17 18

12. System alarms

System alarms Meaning Description

E0 Normal system No action

E1 Battery over-discharge

Turn off load output, after the battery voltage rises to the over

-discharge reconnect voltage, relieve over-discharge to restore

E2 Battery over-voltage Stop charging, check and find out the cause of high battery

voltage. The charging will be automatically restored after the

E3 Battery under-voltage warning Battery voltage below the under-voltage warning threshold,

E4 Load short-circuited Turn off load output

E5 Load over-current Turn off load output, and perform delay protection by a

E6

Over-temperature protection of

device

When the internal temperature is higher than the set

temperature, start the constant temperature control;

Charging is prohibited when the temperature is higher than

75°C, and charging is resumed when the temperature is lower

E7 Battery over-temperature protection Charging will be stopped when the battery temperature is above

65°C, and automatically resumed when it is below 60°C.

E10 Solar panel over-voltage Charging is stopped, and then automatically resumed when

the solar panel voltage is below the safety limit

E15 Lead acid battery is not connected In lead-acid battery mode, the battery is damaged or not

E16 Battery high temperature discharging

protection

Load output will be turned off when the battery temperature is

above 75°C and resumed when it is below 70°C.

E17 Battery low temperature discharging

protection

Load output will be turned off when the battery temperature is

below -35°C and resumed when it is above -30°C

E18 Overcharge protection Charging is stopped and then resumed 10s after the battery

E19 Battery low temperature charging

protection

Charging will be stopped when the battery temperature is

below -35°C and resumed when it is above -30°C

E30 Charging and discharging disabled

by system setting Off by default (set relevant registers by protocol)

E31 Charging overvoltage, overcurrent

and reverse current protection etc.

After the abnormal conditions are removed, the equipment

will recover automatically Be careful when installing battery. Wear protective goggles when installing a flooded lead-acid

battery. Once in contact with the battery acid, please rinse with water immediately.

Keep away from metal objects to prevent short-circuit of battery.

The battery may produce acid gas when charging. Make sure that the ambient environment is well-

ventilated.

The battery may produce combustible gas. Stay away from sparks.

When installing outdoors, avoid direct sunlight and rain seeping.

The falsely connected connection points and corroded wires may cause great heat, melt the wire

insulation, burn the surrounding materials, and even cause fire. Therefore, it is necessary to ensure

that all connectors are tightened, and the wires are preferably fixed with ties to avoid shaking of the

wires during mobile applications loose connector.

13.Common problems and solutions

Phenomenon Troubleshooting

LCD screen does not light up

There is voltage in the solar panel, there is no

voltage output from the battery side, and code

E1/E15 is displayed

The battery is not detected at the lead-acid battery end,

there is no voltage output from both ends of the battery.

Connect the battery to return to normal or turn on the

lead-acid battery activation switch

12V/24V normal voltage battery is connected,

the battery icon on the LCD screen flashes

slowly, and code E1 is displayed

Check the battery system voltage, or set it to automatically

identify and reboot the controller

The system voltage 12V/24V icon on the

screen flashes

Set system voltage change, prompting the user to reboot

the system for the change to take effect

The controller fails to charge

Check whether there is wrong wiring, whether the solar

panel voltage exceeds the rated value, whether the battery

is over-voltage, whether the LCD screen displays any

error code of internal over-temperature, external over-

temperature,external lithium battery low temperature, or

lead-acid battery open-circuit, and whether it displays

E7/E10, etc.

Charging power does not reach the rated

value

Perform system current limiting and thermostatic control;

Check to see if the system has reset charging current

Other problems or exceptions difficult to

resolve

Try to reboot (F01) or reset controller (F02), and reset

relevant parameters again as per system configurations.

Be careful!

Fail to start some loads Try enabling the load short-circuit function after checking

that the wiring is correct

The screen displays "full", and charging stops

Charging stops as the charging cut-off current conditions

are met. When the voltage is below the boost charging

reconnect voltage, the charging will be automatically

resumed

There is a system alarm code See "12. System alarms" for details

Check whether the battery and solar panel are properly

connected and whether the LCD connection cable has a

poor connection

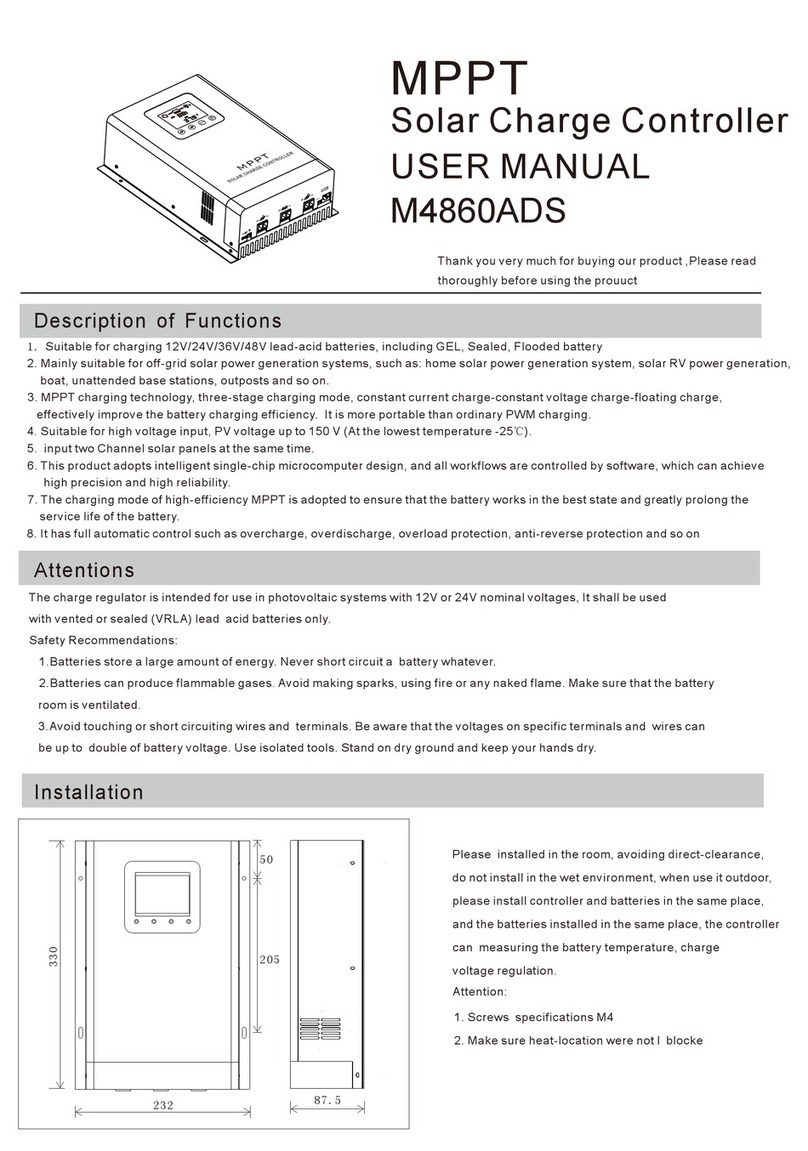

14.1 Installation precautions

14. Product Installation

multiple of rated current

voltage is lowered

load output

battery voltage is lowered

warning only

than 75°C.

connected.