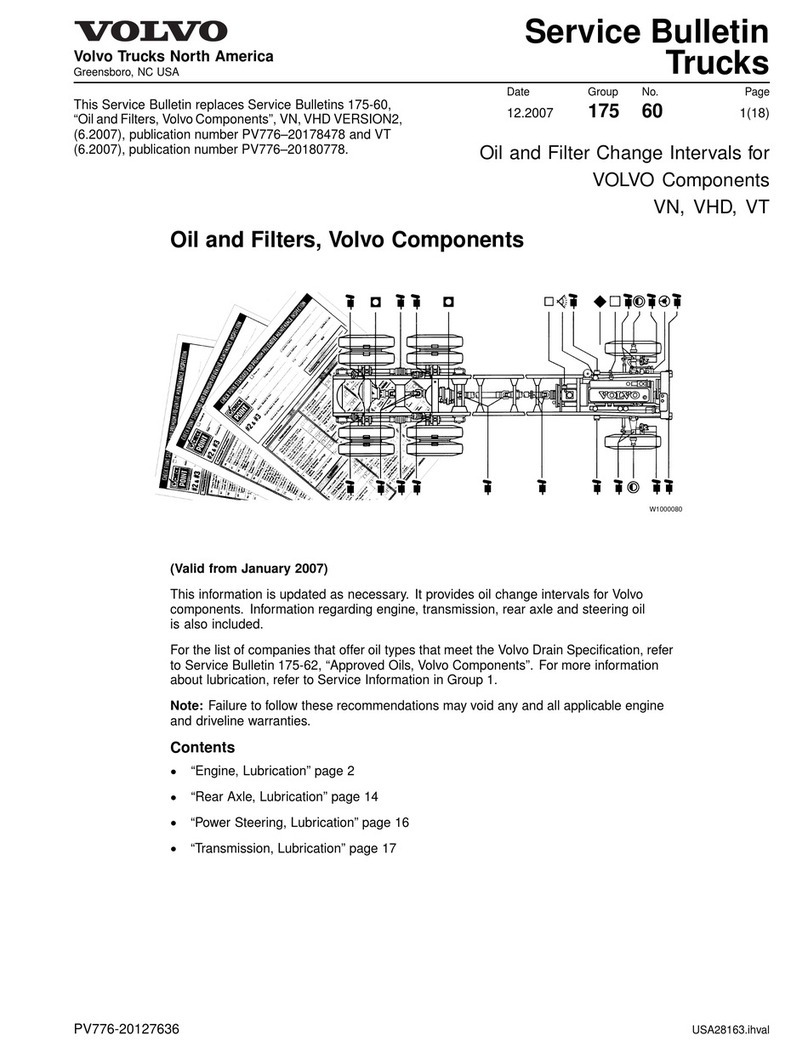

This maintenance program has been based on the

progress in vehicle technology and increases in oil quality

to simplify the maintenance.

For simplified scheduling, the program has tied

maintenance to logical time or mileage limits that make it

easy to anticipate needed servicing. For the majority of

on-highway operators, the 24,000 km (15,000 miles) or 4

months for basic service and 96,000 km (60,000 miles)

or 12 months for annual service, schedule can be used

with little change.

For further information concerning maintenance

scheduling, see service information in Group 1, “Oil and

Filter Change Intervals for Volvo Components,” publication

number 175-60, “Approved Oils Lists, Volvo Components”.

Advantages

A well-planned preventive maintenance program offers

the following advantages:

The lowest attainable maintenance cost.

Maximum vehicle uptime.

Better fuel economy.

Reduced road failures; greater dependability.

Increased customer confidence, better public relations.

Less possibility of accidents due to defective

equipment.

Fewer driver complaints.

Regardless of the planning and the details of the

maintenance program, the success of the program

hinges on the caliber of workmanship in performing

the actual inspection. A major cause of failure is a

“pencil inspection;” that is, the mechanic checks off

each operation as being OK without making the actual

inspection. A “pencil inspection” defeats the purpose of

the inspection, which is to detect an impending failure.

Maintenance Form

A Service Manual is issued detailing the current inspection

forms. Forms are created for different users but all

with the same references to this document. When the

inspection point is carried out, check the box if the item

is OK. If further work, such as adjustment, repair, etc.,

needs to be performed, record this information and go

on with the next inspection point. Items noted as being

faulty or in need of adjustment need to be shown to the

customer and scheduled for repair.

There are many time — and/or mileage-based — service

items that are not listed on the form. Look at the end of

this document for a listing of additional components that

may need to be serviced, depending on the mileage or

time since last service.

Maintenance Records

It is important to use the inspection form together with

other reports to come up with the best maintenance

program for a specific application. Use driver’s reports,

complaints, parts usage, repetitive failures, previous

repair orders, road failures, etc. to build a maintenance

history.

Records should be collected over the lifetime of the

vehicle to form a permanent vehicle record file. The

vehicle file should be used to customize the operational

maintenance needs.

The “Driver Inspection Form” is also required by Federal

law. The use of this inspection report makes the driver

a part of the maintenance program and places direct

responsibility on the driver to report problems that may

come up during operation. When properly used, there

should be no excuse for a defective vehicle being in

service.

Basic Inspection

Note: The included Basic Service checklist is an

original copy. The document can be updated without

notice.

The Basic inspection is carried out at a maximum of

24,000 km (15,000 miles) or 4 months, whichever comes

first.

All inspection points are to be carried out as verification

of function or condition. Any defects are noted on the

inspection form for later correction, if so ordered by the

vehicle owner.

Note: The standard repair time for performing the

Basic Service Preventive Maintenance is based on

inspection and Oil and Filter Change, without repair

or adjustment.

Annual Inspection

The Annual inspection is carried out yearly in addition to

a Basic inspection. This inspection is designed to open

up components for inspection or using test equipment to

record performance.

The ideal time to carry out the Annual inspection is right

before the hardest season, which means just before

winter in the cold weather climates and just before

summer in the hot weather climates.

For further information refer to “Annual Preventive Service

Manual,” Group 17.

4