IN-9 Nixielyzer Assembly Manual

Page 3

We will build an assembling aid for the resistors and diodes

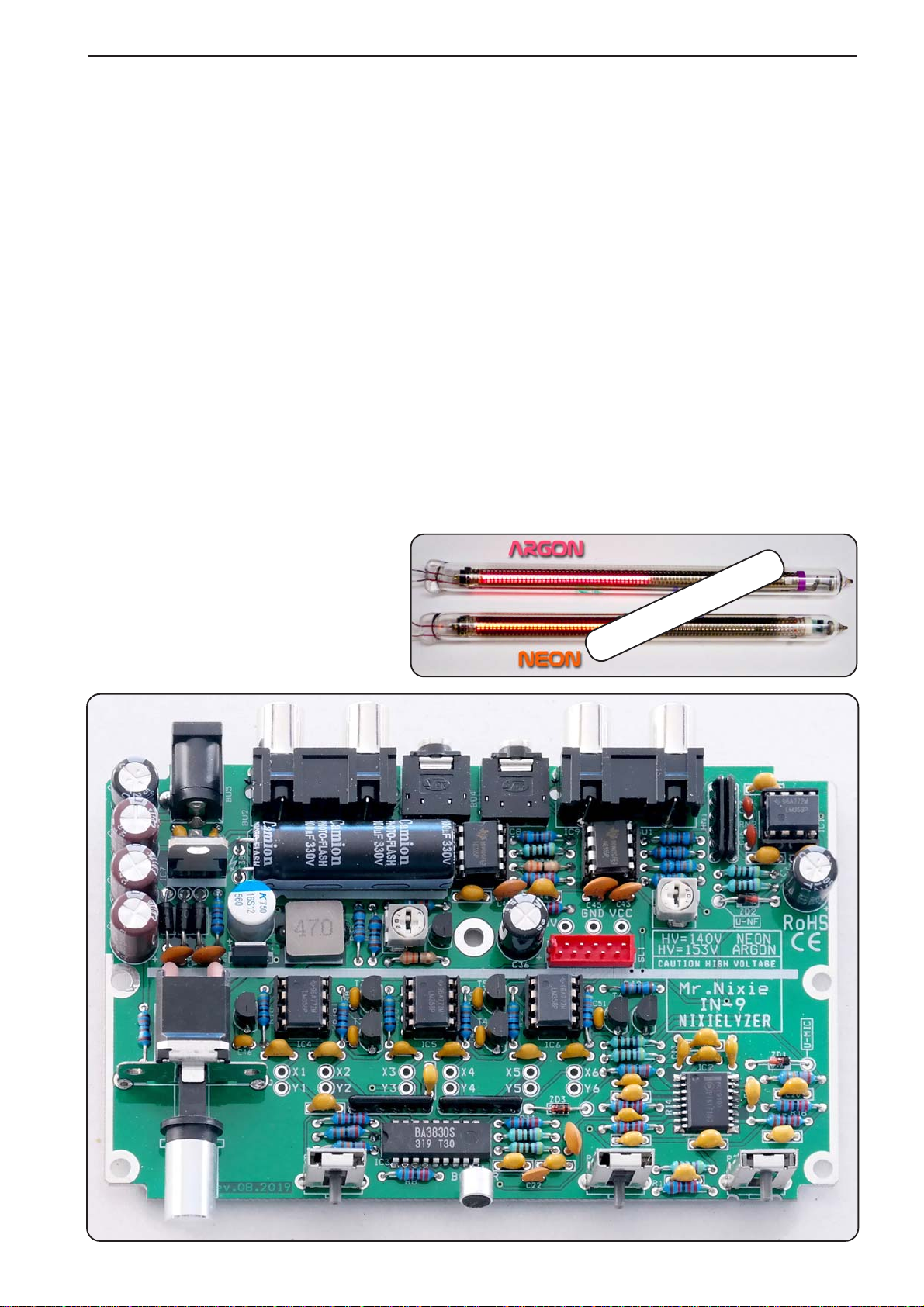

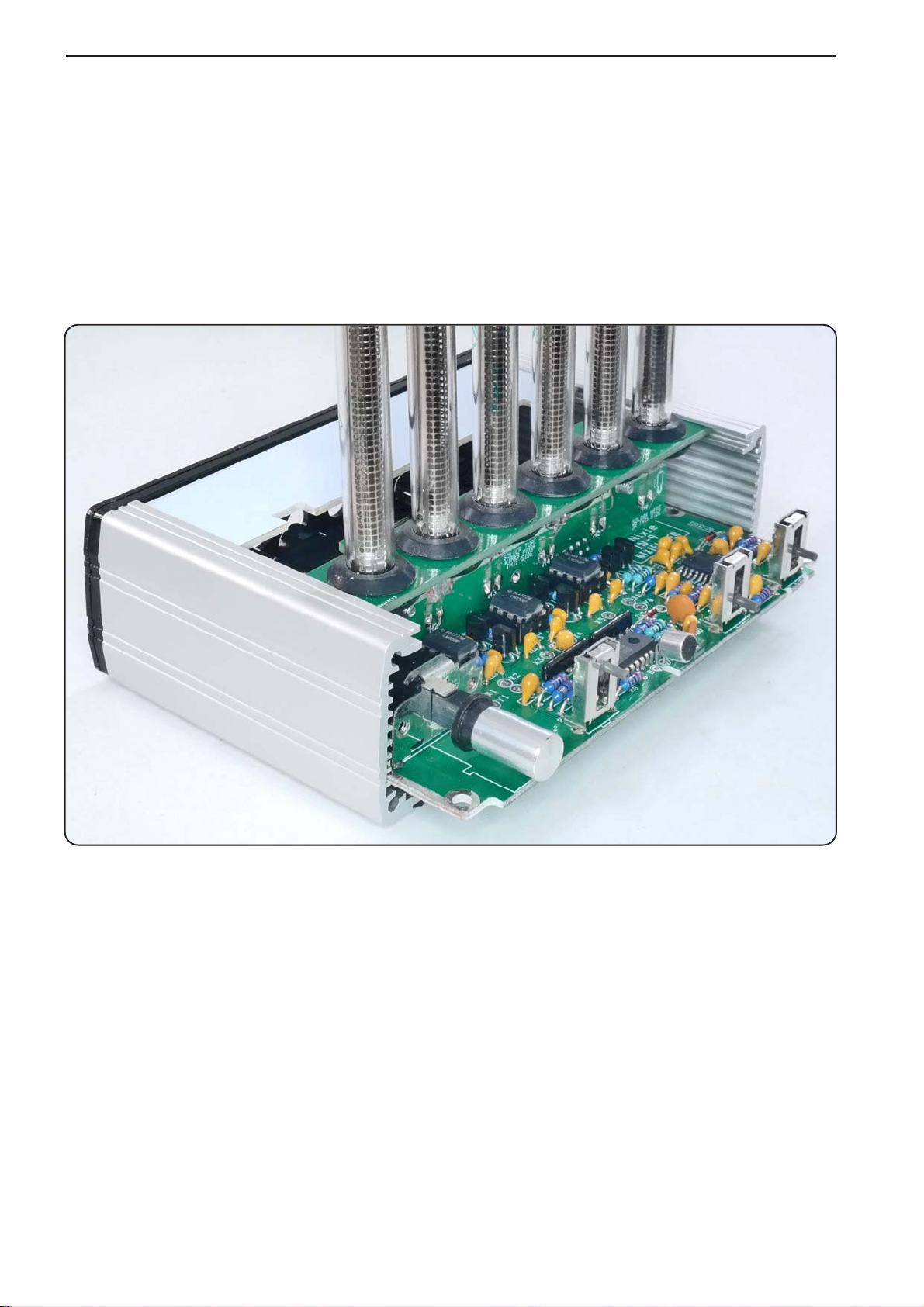

Pick up the Main Board and the aluminum frame. Slide

the PCB in the second wider upper groove as shown in the

picture. Pick up from the components box the bag with the

Resistors. We will now start assembling and soldering

the parts from components side. This is much faster and

easier. Start assembling and soldering the resistors value

by value, start with the lowest count = 590 kohms, followed

by 2 x 33 ohms, etc. Stop when you reach the 9 x 430 ohms

and clip all the soldered wires first on solder side. Then

continue assembling. For assembling and soldering R3 and

R16 you’ll need to pull out the board a little as they are

partially hidden by the frame on the right-hand side. Don’t

assemble the Trimmers, Potentiometes and Arrays yet.

Pick up now from the Semiconductor bag only all diodes and zenerdiodes (D1...3

and ZD1...3) and assemble and solder them in the same way. Pay attention about

the correct orientation and do not mismatch ZD3 (2V7) with ZD1...2 (5V6 each).

When finished check all solderings and than clip all the wires on solder side.

Now you can put the aluminum frame on a safe place.

Assemble the four Resistor Arrays RN1...4. They have no preferred orientation,

so you can negligible the dot on the part’s silk screen.

Pick from the Capacitor bag the two 220pF C16/17 and fit them next to RN2.

On the other hand the six IC sockets from the Semiconductor bag are well

poarized, so take attention when fitting them. If you have done a mistake, try not

to unsolder the sockets. When you later fit the IC’s in the correct orientation, that

will be fine.

Also fit the two jacks BU3 and BU4 from the Divers bag. Now solder all the parts.

Pick from the Capacitor bag the six taped 1nF capacitors C46...51 and fit them.

They are located between the transistors T1...T6 and are marked with a small filled

box decale between their pads. Pick up the remaining seven taped 10nF

capacitors, fit and solder than all parts.

Flip the board now and pick LED1 from the Semiconductor bag. Bend it legs as

shown on the PCB’s silk screen. Note that the Anode is the longer wire and the

Cathode (shorter wire) is marked with an annular ring on the PCB’s silk screen. Fit

the LED and solder it from solder side. Next clip the wires on component side.

Let’s start now assembling the remaining ceramic capacitors, therefore only get the

two small bags market with 4u7 and 1u from the Capacitor bag, but keep them

in their bags for the moment!

Have first a close look on the PCB’s silk screen for the 4u7 and 1uF capacitors. They

are marked with different decales. The 1uF have only a single dash between it’s pad

whereas the 4u7 have a squared decale. Let’s start first by assembling all 1uF

capacitors, next all 4u7 capacitors. Note that there should be remain one capacitor

for each value just for spare when you have dropped one as they are hard to find by

the common suppliers. When finished, solder and clip all wires.