4

SERVICE CHECKS

OPERATING CHECK

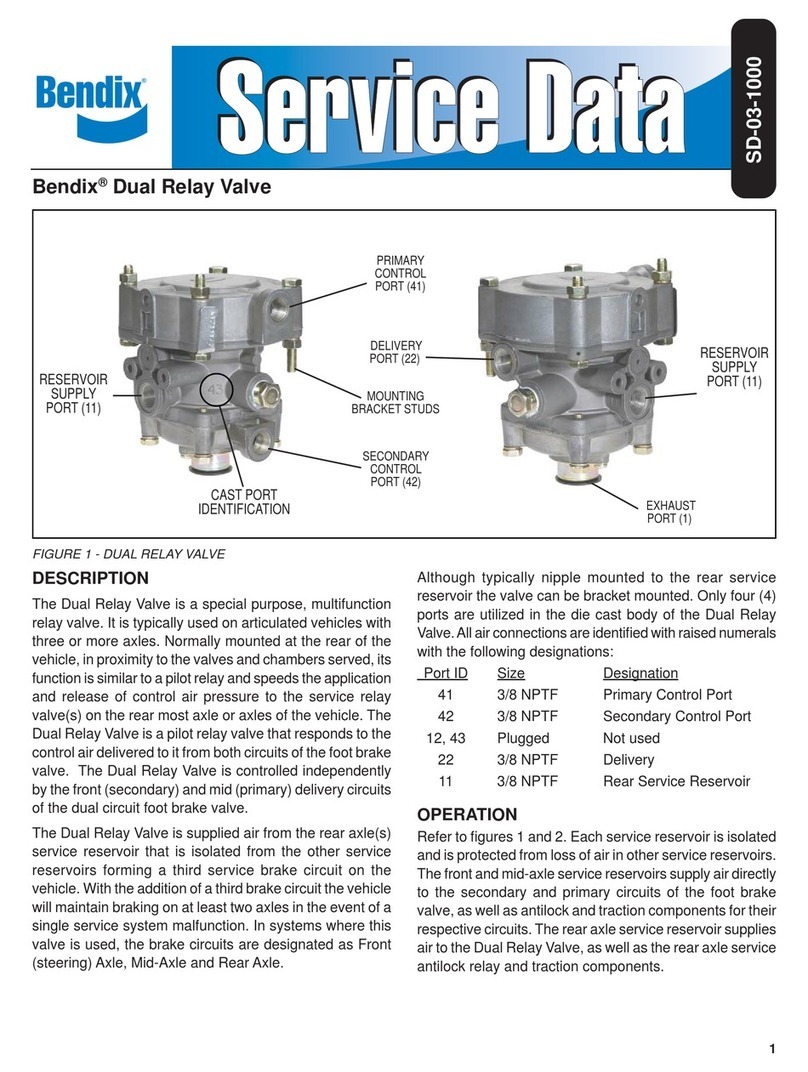

Checkthedeliverypressureof both primaryandsecondary

circuits using accurate test gauges. Depress the treadle

to several positions between the fully released and fully

appliedpositions,andcheckthe delivered pressure on the

testgaugestoseethatitvaries equally and proportionately

with the movement of the brake pedal.

After a full application is released, the reading on the test

gauges should fall off to zero promptly. It should be noted

that the primary and secondary delivery pressures may

vary by up to 5 psi for standard valves or up to 7.5 psi for

high differential valves with both supply reservoirs at the

same pressure. This is normal for this valve.

Important: A change in vehicle braking characteristics or

a low pressure warning may indicate a malfunction in one

or the other brake circuit, and although the vehicle air

brake system may continue to function, the vehicle should

not be operated until the necessary repairs have been

made and both braking circuits, including the pneumatic

and mechanical devices, are operating normally. Always

check the vehicle brake system for proper operation after

performing brake work and before returning the vehicle

to service.

LEAKAGE CHECK

1. Make and hold a high pressure (80 psi) application.

2. Coat the exhaust port and body of the brake valve with

a soap solution.

3. Leakage permitted is a 1” bubble in 3 seconds. If the

brake valve does not function as described above or

leakage is excessive, it is recommended that it be

replacedwithaneworremanufacturedunit,orrepaired

with genuine Bendix®parts available at authorized

Bendix®parts outlets.

REMOVAL

1. Check the vehicle wheels or park the vehicle by

mechanical means. Drain all air system reservoirs.

2. Identify and disconnect all supply and delivery lines at

the brake valve.

3. Remove the brake valve and treadle assembly from

the vehicle by removing the three cap screws on the

outer bolt circle of the mounting plate. The basic brake

valvealonecanberemovedbyremovingthethreecap

screws on the inner bolt circle.

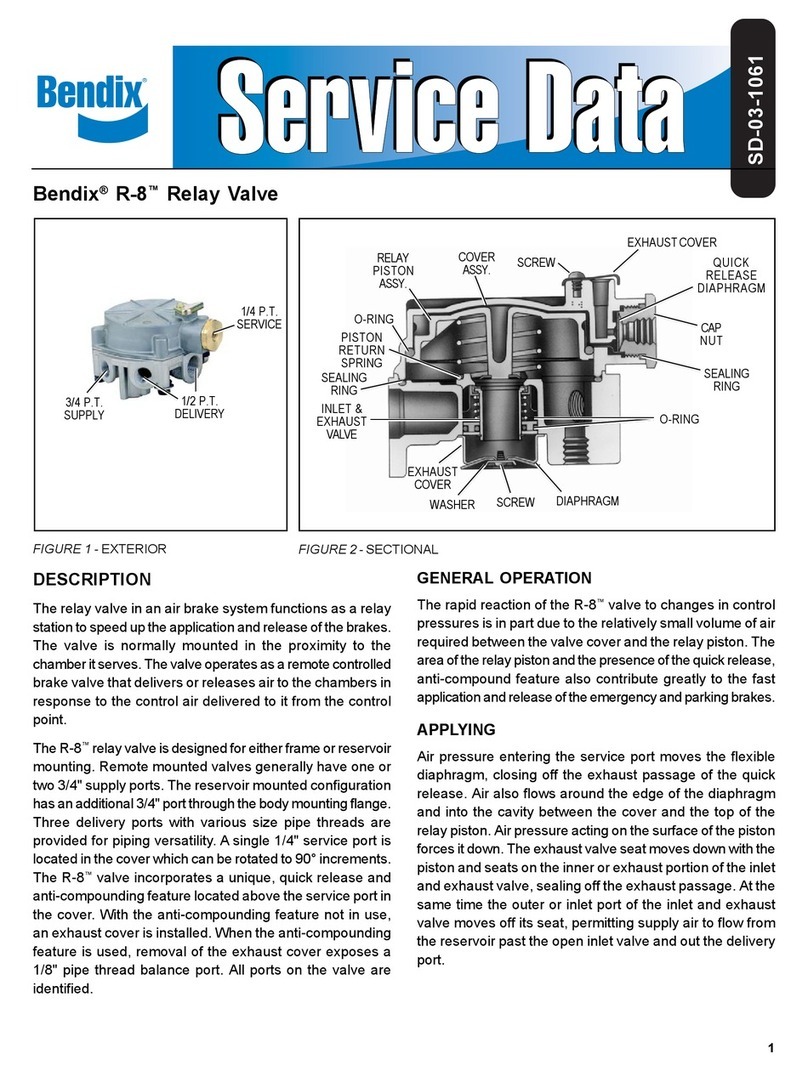

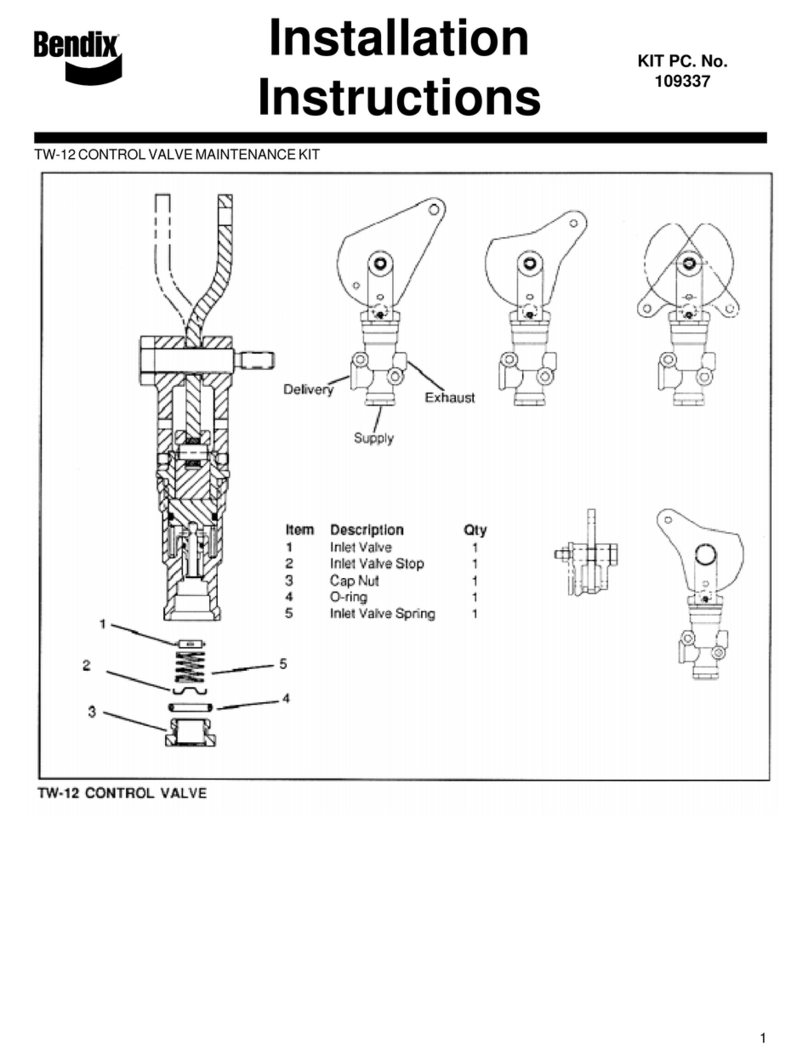

DISASSEMBLY (Figures 3 and 4)

1. If the entire brake valve and treadle assembly was

removedfromthevehicle, remove thethreecapscrews

securing the treadle assembly to the basic brake

valve.

2. Removethescrew(9)securingtheexhaustdiaphragm

(10) and washer (11) to the exhaust cover (12).

3. Removethefour screws that secure the exhaust cover

(12) to the lower body.

4. Remove the Secondary inlet and exhaust valve

assembly (13) from the lower body.

5. Remove the four hex head cap screws securing the

lower body to the upper body and separate the body

halves.

6. Remove the rubber seal ring (14) from the lower body.

BENDIX®E-6®BRAKE VALVE ONLY (Figure 3):

7. Whileapplyingthumbpressuretothe primary piston, lift

out and up on the three lock tabs of the primary piston

retainer (15).

BENDIX®E-10™BRAKE VALVE ONLY (Figure 4):

8. A. While depressing the spring seat (7), remove

retaining ring (8).

B. Remove the spring seat and coil spring (5).

9. Using a 3/8” wrench, hold the lock nut (16) on the

threaded end of the stem (17) in the primary piston (2).

Insertascrewdriverintheexhaustpassagethroughthe

center of the valve and engage the slotted head of the

stem.

10.Remove lock nut (16), spring seat (18), stem spring

(19),primarypiston(2), andprimarypistonreturnspring

(6). Remove o-ring (34).

11. Remove adapter (1). Remove o-ring (4) from adapter.

Caution:Beforeproceedingwiththedisassembly, refer

toFigure4andnote that thelocknutandstemareused

tocontaintheprimarypiston return spring, stem spring

andtherelay pistonspring.The combinedforceofthese

springs is approximately 50 pounds and care must be

taken when removing the lock nut as the spring forces

will be released. It is recommended that the primary

piston and relay piston be manually or mechanically

contained while the nut and stem are being removed.

BENDIX®E-6®BRAKE VALVE ONLY:

12.Using a screwdriver to restrain the stem, as in step

nine, remove the lock nut (16), spring seat (18) and

stem spring (19).

13.Remove the relay piston (20), relay piston spring

(21), primary piston and primary piston return spring

(23) from the upper body. Use care so as not to nick

seats.

Note: Certain E-6®brake valves do not have a relay

piston spring (21). If this spring is not found, do not

install a replacement.

14.On valves manufactured after October 7,1976, a small

washer (24) will be found in the cavity in the lower side

of the primary piston (22).