MR CARTOOL V310 User manual

Fuel Injector Cleaner & Tester

V310

Fuel injector diagnostic and cleaning

equipment is a mechatronics product

that combines ultrasonic cleaning

technology and microcomputer oil

pressure closed-loop control clean-

ing and detection technology. This

product simulates various operating

conditions of the engine, and cleans

and inspects the fuel injectors of

various automobiles and motorcy-

cles. This equipment is the neces�

sary and preferred equipment for the

automobile and motorcycle repair

and maintenance industry, research

and teaching and training depart-

ments.

Ultrasonic cleaning: Ultrasonic

cleaning can be performed on

single or multiple injectors at the

same time, which can remove the

attachments and internal blockages

on the injectors.

Uniformity detection: to detect the

uniformity of the injection volume of

each injector.

Atomization observation: Using the

background light, you can observe

the spray atomization situation of the

nozzle in a comprehensive and

careful manner.

Tightness test: It can detect the

tightness and dripping of the fuel

injector under high pressure.

Fuel injection volume detection: It

can detect the fuel injection volume

of the fuel injection nozzle under

specific working conditions (such as

the same time and the same number

of times).

All rights reserved by SHENZHEN

MRCARTOOL CO., LTD. No part of

this publication may be reproduced,

stored in a retrieval system, or transmit-

ted in any form by any means, recording,

mechanical, electronic, photocopy-

ing or otherwise, without the prior

written permission of MRCARTOOL.

The information contained herein is

designed only for the use of this unit.

MRCARTOOL is not responsible for

any use of this information as applied

to other units.

Copyright Information

Overview

1.1 Functions And Features

Main Functions

Using ultrasonic powerful cleaning

technology, strong cleaning ability.

Using electronic pressure regulat-

ing control technology, stable oil

pressure and wide adjustable

range.

Use high-quality oil pump to ensure

long-term stable use.

The use of high-definition digital

tube display makes the operation

clear and easy to learn.

The oil tank liquid level is displayed

visually, and the detection liquid

can be recycled.

Main Features

Power Supply

AC 110/220V±10%

Frequency

50HZ±0.5

Relative Humidity

<85%

Environment Temperature

0℃~+40℃

External Magnetic Field Strength

<400A/m

No Open Flames Are Allowed

Around

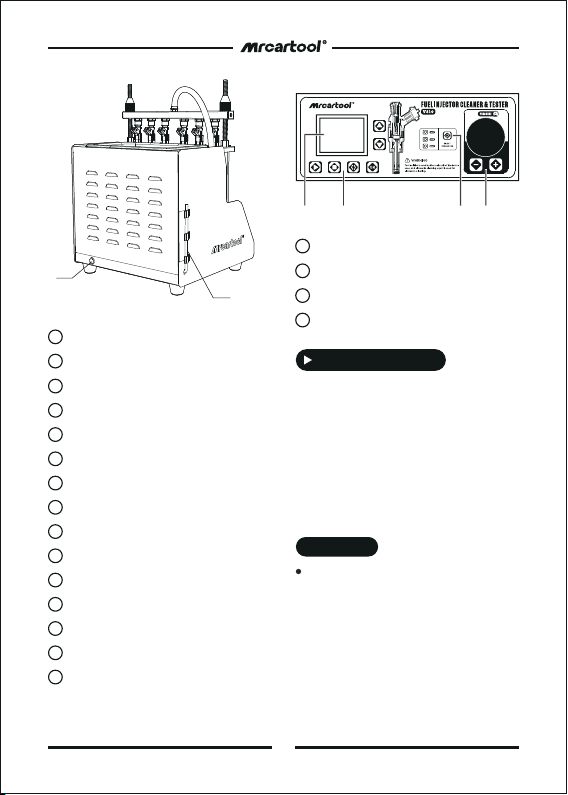

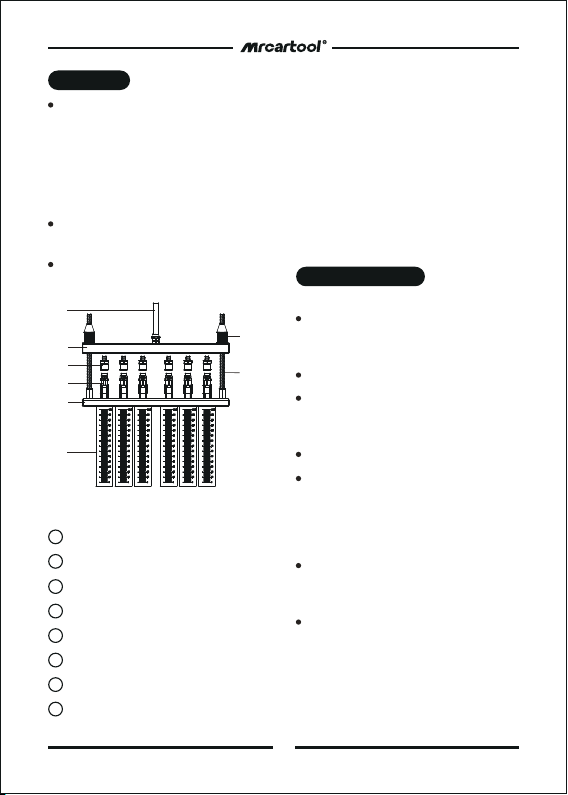

Structure And Composition

2.1 Structure

1.2 Working Environment And

Technical Parameters

Bright background light, you can

clearly see the various situations of

the fuel injector when it is working.

It has replaceable composite joints

suitable for a variety of vehicle

types.

Within the allowable adjustment

range, the test time, working

frequency, fuel injection times,

shortest switching period, etc. of

the fuel injector can be adjusted

arbitrarily.

Working Environment

Tank Capacity

2000 ml

Range Of Rotation

0-7500 r/min

PWM Pulse Width

0~20.0 ms step 0.1ms

Time

0~10 min

Cleaning Frequency

40 kHz

Cylinder Volume

180 ml

Injection Times

0~9900 times, step 100ms

System Pressure

0~0.6 Mpa

Ultrasonic Cleaning Power

70 W

Package Dimensions

340*295*360 mm

Technical Parameters

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑪

⑫

⑬

⑩

Lock pole;1

Lock nut;

2

Top oil inlet connector;

4

Glass measuring cylinder;

5

Oil drain handle;

6

Operation panel;

7

Pressure gauge;

8

Oil outlet pipe;

9

Ultrasonic cleaning tank;

10

Signal wire;

11

Power switch;

12

Power socket;

13

Cleaning agent drain valve;

14

Testing agent liquid level

15

Oil rail;

3

3

2.2 Operation Panel Diagram

⑭

⑮

TFT color screen;

1

Function buttons;

2

Pressure adjustment;

4

Voltage selection of injectors;

3

① ② ③ ④

Ultrasonic cleaning is to use the

penetrating and cavitation shock

waves generated when ultrasonic

waves propagate in the medium, and

powerfully clean objects with complex

shapes, cavities and pores to

completely remove stubborn carbon

deposits on the fuel injector.

Operation Process

3.1 Ultrasonic Cleaning

Remove the fuel injector from the

vehicle and check whether its rubber

seal is damaged. If it is damaged, it

should be replaced in time before the

cleaning test to avoid leakage during

the test. Then put the fuel injection

nozzle into the cleaning agent,

carefully remove the external grease

and wipe it with a soft cloth.

Preparation

4

During the cleaning process, you can

hear the intermittent (approximately

5 seconds) vibrating sound when you

take the fuel injector out and put it to

your ear, so you can judge whether

the fuel injector is working normally.

Ultrasonic cleaning is strictly

prohibited when there is no cleaning

agent in the ultrasonic tank to avoid

equipment damage.

Only the ultrasonic cleaning agent

dedicated to cleaning the fuel

injection nozzle can be added to the

ultrasonic tank, and other reagents

cannot be used instead,

otherwise any malfunctions and

damages caused will not be covered

by the warranty.

NOTICE:

This function is to detect the atomiza-

tion, dripping, blockage, fuel injection

angle status of the fuel injectors and

the size and balance of the fuel

injection of each fuel injector at

different speeds.

3.2 Injector Diagnostic

Add an appropriate amount of

cleaning agent to the ultrasonic

tank and spread the cleaning agent

over the bottom of the cleaning

stand.

Insert the plugs of the drive wires

into the injector sockets in turn.

(Special fuel injectors need to be

connected with an adapter cable)

Press the item selection up and

down keys to select the “01

ultrasonic cleaning" item, and then

press the working time up and

down keys to set the time. (The

system defaults to 10 minutes, if

you need to modify the time, you

can use the up and down keys to

change)

Press the start button and turn on

the ultrasonic cleaning switch on

the side of the device to start

cleaning. When working, you can

press the pause button to suspend

work or press the stop button to

exit.

During the cleaning process, the

heating switch on the side of the

equipment can be turned on to

improve the cleaning effect.

The working time gradually decreas-

es. When it is 0, the system automat-

ically stops.

Take out the fuel injection nozzle

from the ultrasonic tank, wipe the

cleaning liquid on it with a soft cloth,

and prepare for the next job.

Methods And Steps

Turn on the power and turn on the

power switch on the side of the

main unit.

Put the cleaning bracket in the

accessories into the ultrasonic

cleaning tank, and place the wiped

fuel injector in the cleaning bracket

positioning hole of the ultrasonic

tank.

Oil outlet pipe;

1

Oil rail;

2

Injectors;

4

Upper plate seat;

5

Glass measuring cylinder;

6

Lock nut;

7

Lock pole

8

Top oil inlet connector;

3

Confirm that the injector to be tested

has been installed properly and the

signal wire has been plugged in.

Select "02 Idle Speed Test".

Press the working time up and down

keys to set the time. (Generally set to

2 minutes)

Press the start button to start work.

Turn the pressure adjustment knob to

adjust the pressure to 0.25~ 0.3 MPa.

(In the electronic injection system, the

general oil pressure works at

0.25-0.3MPa)

Press the up and down keys to select

the appropriate pulse width. (The

system default is 3ms).

The working time gradually decreas-

es. When it is 0, the system automat-

ically stops.

02 Idle Speed Test

Confirm that the oil drain handle is

open, use the funnel in the

accessories to add the test liquid to

the equipment through the glass

window, and pay attention to

control the flow rate during the

addition to avoid overflow.

Add 1 bottle (about 1000ml) of

testing agent each time.

Install the fuel injector.

Preparation

Methods And Steps

5

(1)Select the top oil inlet connector

from the accessories and install it into

the oil separator.

(2)Install the fuel injector in the

forward direction (apply a little grease

on the “O" ring of the fuel injector)

(3)Put the horizontal end of the oil

separator and the fuel injector on the

upper plate seat, and tighten the two

ends with the locking rod. Ready to

test.

Top-in Fuel Injector Installation Diagram

①

②

③

④

⑤

⑥

⑦

⑧

Select "03 Medium Speed Test".

Press the start button.

The rest of the operation steps are

consistent with item 02.

03 Medium Speed Test

Select "04 High Speed Test".

Press the start button.

The rest of the operation steps are

consistent with item 02.

04 High Speed Test

The fuel pressure, working time and

pulse width are automatically set by

the system. The time system

defaults to 10s as a cycle period,

and the user does not need to set it

separately.

The system will automatically and

continuously cycle three times to

simulate the working condition and

fuel injection volume of the fuel

injector when the engine is

accelerating uniformly at 750 to

7500 rpm.

NOTICE:

The pulse width system defaults to

3ms, no need to set it again.

Whether the fuel injection nozzle is

dripping and leaking when the

simulated oil pressure is 0.3Mpa.

NOTICE:

6

Select “05 Accelerating Test”.

Press the start button.

05 Accelerating Test

The fuel pressure, working time and

pulse width are automatically set by

the system. The time system

defaults to a cycle of 10s, and the

user does not need to set it

separately.

The system will automatically and

continuously cycle three times to

simulate the working condition and

fuel injection volume of the fuel

injector when the engine is idling

(750 rpm), medium speed (4500

rpm), and high speed (7500 rpm).

NOTICE:

Select “06 Variable Speed Test”.

Press the start button.

06 Variable Speed Test

Select "07 Leak Test".

Press the working time up and

down buttons to set the time.

(Generally set to1minute)

The rest of the operation steps are

consistent with item 02.

07 Leakage Test

Select "08 Idle Spray Volume".

Press the up and down buttons to

set the number of times. (Generally

set to 2000 times)

Press down on the oil drain handle

to observe the fuel injection

volume.

Press the start button to start the

test.

08 Idle Speed Spray Volume Test

Simulate the working conditions

and fuel injection volume of the

engine when the fuel injection

nozzle works for a certain number

of times when the engine is idling.

DESCRIPTION::

Storage And Maintenance

4.1 Storage

7

Flow balance Test the flow balance

at different speeds. When the liquid

level in the measuring cylinder is

2/3 of the measuring cylinder,

pause or stop work to observe the

balance of the fuel injection

volume. The deviation of the fuel

injection volume of all fuel injection

nozzles on a vehicle should not

exceed 2%. Or refer to the relevant

technical manual of the fuel

injector to judge the flow balance

of the fuel injector.

Observation of fuel injection shape

Observe whether the fuel injection

shapes and angles of all fuel

injection nozzles on the same car

are uniform at various speeds. At the

same time, you can adjust the

opening pulse width of the fuel

injection nozzle to check whether the

minimum opening pulse width of the

fuel injection nozzle is consistent.

Leak detection test Leak detection

test is to detect the tightness of the

injector needle valve under the high

pressure of the system. (Observe the

tightness of the fuel injector,

generally there should be no leakage

within one minute)

NOTICE:

Select “10 High Spray Volume”.

The rest of the operation steps are

consistent with item 08.

10 High Speed Spray Volume Test

After the test, raise the drain

handle and put the testing agent

back into the tank.

Select “09 Medium Spray Volume”.

The rest of the operation steps are

consistent with item 08.

09 Medium Speed Spray Volume Test

Display the product number and date

of manufacture of the device.

Turn off the power and unplug the

power plug.

Put all connectors back into the

accessory box for storage.

Drain the ultrasonic cleaning agent.

Wipe the equipment clean with a dry

soft cloth.

If the machine needs to be stored for

a long time, discharge the testing

agent into a bottle and seal it.

4.2 Maintenance

Replacement of testing agent After

the testing agent has been used for a

period of time, a lot of impurities will

11 Unit Info

Since the test device is part of quartz

glass, it is easy to break, so do not

place other objects around the

equipment to avoid bumping and

breaking.

Precautions

8

If there is no digital display after

power on, please check whether

the power supply is powered; if so,

check whether the plug is connect-

ed firmly, or whether the fuse is

blown. If it is not broken, and the

switch is still invalid after pressing

the switch several times intermit-

tently, please contact the manu-

facturer and must not disassemble

it by yourself, otherwise our com-

pany will not provide warranty.

When no cleaning agent is added to

the ultrasonic tank, it is strictly

prohibited to open the ultrasonic

cleaning item to avoid damage to

the ultrasonic system.

Every time the test solution is

changed, it must be cleaned up,

and then 1L of new test solution

should be added.

The use of unqualified testing

agent will cause corrosion of the oil

pump, oil supply pipeline and failure

of the pressure gauge.

Using other cleaning agent and

testing agent will cause the

equipment surface coating to peel

off.

It is strictly forbidden to use

kerosene, gasoline or other testing

agent and cleaning agents as

testing agent and cleaning agents

for this machine. Otherwise, the

“O" ring and pipeline rubber parts

in the equipment will be damaged,

causing leakage.

The cleaning agent and testing

agent should not be mixed up.

will accumulate, and the agent

containing dirt cannot be used,

otherwise it will easily block the fuel

injector. When replacing the agent,

first open the testing agent drain

valve to empty the tank, and then

inject a little testing agent to clean

the interior of the tank. After

cleaning, drain the fuel tank again

and then pour 1L of new testing

agent into the tank.

Fuse replacement there is a square

box marked with a fuse on the

power socket on the left side of the

device, and the fuse can be seen by

opening the box. If it is blown,

replace it with a new one.

9

This manual introduces the product

in detail to the functional features,

working parameters, structure, opera-

tion methods and principles. The

company reserves the right to change

the product design and specifica-

tions. the physical configuration shall

prevail on the content of the product

packaging.

Special Note

Repair or replace the equipment will

be done according to the specific

fault conditions.

We guarantee that all replacement

parts, accessories or equipment are

brand new.

When there is a product breakdown

that can not be solved within 90

days, customer should provide video

and pictures as proof, we will bear

the freight cost and provide custom-

er the accessories in need to replace.

After receiving the product for more

than 90 days, the customer shall

bear the freight cost, we will provide

the accessory for free to replace.

There are 2 years’ warranty for MRCAR-

TOOL product main unit and 1 year

warranty for the accessories since the

day the customers have received the

product parcel.

Warranty Service

Warranty Access

Items that come through the unoff

icial MRCARTOOL purchase channel.

Product failure is caused by incorrect

use of the product, use for other

wrong purpose or human factors.

Not Covered Warranty

Table of contents

Other MR CARTOOL Test Equipment manuals