EP Equipment J1HD User manual

I

Part No.508000003143

V1 10/2019

2

EP EQUIPMENT CO.,LTD. is one of the

world’s leading companies manufacture,

design material handling equipment and

provide related service. With over

100,000m2plant it produces over

100,000 trucks per year, and provides

professional, effective and optimized

material handling solutions worldwide,

until now it has developed three major

kinds of business:

· Material handling equipment: Focus

on electric forklift and warehouse

equipment

·OEM parts: Global parts supply

·Imow industry,online: One stop

industrial products supply

Guided by our customer-oriented

concept, EP has developed service

centers in more than 30 countries

around the world, from which customers

are able to receive timely local service.

Moreover, 95% of warranty parts can be

shipped out within 24 hours after been

ordered. Through our online after-sales

service system, customers can process

their warranty claims, order spare parts

and consult the operation manuals,

maintenance materials and spare parts

catalogs.

With business all over the world, EP has

thousands of employees and hundreds

of agents worldwide to provide our

global customers with prompt local

service.

Based on the concept of sharing

economy , EP also offer rental service

for various logistics equipment. Adhering

to the idea “Making the leasing of logistic

equipment more simple”, EP is devoted

to providing customized one-stop

leasing solutions for our customers with

our high quality, reasonable price and

prompt rental service.

EP’s mission&vision is “ Let more people

apply the electrical material handling

equipment to relieve the intensity of

labour” and “Let’s grow together”.

EP EQUIPMENT CO., LTD

Address: XIAQUAN, DIPU, ANJI,

ZHEJIANG, CHINA

Tel: + 86-0571-28023920

Fax: + 86-0571-28035616

Website: www.ep-ep.com

Email: servi[email protected]m

I

Foreword

Thanks for purchasing our task support vehicle.

The present original operating instructions are designed to provide sufficient

instruction for the safe operation and maintenance of the truck.Please be sure to read

this operator manual carefully if you are operator or are in charge of the truck,before

you operate and service the truck. Only in this way can you protect yourself and make

the truck play a role as much as possible.

Our trucks are subject to ongoing development, so maybe there are some

differences between your product and the description in this manual. And the operator

manual details will be different because of customer's special requirements.

If you have any questions ,please keep in touch with the sales department of

Equipment or let the dealer know.

Notes:

1. This manual is used for operation and maintenance , the detail parameters, size

and specifications in context is only for reference , the real parameters will depend on

sale files.

2. Manual pictures for reference only, the real car shall prevail, and shall not affect the

manual use.

Warning!

The truck can only be used indoors !

EP EQUIPMENT CO.,LTD.

Address: XIAQUAN,DIPU,ANJI,ZHEJIANG,CHINA

Tel:86-571-28031990

Fax:86-571-28035616

Net:www.ep-ep.com

Email:Service@ep-ep.com

2019.10 1st EDITION

II

WARNING!

TO PREVENT SETIOUS RISK OF INJURY TO

YOUORSELF AND OTHERS OBSERVE THE

FOLLOWING SAFETY INSTRUCTIONS.

These trucks may become hazardous if adequate maintenance is neglected.

Therefore, adequate maintenance facilities, trained personnel and procedures should

be provided.

Maintenance and inspection shall be performed in conformance with the following

practices:

1. A scheduled planned maintenance,lubrication and inspection system should be

followed.

2. Only qualified and authorized personnel shall be permitted to maintain, repair,

adjust, and inspect truck.

3. Before leaving the truck:

– Do not park the truck on an incline.

– Fully lower the operator position.

– Press the emergency brake switch .

– Set the key switch to the "OFF" position and remove the key.

4. Before starting to operate truck:

– Be in operating position

– Place directional control in neutral

– Before operating truck, check functions of lift systems, directional control,speed

control,steering, warning devices and brakes.

5. Do not use open flame to check lever, or for leakage of electrolyte and fluids or oil.

Do not use open pans of fuel or flammable cleaning fluids for cleaning parts.

6. Brakes,steering mechanisms, control mechanisms,guards and safety devices shall

be inspected regularly and maintained in legible condition.

7. Capacity, operation and maintenance instruction plates or decals shall be

maintained in legible condition.

8. All parts of lift mechanisms shall be inspected to maintain them in safe operating

condition.

9. All hydraulic systems shall be regularly inspected and maintained in conformance

with good practice. Cylinders, valves and other similar parts shall be checked to

III

assure that "drift" has not developed to the extent that it would create a hazard.

10. Truck shall be kept in a clean condition to minimize fire hazards facilitate

detection of loose or detective parts.

11. Modifications and additions which affect capacity and safe truck operation shall

not be performed by the customer or user without manufacturers prior written

approval. Capacity, operation and maintenance plates or decals shall be changed

accordingly.

IV

Catalog

Correct use and Application........................................................................................1

1. Truck Description.................................................................................................... 2

1.1 Application............................................................................................................................ 2

1.2 Truck Assemblies...................................................................................................................3

1.3 Standard Version Specifications............................................................................................5

1.4 Identification points.............................................................................................................. 8

2. Commissioning....................................................................................................... 10

2.1 Using the truck for the First Time....................................................................................... 10

2.2 During brake-in....................................................................................................................10

3.Operation................................................................................................................. 11

3.1 Safety Regulations for the Operation of trucks.................................................................. 11

3.2 Controls and Displays..........................................................................................................12

3.2.1 Control panel controls and displays.........................................................................12

3.2.2 Display unit controls and displays............................................................................14

3.3 Run the truck.......................................................................................................................17

3.4 Industrial Truck Operation.................................................................................................. 18

3.4.1 Safety regulations for truck operation.....................................................................18

3.4.2 Travel, Steering, Braking.......................................................................................... 18

3.4.3 Lifting - Lowering..................................................................................................... 20

3.4.4 Order picking and placing load units....................................................................... 22

3.5 Parking the truck securely...................................................................................................23

4.Battery Maintenance & Charging......................................................................... 25

4.1 Safety regulations for handling acid batteries....................................................................25

4.2 Battery type & dimension...................................................................................................25

4.3Charging the battery............................................................................................................ 26

4.4 Battery removal and installation.........................................................................................26

4.5 Battery maintenance...........................................................................................................27

5. Maintenance............................................................................................................28

5.1 Operational safety and environmental protection.............................................................28

5.2 Maintenance Safety Regulations........................................................................................ 28

5.3 Servicing and inspection..................................................................................................... 29

5.3.1 Maintenance Checklist............................................................................................ 30

5.3.2 Lubrication Schedule............................................................................................... 32

5.3.3 Maintenance Instructions........................................................................................33

5.3.4 Recommissioning..................................................................................................... 34

5.4 Decommissioning the truck................................................................................................ 35

5.4.1Prior to decommissioning.........................................................................................35

5.4.2 Restoring the truck to operation after decommissioning.......................................35

5.5 Safety checks to be performed at regular intervals and following any unusual incidents 36

5.6 Final de-commissioning, disposal....................................................................................... 36

6.Troubleshooting.......................................................................................................37

6.1 Error Message..................................................................................................................... 38

V

6.1.1 Traction Controller (COMBIAC0 _MASTER uc)........................................................ 38

6.1.2 Traction Controller (COMBIAC0_SLAVE uc)............................................................. 69

6.1.3 Steering Controller (EPS-AC0)..................................................................................75

1

Correct use and Application

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are

supplied with the truck. The guidelines is an important component of these operating

instructions and must be observed. Your country's relevant laws and regulations is not

affected.

The truck described in the present operator manual is an industrial truck designed for

lifting and transporting load units.

It must be used, operated and serviced in accordance with the present instructions.

Any other type of use is beyond the scope of application and can result in damage to

personnel, the truck or property. In particular, avoid overloading the truck with loads

which are too heavy or placed on one side. The data plate attached to the truck or the

load diagram are binding for the maximum load capacity. The truck must not be used

in fire or explosion endangered areas, or areas threatened by corrosion or excessive

dust.

Proprietor responsibilities

For the purposes of the present operator manual the “proprietor” is defined as any

natural or legal person who either uses the truck himself, or on whose behalf it is used.

In special cases (e.g. leasing or renting) the proprietor is considered the person who,

in accordance with existing contractual agreements between the owner and user of

the truck, is charged with operational duties.

The proprietor must ensure that the truck is used only for the purpose it is intended for

and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The proprietor must ensure that all

truck users have read and understood this operator manual.

Failure to comply with the operator manual shall invalidate the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer’s customer service department.

Adding accessories

The mounting or installation of additional equipment which affects or enhances the

performance of the truck requires the written permission of the manufacturer. Local

authority approval may also need to be obtained.

Local authority approval does not however constitute the manufacturer’s approval.

2

1. Truck Description

1.1 Application

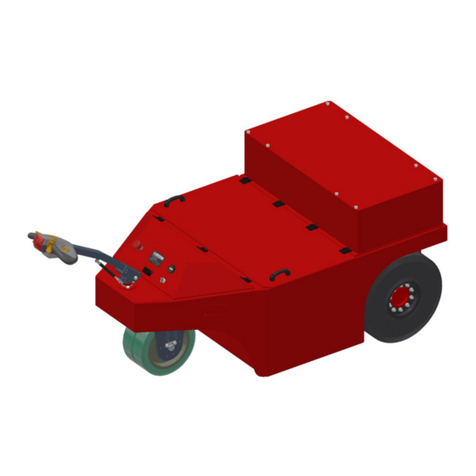

The J1HD is an electric truck.The J1HD is designed to transport and pick goods on

level surfaces.Loads can be stacked,unstacked and transported over long distances.

The capacity can be obtained from the data plate.

Warning!

The truck can only be used indoors !

3

1.2 Truck Assemblies

Item

Component

Item

Component

1

Control panel

11

Battery

2

Load handler

12

Dead man switch

3

Warning lamp

13

Height-adjustable operator position

4

Cover

14

Load wheel

5

Controller

15

Gates

6

Balance wheel

16

Pallet

7

Frame

17

Mast

8

Drive wheel

18

Blue lamp

9

Hydraulic pump

19

White lamp

10

Battery baffle

4

Safety mechanisms: An enclosed truck geometry with rounded edges ensures safe

handling of the truck. Pressing the Emergency brake switch disconnects all

electrical functions in hazardous situations.Gates on either side of the cab interrupt all

truck operations as soon as they are opened.When you start up the truck the drive

pedal must be applied.

Drive: The entire drive unit is enclosed in the truck chassis.

The electronic traction controller ensures the smooth rotation of the drive motor and

as a result smooth driving, powerful acceleration.

Brake system: The operator can brake gently and wear-free by pulling back the

travel control button.The electromagnetic spring pressure brake acting on the drive

motor serves as both parking and handbrake.

Steering system:Extremely smooth steering with three phase drive system.The

steering wheel is integrated in the control panel. The position of the steered drive

wheel is shown in the control panel display unit. The maximum steer angle is

90°.

Controls and Displays:The functions are activated via ergonomic thumb movement

to ensure fatigue-free operation without stressing the wrists; sensitive application of

travel and hydraulic movements to spare and position the goods precisely.Driver's

display unit for all important driver information such as steering wheel position,overall

lift, truck status reports (e.g. faults), battery capacity and time etc..

Hydraulic system :All hydraulic operations are controlled by a sturdy,

maintenance-free AC motor with no wear parts and with a flanged low emission gear

pump.Oil is distributed via magnetic switch valves. The varying oil requirements are

controlled by the speed of the motor.

Electrical system:Standard electronic drive, lift and steering control system.The

electronic drive control enables plugging when changing direction.

For controls options see chapter three.

5

1.3 Standard Version Specifications

Technical specification details in accordance with VDI2198. Technical modifications

and additions reserved.

Unit

Distinguishing mark

1.1

Manufacturer

EP

EP

1.2

Model designation

J1HD(4110)

J1HD(5330)

1.3

Drive unit

Electrics

Electrics

1.4

Operator type

standing

standing

1.5

rated capacity on front platform

Q1

Kg

Δ318

Δ318

rated capacity on behind platform

Q2

Kg

137

137

rated capacity on standing platform

Q3

Kg

136

136

1.9

Wheelbase

y

mm

1300

1300

Weight

2.1

Service weight (include battery)

kg

1440

1630

2.2

Axle loading, laden driving side/loading

side

kg

740/1100

780/1220

2.3

Axle loading, unladen driving

side/loading side

kg

520/820

540/990

Types,Chassis

3.1

Tyre type, Driving wheels/Loading wheels

polyurethane

/polyurethane

polyurethane

/polyurethane

3.2

Tyre size, driving wheels

(Diameter×Width)

mm

Φ260*125

Φ260*125

3.3

Tyre size, loading wheels

(Diameter×Width)

mm

Φ204*76

Φ204*76

3.4

Tyre size, caster wheels(diameter×width)

mm

Φ74*48

Φ74*48

3.5

Wheels, number driving,caster/loading

(x=drive wheels)

mm

1x,2/2

1x,2/2

Dimensions

4.2

Height, mast lowered

h1

mm

2120

2250

4.8

Seat height/standing height)

h7

mm

250

250

4.14

Stand height, elevated

h12

mm

4110

5330

4.19

Overall length

L1

mm

1685

1685

4.21

Overall width

b1/b2

mm

914

914

4.32

Ground clearance, center of wheelbase

m2

mm

50

50

4.33

front cargo platform width

B0×L2

mm

900×700

900×700

4.34

initial height of front cargo platform

h2

mm

1082

1082

4.35

Control handle height

h5

mm

1010

1010

6

4.36

behind platform width

L4×B1

mm

346×714

346×714

4.37

Overall length platform launch

L3

mm

2000

2000

4.38

The channel width

Ast

mm

2260

2260

4.39

Turning radius

Wa

mm

1600

1600

Performance data

5.1

drive speed, laden/unladen

km/ h

10.5

10.5

drive speed, laden/unladen

km/ h

5

5

drive speed, laden/unladen

km/ h

3.2

3.2

drive speed, laden/unladen

km/ h

1.6

1.6

5.2

Lifting speed, laden/ unladen

m/ s

0.20/0.28

0.20/0.28

5.3

Lowering speed, laden/ unladen)

m/ s

0.35/0.30

0.35/0.30

5.8

Max. gradeability, laden/unladen

%

0

0

5.10

Service brake type

Electromagnetic

Electromagnetic

Electric-engine

6.1

Drive motor rating S2 60 min

kW

4

4

6.2

Lift motor rating at S3 15%

kW

4

4

6.3

The maximum allowed size battery

mm

300x840x670

300x840x670

6.4

Battery voltage/nominal capacity K20

V/ Ah

48V/360AH

48V/360AH

6.5

Battery weight

kg

300

300

Addition data

8.1

Type of drive unit

AC

AC

10.5

Steering type

Electronic

Electronic

10.7

Sound pressure level at the driver’s ear

dB (A)

74

74

1)Including safety distance a = 200mm

7

J1HD

8

1.4 Identification points

9

Item

Description

1

Sling label

2

Information sign "Never standing"

3

Operator warning decal

4

Emergency Lowering label

5

AC Power Decal

6

“Never put your hands in inner and outer mast.“ warning

7

Nameplate

8

Operator danger decal

9

Key Switch decal

10

Lift Lower Horn decal

11

Forward/Reverse travel

12

Power shut off

13

Foot pedal label

14

Operator caution decal

10

2. Commissioning

2.1 Using the truck for the First Time

Only operate the truck with battery current.

Preparing the truck for operation after delivery or transport.

Procedure

•Check the equipment is complete.

•Check the hydraulic oil level.

•Install the battery if necessary (where required), (see "4.4 Battery removal and

installation" on page 23) do not damage battery cable.

•Charge the battery, (see "4.3 Charging the battery" on page 23).

When the truck is parked the surface of the tyres will flatten. The flattening will

disappear after a short period of operation.

2.2 During brake-in

We recommended operating the machine under light load conditions for the first stage

of operation to get the most from it. Especially the requirements given below should

be observed while the machine is in a stage of 100 hours of operation.

•Must prevent the new battery from over discharging when early used. Please

charging when remain power less than 20%.

•Perform specified preventive maintenance services carefully and completely.

•Avoid sudden stop, starts or turns.

•Oil changes and lubrication are recommended to do earlier than specified.

•Limited load is 70~80% of the rated load.

11

3.Operation

3.1 Safety Regulations for the Operation of trucks

Driver authorization: The truck may only be used by suitably trained personnel, who

have demonstrated to the proprietor or his representative that they can drive and

handle loads and have been authorized to operate the truck by the proprietor or his

representative.

Driver’s rights, obligations and responsibilities: The driver must be informed of

his duties and responsibilities and be instructed in the operation of the truck and

shall be familiar with the operator manual . The driver shall be afforded all due rights .

Safety shoes must be worn with pedestrian operated trucks.

Unauthorized Use of truck: The driver is responsible for the truck during the time it

is in use. He shall prevent unauthorized persons from driving or operating the truck. It

is forbidden to carry passengers or lift personnel.

Damage and Faults: The supervisor must be immediately informed of any damage or

faults to the truck. trucks not safe for operation (e.g. wheel or brake problems) must

not be used until they have been rectified.

Repairs: The driver must not carry out any repairs or alterations to the truck without

the necessary training and authorization to do so. The driver must never disable or

adjust safety mechanisms or switches.

Hazardous area: A hazardous area is defined as the area in which a person is at

risk due to truck movement, lifting operations, the load handler (e.g. forks or

attachments) or the load itself. This also includes areas which can be reached by

falling loads or lowering operating equipment.

·Unauthorized persons must be kept away from the hazardous area.

·Where there is anger to personnel, a warning must be sounded with sufficient

notice.

·If unauthorized personnel are still within the hazardous area the truck shall be

brought to a halt immediately.

Safety Devices and Warning Signs: Safety devices, warning signs and warning

instructions shall be strictly observed.

12

3.2 Controls and Displays

3.2.1 Control panel controls and displays

13

Item

Control / Display

Function

1

Steering wheel

Steers the truck in the required direction.

2

Display unit

Operating information and warning message display.

3

"Lifting" button

Lift the operator position.

4

"Lowering" button

Lower the operator position.

5

"Horn" button

Activates the horn.

6

Emergency stop switch

Disconnects the supply current, deactivates all electrical

functions, causing the truck to brake automatically.

7

Travel switch

Select the required driving direction.

8

Key switch

Switches control current on and off. Removing the key prevents

the truck from being switched on by unauthorized personnel.

9

White lamp button

Control white light lights on and off.

This manual suits for next models

1

Table of contents

Other EP Equipment Truck manuals

EP Equipment

EP Equipment HPL152 User manual

EP Equipment

EP Equipment EPT20-15ET User manual

EP Equipment

EP Equipment LIST JX0 User manual

EP Equipment

EP Equipment ES16-RS User manual

EP Equipment

EP Equipment CQE12R User manual

EP Equipment

EP Equipment EPT16-ET User manual

EP Equipment

EP Equipment EPL152 User manual

EP Equipment

EP Equipment CQD15S-E User manual

EP Equipment

EP Equipment HPL152 User manual

EP Equipment

EP Equipment LIST JX0 User manual