4

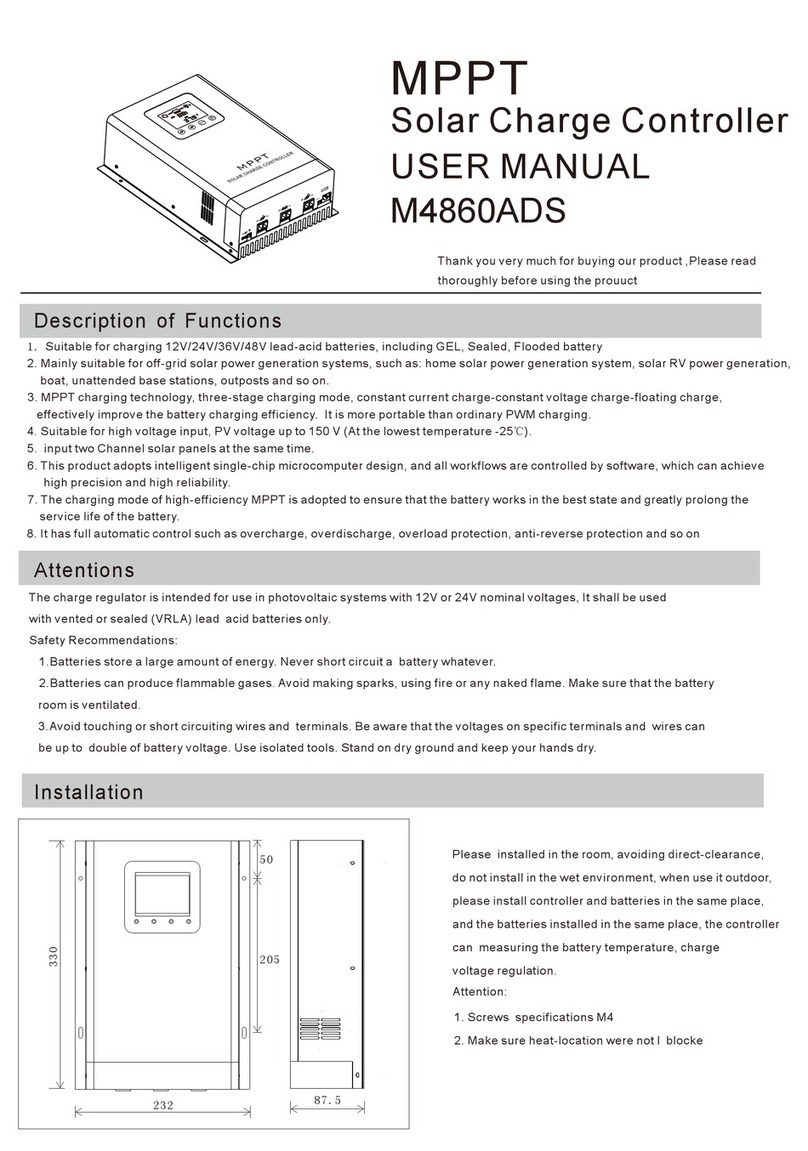

2. Installation Instructions

2.1 General Installation Notes

Please read the entire installation instructions to get familiar with the installation

steps before installation.

Be very careful when installing the batteries, especially flooded lead-acid battery.

Please wear eye protection, and have fresh water available to wash and clean any

contact with battery acid.

Keep the battery away from any metal objects, which may cause short circuit of the

battery.

Explosive battery gases may come out from the battery during charging, so make

sure ventilation condition is good.

Ventilation is highly recommended if mounted in an enclosure. Never install the

controller in a sealed enclosure with flooded batteries! Battery fumes from vented

batteries will corrode and destroy the controller circuits.

Loose power connections and corroded wires may result in high heat that can melt

wire insulation, burn surrounding materials, or even cause fire. Ensure tight

connections and use cable clamps to secure cables and prevent them from swaying

in mobile applications.

The controller can work with lead-acid battery and lithium battery within its control

scope.

Battery connection may be wired to one battery or a bank of batteries. The following

instructions refer to a singular battery, but it is implied that the battery connection

can be made to either one battery or a group of batteries in a battery bank.

Multiple same models of controllers can be installed in parallel on the same battery

bank to achieve higher charging current. Each controller must have its own solar

module(s).

Select the system cables according to 5A/mm2or less current density in accordance

with Article 690 of the National Electrical Code, NFPA 70.

2.2 PV Array Requirements

(1) Serial connection (string) of PV modules

As the core component of solar system, controller could be suitable for various types

of PV modules and maximize converting solar energy into electrical energy. According

to the open circuit voltage (Voc) and the maximum power point voltage (VMpp) of the

MPPT controller, the series number of different types PV modules can be calculated.

The below table is for reference only.