MPA Mini Series Instruction manual

ADJUSTABLE

MULTISPINDLE

HEADS

MANUAL ON USE

AND MAINTENANCE

TOOLS TO SHAPE THE WORLD

MADE IN

ITALY

COMUNITÀ

EUROPEA

UT1811 - 1010 - UK01

Page 2/32

ADJUSTABLE MULTISPINDLE HEADS

Page 2/32

Dear Customer,

We thank you for having chosen MPA and we hope that it fully satisfies your expectations,

guaranteeing a high quality production.

We kindly request you to read the instructions provided in this manual before starting to use

the product, as they provide important information on how to use and service the product in

absolute safety.

This manual also provides the technical features of the product, (also visible on the website:

www.m-p-a.it).

All rights reserved; this manual can be reprinted or reproduced only prior to formal written

authorisation by MPA srl.

Yours faithfully

MPA srl

Introduction

UT1811 - 1010 - UK01

Page 3/32

ADJUSTABLE MULTISPINDLE HEADS

Page 3/32

Manufacturer’s declaration

EEC MACHINE DIRECTIVE

MANUFACTURER’S DECLARATION

MPA srl

Via Pizzoli, 3 - Bargellino Cà Bianca

40012 Calderara di Reno (Bo) Italy

in the Person of the Legal Representative

declares that the adjustable multispindle heads

are compliant with the provisions of the

Machinery Directive 2006/42/EC

and forbids the start-up

before the machine in which the special series head

has to be fitted in is declared compliant with

Machinery Directive it self.

Signature of issuer

Marco Ceneri

EUROPEAN

COMMUNITY

UT1811 - 1010 - UK01

Page 4/32

ADJUSTABLE MULTISPINDLE HEADS

General warranty conditions

Page 4/32

General warranty conditions

Proper use and maintenance of the head will ensure that it stays in good working order.

Any modification, tampering, or improper use relieves MPA from all liability for accidents or

damage to persons or things occurring during the use the head.

MPA guarantees this product against material and manufacturing defects for a period of 12

months, considering ordinary usage. The use of non-original spare parts or failure to follow

the instructions provided in this manual will void the warranty. MPA guarantees exclusively

the repair or replacement of parts found to be defective by its service centre. MPA remains at

your complete disposal for any clarification and to provide any technical support necessary

for achieving the best performance of the head.

MPA reserves the right to make any modifications to all parts that are believed to be necessary

to improve the quality of the product without prior notice.

UT1811 - 1010 - UK01

Page 5/32

ADJUSTABLE MULTISPINDLE HEADS

Index

INDEX

Introduction....................................................................................................................2

Manufacturer’s declaration.............................................................................................3

General warranty conditions..........................................................................................4

1 GENERAL NOTES........................................................................................................7

1-1 Purpose of the document......................................................................................7

1-2 Symbols ................................................................................................................7

1-3 Main information ...................................................................................................8

1-4 Standard references .............................................................................................8

1-5 Noise level ............................................................................................................8

1-6 Packaging .............................................................................................................8

1-7 Transport...............................................................................................................9

1-8 Storage .................................................................................................................9

1-9 Disposal ................................................................................................................9

2 IDENTIFICATION ........................................................................................................11

2-1 Manufacturers’ Data............................................................................................11

2-2 Head identification data ......................................................................................11

3 MAIN DESCRIPTION..................................................................................................13

3-1 Intended use .......................................................................................................13

3-2 Improper use.......................................................................................................13

4 SAFETY RULES .........................................................................................................15

5 TECHNICAL FEATURES............................................................................................17

6 MACHINE CONNECTION ..........................................................................................19

6-1 Heads suitable for installation to units and drilling/tapping machines.................19

6-2 Special applications ............................................................................................20

7 INSTALLATION...........................................................................................................21

7-1 Balancing ............................................................................................................22

8 ADJUSTMENT............................................................................................................23

9 ASSEMBLY TOOLS AND ADJUSTING......................................................................25

9-1 ER collet DIN 6499 shape B ...............................................................................25

9-2 Tools adjustment and clamping ..........................................................................26

10 MAINTENANCE..........................................................................................................27

10-1 Personnel in charge ............................................................................................27

10-2 Scheduled maintenance .....................................................................................27

11 AFTER-SALES SERVICE AND SPARE PARTS ........................................................29

11-1 Customers service..............................................................................................29

11-2 Spare parts service.............................................................................................29

UT1811 - 1010 - UK01

Page 6/32

ADJUSTABLE MULTISPINDLE HEADS

Index

UT1811 - 1010 - UK01

Page 7/32

ADJUSTABLE MULTISPINDLE HEADS

1 General notes

1 GENERAL NOTES

1-1 Purpose of the document

The information in this manual has been provided to highlight the operations necessary for

the end user to correctly use and service the MPA heads. Information concerning installation,

adjustment and maintenance relating to the head you have purchased can be found in this

document.

Special attention has been given to questions matters involving the safety and safeguard of

the operators’ security, together with the safeguard and respect of the work area.

Before using the multispindle head, read carefully this manual and, in case of doubts, contact

the MPA After-sales technical service.

1-2 Symbols

In order to direct the readers’ attention on particularly important points in this manual, the

following graphs have been used:

DANGER Indicates an operation that must be carried out scrupulously in that it may

expose the operator to serious injuries.

IMPORTANT Indicates an operation that may cause damages to the adjustable head,

or simply recall the attention of the reader on certain particularly important

operations.

ADJUSTMENT Indicates adjusting operations. The operations marked with this symbol must

be carried out by technically qualified staff and with adequate mechanical

knowledge.

UT1811 - 1010 - UK01

Page 8/32

ADJUSTABLE MULTISPINDLE HEADS

1 General notes

1-3 Main information

To obtain maximum product yield in time, we recommend complying with the following

notes:

• Ensure to have correctly installed the multispindle head to the machine.

While choosing the connection to the tool machine, verify compatibility with the

declared performances.

The MPA head can be fitted to a tool machine equipped with regulatory accident-

prevention protections and in compliance with Machinery Directive 2006/42/EC.

• Absolutely avoid any improper use of the equipment and work with care and attention.

• Carry out regularly all routine maintenance interventions (see chap. 10).

• Use only original MPA spare parts (see chap. 11).

1-4 Standard references

The MPA head you have purchased is compliant with Machinery Directive 2006/42/EC (ex

98/37/EC).

1-5 Noise level

The MPA head complies with current Standards with regard to noise levels.

The manufacturer of the machine on which the head is fitted must provide the data

concerning the noise levels in the relative manual.

1-6 Packaging

The multispindle head you have purchased is supplied packed in cardboard boxes and

protected with shock-resistant protections.

IMPORTANT Upon receipt, check that the supply corresponds to the order specifications and

that no damages have occourred during the transport. In case of anomalies,

do not use the head and contact the manufacturer immediately.

Packaging must be disposed of in compliance with the local waste disposal Standards.

UT1811 - 1010 - UK01

Page 9/32

ADJUSTABLE MULTISPINDLE HEADS

1 General notes

1-7 Transport

During transport, keep in mind that you are handling a precision tool requiring adequate

caution. When carrying out the operation, observe the safety Standards in force with regard

to safety at work.

DANGER Do not disassemble, transport or re-assemble the head with tools fitted in

the spindles, as the sharp cutting parts could cause injuries.

For models with a weight above 10 kg, use a suitable hoisting mean for the operation.

1-8 Storage

In case you don’t use the head for a long time, it is a good rule to clean the head and to

protect it against salty, damp or chemically aggressive environments.

IMPORTANT

For inactivity periods of more than 6 months,before start-up, we recommend

to replace the lubricant inside the head (see chap. 10).

1-9 Disposal

The MPA heads are manufactured using the following substance:

• aluminium;

• steel;

• cast iron;

• lubricants.

IMPORTANT The head must be disposed of per type of substance, in strict compliance with

the legal regulations with regard to recycling and management of waste in

force in the country where the head is used.

In particular, exhaust lubricants must not be thrown outdoors but must

be handed over to specialised and authorised waste collection centres.

UT1811 - 1010 - UK01

Page 10/32

ADJUSTABLE MULTISPINDLE HEADS

1 General notes

UT1811 - 1010 - UK01

Page 11/32

ADJUSTABLE MULTISPINDLE HEADS

2 Identification

2 IDENTIFICATION

2-1 Manufacturers’ Data

MPA srl

Via Pizzoli, 3 Bargellino Cà-Bianca

40012 Calderara di Reno (Bo) Italy

VAT Number 00522081207

Tax Code 00739970374

+39 (051) 727073 +39 (051) 727730

[email protected] www.m-p-a.it

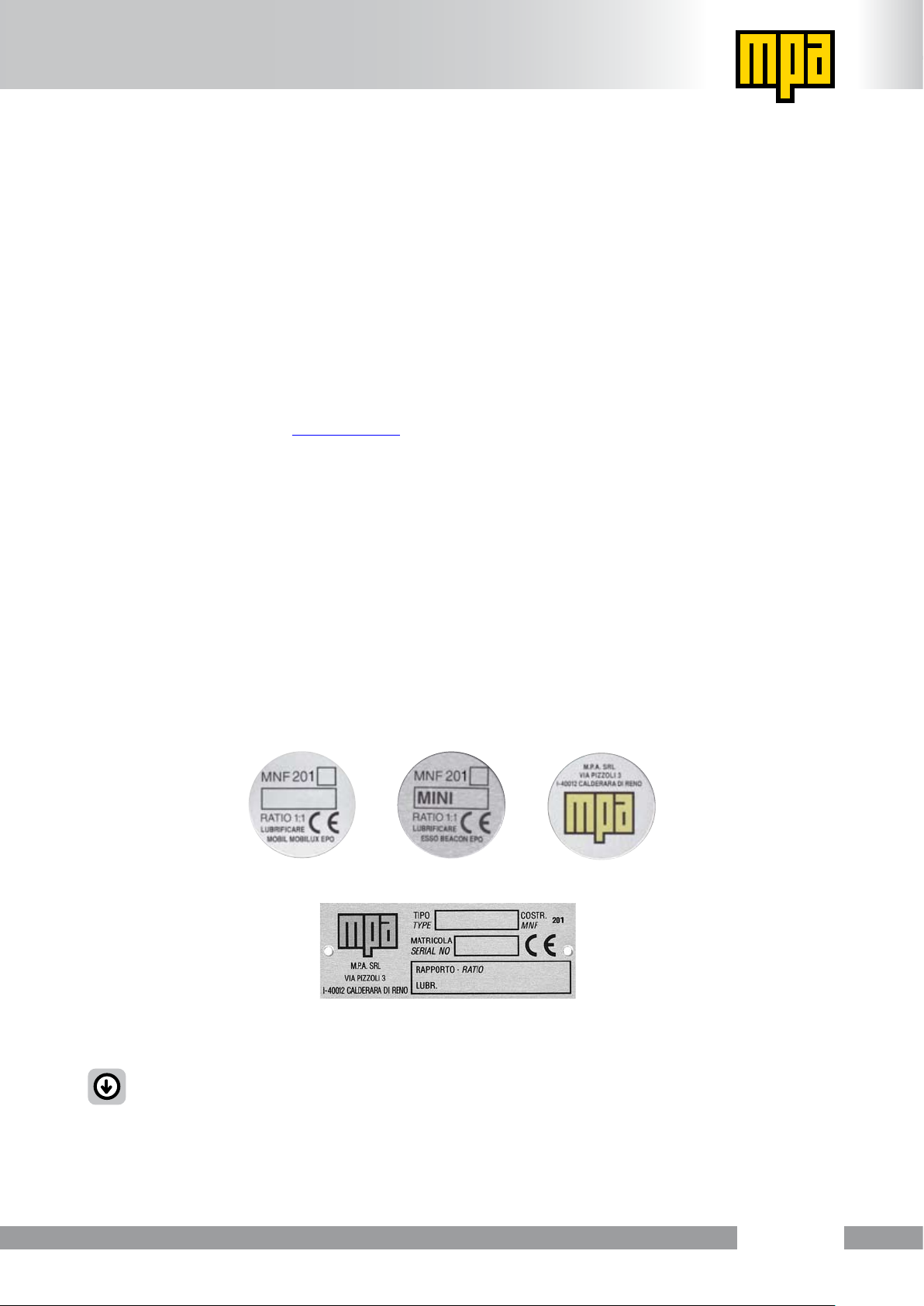

2-2 Head identification data

An aluminium identification nameplate is fitted on each MPA head indicating the main features

of the product. Fig. 1 illustrates example of identification nameplates displaying the data that

should be written on it.

As each model of MPA head is different in shape and size, the position and the shape of the

identification nameplate will vary depending on the model. It will could be of adhesive type

or riveted on one of the external surfaces.

Fig. 1

IMPORTANT It is forbidden to remove or tamper with the identification nameplate.

UT1811 - 1010 - UK01

Page 12/32

ADJUSTABLE MULTISPINDLE HEADS

2 Identification

UT1811 - 1010 - UK01

Page 13/32

ADJUSTABLE MULTISPINDLE HEADS

3 Main description

3 MAIN DESCRIPTION

The adjustable multispindle head you have purchased is composed as follows:

Fig. 2

ADJUSTABLE

SPINDLE

FASTENING SCREW

HEAD MAIN

BODY

ADJUSTABLE

SPINDLE UNIT

ADJUSTABLE

SPINDLE UNIT

VERSION WITH

ER COLLET

DIN 6499 shape B

VERSION WITH

SPINDLE

DIN 55058

3-1 Intended use

• The MPA heads have been designed and manufactured to drill, tap, chamfer and mill

(for 900 series), metal, plastic and wood materials. Any other use is to be considered

improper and relieves MPA from all liabilities.

3-2 Improper use

• The MPA heads are not suitable for tapping by means of interpolation.

Any different use to those indicated in point 3-1 of this manual, is to be considered improper

and, therefore, unauthorised, and relieves MPA from every liability for damages to persons

or things.

UT1811 - 1010 - UK01

Page 14/32

ADJUSTABLE MULTISPINDLE HEADS

3 Main description

UT1811 - 1010 - UK01

Page 15/32

ADJUSTABLE MULTISPINDLE HEADS

4 Safety rules

4 SAFETY RULES

• Before starting the tool machine, make sure that the head is correctly connected to the

machine and, consequently, that there is no risk of it releasing and falling off.

• Wear always industrial safety gloves when handling. Be sure that no cutting tools are

in the spindles. Don’t power up the head while carrying out service. Disassemble the

multispindle head, as the sharp parts may cut or injure the personnel.

• Don’t touch the head when it is moving. Any adjustments and interventions must be carried

out when the machine is inactive and in absolute safe conditions for the operator.

• The operating machine on which the MPA head is fitted, must be manufactured in

compliance with current safety Standards. All operator safety guards must be correctly fitted

and efficient and approved according to Machinery Directive 2006/42/EC (ex 98/37/EC).

The design of these safety guards is under the sole responsibility of the Manufacturer of

the machine on which the head is fitted; safety parameters must be cheched exclusively

by the factory manager where the head is used.

• Suitable clothing for workshop jobs must always be worn when using the MPA head.

It is therefore forbidden to wear ties, necklaces and any other non-adhering clothes or

accessories that may create a hazard.

The safety at work Standard in force must be complied with.

• During cleaning operations, especially when compressed air is being used, proceed with

caution and wear safety goggles or other suitable means of protection.

• The maximum rotation speed or the maximum spindle torque must not be exceeded (see

data published on the official website www.m-p-a.it).

Keep always transmission and rotation direction ratio under control; the values are shown

both on the nameplate and on the attached technical drawing.

• The use manual must always be kept handly where the head is being used. You also

must comply with the precautions in this manual, the general and local Standards in force

regarding accident prevention, and environmental protection.

DANGER If tools involving consistent rotating cams are used, operate at rotation speeds

such to prevent the centrifugal force created by the cams from compromising the

integrity of the spindle.

MPA engineering department is always at your complete disposal for any

advice on ideal operating conditions.

UT1811 - 1010 - UK01

Page 16/32

ADJUSTABLE MULTISPINDLE HEADS

4 Safety rules

• The forward movement speed of the tool must be adjusted so that no excessive axial

force is put on the tool, which could cause it to collapse with the consequent hazardous

cast-off of chips of material.

• Check the conditions and state signs of wear on the tool.

• Any anomalies on the head may cause serious damages and reduce significantly the life-

time and precision of the head. When in doubt, always contact MPA.

• The normal temperature of the head while it is working must not tendentiously exceed

60°C. Only during the first 100 hours of use the temperature can increase its maximum

value by about 25%.

UT1811 - 1010 - UK01

Page 17/32

ADJUSTABLE MULTISPINDLE HEADS

5 Technical features

5 TECHNICAL FEATURES

Sizes and technical features are available on the official website www.m-p-a.it.

UT1811 - 1010 - UK01

Page 18/32

ADJUSTABLE MULTISPINDLE HEADS

5 Technical features

UT1811 - 1010 - UK01

Page 19/32

ADJUSTABLE MULTISPINDLE HEADS

6 Machine connection

6 MACHINE CONNECTION

6-1 Heads suitable for installation to units and drilling/tapping

machines

• The power transmission works by means of driver and joint, depending on the type of

connection of the machine spindle.

Fig. 3 shows the different connection systems between the machine and the adjustable

multispindle head.

Fig. 3

CONNECTION

COUPLING

FLANGE

JOINT FOR

ISO SPINDLES

DRIVER FOR

SPINDLES DIN 55058

DRIVER

DIN 238

DRIVER

MORSE TAPER

JOINT

DRIVER FOR

SPINDLES

WITH COLLET

ADJUSTABLE

MULTI SPINDLE

HEAD

UT1811 - 1010 - UK01

Page 20/32

ADJUSTABLE MULTISPINDLE HEADS

6 Machine connection

6-2 Special applications

For other special connection, contact MPA Technical Department.

This manual suits for next models

15

Table of contents