Semi Automated Plate Sealer Operation Manual Chapter 1 Instruction

─1─

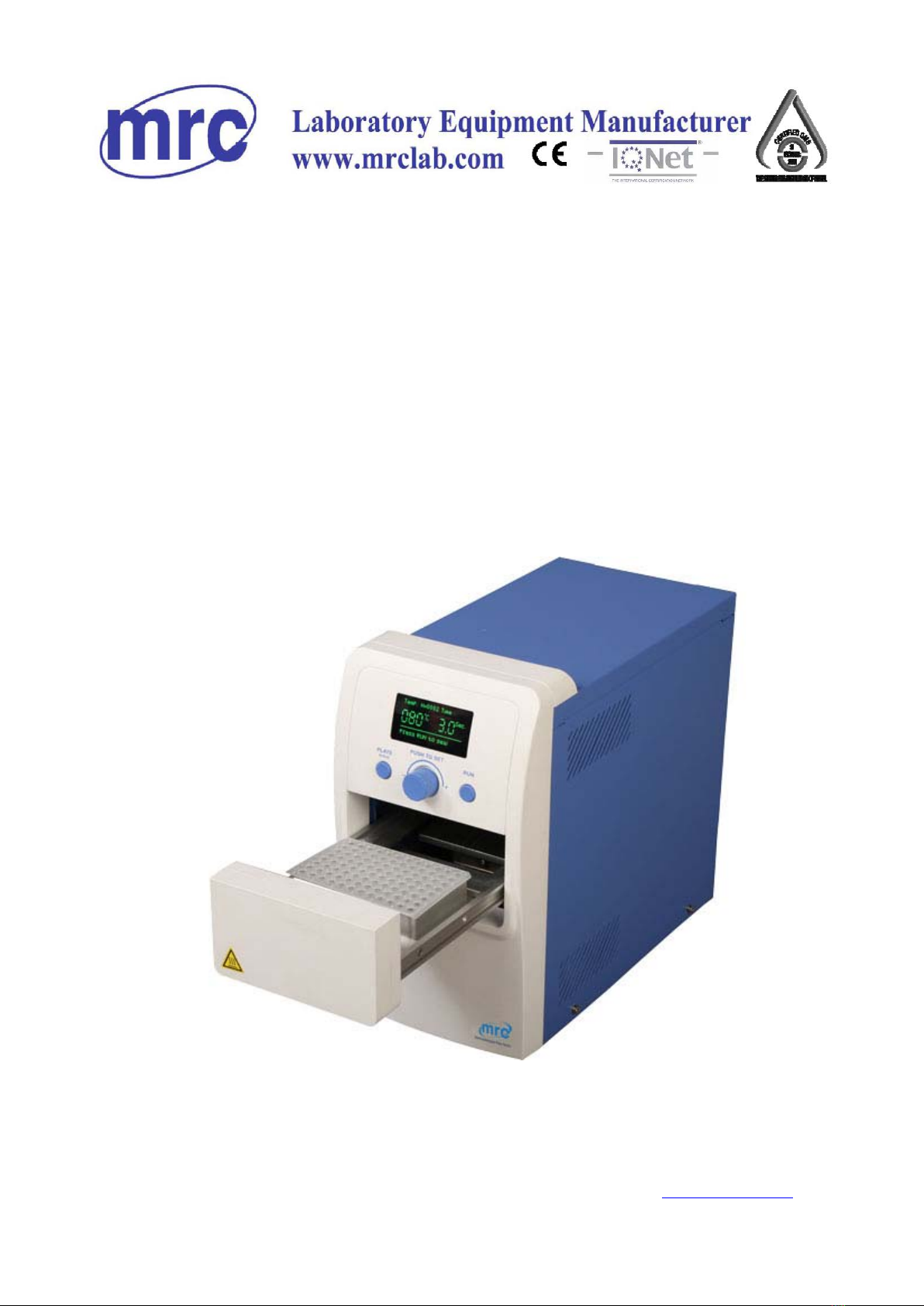

Chapter 1 Introduction

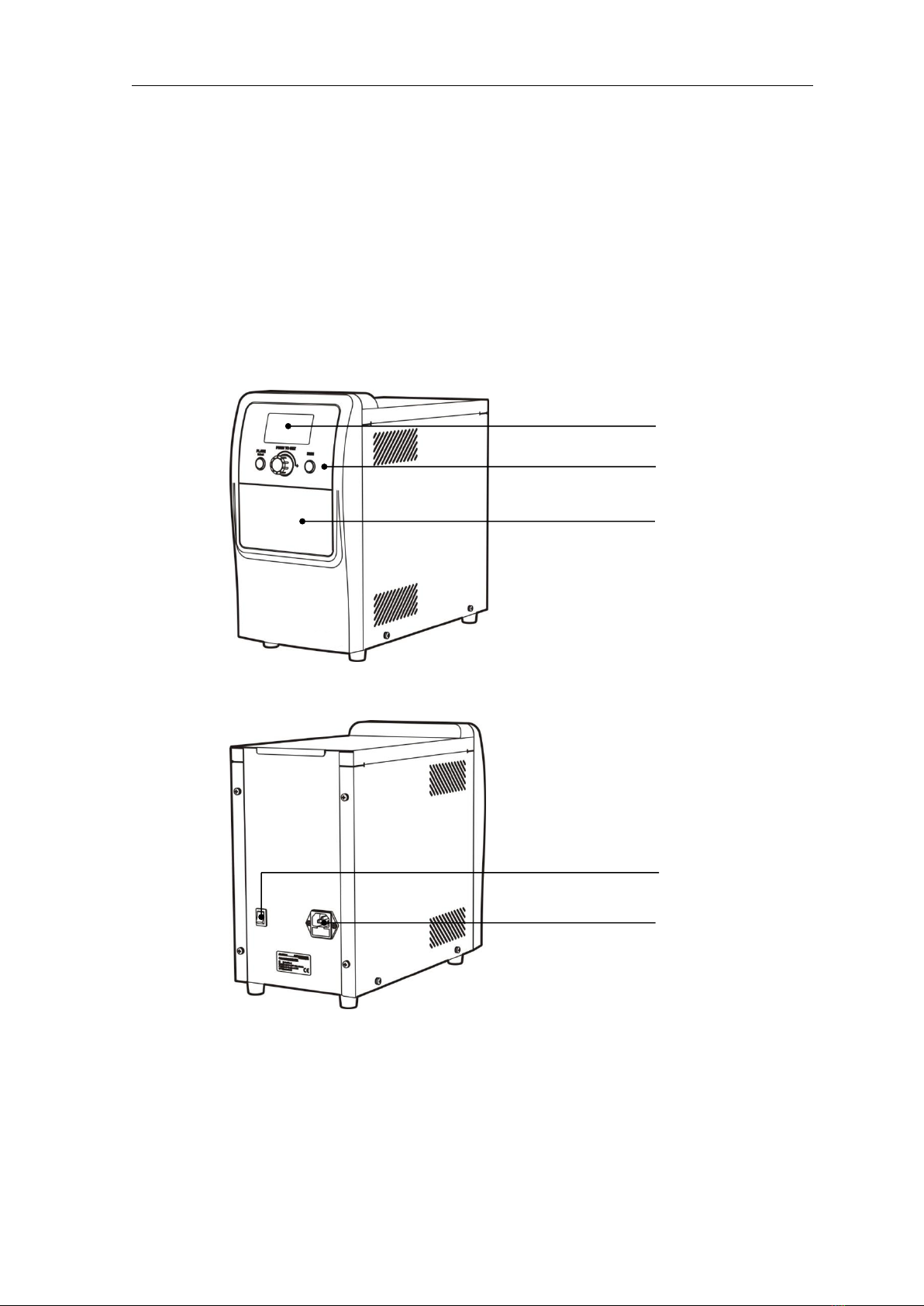

The UT-1001 Plate Sealer is a semi-automatic thermal sealer which is ideal for the low to

medium throughput laboratory that requires uniform and consistent sealing of micro-plates.

Unlike manual plate sealer , the UT-1001 produces repeatable plate seals. With variable

temperature and time settings, sealing conditions are easily optimised to guarantee

consistent result, eliminating sample loss. The UT-1001 apply in product’s quality control of

many manufacture enterprise such as plastic film, food, medical, inspection institute,

scholastic scientific research and teaching experiment.

Feature:

1. Format different micro well plates and heat seals

2. Seals plate heights: 9 to 48mm high

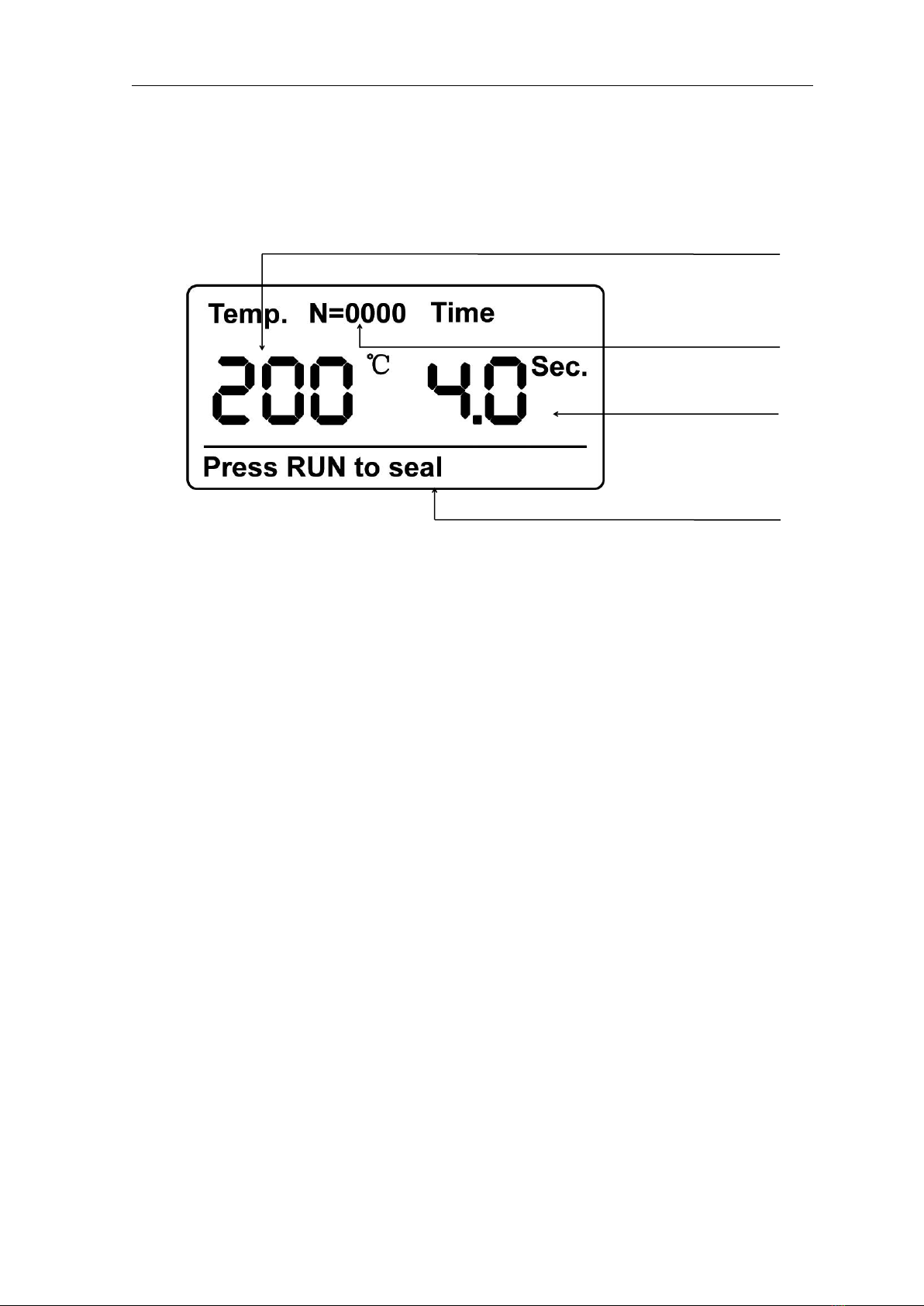

3. Adjustable Sealing Temperature: 80 - 200℃

4. OLED display screen, high light and no visual angle limit

5. Precise temperature, timing and pressure for consistent sealing

6. Compact footprint: only 7.0 inches (17.8cm) wide

7. Automatic counting function

8. The drawer is controlled by high grad MCU, if a hand or objects blocked the drawer when

it’s moving, the drawer motor will automatically reverse. This feature prevents injury to the

user and unit

9. Special and smart design on the drawer, it’s detachable from the main device. So user can

maintain and clean easily the heating element

10.When the unit is left idle more than 60min, it automatically switches into stand-by mode

during which the temperature of the heating element is reduced to 60°C to save energy

11. When the unit is left idle more than 120min, it switches off automatically for added safety. It

switched off the display and heating element. After, user will push any button to awaken it