Andco Eagle Actuator IOM NGS.IPG.0031| 3

In all mounting situations, the nal trimming

adjustment of the actuator installation is ±1/8 inch.

NOTICE

8. After Installation the actuator length can be adjusted

+/-1/8 inch

a. Loosen the jam nut (28).

b. Turn the Clevis (29) clockwise to decrease or counter

clockwise to increase the actuators installed length.

Because the thread grip is limited, make sure the clevis (29) is

engaged by a minimum of four threads and that it does not contact

the drive screw (4) when the extension rod (6) is fully retracted.

CAUTION

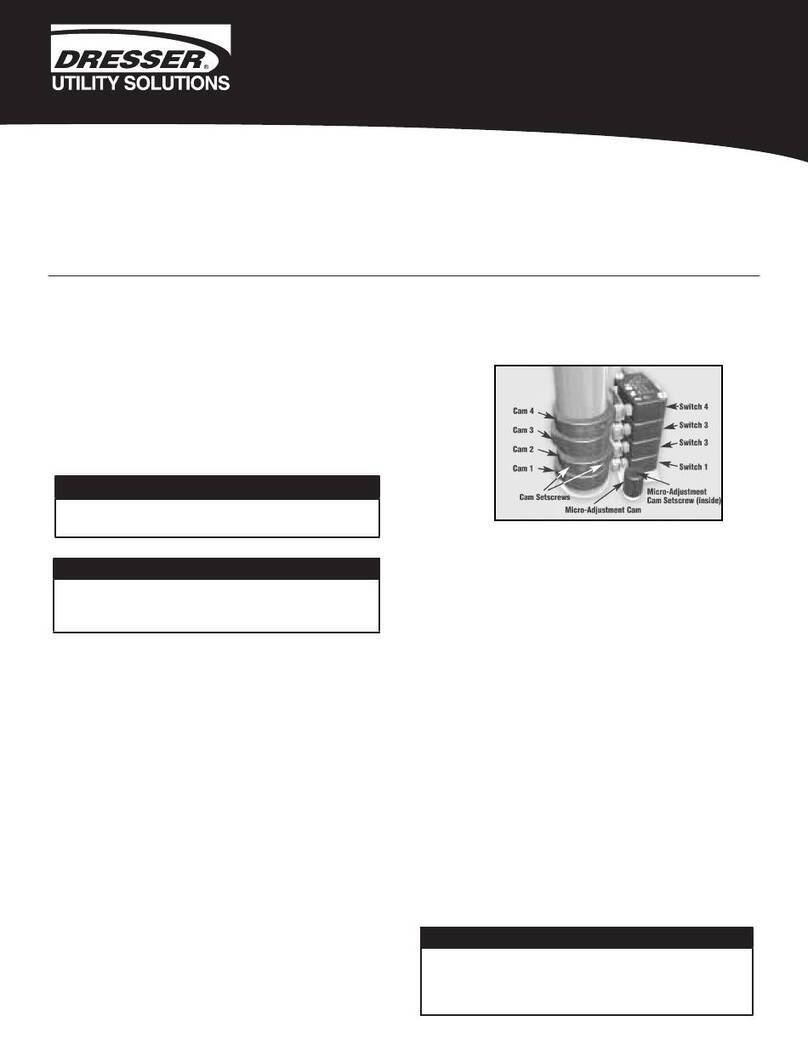

13. Keep limit switch compartment dry and clean.

To minimize the possibility of condensation damage, it is

suggested that moisture/gas tight conduit seals be installed

at the conduit connections.

14. Dust Ignition Proof Enclosure, Class II, Division 1, Groups E, F

& G.

Indoor and Outdoor Locations.

All actuators provided with dust-ignition proof enclosures must

have properly installed electrical access covers to exclude ignitable

amounts of dust. When reinstalling these covers make sure the

mating seating surfaces and gaskets are clean and the attachment

bolts are securely tightened. If the motor end bell pipe plug has

been removed to adjust the actuator, the pipe plug must be

reinstalled tightly. The actuators must be able to operate at full

rating without developing surface temperatures high enough

to cause excessive dehydration or gradual carbonization of any

organic dust deposits on the actuator enclosure.

The grounding lug on the actuator enclosure exterior must be

wired to a suitable grounding system with a minimum of #10

AWG wire as noted in the electric wiring diagram provided with

the actuator.

CAUTION

CONDUCTOR TEMPERATURE RATING

All conductors used for eld wiring connections to the actuator

shall carry a rating for a minimum temperature of 90°C.

CAUTION

LIFTING HAZARD

Single person lift could cause injury.

Use assistance when moving or lifting.

CAUTION

VOLTAGE SUPPLY

Verify that the supply voltage to the actuator matches the voltage

on the nameplate (33) on the gear compartment cover (21).

3. To prevent premature wear of the drive nut (7) or extension

rod seal/wiper (2), verify that the alignment between the

actuator mounting support and the driven equipment

places no side loading on the extension rod (6) at any point

throughout the full stroke length. Refer to Figure 2 on page

7.

4. Do not hammer or gouge the outside surface of the

extension rod (6). This may damage the plating integrity or

cause surface irregularities which can damage rod seals.

5. Face ange or trunnion mounted:

a. Position the body tube adapter (57) to the desired

orientation.

b. Verify that the pins of the trunnion mounting

conguration are parallel with the clevis pin.

c. Tighten the nut and bolt arrangement of the body tube

adapter to 50-55 ft-lbs. of torque.

6. For Clevis mounting: Verify the pins of the Clevis bracket

and for Clevis (29) are parallel.

7. Apply a light lm of lubricant to all pinned connections.

ATTENTION

TEMPÉRATURE NOMINALE DES CONDUCTEURS

Tous les conducteurs utilisés pour les raccordements du câblage sur

site de l’actionneur doivent présenter une température nominale

minimum de 90°C.

ATTENTION

RISQUE LIÉ AU LEVAGE

Le levage de l’unité par une seule personne est dangereux.

Demandez de l’aide lors du déplacement ou du levage de l’unité.

Dans toutes les situations de montage, le réglage nal de coupe de

l'installation de l'actionneur est de ±1/8 pouce (3,175 mm).

AVIS

Étant donné que le letage de la poignéeest limité, assurez-vous

que la chape (29) est engagée d'un minimum de quatre lets

et qu'elle ne touche pas la vis d'entraînement (4) lorsque la tige

d'extension (6) est complètement rétractée.

PRUDENCE

PRUDENCE

TENSION D'ALIMENTATION

Vérier que la tension d'alimentation vers l'actionneur correspond

sur la plaque signalétique (33) du couvercle du compartiment de

l'engrenage (21).

9. Upon completion of all mounting operations verify that

the jam nut (28) is tight, and that all cotter pins have been

secured.

10. The actuator must be installed and wired in accordance

with all local electrical codes and the most current edition

of the National Electrical Code.

11. Grounding connection must be wired to a TN-S, IT (with

insulation monitoring device), or TT (with residual current

device) type grounding system with a minimum of #10

AWG wire. (see below for picture).

12. Route the electrical conduit up into the actuator to prevent

internal condensation from running into the limit switch

compartment.