Type S402Y

4

applicable codes) to prevent service

conditions from exceeding those limits.

Additionally, physical damage to the

regulator could result in personal

injury or property damage due to

escaping gas.

To avoid such injury and damage, install

the regulator in a safe location.

1. Only personnel qualied through training and

experience should install, operate, and maintain a

regulator. Before installing a Type S402Y

regulator, check for damage which have might

ocurred in shipment. Also check for dirt or foreign

materials which may have accumulated in the

regulator body or in the pipeline.

2. The Type S402Y may be installed in any position

(vertical or horizontal). Apply a good grade of

pipe compound to the male threads (being

sure not to apply pipe compound to ow path

of the pipe) of the pipe and install the regulator

so the ows is in the direction of the arrow cast

on the body. Use approved piping procedures

when installing the regulator. The spring case can

be rotated to any position relative to the body.

!

WARNING

A regulator may vent some gas to

the atmosphere. In hazardous or

ammable gas service, vented gas

may accumulate, and cause personal

injury, death, or property damage due

to re or explosion. Vent a regulator

in hazardous gas service to a remote,

safe location away from air intakes or

any hazardous location. The vent line

or stack opening must be protected

against condensation or clogging.

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the Type S402Y vent should be piped

away from the regulator to a safe

location outdoors.

3. On outdoors installations, regulators installed with

vents in positions other than vertically down

require additional vent protection from the

elements. Such protection may be with separate

hood, shields, or the Fisher®Y602 Series vents.

4. Regulator operation within the ratings does not

preclude the possibility of damage from the debris

in the lines or from external sources. A regulator

should be inspected for damage periodically and

after any overpressure condition.

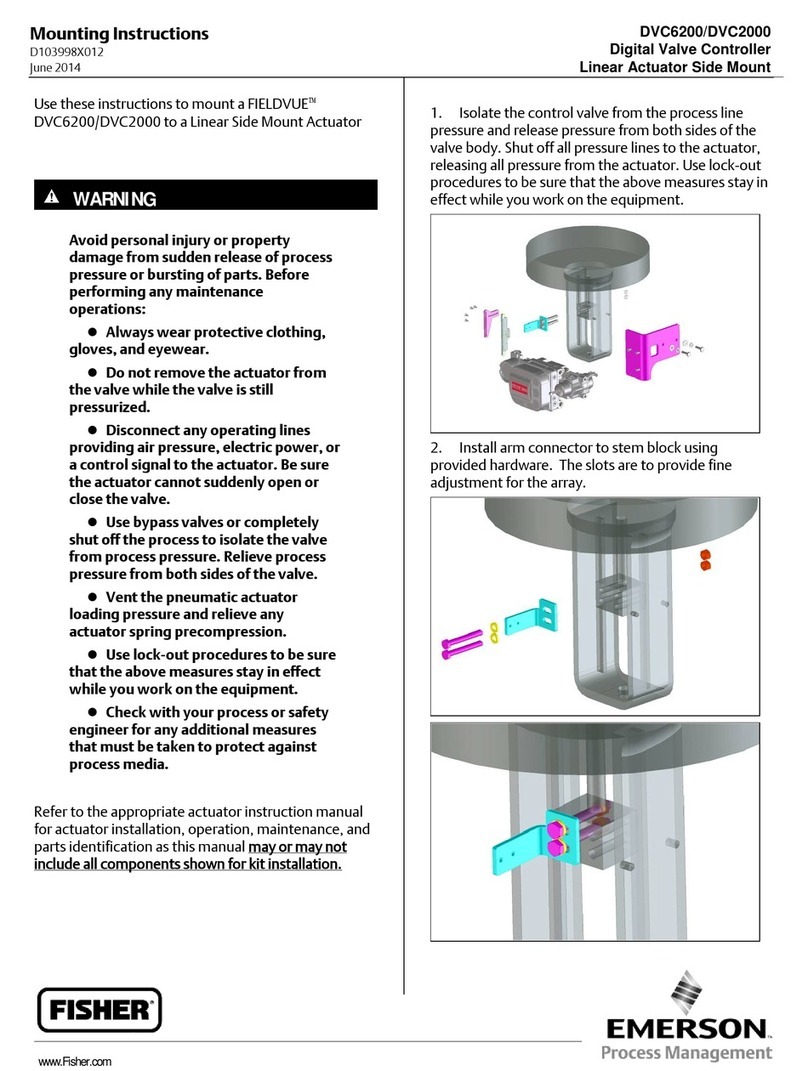

5. With proper installation completed, slowly open

the upstream and downstream shutoff valves.

Check all connections for leaks. Check the

downstream equipment for proper operation.

6. If outlet pressure adjustment is necessary, monitor

downstream pressure with a gauge during the

adjustment procedure. To increase the outlet

pressure, the adjusting screw (key 12, Figure 1)

must be turned clockwise. This requires removal of

the closing cap (key 11, Figure 1). To reduce the

outlet pressure setting, turn the adjusting screw

counter-clockwise. Do not adjust the spring to

procedure an outlet pressure setting above the limit

stamped on the regulator.

Overpressure Protection

The wide-open Cg for relief sizing along with the

capacity information should be used in choosing

appropriate overpressure protection devices to

ensure that none of the limits in the Specications

section, Table 1, or Table 2 are exceeded.

Overpressuring any portion of a regulator or

associated equipment may cause leakage,

parts damage, or personal injury due to bursting

of pressure-containing parts or explosion of

accumulated gas. Regulator operation within ratings

does not prevent the possibility of damage from

external sources or from debris in the pipeline. A

regulator should be inspected for damage after any

overpressure condition.

Startup

!

WARNING

In order to avoid an overpressure

condition and possible equipment

damage, pressure gauges should

always be used to monitor pressures

during startup.