Strongarm le100 User manual

273100085 EN

(Original instruction manual)

Edition 06.2015

Instruction manual for rescue equipment

Combination tools e100 and le100

e100

le100

2

Inhalt Seite

1.Danger classi¿cations 4

2.Product safety 5

3.Intended use 8

4.Functional description 10

4.1 Description 10

4.2 Structure and functions 11

4.3 Hydraulic circuit diagram 13

4.4 Operating movement controls 14

5.Operation 14

5.1 Battery for StrongArm™ e100/le100 14

5.2 Operating the star grip 15

6.Cutting, spreading, spread open doors 15

6.1 Safety notes 15

6.2 Cutting 16

6.3 Spreading 17

6.4 Spreading open doors 18

7.Accessories 20

7.1 Battery 20

7.2 Battery charger 21

7.3 Attachment strap 21

7.4 Accessory rail 22

8.Dismantling the equipment / deactivation following operation 23

9.Maintenance and service 23

9.1 Inspections StrongArm™ e100/le100 24

9.2 Protective equipment 24

9.3 Checking and exchanging the ¿lter element 25

10.Repairs 26

10.1 General information 26

10.2 Preventive service 27

10.3 Repairs 27

3

11.Troubleshooting 30

12.Technical data 31

12.1 StrongArm™ e100/le100 32

12.2 Noise emission 33

12.3 Operating and storage temperature ranges 33

12.4 Oscillation / vibration 33

12.5 Torque speci¿cation and wrench size for pivot bolt 33

13.Lighting (optional expansion possibility) 34

14.Instructions regarding disposal 36

15.Notes 37

Inhalt Seite

4

1. Danger classi¿cations

Wear a helmet with a face guard.

Wear protective gloves.

Wear safety shoes

Proper recycling

Protect the environment

Read and follow the operating instructions.

We differentiate between various categories of safety instructions. The table shown below

provides an overview of the assignment of symbols (pictograms) and signal words to the

speci¿c danger and the possible consequences.

Pictogram Damage /

injury to Keyword De¿nition Consequences

Persons

DANGER! Immediate danger Death or severe

injury

WARNING! Potentially

dangerous

situation

Potential death or

serious injury

CAUTION! Less dangerous

situation Minor or slight

injury

Property

ATTENTION! Risk of damage

to property/

environment

Damage to the

equipment,

damage to the

environment,

damage to

surroundings

- NOTE

Handling tips and

other important/

useful information

and advice

No injury/damage

to persons/

environment/

device

5

Please ensure that no body

parts or clothing are caught

between the visibly moving

parts (e.g. blade arms).

Working under suspended

loads is not permitted where

such loads are being lifted

only by means of hydraulic

or electro-hydraulic devices.

If this work is unavoidable,

suitable mechanical supports

are also required.

Wear protective clothing,

a safety helmet with visor,

protective footwear and

gloves.

Inspect the device before and

after use for visible defects or

damage.

2. Product safety

HURST products are developed and manufactured to ensure the best performance and

quality when used as intended.

Thesafetyoftheoperatoristhemostimportantconsiderationinproductdesign.Furthermore,

the operating instructions are intended to help you use HURST products safely.

The generally applicable legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be complied with in addition to

the operating instructions.

The equipment may only be operated by persons with appropriate training in the safety

aspects of such equipment, otherwise, there is a risk of injury.

Wewouldliketo point outtoall usersthatthey shouldcarefullyread the operatinginstructions

and the instructions they contain before they use the equipment and carefully follow them.

We further recommend that you have a quali¿ed trainer show you how to use the product.

CAUTION!

The operating instructions for accessories must also be taken into account!

Even if you have already received instructions on how to use the equipment, you should still

read through the following safety instructions again.

WARNING / CAUTION!

Please ensure that the accessories you use are appropriate for the maximum

operating pressure and the performance of the rescue device!

6

Immediately report any

changes that occur (including

changes in operating

behavior) to the appropriate

persons/departments! If

necessary, the equipment is

to be shut down immediately

and secured!

All bolted connections must

be checked for leaks and

externally visible damage,

which must be repaired

immediately! Escaping

hydraulic Àuid can cause

injuries and ¿res.

In the event of malfunction,

immediately deactivate the

device and secure it. Repair

the fault immediately.

Do not carry out any changes

(additions or conversions)

to the equipment without

obtaining the prior approval of

HURST.

Observe all safety and danger

information on the device and

in the operating instructions.

All safety and danger

instructions on the device

must always be complete and

in a legible condition.

Any mode of operation which

compromises the safety and/

or stability of the device is

forbidden!

Repairs to the equipment

may only be carried out by

a trained service technician

with speci¿c knowledge of the

device.

Safety devices may never be

disabled! Only genuine HURST

accessories and spare parts

are to be used for repairs.

Before switching on/starting

up the device and during its

operation, make sure that

nobody will be endangered

by this.

Observe all intervals

for recurring tests and/

or inspections that are

prescribed or stated in the

operating instructions.

When working close to live

components and cables,

suitable measures must

be taken to avoid current

transfers or high-voltage

transfers to the equipment.

Please note that material

could fall down or suddenly

break free during spreading,

cutting operations as a

result of shearing, tearing or

breaking; appropriate steps

must be taken to avoid this.

7

Please ensure that you do not

become entangled in cables

and trip when working with or

transporting the device.

Please ensure that the

battery contacts are not short-

circuited.

The build-up of static charges

and therefore possible

sparking must be avoided

when handling the device.

Only touch broken-off or

cut-off parts while wearing

protective gloves, as the torn /

cut edges can be very sharp.

Protect the device against

humidity and moisture. StrongArm™ e100/le100 is

NOT suitable for use under

water.

The equipment is ¿lled with

hydraulic Àuid. This hydraulic

Àuid can be detrimental to

health if it is swallowed or

its vapor is inhaled. Direct

contact with the skin must

be avoided for the same

reason. Also, when handling

hydraulic Àuid, note that it can

negatively affect biological

systems.

When working with or storing

the equipment, ensure that

the function and the safety

of the equipment are not

impaired by the effects of

severe external temperatures

and that the equipment is not

damaged in any way. Please

note that the equipment can

also heat up over a long

period of use.

Make sure that there is

adequate lighting while

working.

Before transporting the

equipment, always ensure

that the accessories are

positioned in such a way

that they cannot cause an

accident.

Always keep these operating

instructions easily accessible

at the place of operation.

Ensure the proper disposal of

all removed parts, left-over oil

and hydraulic Àuid as well as

packaging materials!

8

3. Intended use

StrongArm™ e100/le100 has been especially designed as a lightweight personal tool with

many uses. It can cut, spread and lift making it versatile from a RIT (Rapid Intervention

Team) situation, technical rescue, drug interdiction to a SWAT scenario.

The StrongArm™ tool will lift debris, cut through wires, cables, studs or be used as a

forcible entry tool to pry open doors, cut locks and spread or cut security bars.

Although the StrongArm™ tool is not a vehicle extrication tool it can be used to gain

access through the hood, trunk or doors in most situations.

It is cross-functional and proper training is required.

StrongArm™ e100/le100 is NOT suitable for use under water.

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and

are to be implemented in addition to the instruction manual .

WARNING / CAUTION / PLEASE NOTE!

The device is intended exclusively for the purpose stated in the operating instructions (see

chapter “Proper Use”). Any other use is not in accordance with its designated purpose.

The manufacturer/supplier is not liable for any damage resulting from improper use. The user

bears sole responsibility for such use.

Proper use includes observance of the operating instructions and compliance with the

inspection and maintenance conditions.

CAUTION / PLEASE NOTE!

Always take care in keeping any object or load properly secured while working.

When lifting, always use cribbing to shore and stabilize the load. Lift an inch, crib

an inch. Do not cut anything that is under tension (cables) or is a loose end.

WARNING / CAUTION!

StrongArm™ e100/le100 may only be operated with the proper tool tips

installed. Only use combi tips together OR only door opening tips together.

NEVER interchange tips! If tips are mixed and used on the tool any warranty or

guarantee claims will be voided.

Never work in a fatigued or intoxicated state!

9

WARNING / CAUTION / PLEASE NOTE!

The following may not be cut or spread:

- live cables

- prestressed and hardened parts such as springs, spring steels,

steering columns and rollers

- pipes under gas or liquid pressure,

- compound materials (steel/concrete)

- explosive bodies such as airbag cartridges

The operating pressure placed on the rescue device may only be directly changed

after consultation with HURST. A change in settings may result in damage to

property and/or injuries.

The StrongArm™ e100/le100 device is not explosion-protected!

When using the devices in potentially explosive environment, the following

must be excluded:

- that the device could trigger an explosion.

- that working with the device could trigger an explosion; e.g. sparks may result

from cutting an object.

The responsibility for explosion prevention or for ruling out work with the device is

with the operator of the device or with the person responsible at the place of use.

When working in areas at risk of explosion, all applicable legal,

national and international regulations, standards and safety rules

for avoiding explosions must be observed without restriction!

Thedeviceshouldnotcomeintocontactwithacidsoralkalies.Ifthisisunavoidable,

clean the equipment immediately afterwards with a suitable cleaning agent.

You can obtain replacement parts for the rescue tools from your authorized HURST dealer!

10

4. Functional description

4.1 Description

The cutting and spreading tool StrongArm™ e100/le100 has been designed in such a way

that a hydraulically operated piston activates mechanical joints symmetrically to open or

close a set of two opposing tool arms, thus enabling objects to be cut or spread.

Additionally, door opener tool tips especially designed for that purpose can be positioned in

very narrow gaps or cracks to spread them apart.

For all devices, the movement is activated by means of a valve in the form of a star grip.

All devices employee a deadman switch and full load-supporting function when the star grip

is released.

The StrongArm™ e100/le100 device does not need to be connected to an external hydraulic

source (e.g. a motor pump). Generation of the required hydraulic pressure takes place within

the body of the device.

A rechargeable battery serves as drive and energy source.

The accumulator battery can be inserted into the opening provided in the body of the tool.

It is then automatically locked into position.

You can extend the operating time of your device by using several batteries. The batteries

can be recharged after use, using the external charger.

A universal accessory rail is mounted to the top of the StrongArm™ to allow optional equip-

ment to be mounted to the tool. For example, a Àashlight can be mounted to facilite work

being done under poor lighting conditions.

There is an illuminated ring around the switch on the e100 (blue) StrongArm™ tool to in-

dicate the tool is on and ready for operation. The le100 (black) StrongArm™ tool does not

have this feature in order to keep visibility low.

Another indicator that either tool is ready for operation is that that the switch is recessed

when it is “on”. This also prevents accidental activation.

11

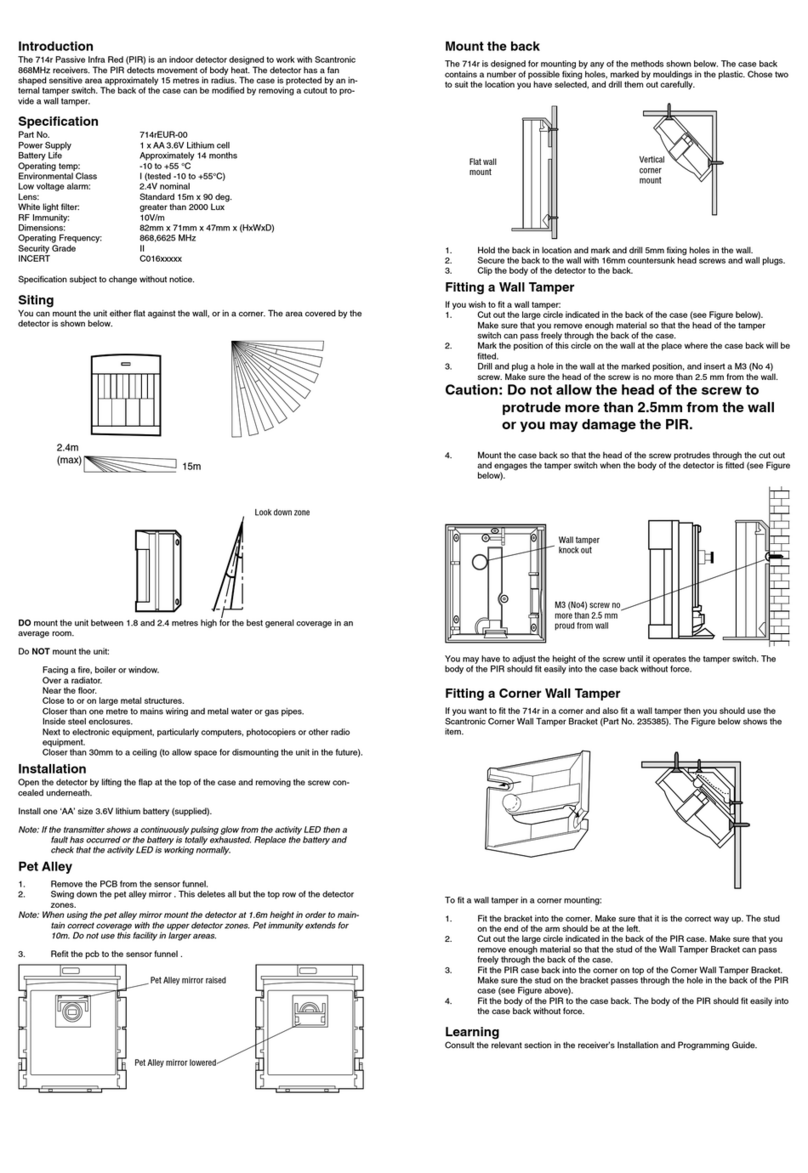

4.2 Structure and functions

4.2.1 Illustration with combination tips

16

1 Star grip

2 Main switch

3 Quick exchange battery

4 Release button for battery

5 Handle (rotates 360°)

6 Locking bolt, pull up to unlock

7 Ventilation slots

8 Tool tips

(combination snap-on tips)

9 Blade arms

10 Pivot bolt with secured nut

11a Front plastic housing

11b Rear plastic housing

12 Tool body

13 Protective cover

14 Accessory rail for optional light

15 Universal rail for optional

light

16 Light (optional expansion)

2

3

4

5

7

8

10

11a

1

13

12

15

6

911b

14

12

4.2.2 Blade arms without combi or door opening tips

Blade arm Cutting edge Blade arm

4.2.3 Combination tips (snap-on tips)

Combination tip

Push button to release and

automatically lock the tool tip

Please note!

Use caution installing or

emoving tips. Wear PPE

(gloves) to avoid injury.

13

4.2.4 Door opening tips (snap-on tips)

4.3 Hydraulic circuit diagram

Below a simpli¿ed hydraulic ram representing the tool is depicted.

A = tool B = star grip valve

AB

cutting / gripping / closing

spreading / opening

or extending the piston

or retracting the piston

2-Finger door

opening tip

3-Finger door opening tip

Push button to release

and automatically lock

the tool tip

4.2.5 Rotatable handle

The handle can be rotated about 360 degrees with four set points every 90 degrees. This

allows for easy change of position of the tool for the best angle attack. To do this, pull the

locking pin upwards while turning the handle to the desired position. Let go of the locking pin

and it will automatically engage the next locking position, thus securing the handle again.

Please note!

Use caution installing or

removing tips. Wear PPE

(gloves) to avoid injury.

14

4.4 Operating movement controls

The piston movement is controlled by the star grip on the attached valve (see illustration

below). The symbols show the turning direction for opening and closing the tool tips.

Star grip

5.1 Battery for StrongArm™ e100/le100

5. Operation

Commissioning

Before initial operation, the battery of the rescue device must be fully loaded, using the

external charger.

Procedure:

1. Fully press back the red release button and

pull the battery carefully out of the battery

cradle.

Do not use force!

2. The battery can now be recharged in the

battery charger and replaced again

(observe also the separate instruction

manual for the battery charger).

3. Insert the recharged or new battery into

the cradle so that the red release button

automatically engages. Thus, the battery is

locked again.

Battery cradle

1

2

15

Open the device or extend the piston ( ):

Turn the star grip in the direction of the corresponding symbol

(open / extend) and hold it in this position.

Close the device or retract the piston ( ):

Turn the star grip in the direction of the corresponding symbol

(close / retract) and hold it in this position.

Deadman function:

Following release, the star grip automatically returns to the pivot

position, fully guaranteeing load retention.

5.2 Operating the star grip

6. Cutting, spreading, spread open doors

6.1 Safety notes

Before rescue work can commence, the object must be stabilized in its current position.

Ensure that the objects to be worked on are adequately stabilized/shored to ensure that

there is no risk of sliding or shifting.

Worldwide safety guidelines pertaining to the speci¿c country must be observed and

complied with.

WARNING / CAUTION / PLEASE NOTE!

The StrongArm™ e100/le100 device is not explosion-protected!

When using the device in potentially explosive environments, the following

must be excluded:

- that the device could trigger an explosion.

- that working with the device could trigger an explosion; e.g. sparks may result

from cutting an object.

The responsibility for explosion prevention or for ruling out work with the device

lies with the operator of the device or with the person responsible at the place of

use.

When working in areas at risk of explosion, all applicable legal,

national and international regulations, standards and safety rules

for avoiding explosions must be observed without restriction!

16

It is strictly prohibited to reach into the path of the

device (e.g. between the blades/spreader arms and the

material/object to which the force is to be applied)!

CAUTION / PLEASE NOTE!

The strong effect of the force of the rescue equipment during operation could

cause pieces of the vehicle to break off or Ày off, posing a danger to persons.

Those not involved in the emergency operation should therefore keep at a safe

distance appropriate to the situation.Any trapped or enclosed persons must be

protected.

The following are to be worn when working with the rescue equipment:

- protective clothing,

- safety helmet with visor or protective goggles,

- protective gloves

- and, if necessary, ear protection

- wear special protective clothing in case of extremely high temperatures

Before operating the device, you should ensure that no participants or bystanders are at risk

from the movements of the device or from Àying fragments! Avoid unnecessary damage to

property belonging to others or to objects not involved in the rescue or damage caused by

Àying fragments.

6.2 Cutting

The blades should be positioned at a 90° angle to the object to be cut, if possible.

RIGHT

WRONG

12

93

15°

15°

90°

17

During cutting, the gap between the blade tips (in the transverse direction) must not be

exceeded, otherwise the blade is in danger of breaking:

ATTENTION!

Where possible, avoid cutting through high-strength parts of the vehicle body

(e.g. side impact protection). This may result in damage to the blades or to

increased wear and tear!

StrongArm™ max. gap at the blade tips

Unit [mm] / [in.]

e100 / le100 2 / 0.08

Higher cutting capacities can be achieved by cutting as close as possible to the blade’s pivot point.

RIGHT

WRONG

6.3 Spreading

Use the front of the tips only to increase an existing gap. To increase grip and to avoid having

the tips slip or break out of the part to be processed, the grip should be reapplied at an early

stage. The highest force develops in the rear area of the cutting tip or in the rear spreading

area of the

-on combi tip.

WARNING / CAUTION / PLEASE NOTE!

The steel tool arms may not be damaged.

Spreading Enlarging a gap

approx. 30 mm

approx. 1.2 in.

18

Working surface is too small,

tips slip off.

Only for increasing the size

of a gap (not suitable for

spreading)

Tips get a safe grip. Work with the tips only.

Do not damage the tool

arms!

(Illustration of the

spreader tips as an

example.)

6.4 Spreading open doors

The door opener tips are especially designed for using them for forced opening of locked

doors.

6.4.1 Points of application:

Doors with single protection: locking furniture and hinge plates.

Doors with multiple protection: locking furniture, hinge plates

and at each locking bolt, if required.

6.4.2 Procedure

When applying the unit, the claws must be pressed

or beaten into the door crack as hard and deep as

possible (refer to application examples).

When working in an environment which involves the

risk of explosions, sparks must be avoided when the

claws are pushed into the door gap!

WARNING / CAUTION / ATTENTION!

- There is the risk of sparks, if the device gets in contact with metal or stone!

- There is the danger of injuries in the area doors breaking open.

19

6.4.3 Operating safety instructions and application examples

When operating rescue devices, wear

• protective clothing

• helmet with visor or goggles

• protective gloves.

Application example - of¿ce door

Application example - steel door

WARNING / CAUTION / ATTENTION!

During operation of this rescue device, parts of the object worked on with this

device may break away and endanger people standing nearby. Onlookers must

be kept at a safety clearance (of at least 5 m / 16 ft.).

20

7.1 Battery

Only HURST lithium-ion rechargeable batteries may be used to operate the device. These

guarantee optimum performance and maximize the operating time of the device.

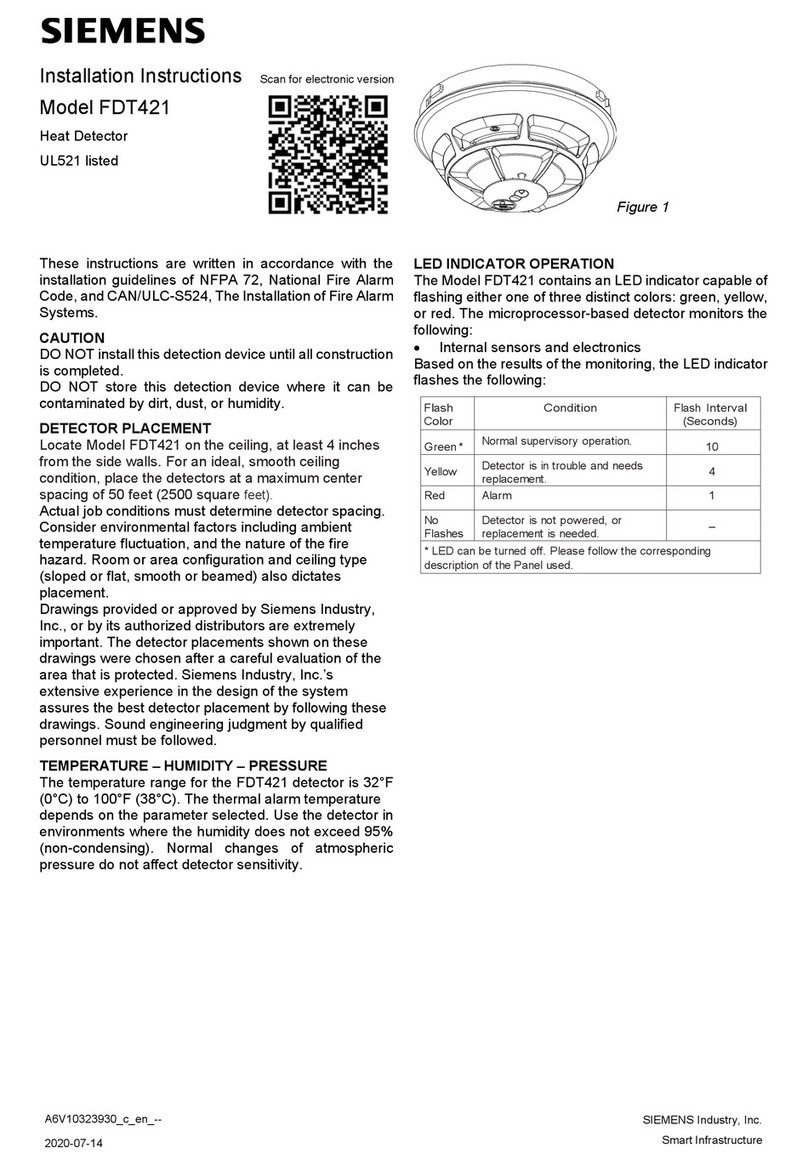

Charging state

display Query button(I)

Technical Data nom. Voltage Capacity Energy Weight

Unit V DC Ah Wh kg lb

Battery 25.2 3.9 98.3 1.2 2.6

NOTE:

To ensure maximum

operating time and maximum

uptime, you must make sure

that the battery is always fully

charged before connecting it

to a rescue device.

Release button

7. Accessories

NOTE:

Indicator lights are the

same as found on SCBA

systems (Self-Contained

Breathing Apparatus -

Symbols G, G, Y, R).

The charge status display is activated either by pressing a switch or activates automatically

when reaching a certain charge level (see table below).

Constant light

Constant light

Flashing yellow,

red continuous

light

Flashing red

till battery is

discharged

Automatic activationActivated by switch

Capacity No

No

Yes

15 seconds activated and 45

seconds off.After 8 hours the

activation cycle will terminate

automatically.

Yes

After 8 hours the activation cycle

will terminate automatically.

This manual suits for next models

1

Table of contents

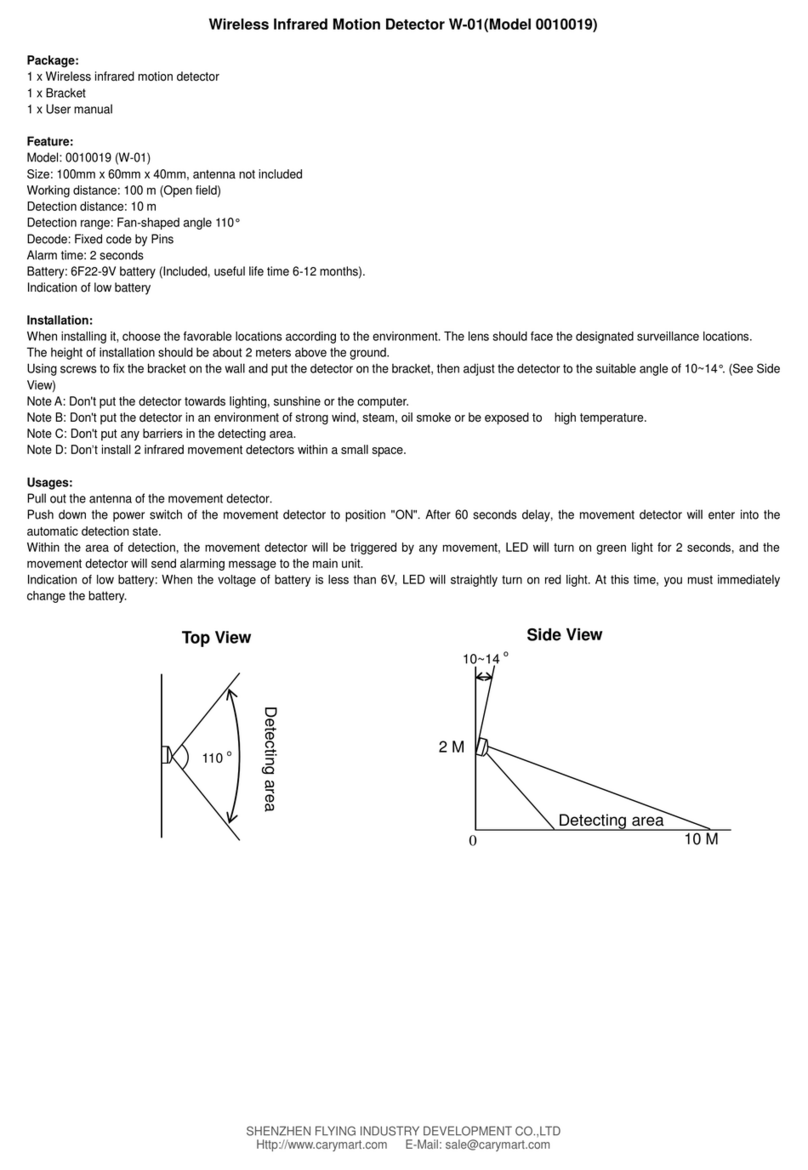

Popular Security Sensor manuals by other brands

STEINEL

STEINEL IS 1 quick start guide

Allen-Bradley

Allen-Bradley SensaGuard 440N-Z21SS2H-AS installation instructions

DEFA

DEFA LedgeCircle RF manual

SHENZHEN FLYING INDUSTRY DEVELOPMENT

SHENZHEN FLYING INDUSTRY DEVELOPMENT W-01 quick start guide

Cooper Menvier

Cooper Menvier Scantronic 714r manual

Siemens

Siemens FDT421 installation instructions