MPV MN 11 User manual

BENNING MM 11

Aufwicklung der Sicherheitsmessleitung

Wrapping up the safety test leads

Enroulement du câble de mesure de sécurité

Arrollamiento de la conducción protegida de medición

Navíjení měřících kabelů

Τυλίξτε τα καλώδια μέτρησης

Avvolgimento dei cavetti di sicurezza

Wikkeling van veiligheidsmeetsnoeren

Zwijanie przewodów pomiarowych

Намотка безопасного измерительного провода

Placering av säkerhetsmätsladdar

Emniyet Ölçüm tesisatının sarılması

Aufstellung des BENNING MM 11

Standing up the BENNING MM 11

Installation du BENNING MM 11

Colocación del BENNING MM 11

Postavení BENNING MM 11

Κρατώντας όρθιο το BENNING MM 11

Posizionamento del BENNING MM 11

Opstelling van de multimeter BENNING MM 11

Przyrząd BENNING 11 w pozycji stojącej

Установка прибора BENNING MM 11

Instrumentstöd BENNING MM 11

BENNING MM 11 ‘in kurulumu

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

8VHUVPDQXDO

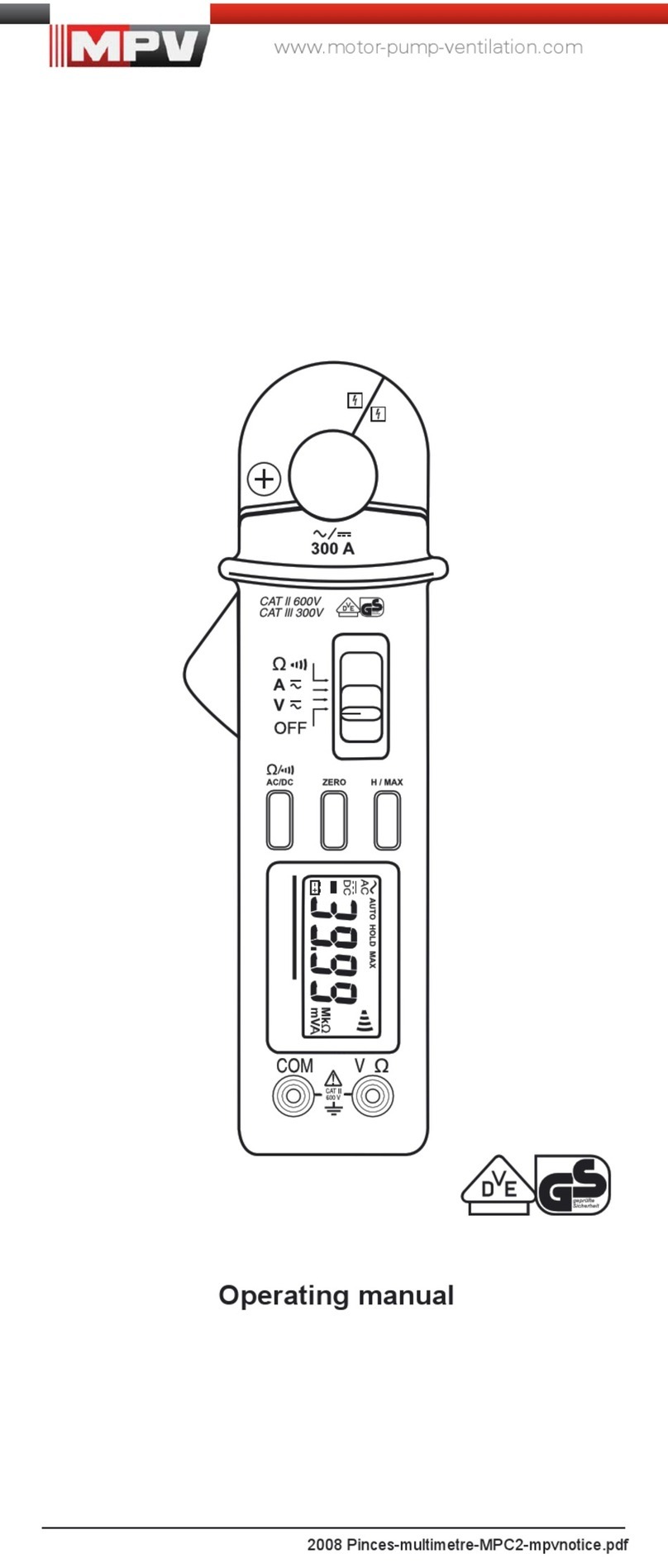

M1

Benning Elektrotechnik & Elektronik GmbH & Co. KG

Münsterstraße 135 - 137

D - 46397 Bocholt

Telefon ++49 (0) 2871- 93 - 0 • Fax ++49 (0) 2871- 93 - 429

Bild 10: Frequenzmessung

Fig. 10: Frequency measurement

Fig. 10: Mesure de fréquence

Fig. 10: Medición de frecuencia

obr. 10: Měření frekvence

σχήμα 10:

Μέτρηση συχνότητας/ λόγος μηχανικού παλμού

ill. 10: Misura di frequenza

Fig. 10: Frequentiemeting

Rys.10: Pomiar częstotliwości

рис. 10 Измерение частоты

Fig. 10: Frekvensmätning

Resim 10: Frekans Ölçümü

Bild 11: Temperaturmessung

Fig. 11: Temperature measurement

Fig. 11: Mesure de la température

Fig. 11: Medición de temperatura

obr. 11: Měření teploty

σχήμα 11: Μέτρηση θερμοκρασίας

ill. 11: Misura di temperatura

Fig. 11: Temperatuurmeting

Rys.11: Pomiar temperatury

рис. 11 Измерение температуры

Fig. 11: Temperaturmätning

Resim 11: Isı Ölçümü

Bild 12: Batteriewechsel

Fig. 12: Battery replacement

Fig. 12: Remplacement de la pile

Fig. 12: Cambio de pila

obr. 12: Výměna baterií

σχήμα 12: Αντικατάσταση μπαταρίας

ill. 12: Sostituzione batterie

Fig. 12: Vervanging van de batterijen

Rys.12: Wymiana baterii

рис. 12 Замена батарейки

Fig. 12: Batteribyte

Resim 12: Batarya Değişimi

Bild 13: Sicherungswechsel

Fig. 13: Fuse replacement

Fig. 13: Remplacement des fusibles

Fig. 13: Cambio de fusible

obr. 13: Výměna pojistek

σχήμα 13: αντικατάσταση ασφάλειας

ill. 13: Sostituzione fusibile

Fig. 13: Vervanging van de smeltzekeringen

Rys.13: Wymiana bezpiecznika

рис. 13 Замена предохранителя

Fig. 13: Säkringsbyte

Resim 13: Sigorta Değişimi

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

Benning Elektrotechnik & Elektronik GmbH & Co. KG

Münsterstraße 135 - 137

D - 46397 Bocholt

Telefon ++49 (0) 2871- 93 - 0 • Fax ++49 (0) 2871- 93 - 429

D F E I S

09/ 200709/ 2007

BENNING MM 11

BENNING MM 11

Bild 10: Frequenzmessung

Fig. 10: Frequency measurement

Fig. 10: Mesure de fréquence

Fig. 10: Medición de frecuencia

obr. 10: Měření frekvence

σχήμα 10:

Μέτρηση συχνότητας/ λόγος μηχανικού παλμού

ill. 10: Misura di frequenza

Fig. 10: Frequentiemeting

Rys.10: Pomiar częstotliwości

рис. 10 Измерение частоты

Fig. 10: Frekvensmätning

Resim 10: Frekans Ölçümü

Bild 11: Temperaturmessung

Fig. 11: Temperature measurement

Fig. 11: Mesure de la température

Fig. 11: Medición de temperatura

obr. 11: Měření teploty

σχήμα 11: Μέτρηση θερμοκρασίας

ill. 11: Misura di temperatura

Fig. 11: Temperatuurmeting

Rys.11: Pomiar temperatury

рис. 11 Измерение температуры

Fig. 11: Temperaturmätning

Resim 11: Isı Ölçümü

Bild 12: Batteriewechsel

Fig. 12: Battery replacement

Fig. 12: Remplacement de la pile

Fig. 12: Cambio de pila

obr. 12: Výměna baterií

σχήμα 12: Αντικατάσταση μπαταρίας

ill. 12: Sostituzione batterie

Fig. 12: Vervanging van de batterijen

Rys.12: Wymiana baterii

рис. 12 Замена батарейки

Fig. 12: Batteribyte

Resim 12: Batarya Değişimi

Bild 13: Sicherungswechsel

Fig. 13: Fuse replacement

Fig. 13: Remplacement des fusibles

Fig. 13: Cambio de fusible

obr. 13: Výměna pojistek

σχήμα 13: αντικατάσταση ασφάλειας

ill. 13: Sostituzione fusibile

Fig. 13: Vervanging van de smeltzekeringen

Rys.13: Wymiana bezpiecznika

рис. 13 Замена предохранителя

Fig. 13: Säkringsbyte

Resim 13: Sigorta Değişimi

Bild 14: Aufwicklung der Sicherheitsmessleitung

Fig. 14: Wrapping up the safety test leads

Fig. 14: Enroulement du câble de mesure de sécurité

Fig. 14: Arrollamiento de la conducción protegida de medición

obr. 14: Navíjení měřících kabelů

σχήμα 14: Τυλίξτε τα καλώδια μέτρησης

ill. 14: Avvolgimento dei cavetti di sicurezza

Fig. 14: Wikkeling van veiligheidsmeetsnoeren

Rys.14: Zwijanie przewodów pomiarowych

рис. 14 Намотка безопасного измерительного провода

Fig. 14: Placering av säkerhetsmätsladdar

Resim 14: Emniyet Ölçüm tesisatının sarılması

Bild 15: Aufstellung des 01

Fig. 15: Standing up the 01

Fig. 15: Installation du 01

Fig. 15: Colocación del 01

obr. 15: Postavení 01

σχήμα 15: Κρατώντας όρθιο το 01

ill. 15: Posizionamento del 01

Fig. 15: Opstelling van de multimeter 01

Rys.15: Przyrząd 01 w pozycji stojącej

рис. 15 Установка прибора 01

Fig. 15: Instrumentstöd 01

Resim 15: 01 ‘in kurulumu

DBedienungsanleitung

Operating manual

FNotice d‘emploi

EInstrucciones de servicio

Návod k obsluze

Οδηγίες χρήσεως

IIstruzioni d’uso

Gebruiksaanwijzing

Instrukcja obsługi

Инструкция по эксплуатации

индикатора напряжения

SBruksanvisning

Kullanma Talimati

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

BENNING MM 11

D F E I S

09/ 2007

BENNING MM 11

09/ 2007

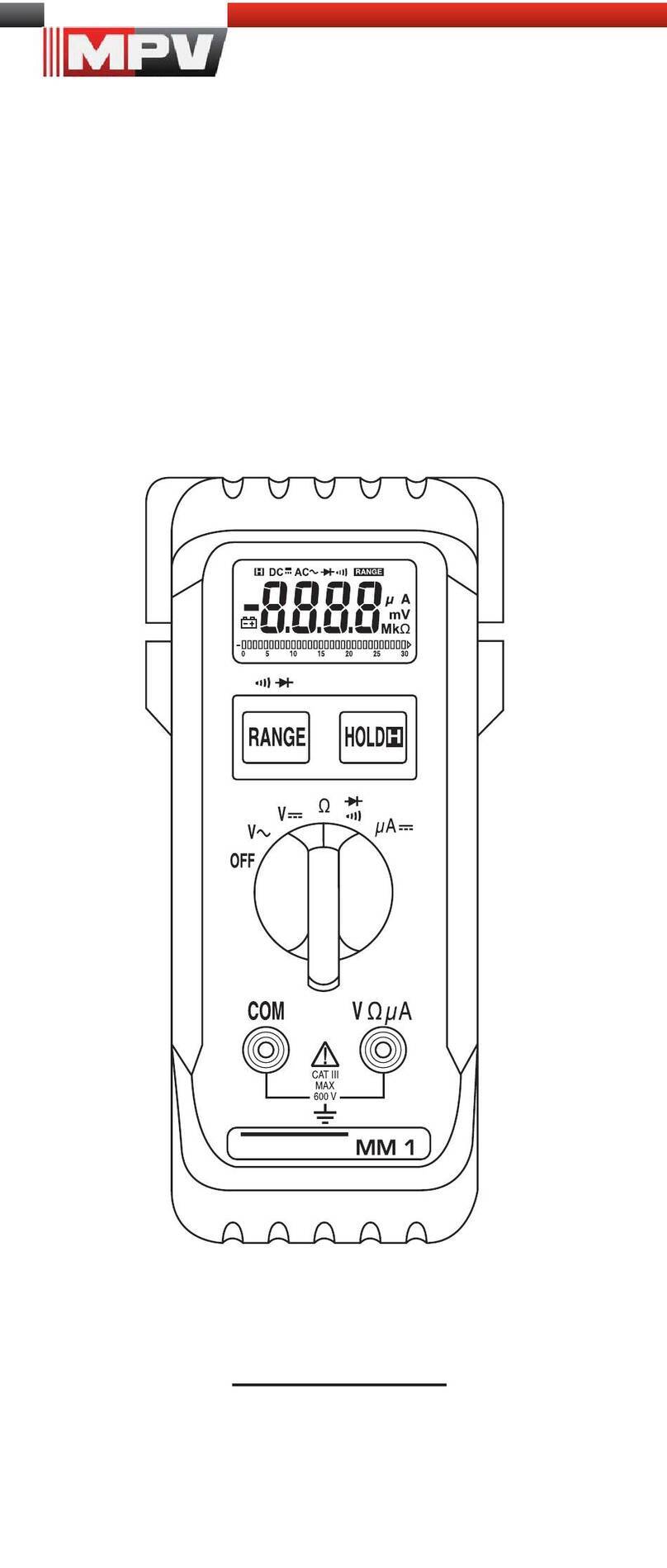

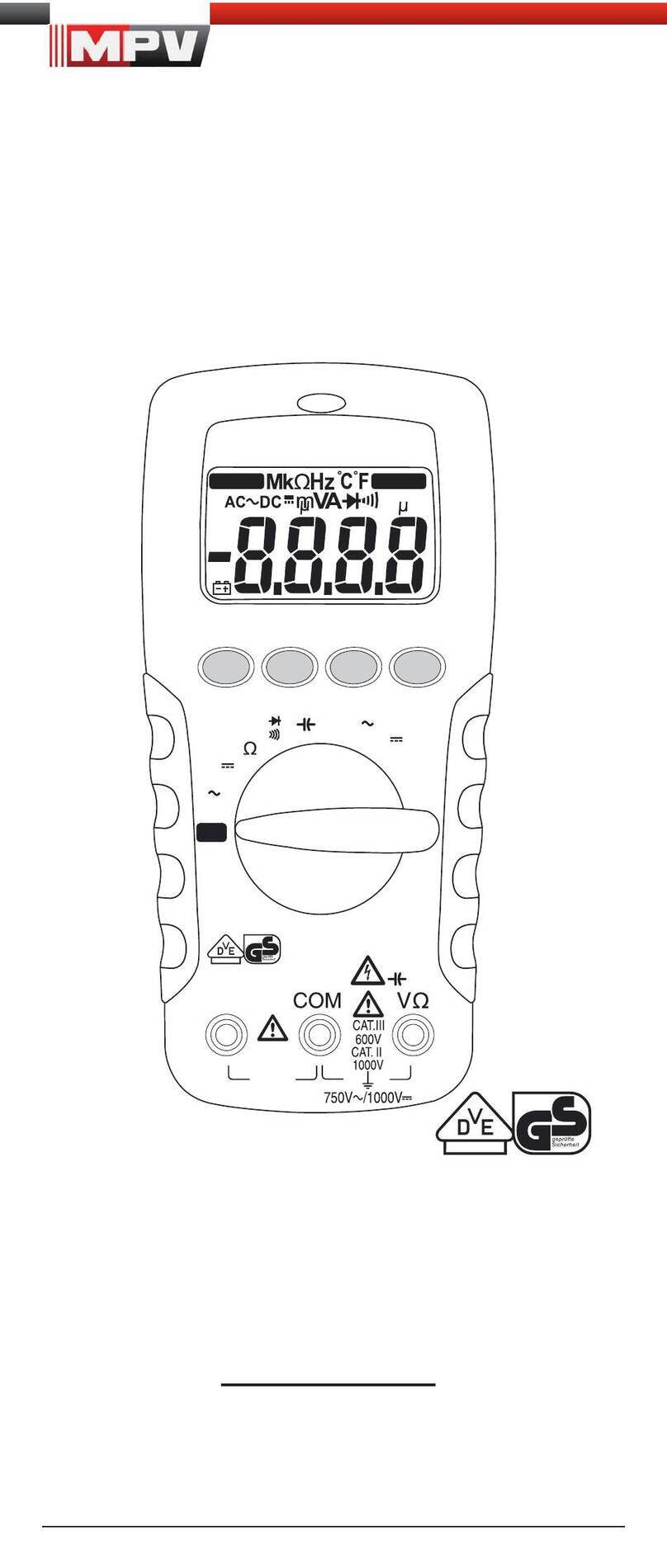

Bild 1: Gerätefrontseite

Fig. 1: Front tester panel

Fig. 1: Panneau avant de l‘appareil

Fig. 1: Parte frontal del equipo

obr. 1: Přední strana přístroje

σχήμα 1: Μπροστινή όψη

ill. 1: Lato anteriore apparecchio

Fig. 1: Voorzijde van het apparaat

Rys.1: Panel przedni przyrządu

рис. 1 Фронтальная сторона прибора

Fig. 1: Framsida

Resim 1: Cihaz Ön Yüzü

Bild 2: Gleichspannungsmessung

Fig. 2: Direct voltage measurement

Fig. 2: Mesure de tension continue

Fig. 2: Medición de tension contínua

obr. 2: Měření stejnosměrného napětí

σχήμα 2: DC- μέτρηση

ill. 2: Misura tensione continua

Fig. 2: Meten van gelijkspanning

Rys.2: Pomiar napięcia stałego

рис. 2

Измерение напряжения постоянного тока

Fig. 2: Likspänningsmätning

Resim 2: Doğru Gerilim Ölçümü

Bild 3: Wechselspannungsmessung

Fig. 3: Alternating voltage measurement

Fig. 3: Mesure de tension alternative

Fig. 3: Medición de tensión alterna

obr. 3: Měření střídavého napětí

σχήμα 3: AC- μέτρηση

ill. 3: Misura tensione alternata

Fig. 3: Meten van wisselspanning

Rys.3: Pomiar napięcia przemiennego

рис. 3

Измерение напряжения переменного тока

Fig. 3: Växelspänningsmätning

Resim 3: Alternatif Gerilim Ölçümü

Bild 4: Gleichstrommessung

Fig. 4: DC current measurement

Fig. 4: Mesure de courant continu

Fig. 4: Medición de corriente contínua

obr. 4: Měření stejnosměrného proudu

σχήμα 4: DC- μέτρηση

ill. 4: Misura corrente continua

Fig. 4: Meten van gelijkstroom

Rys.4: Pomiar prądu stałego

рис. 4 Измерение постоянного тока

Fig. 4: Likströmsmätning

Resim 4: Doğru Akım Ölçümü

Bild 5: Wechselstrommessung

Fig. 5: AC current measurement

Fig. 5: Mesure de courant alternatif

Fig. 5: Medición de corriente alterna

obr. 5: Měření střídavého proudu

σχήμα 5: AC- μέτρηση

ill. 5: Misura corrente alternata

Fig. 5: Meten van wisselstroom

Rys.5: Pomiar prądu przemiennego

рис. 5 Измерение переменного тока

Fig. 5: Växelströmsmätning

Resim 5: Alternatif Akım Ölçümü

Bild 8: Durchgangsprüfung mit Summer

Fig. 8: Continuity Testing with buzzer

Fig. 8: Contrôle de continuité avec ronfleur

Fig. 8: Control de continuidad con vibrador

obr. 8: Zkoušku obvodu

σχήμα 8: Έλεγχος συνέχειας με βομβητή

ill. 8: Prova di continuità con cicalino

Fig. 8: Doorgangstest met akoestisch signaal

Rys.8: Sprawdzenie ciągłości obwodu

рис. 8

Проверка прохождения тока с зуммером

Fig. 8: Genomgångstest med summer

Resim 8: Sesli Uyarıcı ile Süreklilik Kontrolü

Bild 9: Kapazitätsmessung

Fig. 9: Capacity Testing

Fig. 9: Mesure de capacité

Fig. 9: Medición de capacidad

obr. 9: Měření kapacity

σχήμα 9: Μέτρηση χωρητικότητας

ill. 9: Misura di capacità

Fig. 9: Capaciteitsmeting

Rys.9: Pomiar pojemności

рис. 9 Измерение емкости

Fig. 9: Kapacitansmätning

Resim 9: Kapasite Ölçümü

Bild 6: Widerstandsmessung

Fig. 6: Resistance measurement

Fig. 6: Mesure de résistance

Fig. 6: Medición de resistencia

obr. 6: Měření odporu

σχήμα 6: Μέτρηση αντίστασης

ill. 6: Misura di resistenza

Fig. 6: Weerstandsmeting

Rys.6: Pomiar rezystancji

рис. 6 Измерение сопротивления

Fig. 6: Resistansmätning

Resim 6: Direnç Ölçümü

Bild 7: Diodenprüfung

Fig. 7: Diode Testing

Fig. 7: Contrôle de diodes

Fig. 7: Verificación de diodos

obr. 7: test diod

σχήμα 7: Έλεγχος διόδου.

ill. 7: Prova diodi

Fig. 7: Diodecontrole

Rys.7: Pomiar diody

рис. 7 Проверка диодов

Fig. 7: Diod-test

Resim 7: Diyot Ölçümü

09/ 2007

BENNING MM 11

D F E I S

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

Bild 2: Gleichspannungsmessung

Fig. 2: Direct voltage measurement

Fig. 2: Mesure de tension continue

Fig. 2: Medición de tension contínua

obr. 2: Měření stejnosměrného napětí

σχήμα 2: DC- μέτρηση

ill. 2: Misura tensione continua

Fig. 2: Meten van gelijkspanning

Rys.2: Pomiar napięcia stałego

рис. 2

Измерение напряжения постоянного тока

Fig. 2: Likspänningsmätning

Resim 2: Doğru Gerilim Ölçümü

Bild 3: Wechselspannungsmessung

Fig. 3: Alternating voltage measurement

Fig. 3: Mesure de tension alternative

Fig. 3: Medición de tensión alterna

obr. 3: Měření střídavého napětí

σχήμα 3: AC- μέτρηση

ill. 3: Misura tensione alternata

Fig. 3: Meten van wisselspanning

Rys.3: Pomiar napięcia przemiennego

рис. 3

Измерение напряжения переменного тока

Fig. 3: Växelspänningsmätning

Resim 3: Alternatif Gerilim Ölçümü

Bild 4: Gleichstrommessung

Fig. 4: DC current measurement

Fig. 4: Mesure de courant continu

Fig. 4: Medición de corriente contínua

obr. 4: Měření stejnosměrného proudu

σχήμα 4: DC- μέτρηση

ill. 4: Misura corrente continua

Fig. 4: Meten van gelijkstroom

Rys.4: Pomiar prądu stałego

рис. 4 Измерение постоянного тока

Fig. 4: Likströmsmätning

Resim 4: Doğru Akım Ölçümü

Bild 5: Wechselstrommessung

Fig. 5: AC current measurement

Fig. 5: Mesure de courant alternatif

Fig. 5: Medición de corriente alterna

obr. 5: Měření střídavého proudu

σχήμα 5: AC- μέτρηση

ill. 5: Misura corrente alternata

Fig. 5: Meten van wisselstroom

Rys.5: Pomiar prądu przemiennego

рис. 5 Измерение переменного тока

Fig. 5: Växelströmsmätning

Resim 5: Alternatif Akım Ölçümü

BENNING MM 11

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

09/ 2007

BENNING MM 11

Bild 1: Gerätefrontseite

Fig. 1: Front tester panel

Fig. 1: Panneau avant de l‘appareil

Fig. 1: Parte frontal del equipo

obr. 1: Přední strana přístroje

σχήμα 1: Μπροστινή όψη

ill. 1: Lato anteriore apparecchio

Fig. 1: Voorzijde van het apparaat

Rys.1: Panel przedni przyrządu

рис. 1

Fig. 1: Framsida

Resim 1: Cihaz Ön Yüzü

Bild 8: Durchgangsprüfung mit Summer

Fig. 8: Continuity Testing with buzzer

Fig. 8: Contrôle de continuité avec ronfleur

Fig. 8: Control de continuidad con vibrador

obr. 8: Zkoušku obvodu

σχήμα 8: Έλεγχος συνέχειας με βομβητή

ill. 8: Prova di continuità con cicalino

Fig. 8: Doorgangstest met akoestisch signaal

Rys.8: Sprawdzenie ciągłości obwodu

рис. 8

Проверка прохождения тока с зуммером

Fig. 8: Genomgångstest med summer

Resim 8: Sesli Uyarıcı ile Süreklilik Kontrolü

Bild 9: Kapazitätsmessung

Fig. 9: Capacity Testing

Fig. 9: Mesure de capacité

Fig. 9: Medición de capacidad

obr. 9: Měření kapacity

σχήμα 9: Μέτρηση χωρητικότητας

ill. 9: Misura di capacità

Fig. 9: Capaciteitsmeting

Rys.9: Pomiar pojemności

рис. 9 Измерение емкости

Fig. 9: Kapacitansmätning

Resim 9: Kapasite Ölçümü

Bild 6: Widerstandsmessung

Fig. 6: Resistance measurement

Fig. 6: Mesure de résistance

Fig. 6: Medición de resistencia

obr. 6: Měření odporu

σχήμα 6: Μέτρηση αντίστασης

ill. 6: Misura di resistenza

Fig. 6: Weerstandsmeting

Rys.6: Pomiar rezystancji

рис. 6 Измерение сопротивления

Fig. 6: Resistansmätning

Resim 6: Direnç Ölçümü

Bild 7: Diodenprüfung

Fig. 7: Diode Testing

Fig. 7: Contrôle de diodes

Fig. 7: Verificación de diodos

obr. 7: test diod

σχήμα 7: Έλεγχος διόδου.

ill. 7: Prova diodi

Fig. 7: Diodecontrole

Rys.7: Pomiar diody

рис. 7 Проверка диодов

Fig. 7: Diod-test

Resim 7: Diyot Ölçümü

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

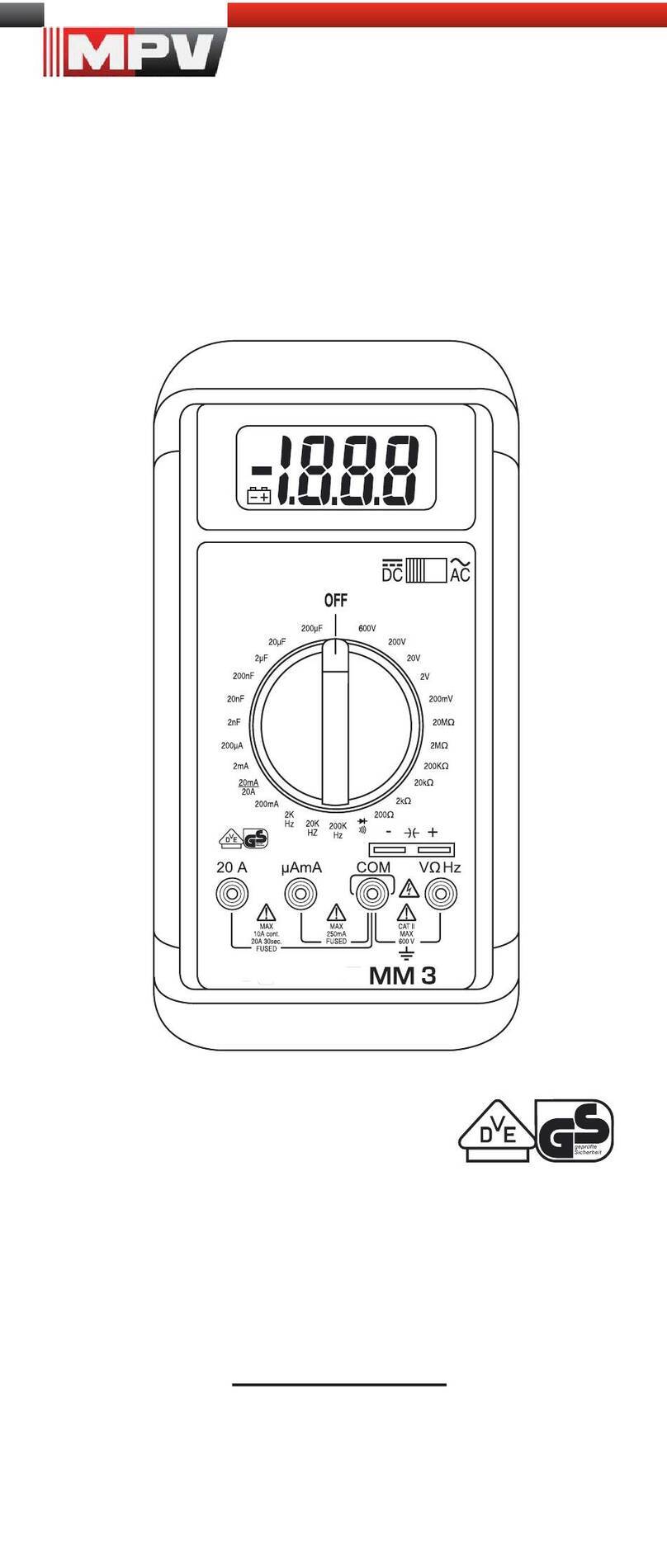

Operating instructions

Digital multimeter for

- Direct voltage measurements

- Alternating voltage measurements

- Direct current measurement

- Alternating current measurement

- Resistance measurements

- Diode test

- Continuity testing

- Capacity measurement

- Frequency measurement

- Pulse duty ratio measurement

- Temperature measurement

Table of contents

1. User notes

2. Safety note

3. Scope of delivery

4. Unit description

5. General information

6. Environment conditions

7. Electricalspecications

8. Making measurements with the 01

9. Maintenance

10. Application of rubber protection frame

11. Technical data of the measuring accessories

12. Environmental notice

1. User notes

These operating instructions are intended for

- skilled electricians and

- trained electronics personnel.

The 01 is intended for making measurements in dry environ-

ment. It must not be used in power circuits with a nominal voltage higher than

1000 V DC and 750 V AC (More details in Section 6. “Environmental condi-

tions”) The following symbols are used in these operating instructions and on

the 01:

Warning of electrical danger!

Indicates instructions which must be followed to avoid danger to

persons.

Important, comply with the documentation!

The symbol indicates that the information provided in the operating

instructions must be complied with in order to avoid risks.

This symbol on the 01 means that the

01 is totally insulated (protection class II).

This symbol on the 01 indicates the built in fuses.

This symbol appears in the display to indicate a discharged battery.

This symbol designates the „diode test” range.

This symbol designates the „continuity test” range.

The buzzer is used for the acoustic result output.

This symbol designates the „capacity test” range.

(DC) Direct voltage or current.

(AC) Alternating voltage or current.

Ground (Voltage against ground).

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

2. Safety note

The instrument is built and tested in accordance with

DIN VDE 0411 part 1/ EN 61010-1

and has left the factory in perfectly safe technical state.

To maintain this state and ensure safe operation of the appliance tester, the user

must observe the notes and warnings given in these instructions at all times.

The unit may be used only in power circuits within the

overvoltage category III with a conductor for 600 V max. to

earth, or within overvoltage category II with a conductor for

1000 V against ground.

Remember that work on electrical components of all kinds is

dangerous. Even low voltages of 30 V AC and 60 V DC may be

dangerous to human life.

Before starting the appliance tester up, always check it as well

as all cables and wires for signs of damage.

Should it appear that safe operation of the appliance tester is no longer possible,

it should be shut down immediately and secured to prevent it being switched

on accidentally.

It may be assumed that safe operation is no longer possible:

- if the instrument or the measuring cables show visible signs of damage, or

- if the appliance tester no longer functions, or

- after long periods of storage under unfavourable conditions, or

- after being subjected to rough transport.

In order to avoid danger,

- do not touch the bare prod tips of the measuring cables

- insert the measurement lines in the appropriately

designated measuring sockets on the multimeter

3. Scope of delivery

The scope of delivery for the 01 comprises:

3.1 one 01

3.2 one software 01 PC-Win MM 11

3.3 one serial data cable with USB 2.0 compatible connection

3.4 one safety measuring cable, red (L = 1.4 m; prod tip diameter = 4 mm)

3.5 one safety measuring cable, black (L=1.4 m; prod tip diameter = 4 mm)

3.6 one wire temperature sensor type K,

3.7 one adapter for wire temperature sensor,

3.8 one rubber protection frame,

3.9 one magnetic holder with adapter and strap

3.10 one compact protective pouch,

3.11

a 9 V block battery and two different fuses (fitted in unit as first equipment),

3.12 one operating instructions manual

Note on optional accessory:

- Temperature probe (K-type) made of V4A tube (P.no 044121)

application: insertion probe for soft-plastic materials, liquids, gas and air

measuring range: - 196 °C up to 800 °C

dimensions: length = 210 mm, tube length = 120 mm, tube diameter =

3 mm, V4A

Parts subject to wear:

- The 01 contains fuses as protection against overload:

One fuse, rated current 1 A quick-acting (600 V), 10 kA, D = 10 mm, L = 35

mm (P.no 749598) and one fuse, rated current 15 A quick-acting (600 V),

100 kA, D = 10 mm, L = 38 mm (P.no 749595).

-

The 01 is supplied by a fitted 9 V block battery (IEC 6 LR 61).

- The above-mentioned safety measuring cables ATL-2 (tested accessories,

P.no 044118) correspond to CAT III 1000 V and are approved for a current

of 10 A.

4. Description of appliance tester

See figure 1: Appliance front face

The display and operator control elements specified in Fig. 1 are designated

as follows:

Digital display, for the measurement value, bar graph display, overranging

display

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

Sub-display

Polarity indication

Battery condition indicator

Button (yellow), display lighting,

Button BAR, Bar graph centring and switchover of numerical value (4000/

20000),

Button PEAK H, (Peak hold), peak value storage,

Button AUTO H, (Auto-Hold), measured value storage,

Button (blue), for DC voltage/ direct current or AC voltage/ current (AC),

resistance measurement Ω or LVΩ, diode or continuity testing, frequency or

pulse ratio measurement, temperature measurement in °C or in °F,

Button M/M/A, storage of the highest, lowest measured values, and the

mean value,

Button REL ∆, relative value function,

Button RANGE, switchover automatic/ manual measuring range,

Rotary switch, for selecting the measurement function,

Jack (positive1), for V, Ω, Hz, °C,

COM jack, common socket for current voltage, resistance, frequency, tem-

perature, capacity measurement, continuity and diode testing,

Jack (positive1), for mA range, for currents up to 200 mA,

Jack (positive1), for 10 A range, for currents up to 10 A,

Rubber protective frame

Optical interface, for accommodating the adapter located on the data

cable,

1)

This is what the automatic polarity indication for DC current and voltage refers to

5. General information

5.1 General details on the multimeter

5.1.1 The digital display is a 3 ¾ or 4 ½ digit liquid crystal display with a

13 mm font size and decimal point. The largest display value is 4.000/

20.000.

5.1.2 The bar graph display comprises 42 segments.

5.1.3 The polarity indication is automatic. Only one polarity with respect to

the socket marked “-” is indicated.

5.1.4 The overranging is indicated by “0L” or “- 0L” and, in part, an acoustic

warning.

Warning, no indication and prior warning in the event of an overload

condition! A exceeding of dangerous contact voltage (> 60 V DC/ 30 V

AC rms) is indicated by an additional flashing symbol “”.

5.1.5 The 01 confirms each button press with a signal sound.

Invalid button presses are confirmed by a double signal sound.

In the event of an incorrect circuit of the jack for the mA / A range

the 01 warns with a signal sound and the indication

of in the display .

The acoustic alarm and the indication in the display extinguish

if a safety measuring cable is plugged into the jack for the mA or

A range and the corresponding current measurement range was

selected by means of the rotary switch .

The acoustic alarm and the indication in the display also appear

in the case of a defective fuse, if the safety measuring cable is plugged

into the jack for the mA or A-range and the corresponding current

measurement range was selected by means of the rotary switch .

5.1.6 The 01 features individual setting options which in part

remain active even after a shutdown. In order to change a setting,

press one of the following buttons and simultaneously activate the

01 from its “OFF” switch position.

Button- : Deactivates/ activates the automatic shutdown of the

background lighting after 15 minutes.

Button- 7:

Presetting of the nominal mains frequency (50 Hz or

60 Hz). This adjustment ensures improved stability

and accuracy in AC V mode. These settings are main-

tained even after the 01 is switched off.

The settings are modified only after a new presetting!

Button- :Presetting the temperature measurement in °C or °F.

The settings are modified only after a new presetting!

Button-BLUE : Deactivates/ activates the automatic switch-off after

approx. 30 minutes (APO, Auto-Power-Off).

Button- :Deletion of the internal measuring value memory (see

also Chapter 5.2)

Button- :Deactivates/ activates the fitted buzzer.

5.1.7 The button (yellow) switches on the display illumination. Shutdown

is effected by a renewed press of the button or automatically after 15

mins.

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

5.1.8 The button centres the zero point of the analogue bar graph

display in the centre of the display (function: DC voltage/ current). In

the DATA LOG function, the bar graph centring function is not available.

Switch-over by briefly pressing a key. By pressing the key 6

longer (2 seconds), the displayed value can be switched over from

20,000 digits to 4,000 digits. This can be reset by pressing the key

again (2 seconds) or by switching off the 01. This mode

is not available for the following ranges:

7.5/ 7.6 Resistance measurement 200 MΩ and 2 GΩ

7.7 Diode and continuity testing

7.8 Capacity measurement

7.9/ 7.10 Frequency and pulse duty ratio measurement

7.11/ 7.12 Temperature measurement

A switch-over to the lower displaying value might be necessary, if for

V AC and A (mA) AC measurements the frequency shall be displayed

simultaneously in the lower display 2. For this, the measured value (V;

A; mA) must be at least 30 % of the displayable range.

5.1.9 The button (peak value storage) inputs and stores the “Peak

Max-/ Peak Min” value (function: mV, V, mA, and A) with a simultane-

ous indication of “PH” in the display. Each new save of the “Peak Max-/

Peak Min” value is confirmed by an acoustic signal. The “Peak Max-/

Peak Min” value is retrieved by pressing the button and indi-

cated in the subdisplay . A renewed operation of -Button

switches back into a standard mode.

5.1.10 The function (measured value store) stores stable display

values in the subdisplay . In the display the symbol “AH” is shown

simultaneously. As soon as a measured value is input, the subdisplay

is updated with the new value. Unstable measured values or noisy

signals cannot be stored via the -function. A renewed press of the

button switches back into measuring mode. In the following measuring

functions, the device switches over from the automatic to the manual

measuring range to store the measured values ( ). Resistance

measurement, capacity measurement and frequency measurement.

5.1.11 The button (blue) selects the secondary or tertiary functions of the

rotary switch setting:

Rotary switch setting: Secondary function: Tertiary function:

V AC, mV AC V DC, mV DC V AC + DC, mV AC + DC

Ω (Messspannung: 3,3 V) LVΩ (reduced

measuring voltage: 0,6 V)

Diode acoustic continuity testing

mA AC, A AC mA DC, A DC mA AC + DC, A AC + DC

Capacitor

Hz % DF (Duty Factor),

pulse duty ratio

°C °F

Note:

- The function LVΩ(resistance measurement) reduces the measuring

voltage to 0.6 V, so that semiconductor elements operated in conduc-

tion direction such as diodes or transistors do not open.

- Function %DF (Duty Factor) describes the pulse duty ratio of periodic

signals:

DF [%] = T1

T

5.1.12 The button inputs and stores automatically the highest and

lowest measured value as well as the mean value in the subdisplay

. The following values are indicated by indexing: “MAX” indicates the

highest measured value stored, “MIN” indicates the lowest measured

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

value and “AVG” the mean value. Press the button for an extended

period of time (2 seconds) to switch back into normal mode.

5.1.13 The button (relative value - function) stores the current

display value in the subdisplay and indicates the difference (offset)

between the stored measured value and the following measured values

in the display .

Example:

Stored reference value: 235 V (subdisplay ), current measured value:

230 V, yields a difference (offset) of 5 V (main display ). A renewed

press of the button switches back into normal mode.

5.1.14 The range button is used to index the manual measuring

ranges whilst simultaneously fading out “AUTO” in the display. Press

the button for an extended period (2 seconds) to select the automatic

range selection (indication “AUTO”):

5.1.15 Level measurement in dB/ dBm: The level measurement in decibel is

the logarithmic ratio of two quantities such as e.g. voltage or current.

If the 01 is in the function mode for alternating voltage

measurement (V AC), press the button (dB/ dBm) for an

extended period of time (2 seconds) to activate the level measurement.

In the subdisplay the voltage level is indicated in dB with a reference

value of 1 V. A renewed press of the Range button (dB/ dBm)

indicates the performance level in dBm (reference value: 1 mW for

600 Ω). The voltage and performance levels are calculated as follows:

Voltage level

in dB:

Reference

value: 1 V LU= 20 x log U

1 V [dB]

Performance

level in dBm:

Reference value:

1 mW an 600 ΩLP= 10 x log P

1 mW [dBm]

U²

LP= 10 x log 600 Ω [dBm]

1 mW

By pressing the button for an extended period of time (2

seconds) (dB/ dBm), there will be a switch back into normal mode.

5.1.16 The measuring rate of the 01 amounts nominally to

2 measurements (20,000 digit) respectively 4 measurements (4,000

digit) per second for the digital display and 20 measurements for the

bar graph display.

5.1.17 The 01 is switched on and off with the rotary switch.

Shutdown position “OFF”.

5.1.18 The 01switches off automatically after approx. 30 min-

utes (APO, Auto-Power-Off). It switches back on again if a button or the

rotary switch is operated.

5.1.19 Temperature coefficient of the measured value: 0.1 x (stated measuring

precision)/ °C < 18 °C or > 28 °C, related to the value for the reference

temperature of 23° C.

5.1.20 The 01is supplied by a fitted 9 V block battery (IEC 6 LR 61).

5.1.21 If the battery voltage drops below the specified operating voltage

(approx. 7 V) of the 01, then an empty battery symbol

( ) appears in the display.

5.1.22 The life span of a battery amounts to approx. 100 hours (alkali bat-

tery).

5.1.23 Appliance dimensions:

(L x W x H) = 200 x 90 x 42 mm without rubber protection frame

(L x W x H) = 212 x 100 x 55 mm with rubber protection frame

Appliance weight:

400 g without rubber protection frame

600 g with rubber protection frame

5.1.24 The safety measuring cables are designed in 4 mm plug-in type tech-

nology. The safety measuring cables supplied are expressly suited for

the rated voltage and the rated current of the 01.

5.1.25 The 01 is protected by a rubber protection frame

against mechanical damage. The rubber protection frame allows the

01 to be set up or hung up during the measurements.

5.1.26 The 01 features at its head an optical interface S. This

is used for the galvanic separation of the measuring signal to a PC/ lap-

top. The enclosed data cable is used for the transmission of measuring

data and is equipped with a USB 2.0 compatible connection.

5.2 Memory function

The 01 is equipped with a measured value memory of

1.000 memory locations. These memory locations can be used to store

display values and retrieve the same at a later date via the display.

5.2.1 STORE (Store display values) 0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

By an extended operation (2 seconds) of the -button the

01 is set into memory mode. The digital display

shows the symbol “MEM”. The display value is stored by re-pressing

the - button (STORE). The stored value is indicated as a flashing

value in the subdisplay , stating the memory location number. Display

values are continuously stored on memory locations 1 - 1000. A double

acoustic alarm sound signals a full memory store. By an extended

operation (2 seconds) of the -button (STORE), there will be a

switch back into normal mode.

5.2.2 RECALL (Retrieve memory values)

By an extended operation (2 seconds) of the -button

(RECALL) the memory can be read out. In the digital display the

symbol “MEM” and the stored measured value appears.

The memory location no. appears on the subdisplay . The memory

locations 1 - 1000 are selected by means of the button (yellow) and

the button BAR , with an extended press of the button (2 seconds)

causing a fast run-through of the memory locations (10 memory loca-

tions/ second). By an extended operation (2 seconds) of the

-button (RECALL) there is a switch-back to normal mode.

5.2.3 Memory deletion

The memory content of the 01 is deleted by pressing the

button- and simultaneously turning the rotary switch out of

the “OFF” switch position.

5.3 DATA-LOG function

By an extended operation (2 seconds) of the button (blue) the

01 is set into DATA-LOG mode. The digital display

shows the symbol “LOG”. Pressing the button again (2 seconds)

switches back into normal mode. The DATA-LOG function provides for

an automatic storage of measurement series with up to 40.000 meas-

ured values. The measured values can be retrieved for further process-

ing at a later date via the display unit or via the optical interface

. The scan rate which defines the period between two successive

measuring points can be selected from 0.5 seconds to 10 minutes.

Note:

- The RANGE button and the automatic switch-off (APO, Auto-

Power-Off) are not functional in this mode of operation.

- Each operation of the rotary switch interrupts the DATA-LOG

mode.

5.3.1 LOG-RATE (Set scan rate)

If the 01 is in DATA-LOG mode, the scan rate is set

by pressing the button (LOG RATE). The preset scan rate

is indicated in the subdisplay and can be selected by means of the

button (yellow) ▲and the button BAR ▼.

Selectable scan rates: 0.5, 1, 10, 30, 60, 120, 180, 240, 300, 360,

480, 600 seconds. Another press of the button (LOG RATE)

confirms the scan rate and exits the setting mode.

5.3.2 DATA-LOG-IN (Store data)

If the 01 is in the DATA-LOG mode, an extended opera-

tion (2 seconds) of the button (DATA LOG) starts the auto-

matic storage of the measuring series. The measured value storage

is indicated in the subdisplay by means of the memory location no.

and a flashing symbol “-”. The highest memory location no. indicated

in the subdisplay is 10.000. If the memory location no. 10.000 is

exceeded, counting restarts again at 0. and the bar graph display adds

respectively ¼ of the maximum deflection for 10.000 measured values

read in.

A renewed operation of the button (DATA LOG) interrupts the

measured value storage whilst simultaneously indicating “Pause” in the

subdisplay . The maximum break period is 4095 seconds. In the event

of this period being exceeded the measuring series is continued after

4095 seconds. The break period can be utilised to set another scan rate

or to interrupt the measured value storage for a short period of time.

An extended press of the button (DATA LOG) exists the

DATA-LOG-IN mode.

If the memory is full (4 x 10,000 measured values), „FULL“ is displayed

in the lower display 2and the measurement is stopped.

5.3.3 DATA-LOG-OUT (retrieve data)

If the 01 is in the DATA-LOG mode, operate the but-

ton (DATA LOG) to retrieve the memory. The measured

value most recently read in appears in the digital display unit , stating

the memory location no. in the subdisplay . The memory locations

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

1 - 40000 are selected by means of the button (yellow) ▲ and te button

▼ wit an extended operation (2 seconds) of te button causing a

fast run-through of the memory locations (10 memory locations/ sec.).

- The maximum and minimum values of the measuring series are

retrieved by pressing the button . An extended operation

(2 seconds) of the button exits this mode.

- The extreme values (MAX/ MIN) of the measuring series are

retrieved by pressing the button

and subsequently oper-

ating the button (yellow) ▲ or te button ▼. Another

press of the button

exits this mode.

A press of the button (DATA LOG) exists the DATA-LOG-

OUT mode.

Alternatively, the measured value store can be read out also via the

supplied PC- Win MM 11 software.

A renewed automatic save of a measuring series deletes the existing data.

6. Environment conditions:

- The 01 is intended for making measurements in dry environ-

ment.

- Maximum barometric elevation for making measurements: 2222 m,

- Overvoltage category/ Siting category: IEC 60664-1/ IEC 61010-1 → 600 V

category III; 1000 V category II,

- Contamination class: 2,

- Protection Class: IP 30 (DIN VDE 0470-1 IEC/ EN 60529)

IP 30 means: Protection against access to dangerous parts and protection

against solid impurities of a diameter > 2.5 mm, (3 - first index). No protec-

tion against water, (0 - second index).

- Operating temperature and relative humidity:

For operating temperature from 0 °C to 30 °C: relative humidity less than 80 %

For operating temperature from 31 °C to 40 °C: relative humidity less than 75 %

For operating temperature from 41 °C to 50 °C: relative humidity less than 45 %

- Storage temperature: The 01 can be stored at any tempera-

ture in the range from - 20 °C to + 60 °C (relative humidity from 0 to 80 %).

The battery should be taken out of the instrument for storage.

7. Electricalspecications

Note: The measuring precision is specified as the sum of

- a relative fraction of the measured value and

- a number of digits (counting steps of the least significant digit).

This specified measuring precision is valid for temperatures in the range from

18 °C to 28 °C and relative humidity less than 80 %.

For the 4,000 digit counter mode, the figures with the lowest value have to be

divided by 10!

7.1 Direct voltage ranges (Switch setting: V DC, mV DC)

The input resistance amounts to 10 MΩ(within the 400 mV range 1 GΩ).

Measuring range Resolution Meas. precision Overload protection

20 mV 1 µV

± (0.06 % of the measured value + 60 Digit)

1000 VDC

200 mV 10 µV

± (0.06 % of the measured value + 20 Digit)

1000 VDC

2 V 100 µV

± (0.06 % of the measured value + 10 Digit)

1000 VDC

20 V 1 mV

± (0.06 % of the measured value + 10 Digit)

1000 VDC

200 V 10 mV

± (0.06 % of the measured value + 10 Digit)

1000 VDC

1000 V 100 mV

± (0.06 % of the measured value + 10 Digit)

1000 VDC

7.2 Alternating voltage ranges (Switch setting: V AC, mV AC)

The input resistance amounts to 10 Min parallel 100 pF. The measured value

is obtained and displayed as a real effective value (TRUE RMS).

Selectable coupling type: AC or AC+DC. For the coupling AC+DC an additional

error of 1 % + 80 Digit must be taken into account. In the case of non-sinus-

shaped curves the display value becomes less precise. Thus an additional error

results for the following crest factors:

Crest factor from 1.4 to 3.0 additional errors + 1.5 %

Crest factor from 3.0 to 4.0 additional errors + 3.0 %

Measuring range Frequency range Meas. precision *1

Overload protection

20 mV, 200 mV 40 Hz ~ 100 Hz

± (0.7 % of the measured value + 80 Digit)

750 Veff

100 Hz ~ 1 kHz

± (1.0 % of the measured value + 80 Digit)

750 Veff

2 V, 20 V

40 Hz ~ 100 Hz

± (0.7 % of the measured value + 50 Digit)

750 Veff

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

100 Hz ~ 1 kHz

± (1.0 % of the measured value + 50 Digit)

750 Veff

1 kHz ~ 10 kHz

± (2.0 % of the measured value + 60 Digit)

750 Veff

10 kHz ~ 20 kHz

± (3.0 % of the measured value + 70 Digit)

750 Veff

20 kHz ~ 50 kHz

± (5.0 % of the measured value + 80 Digit)

750 Veff

50 kHz ~ 100 kHz

± (10.0 % of the measured value + 100 Digit)

750 Veff

200 V 40 Hz ~ 100 Hz

± (0.7 % of the measured value + 50 Digit)

750 Veff

100 Hz ~ 1 kHz

± (1.0 % of the measured value + 50 Digit)

750 Veff

1 kHz ~ 10 kHz

± (2.0 % of the measured value + 60 Digit)

750 Veff

10 kHz ~ 20 kHz

± (3.0 % of the measured value + 70 Digit)

750 Veff

20 kHz ~ 50 kHz

± (5.0 % of the measured value + 80 Digit)

750 Veff

750 V 40 Hz ~ 100 Hz

± (0.7 % of the measured value + 50 Digit)

750 Veff

100 Hz ~ 1 kHz

± (1.0 % of the measured value + 50 Digit)

750 Veff

Maximum resolution: 1 µV within the 20 mV measuring range

*1In the frequency range 5 kHz

~

50 kHz 20 digits must be added to the speci-

fied measuring range limit value - for display values less than 50 % of the

measuring range limit value.

Within a frequency range of 50 kHz

~

100 kHz, display values less than

40 % of the measuring range limit value are not specified.

7.3 Direct current ranges (Switch setting: A DC, mA DC)

overload protection:

- F 1 A (600 V) fuse, 10 kA, (Bussmann BBS-1 or equivalent) on the mA

input,

- F 15 A (600 V) fuse, 100 kA, (Bussmann KLK-15 or equivalent) 10 A on the

input,

Measuring range

Resolution Meas. precision Voltage drop

20 mA 1 µA

± (0.2 % of the measured value + 40 Digit)

800 mV max.

200 mA 10 µA

± (0.2 % of the measured value + 40 Digit)

800 mV max.

2 A 100 µA

± (0.2 % of the measured value + 40 Digit)

1 V max.

10 A 1 mA

± (0.2 % of the measured value + 40 Digit)

1 V max.

7.4 Alternating current ranges (Switch setting: A AC, mA AC)

The measured value is obtained and displayed as a real effective value (TRUE

RMS).

Selectable coupling type: AC or AC+DC. For the coupling AC+DC an additional

error of 1 % + 80 Digit must be taken into account. In the case of non-sinus-

shaped curves the display value becomes less precise. Thus an additional error

results for the following crest factors:

Crest factor from 1.4 to 3.0 additional errors + 1.5 %

Crest factor from 3.0 to 4.0 additional errors + 3.0 %

Overload protection:

- F 1 A (600 V)-fuse, 10 kA, (Bussmann BBS-1 or equivalent) on the mA

input,

- F 15 A (600 V)-fuse, 100 kA, (Bussmann KLK-15 or equivalent) 10 A on the

input,

Measuring range

Frequency range Meas. precision Voltage drop

20 mA

40 Hz ~ 500 Hz

± (0.8 % of the measuring range + 50 Digit)

800 mV max.

500 Hz ~ 1 kHz

± (1.2 % of the measured value + 80 Digit)

200 mA

40 Hz ~ 500 Hz

± (0.8 % of the measuring range + 50 Digit)

800 mV max.

500 Hz ~ 1 kHz

± (1.2 % of the measured value + 80 Digit)

1 kHz ~ 3 kHz

± (2.0 % of the measured value + 80 Digit)

2 A

40 Hz ~ 500 Hz

± (0.8 % of the measured value + 50 Digit)

1 V max.

500 Hz ~ 1 kHz

± (1.2 % of the measured value + 80 Digit)

10 A

40 Hz ~ 500 Hz

± (0.8 % of the measured value + 50 Digit)

1 V max.

500 Hz ~ 1 kHz

± (1.2 % of the measured value + 80 Digit)

1 kHz ~ 3 kHz

± (2.0 % of the measured value + 80 Digit)

Maximum resolution: 1 µA in 20 mA measuring range

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

7.5 Resistance measuring ranges (Switch setting: Ω)

Overload protection in the case of resistance measurements: 600 Veff

Meas. range Resolution Meas. precision Max. idling voltage

200 Ω 10 mΩ

± (0.3 % of the measured value + 30 Digit)

3,3 V

2 kΩ 100 mΩ

± (0.3 % of the measured value + 30 Digit)

3,3 V

20 kΩ 1 Ω

± (0.3 % of the measured value + 30 Digit)

3,3 V

200 kΩ 10 Ω

± (0.3 % of the measured value + 30 Digit)

3,3 V

2 MΩ 100 Ω

± (0.3 % of the measured value + 30 Digit)

3,3 V

20 MΩ 1 kΩ

± (5.0 % of the measured value + 50 Digit)

3,3 V

200 MΩ 1 MΩ

± (5.0 % of the measured value + 20 Digit)

3,3 V

2 GΩ *20,1 GΩ

± (5 % of the measured value + 8 Digit)

3,3 V

*2The 2 GΩmeasuring range has to be selected manually by means of the

key L(see item 5.1.1.4).

7.6 Resistance measurement range with reduced measuring voltage: 0.6 V,

(Switch setting: LVΩ, indication in display “LV”)

Meas. range Resolution Meas. precision Max. idling voltage

2 kΩ 0,1 Ω

± (0.6 % of the measured value + 30 Digit)

0,6 V

20 kΩ 1 Ω

± (0.6 % of the measured value + 30 Digit)

0,6 V

200 kΩ 10 Ω

± (0.6 % of the measured value + 30 Digit)

0,6 V

2 MΩ 100 Ω

± (0.6 % of the measured value + 30 Digit)

0,6 V

20 MΩ 1 kΩ

± (7.0 % of the measured value + 50 Digit)

0,6 V

200 MΩ 1 MΩ

± (7.0 % of the measured value + 20 Digit)

0,6 V

7.7 Diode and continuity testing (Switch setting: , )

Overload protection: 600 Veff

The built-in buzzer sounds in the case of a resistance R less than 50 Ω.

Meas. range Resolution Max. meas. current Max. idling voltage

1 mV

1,1 mA

3,3 V

7.8 Capacity ranges (Switch setting: )

Largest display value: 4.000 Points

Conditions: Discharge capacitors and apply according to the specified polarity.

Meas. range Resolution Meas. precision

Overload protection

4 nF 1 pF

± (1.5 % of the measured value + 10 Digit)

600 Veff

40 nF 10 pF

± (1.5 % of the measured value + 10 Digit)

600 Veff

400 nF 100 pF

± (0.9 % of the measured value + 5 Digit)

600 Veff

4 µF 1 nF

± (0.9 % of the measured value + 5 Digit)

600 Veff

40 µF 10 nF

± (1.2 % of the measured value + 5 Digit)

600 Veff

400 µF 100 nF

± (1.2 % of the measured value + 5 Digit)

600 Veff

4 mF 1 µF

± (1.5 % of the measured value + 5 Digit)

600 Veff

40 mF 10 µF

± (1.5 % of the measured value + 5 Digit)

600 Veff

7.9 Frequency ranges (Switch setting: Hz)

Overload protection in the case of frequency measurements: 600 Veff

Minimum input frequency: 5 Hz

Meas. range Resolution Meas. precision for 5 Veff max. Min. sensitivity

20 Hz 0,001 Hz ± (0.01 % of the measured value + 50 Digit) 0,5 VSS

200 Hz 0,01 Hz ± (0.01 % of the measured value + 10 Digit) 0,5 VSS

2 kHz 0,1 Hz ± (0.01 % of the measured value + 10 Digit) 0,5 VSS

20 kHz 1 Hz ± (0.01 % of the measured value + 10 Digit) 0,5 VSS

200 kHz 10 Hz ± (0.01 % of the measured value + 10 Digit) 0,5 VSS

1 MHz 100 Hz ± (0.01 % of the measured value + 10 Digit) 0,5 VSS

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

7.10

Pulse duty ratio (Switch setting: %DF)

Overload protection in the case of pulse ratio measurement: 600 Veff

Meas. range Resolution Meas. precision Frequency range Min. sensitivity

20 % ~ 50 % 0,1 % ± 1 % 20 Hz ~ 10 kHz 5 VSS

50 % ~ 80 % 0,1 % ± 2 % 20 Hz ~ 10 kHz 5 VSS

7.11

Temperature ranges °C (Switch setting: °C)

With temperature sensor type K and sensor adapter

Resolution: 0.1 °C for measuring range: - 200 °C ~ 400 °C

1 °C for measuring range: 400 °C ~ 1200 °C

Meas. range

Meas. precision

Overload protection

- 200 °C ~ 100 °C ± (0,1 % of the measured value + 6 °C) 600 Veff

100 °C ~ 1200 °C ± (0,1 % of the measured value + 3 °C) 600 Veff

Note:

Indicated values < 360 °C are displayed with a resolution of 0.1 °C due to an

improved precision.

If the -button is used to select a lower resolution, the display indi-

cates the symbol ”Er”.

7.12

Temperature ranges °F (Switch setting: °F)

With temperature sensor type K and sensor adapter

Resolution: 0.1 °F for measuring range: - 328 °F ~ 753 °F

1 °F for measuring range: 753 °F ~ 2192 °F

Meas. range

Meas. precision

Overload protection

- 328 °F ~ 212 °F ± (0.1 % of the measured value + 12 °F) 600 Veff

212 °F ~ 2192 °F ± (0.1 % of the measured value + 6 °F) 600 Veff

7.13

PEAK HOLD

Measuring ranges: mV, V, mA, A

Coupling type: AC, DC

In the PEAK-HOLD function (peak value storage) an additional error needs to

be taken into account for the specified precision.

+ [± 0.7% + 20 digits] for display values of 20 % - 100 % of the meas. range limit

value, minimum impulse width: 0.5 ms,

+ [± 0.7% + 30 digits], for display values of 50 % - 100 % of the meas. range

limit value within the 2 V meas. range,

8. Making measurements with the 01

8.1 Preparations for making measurements

Operate and store the 01 only at the specified storage and oper-

ating temperatures conditions. Avoid continuous insulation.

- Check rated voltage and rated current details specified on the safety meas-

uring lines. The nominal voltage and current ratings of the safety measuring

cables included in the scope of delivery correspond to the ratings of the

01

- Check the insulation of the safety measuring cables. Discard the safety

measuring cables immediately if the insulation is damaged.

- Check safety measuring lines for continuity. If the conductor in the safety

measuring line is interrupted, the safety measuring line must be quaran-

tined immediately.

- Before - at the rotary switch - a different function is selected, the safety

measuring lines must be disconnected from the measuring point.

- Strong sources of interference in the vicinity of the 01 can

lead to unstable readings and measuring errors.

8.2 Voltage and current measurement

Do not exceed the maximum permitted voltage with respect to

earth potential! Electrical danger!

The highest voltage which may be applied to the jacks,

- COM socket

- jack for V, , Hz, °C,

- jack for mA range and the

- jack for 10 A range

of the 01against ground, amounts to 1000 V.

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

Electrical danger!

Maximum circuit voltage for a measured current of 600 V! In

the case of a safety triggering in excess of 600 V, damage to the

appliance may be caused. A damaged appliance may represent

an electrical hazard!

8.2.1 Voltage measuring

- Use the rotary switch to select the required function (V) on the

01

- Using the button (blue) select the voltage type to be measured on the

01: direct current (DC) or alternating current (AC).

- The black safety measuring cable has to be connected to the COM jack

on the 01

- The red safety measuring cable has to be connected to the jack for V, ,

Hz, °C, on the 01

- Bring the safety measuring lines into contact with the measuring points, read

off measured value on the digital display unit of the 01.

See figure 2: Direct voltage measurement

See figure 3: Alternating voltage measurement

8.2.2 Current measuring

- Use the rotary switch to select the required range and function (mA or A)

on the 01.

- Using the button (blue) select the voltage type to be measured on the

01: direct current (DC) or alternating current (AC).

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for the mA

range, for currents up to 200 mA or with the jack for 10 A range for

currents greater 200 mA to 10 A on the 01.

- Bring the safety measuring lines into contact with the measuring points, read

off measured value on the digital display unit of the 01.

See figure 4: Direct current measurement

See figure 5: Alternating current measurement

8.3 Resistance measurement

- Using the rotary switch select te required function (Ω) on te

01.

- If necessary, use the button (blue) to select te function LVΩ (reduced

measurement voltage: 0.6 V).

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01.

- Bring the safety measuring lines into contact with the measuring points, read

off measured value on the digital display unit of the 01.

See figure 6: Resistance measurements

8.4 Diode test

- Use the rotary switch to select the required function ( ) unit of the

01.

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01.

- Bring the safety measuring lines into contact with the diode connec-

tions, read off measured value on the digital display unit of the

01.

- For a standard Si diode applied in conduction direction the conduction volt-

age between 0.400 V to 0.900 V is displayed. The display “000” indicates a

short circuit in the diode, display values > 2 V indicate an interruption in the

diode.

- For a diode applied in reverse direction “OL” is displayed. If the diode is

defective, values < 2 V are shown.

see figure 7: Diode test

8.5 Continuity testing with buzzer

- Use the rotary switch to select the required function ( ) on the

MN 11.

- Using the button (blue) carry out the switchover to continuity testing on

the MN 11 (press key once)

- The black safety measuring cable has to be connected to the COM jack

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01.

- The safety measuring lines have to be brought into contact with the measur-

ing points. If the line resistance between the COM jack and the jack for V,

Ω, Hz, °C, 50 Ω, the fitted buzzer sounds on the 01.

See figure 8: Continuity testing with buzzer

8.6 Capacity measurement

Before carrying out capacity measurements discharge

capacitors completely!

Never apply voltage to the capacity measurement jacks! The

appliance can become damaged or even be destroyed! A

damaged appliance may cause an electrical hazard!

- Use the rotary switch to select the required function ( ) on the

01.

- Determine the polarity of the capacitor and discharge capacitor complete-

ly.

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01.

- The safety measuring lines have to be brought into contact with the dis-

charged capacitor according to its polarity, read off measured value on the

digital display unit of the 01.

See figure 9: Capacity measurements

8.7 Frequency measurement

- Using the rotary switch select the required function (Hz, %DF) on the

01.

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01. Note the minimum sensitivity for

the frequency measurements on the 01!

- Bring the safety measuring lines into contact with the measuring points, read

off measured value on the digital display unit of the 01.

See figure 10: Frequency-/ pulse duty ratio measurement

8.8 Pulse duty ratio measurement

- Using the rotary switch select the required function (Hz, %DF) on the

01.

- Using the button (blue) carry out the switchover to pulse duty ratio meas-

urement (%DF) on the 01(press key once)

- The black safety measuring cable has to be connected to the COM jack

on the 01.

- The red safety measuring cable has to be connected to the jack for V, Ω,

Hz, °C, on the 01. Note the minimum sensitivity for

the frequency measurements on the 01!

- Bring the safety measuring lines into contact with the measuring points, read

off measured value on the digital display unit of the 01.

See figure 10: Frequency-/ pulse duty ratio measurement

8.9 Temperature measurement

- Use the rotary switch to select the required function (°C or °F) on the

01.

- Bring the adapter for the temperature sensor in the COM jack and V, ,

Hz, °C, into pole-correct contact.

- The temperature sensor (type K) must be contacted in the adapter.

- The contact point (end of the sensor line) has to be placed at the point to

be measured. Read off measured value on the digital display unit of the

01.

See figure 11: Temperature measurement

9. Maintenance

Before opening the 01, make quite sure that it

is voltage free! Electrical danger!

Work on the opened 01 under voltage may be carried out only

by skilled electricians with special precautions for the prevention of

accidents.

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

Make the 01 voltage free as follows before opening the instru-

ment:

- First remove the two safety measuring lines from the object to be meas-

ured.

- Then disconnect the two safety measuring cables from the

01

- Turn the rotary switch to the switch setting ”OFF”.

9.1 Securing the instrument

Under certain circumstances safe operation of the 01 is no

longer ensured, for example in the case of:

- Visible damage of the casing.

- Incorrect measurement results.

- Recognisable consequences of prolonged storage under improper condi-

tions.

- Recognisable consequences of extraordinary transportation stress.

In such cases the 01 must be switched off immediately, discon-

nected from the measuring points and secured to prevent further utilisation.

9.2 Cleaning

Clean the casing externally with a clean dry cloth (exception: special cleaning

wipers). Avoid using solvents and/or scouring agents for cleaning the instru-

ment. It is important to make sure that the battery compartment and battery

contacts are not contaminated by leaking electrolyte.

If electrolyte contamination or white deposits are present in the region of the

batteries or battery casing, clean them too with a dry cloth.

9.3 Battery change

Before opening the 01, make quite sure that it

is voltage free! Electrical danger!

The 01 is supplied by a 9 V block battery. A battery change (see

Figure 12) is required, if the battery symbol ( ) appears in the display

unit (battery voltage approx. 7 V).

Proceed as follows to replace the batteries:

- Disconnect the safety measuring cables from the measuring circuit.

- Disconnect the safety measuring cables from the 01.

- Set the rotary switch to the switch setting ”OFF”.

- Remove the rubber protection frame from the 01.

- Place the 01 onto its front and turn the slotted screws of the

battery compartment by 90 ° in an anticlockwise direction.

- Lift the battery compartment cover off the bottom section.

- Lift the discharged battery from the battery compartment and carefully

disconnect the battery supply lines from the battery.

- The new battery has to be connected to the battery supply lines, and

arrange these such that they are not crushed between the housing parts.

Then place the battery into the battery compartment provided for this pur-

pose.

- Engage the battery cover into the bottom section and turn the slotted

screws of the battery cover by 90 ° in a clockwise direction.

- Place the 01 into the rubber protection frame

See figure 12: Battery replacement

Make your contribution to environmental protection! Do not

dispose of discharged batteries in the household garbage.

Instead, take them to a collecting point for discharged batteries

and special waste material. Please inform yourself in your

community.

9.4 Fuse replacement

Before opening the 01, make quite sure that it

is voltage free! Electrical danger!

The 01is protected against overload conditions by a fitted fuse

(G-melt insert) 1 A quick-acting and a fitted fuse (G-melt insert) 15 A quick-act-

ing (see Figure 13).

Proceed as follows to replace the fuses:

- Disconnect the safety measuring cables from the measuring circuit.

- Disconnect the safety measuring cables from the 01.

- Set the rotary switch to the switch setting ”OFF”.

- Remove the rubber protection frame from the 01.

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

09/ 2007

- Place the 01 onto its front and turn the slotted screws of the

battery compartment by 90 ° in an anticlockwise direction.

- Lift the battery compartment cover off the bottom section.

- Lift the battery from the battery compartment and carefully disconnect the

battery supply lines from the battery.

Do not undo any screws on the printed circuit. Leave the

printed circuit in the bottom section of the housing. Danger for

the interface LED!

- Remove the top screw (black) and the two screws in the battery compart-

ment from the bottom section (housing bottom).

- Now place the unit on its back again.

- Lift the front end at its bottom section and carefully remove the same.

- Lift one end of the defective fuse from the fuse holder.

- Fully push the defective fuse out of the fuse holder.

- Fit the new fuse with the same rated current, rated voltage, same discon-

nection capacity, same trigger characteristics, and same dimensions.

- Make sure that the new fuse is seated centred in the holder.

- Order the battery supply lines such that they are not crushed between the

housing parts.

- Engage the front end on the housing bottom and fit the three screws.

- The battery must be connected to the battery supply lines and placed in the

position provided for this purpose in the battery compartment.

- Engage the battery cover into the bottom section and turn the slotted

screws of the battery cover by 90 ° in a clockwise direction.

- Place the 01 into the rubber protection frame

See figure 13: Fuse replacement

9.5 Calibration

To maintain the specified precision of the measurement results, the instrument

must be recalibrated at regular intervals by our factory service. We recom-

mend a recalibration interval of one year. Send the appliance to the following

address:

Benning Elektrotechnik & Elektronik GmbH & CO. KG

Service Centre

Robert-Bosch-Str. 20

D - 46397 Bocholt

9.6 Spare parts

Fuse F 1 A, 600 V, 10 kA, D = 10 mm, L = 35 mm, P.no. 749598

Fuse F 15 A, 600 V, 100 kA, D = 10 mm, L = 38 mm, P.no. 749595

10. Application of rubber protection frame

- You can store the safety measuring lines by winding the safety measuring

lines around the rubber protection frame and engaging the tips of the

safety measuring lines with protection against the rubber protection frame

(see Figure 14).

- You can engage a safety measuring line to the rubber protection frame

such that the measuring tip protrudes freely, in order to be able to apply the

measuring tip - jointly with the 01 - to a measuring point.

- The rear support on the rubber protection frame provides for an inclined

set-up of the 01 (facilitates reading) or attachment (see

Figure 15).

- The rubber protection frame is fitted with a lug which can be freely used

for an attachment option.

See figure 14: Winding up of the safety measurement line

See figure 15: Assembly of the 01

11. Technical data of the measuring accessories

4 mm Safety measuring cable ATL 2

- Standard: EN 61010-031,

- Maximum rated voltage to earth ( ) and measuring category: 1000 V

CAT III, 600 V CAT IV,

- Maximum rated current: 10 A,

- Protective class II (), continuous double or reinforced insulation,

- Contamination class: 2,

- Length: 1.4 m, AWG 18,

- Environmental conditions:

Maximum barometric elevation for making measurements: 2000 m,

Temperatures: 0 °C to + 50 °C, humidity 50 % to 80 %

- Only use the measuring cables if in perfect condition and according to this

manual, since the protection provided could otherwise be impaired.

0XOWLPHWUH01PSYQRWLFHSGI

www.motor-pump-ventilation.com

Table of contents

Other MPV Multimeter manuals