MPV BRIO 2000M User manual

Owner’s manual

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 1

ELECTRONIC PRESSURE CONTROL

FOR SINGLEPHASE PUMP

Type BRIO 2000M

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

INSTRUCTIONS FOR USE

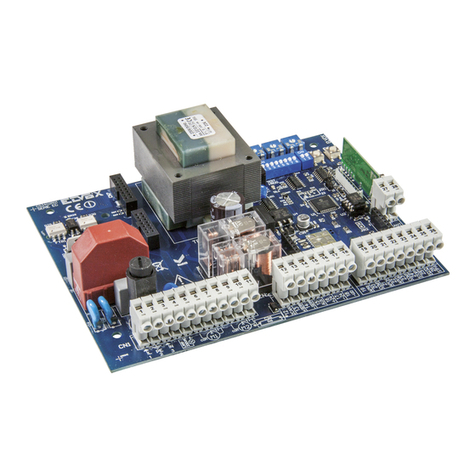

FUNCTIONAL PARTS

1. RESET button 6. 1” male threaded connection

outlet (By request, 1” female

revolving nut)

2. Dry stop indicator 7. Line connection

3. Voltage indicator 8. 1” male threaded connection

inlet (By request, 1” female

revolving nut)

4. Motor connection 9. Pressure gauge (Brio2000-M

and 2000-MT versions only)

5. Operating pressure setting

screw

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 11

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

1. FEATURES

Brio 2000 is designed to automatize the starting and stopping operations of

an electric pump with regard to a drop in pressure (opening of the taps) and to

the stopping of the flow through the system (closing of the taps), respectively.

Brio 2000 stops the pump when senses the lack of water flow, preventing it

from any damaging dry operation.

Furthermore, thanks to a timer, it starts the pump automatically to verify an

eventual new water availability in the suction line – Brio2000-T and 2000-MT

versions only.

It is advisable using Brio 2000 with water systems whose water is without

sediments. In case it is not possible, it is necessary to install a filter before the

inlet of the device.

The pressure gauge checks the starting pressure value and the pressure in

the system.

Furthermore it verifies any possible presence of water leakages in the very

system.

!

2. SAFETY REGULATIONS

To avoid shocks and fire risks, read and follow closely the

following instructions:

• Always unplug the device from the mains before carrying out any

work on it.

• Be sure that the electric line connecting the device to the mains

and the extension leads have a cross-section suitable for pump

power and be sure that the electrical connections are far away from

any water source.

• When Brio 2000 is used for swimming pools, ponds and fountains it

is necessary to use an automatic RCD with IDn=30mA protection.

WARNING: when the pump stops the pipes are under pressure

consequently we recommend opening a tap to discharge the system

before carrying out any work.

PLEASE READ THIS INSTRUCTION LEAFLET CAREFULLY THROUGH

BEFORE INSTALLING AND OPERATING THE DEVICE.

ALL WIRING UP MUST BE CARRIED OUT BY SPECIALLY TRAINED

PERSONNEL.

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 12

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

3. OPERATING INSTRUCTIONS

The switch starts up the pump for 15 seconds once connected to the line. Any

further pump starting occurs when the pre-set operating pressure value is

reached, accordingly to the drop in pressure in the tubing when opening a tap.

In the traditional water systems equipped with pressure switch and pressure

tank, the pump stops when a certain pressure value is reached. Differently

Brio 2000 has been projected to stop the pump depending on the reduction of

the flow to minimum levels.

Once this circustance has been reached, Brio 2000 delays the real stop of the

pump of a timing running from 7 to 15 seconds: the logic of this function is to

reduce the starting operations of the pumps in case of minimum flow

conditions.

4. INSTALLATION

1. Install Brio 2000 anywhere between the pump and the first service outlet

so that the arrows moulded on the case and on the outlet connection are

pointing to the same direction as the fluid flowing through the pipe.

Check perfect water tightness of all water connections. If you are using a

pump with a pressure higher than 10 bar, install a pressure reducer on

the Brio 2000’s inlet.

2. For the electrical connection of the version supplied without electric

leads, follow the wiring diagram on the printed circuit board cover, or on

the drawing following. Furthermore, in case of use of a pump with power

higher than ½ Hp and the ambient temperature is higher than 25° C it is

necessary to wire Brio 2000 with cables with a thermic resistance not

inferior to 99°C. Use only suitable wire nippers to wire the Fastons. If the

leads are included, simply connect the pump’s power plug to the Brio

2000 socket and its own power plug to a current outlet.

3. Operating pressure is pre-set at 1.5 bar which is the optimum value for

the majority of applications. Minimum operating pressure can be

adjusted as needed by turning the screw situated on the inside flange

marked with + and -.

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 13

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

ATTENTION: the check valve installed in the pump outlet and in the Brio 2000

inlet can cause some anomalies during the normal working of Brio 2000.

Therefore it’s advisable avoiding its installation between the pump and Brio

2000.

4. Attention:

To modify the operating pressure adjustment it is necessary to take the

cover away. Skilful people only must handle that operation, taking care

of the electric-shock risks.

Such pressure adjustment modifies the starting pressure limit of the

pump. The exit pressure of device never increases. The pressure

difference between the operating pressure value – set on the device –

and the maximum pressure of the pumps must be higher than 0,6 bar.

When it is necessary to modify the adjustment:

1_When the higher top is situated at more than 15 mt higher of the

device (max water column: 30 mt).

2_For the applications of the pump in load, that is when the loading

pressure is added up to the pressure of the pump, max. 10 bar.

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 14

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

220Vac

110Vac

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 15

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

WARNING: TO ENSURE CORRECT WORKING OF THE BRIO 2000,

MAXIMUM PUMP PRESSURE MUST BE AT LEAST 0,6 BAR HIGHER

THAN BRIO 2000 OPERATING PRESSURE.

5. STARTING BRIO 2000

WARNING: whenever the level of the priming water is lower than the

level of the water where the pump is placed, a suction line equipped

with an antibackflow foot valve is absolutely essential. This valve allows

the line to be filled when it is first used and prevents it from being

emptied when the pump stops.

1. Before turning on, fill up the suction pipe and pump with water and then

start the pump by connecting the Brio 2000 power plug to a current

outlet; when the pump stops open the tap situated higher up.

2. Installation is correct if the flow from the tap is regular and if the pump

works continuously. If there is no water you can try to make the pump

work without interruption - for a period of time longer than the device’s

working time - by keeping the RESET button depressed. If the problem

persists, disconnect the Brio 2000 and repeat the procedure from point

1.

6. DRY STOP

The red FAILURE LED lits up with motor off to indicate a dry stop. To start the

system again press the RESET button after having checked the presence of

water in the suction pipe.

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 16

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 17

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

BRIO 2000 UNICO 72PAG. 6-03-2007 11:50 Pagina 18

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

SPARE PARTS

BRIO 2000 UNICO 72PAG. 6-03-2007 11:51 Pagina 67

Regulateurs-pression-BRIO-200M-mpvnotice.pdf/mai15

www.motor-pump-ventilation.com

Table of contents

Popular Control Unit manuals by other brands

Nordson

Nordson iTRAX PRx II Customer product manual

Warren rupp

Warren rupp Sandpiper HD20F Service & operating manual

Parker

Parker C2 Series Installation & service instructions

Coreline

Coreline 150 Installation, operation & maintenance manual

Vimar

Vimar ELVOX RS11 Installation and operation manual

Assa Abloy

Assa Abloy Incedo InControl 3270 quick guide

Hitachi

Hitachi IR.LINK user manual

Telit Wireless Solutions

Telit Wireless Solutions NE866B1 Hardware Design Guide

Rabbit

Rabbit RabbitCore RCM3000 user manual

Fortec Star

Fortec Star COMe-bSC6 manual

Emerson

Emerson XJ200 Installation and operating instructions

HomeMatic

HomeMatic HmIP-PCBS Installation instructions and operating manual