Press the “AC/DC”function button to selectAC or DC.

Insert: *Black lead in COM terminal.

*Red lead in the 10Aor mA terminal.

IMPORTANT:

Turn OFF all power to the circuit or

disconnect the circult from the power

source.

Connect:

*the Red probe to the side of the circuit

closest to the power source.

*the Black probe to the side of the circuit to

ground .

*Turn the power ON and test .

NOTE :

Current must always be measured with the meter test probes connected in

series as described .

.MAINTENANCE

(1) The multimeter is a precision electronic device . Do not tamper with the

circuity . to avoid damage :

A : Never connect a source of voltage under the condition of resistance

measurement .

B : Never operate the meter unless the cover is in place and fully closed .

C : Battery replacement should be done after the test leads have been

disconnected and POWER IS OFF .

(2) turn off the power if the meter is not in use , removed the battery if the

meter will be free for long period .

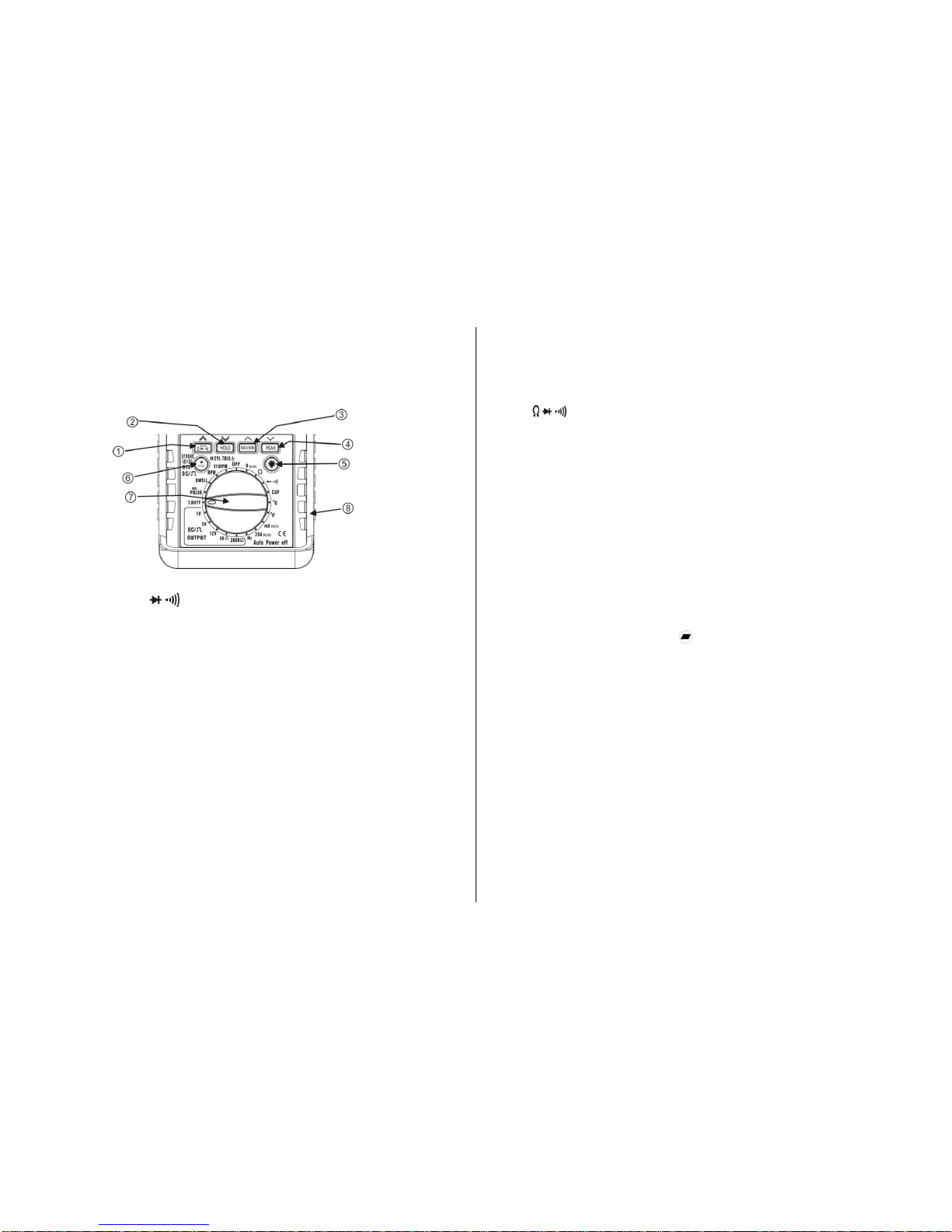

(3) If a sign “ ” appear on the display , open the compartment cover ,

remove the spent battery and replace it with a battery of the same type .

(4) Contact with the maintenance service center of our company if you have

trouble .

Basic Diagnostic Testing

This chapter leads you through a systematic series of tests that check the

vehicle electrical system . These tests should de performed before testing

individual components.

Electrical System Diagnostics

It is important to diagnose a vehicle electrical problem thoroughly and

efficiently .

The series of tests that follow check primary areas that are responsible for the

majority of the electrical problems found in an automobile . perform these basic

tests,even if a vehicle has a trouble code set in the computer .A component

malfunction detected by the computer can be caused by a basic ground

problem in the electrical system . simply replacing a failed component will not fix

the problem if a poor ground caused the component failure .

The tests begin by checking the main source of power and the chassis ground

circuit connections . Ground circuits are one of the least understood but

potentially most troublesome areas of automotive electronics . An excessive

voltage ground in a circuit effects the entire electrical circuit . this is why it is

important to make sure the basic circuit are in good shape before checking

trouble codes and components.

Battery Testing

[1]Battery Test (surface Discharge)

NOTE:

*Remove the positive and negative battery cables and thoroughly clean the

cable terminals and the battery

posts . Reassemble and begin

testing.

*The ignition switch must be OFF

to prevent damaging the vehicle

computer when connecting or

disconnecting battery cables.

This test checks for a low current

discharge across the battery

case.

*Set the rotary switch to voltage.

*connect the negative (-) lead to

the negative battery post.