MRD TNM4000-TP36FF4X16G24P User manual

Installation MRD TNM4000 Technical support

Release 02 12/2020 http://en.mrdcom.net/

User Manual

Installation Guide

Industrial Ethernet Rack-mount Switch

TNM4000-TP36FF4X16G24P

Installation MRD TNM4000 Technical support

Release 02 12/2020 http://en.mrdcom.net/

Industrial Switch >TNM4000

The naming of copyrighted trademarks in this manual, even when not specially

indicated, should not be taken to mean that these names may be considered as free

in the sense of the trademark and trade name protection law and hence that they

may be freely used by anyone.

© 2020 Shanghai MRDcom Co., LTD.

Manuals and software are protected by copyright. All rights reserved. The copying,

reproduction, translation, conversion into any electronic medium or machine

scannable form is not permitted, either in whole or in part. An exception is the

preparation of a backup copy of the software for your own use. For devices with

embedded software, the end-user license agreement on the enclosed CD/DVD

applies.

The performance features described here are binding only if they have been

expressly agreed when the contract was made. This document was produced by

MRDcom according to the best of the company's knowledge. MRDcom reserves the

right to change the contents of this document without prior notice. MRDcom can give

no guarantee in respect of the correctness or accuracy of the information in this

document.

MRDcom can accept no responsibility for damages, resulting from the use of the

network components or the associated operating software. In addition, we refer to

the conditions of use specified in the license contract.

You can get the latest version of this manual on the Internet at MRDcom product

site(http://en.mrdcom.net/).

Printed in China

Shanghai MRDcom Co., Ltd.

No.123, Juli Road, Zhangjiang Hi-Tech Park, Shanghai, P.R.O.C

Tel:86-21-58330762

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

3

Contents

Safety instructions...............................................................................................4

About this manual..............................................................................................11

Legend...................................................................................................................11

1Device description............................................................................................ 12

1.1 General device description.................................................................................12

1.2 Description of the device variants.....................................................................13

1.3 Connections for voltage-carrying lines.............................................................15

1.4 PoE function......................................................................................................... 16

1.5 Alarm relay contact..............................................................................................17

2Assembly and start-up.....................................................................................18

2.1 Installing the device.............................................................................................18

2.1.1 Unpacking and checking......................................................................... 18

2.1.2 Installing the SFP transceivers (optional).............................................18

2.1.3 Connecting the power unit connections for supply voltage and alarm

relay contact..........................................................................................................19

2.1.4 Grounding..................................................................................................21

2.1.5 Installing the device................................................................................. 21

2.1.6 Startup procedure.....................................................................................24

2.1.7 Connecting the data lines....................................................................... 25

2.2 Display elements................................................................................................. 28

2.3 Basic set-up..........................................................................................................30

2.4 Maintenance......................................................................................................... 32

2.5 Disassembling the device...................................................................................33

3Technical data.................................................................................................... 34

A Further Support.............................................................................................38

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

4

Safety instructions

Correct usage

Only use the device for those purposes specified in the catalog and in the

technical description. Only operate the device with external devices and

components that are recommended and permitted by the manufacturer. The

proper and safe operation of this product depends on proper handling during

transport, proper storage, assembly and installation, and conscientious

operation and maintenance procedures.

Supply voltage

Note: The supply voltage is electrically isolated from the housing.

WARNING

ELECTRIC SHOCK

Only connect a supply voltage as described in the data plate of your device.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

For every supply voltage to be connected, make sure the following

requirements are met:

The power supply conforms to overvoltage category I or II.

The voltage supply has an easily accessible disconnecting device (e.g. a

switch or a plug).

The disconnecting device is clearly identified so that in the case of an

emergency, it is clear which disconnecting device belongs to which line.

The lines to be connected are voltage-free.

The ground screw on the back of the device is connected to the protective

conductor.

There is a fuse in the outer conductor (AC) or the positive conductor (DC)

of the voltage supply.

Regarding the properties of this fuse: See “General technical data”on

page 34.

Supply with DC voltage: the fuse is suitable for a DC voltage.

If the neutral conductor (AC) or the negative conductor (DC) is not

grounded: there is a fuse in each of the two wires.

Voltage Supply: the wire diameter for the input supply line is

20AWG~12AWG.

The cross-section of the protective conductor cable is the same size as or

bigger than the cross-section of the voltage supply cables.

The connection cables used are permitted for the specified temperature

range.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

5

Relevant for North America:

For use in Class 2 circuits, the copper wire conforms to class 1, 60/75 °C

or 75 °C.

WARNING

ELECTRIC SHOCK

Only start connecting the supply voltage if all the above mentioned requirements

are fulfilled.

Failure to follow these instructions can result in death, serious injury,or

equipment damage.

Make sure that the electrical installation meets local or nationally applicable

safety regulations.

Use undamaged parts.

The device does not contain any service components. Internal fuses are

only triggered if there is a fault in the device. If the device is not functioning

correctly, or if it is damaged, switch off the voltage supply and return the

device to the plant for inspection.

Only switch on the device when the housing is closed.

First connect the ground screw on the back of the device with the protective

conductor before you set up the other connections. When removing the

connections, you remove the protective conductor last.

For supply voltages with protective conductor connections: first connect the

protective conductor before connecting the lines for the supply voltages.

If your device has a second voltage supply connection of this type: here you

also first connect the protective conductor before connecting the lines for the

supply voltages.

Shielded ground

Note: The shielded ground wire of the twisted pairs lines is connected to the

back panel as a conductor.

Beware of possible short circuits when connecting a cable section with

conductive shield braiding.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

6

Housing

WARNING

ELECTRIC SHOCK

Never insert sharp objects (small screwdrivers, wires, etc.) into the inside of the

device.

Never insert sharp objects (small screwdrivers, wires, etc.) into the connection

terminals for the supply voltage or the signal contact, and do not touch the

terminals!

Only install this device in a switch cabinet or in an operating site with limited

access, to which only maintenance staff have access.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

FIRE HAZARD

Install the device in a fire protected shell if you are mounting it vertically.

Failure to follow these instructions can result in death, serious injury,or

equipment damage.

Only technicians authorized by the manufacturer are permitted to open the

housing.

Do not touch the housing during operation or shortly after switching off the

device. Hot surfaces can cause injury.

The device must be installed in the horizontal or upright position, either in

the switch cabinet or on the wall (see page 18 “Installing the device”). The

device is not intended for operation as a table unit.

Operating the device in the maximum surrounding air temperature and

stacking devices: When installing the device, make sure there is at least one

free rack space (approx. 5 cm) above the device, because heat is

discharged via the housing of the device.

If you are operating the device in a 19" switch cabinet: install

sliding/mounting rails for supporting the weight of the device.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

7

Environment

Operate the device at the specified surrounding air temperature (temperature of

the surrounding air at a distance of up to 1.97 in (5 cm) from the device) and

relative air humidity specified in the technical data.

When you are selecting the installation location, make sure you observe the

climatic threshold values specified in the technical data.

Use the device in an environment within the pollution degree specified in the

technical data.

Relevant for use in explosion hazard areas of the Hazardous Locations

category (Class I, Division 2):

This device is only suitable for use in explosion hazard areas of category“Class

I, Division 2, Groups A, B, C, D”or for use in non-explosion hazard areas.

The maximum operating temperature (ambient air) is 85°C for general use. The

maximum operating temperature (ambient air) is 60°C when the device using

2.5Gbps SFP modules.

For operation in explosion hazard areas of the Hazardous Locations category

(Class I, Division 2), the following applies:

CLASS I; DIV. 2, GROUPS A, B, C, D

TEMPERATURE CODE T4

ENVIRONMENT:

Standard: 0 °C ~ +60 °C

Extended: -40 °C ~ +70 °C

List of standards: ISA 12.12.01, CSA C22.2 no. 213-M1987

Warning: Only disconnect devices when the system is voltage-free or

is located in an area without inflammable concentrations or

substances.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

8

Qualification requirements for personnel

Qualified personnel as understood in this manual and the warning signs, are

persons who are familiar with the setup, assembly, startup, and operation of this

product and are appropriately qualified for their job. This includes, for example,

those persons who have been:

trained or directed or authorized to switch on and off, to ground and to label

power circuits and devices or systems in accordance with current safety

engineering standards;

trained or directed in the care and use of appropriate safety equipment in

accordance with the current standards of safety engineering;

trained in providing first aid.

General safety instructions

This device is operated by electricity. You must follow precisely the prescribed

safety requirements for the voltage connections in this document.

Non-observance of these safety instructions can cause material damage and/or

injuries.

Only appropriately qualified personnel should work on this device or in its

vicinity. The personnel must be thoroughly familiar with all the warnings and

maintenance procedures outlined in this operating manual.

The proper and safe operation of this device depends on proper handling

during transportation, proper storage and assembly, and conscientious

operation and maintenance procedures.

Never start operation with damaged components.

Only use the devices in accordance with this manual. In particular,observe

all warnings and safety-related information.

Any work that may be required on the electrical installation may only be

carried out by personnel trained for this purpose.

Please note that products recommended as accessories may have

characteristics that do not fully correspond to those of the corresponding

product. This may limit their possible usage in the overall system.

Note: LED or LASER components in compliance with IEC 60825-1 (2007):

CLASS 1 LASER PRODUCT

CLASS 1 LED PRODUCT

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

9

National and international safety regulations

Make sure that the electrical installation meets local or nationally applicable

safety regulations.

CE marking

The labeled devices comply with the regulations contained in the following

European directive(s):

2004/108/EC

Directive of the European Parliament and the council for standardizing the

regulations of member states with regard to electromagnetic compatibility.

2006/95/EC

Directive of the European Parliament and the council for standardizing the

regulations of member states with regard to electrical equipment to be used

within specific voltage ranges.

2011/65/EU (RoHS)

Directive of the European Parliament and of the Council on the restriction of the

use of certain hazardous substances in electrical and electronic equipment.

In accordance with the above-named EU directive(s), the EU conformity

declaration will be at the disposal of the relevant authorities at the following

address:

Shanghai MRDcom Co.,Ltd.

No.123, Juli Road, Pudong Zhangjiang Hi-Tech Park, Shanghai, P.R.China

Tel.: 86-21-58330762

The product can be used in the industrial sector.

Interference immunity: EN 61000-6-2

Emitted interference: EN 55022

Reliability: EN 60950-1

Warning! This is a class A device. This device can cause interference in living

areas, and in this case the operator may be required to take appropriate

measures.

Note: The assembly guidelines provided in these instructions must be strictly

adhered to in order to observe the EMC threshold values.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

10

FCC note

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference; (2)

this device must accept any interference received, including interference that

may cause undesired operation.

Appropriate testing has established that this device fulfills the requirements of a

class A digital device in line with part 15 of the FCC regulations.

These requirements are designed to provide sufficient protection against

interference when the device is being used in a business environment.

The device creates and uses high frequencies and can also radiate high

frequencies, and if it is not installed and used in accordance with this operating

manual, it can cause radio transmission interference. The use of this device in a

living area can also cause interference, and in this case the user is obliged to

cover the costs of removing the interference.

Recycling note

After usage, this device must be disposed of properly as electronic waste, in

accordance with the current disposal regulations of your county, state, and

country.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

11

About this manual

The “Installation”user manual contains a device description, safety instructions, a

description of the display, and the other information that you need to install the

device.

The following manuals are available as PDF files on the CD/DVD supplied:

Installation user manual

Reference manual for the graphical user interface

Command Line Interface user manual

The Industrial NetTime Network Management Software provides you with additional

options for smooth configuration and monitoring:

Simultaneous configuration of multiple devices

Graphical user interface with network layout

Auto-topology discovery

Event log

Event handling

Browser/server structure

Browser interface

SNMP

Legend

The symbols used in this manual have the following meanings:

Listing

Work step

Subheading

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

12

1Device description

1.1 General device description

TNM4000-TP36FF4X16G24P industrial switches are designed for the special

requirements of industrial automation. They meet the relevant industry standards,

provide very high operational reliability, even under extreme conditions, and also

provide long-term reliability and flexibility.

The devices allow you to set up switched industrial Ethernet networks that conform to

the IEEE 802.3 standard.

The devices work without a fan.

If required, the devices are PoE-capable.

The following installation options are available:

19" switch cabinet

You have the option to choose various media to connect terminal devices and other

infrastructure components:

twisted pair cable

multimode F/O

singlemode F/O

The ring redundancy concept allows the network to be reconfigured quickly after a

failure.

Product configuration data can be provided by:

diagnosis displays

displaying the operating parameters

There are convenient options for managing the device. Administer your devices via:

a Web browser

Telnet

CLI Port (locally on the device)

management software (such as NetTime Network Management Software)

The devices provide you with a large range of functions, which the manuals for the

operating software inform you about. You will find these manuals as PDF files on the

enclosed CD/DVD.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

13

1.2 Description of the device variants

TNM4000-TP36FF4X16G24P industrial switches support 8 802.3af/at/bt

PoE/PoE+/PoE++ 10/100/1000BaseT Ports, 12 802.3af/at PoE/PoE+

10/100/1000BaseT Ports, 4 802.3af/at PoE/PoE+ 100/1000Base(X/T) COMBO Ports,

8 100/1000BaseX SFP Ports, and 4 100/1000/2500/10000BaseX SFP Ports.

In these devices, all the cable outlet (except CLI port, MGT port)are at the back, i.e.

the ports are on the back of the device.

Rear view of TNM4000-TP36FF4X16G24P

Figure 1: Rear panel

1 - Grounding screw

2 - Power supply unit

3 - Alarm relay port

4 - LED display elements

5 - 8 100/1000BaseX SFP Ports

6 - 8 802.3af/at/bt PoE/PoE+/PoE++ 10/100/1000BaseT Ports

7 - 12 802.3af/at PoE/PoE+ 10/100/1000BaseT Ports

8 - 4 802.3af/at PoE/PoE+ 100/1000Base(X/T) COMBO Ports

9 - 4 100/1000/2500/10000BaseX SFP Ports

Front views of TNM4000-TP36FF4X16G24P

Figure 2: Front panel:

1 - SD slot

2 - CLI port

3 - MGT port

4 - ZTP Button

5 - LED display elements

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

14

The display LEDs are both on the front panel and rear panel of the device.

Each port correspond to a LEDs for displaying the status of the port. There

are as well as 5 LEDs for displaying the device status.

The supply voltage connection and the ports are on the back of the device.

The device allows you to connect a maximum of 36 service ports as well as

additional CLI port and MGT port on the front of the device that you can use

for diagnosis purposes.

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

15

1.3 Connections for voltage-carrying lines

Note: The supply voltage is electrically isolated from the housing.

A device has two internal power supply units. Each power supply unit has a

connection for the supply voltage and a connection for the alarm relay contact.

The power supply unit types have the following different properties:

Type of connectable supply voltages: DC voltage

Level of connectable supply voltages:

The following tables provide an overview of the possible connections for

voltage-carrying lines:

1

Grounding screw

Requiring good ground connection

2

Power supply

unit(PWR1/PWR2)

►DC voltage connectable

►Dual 44-57VDC Power Inputs

►European terminal

►5-pin

3

Alarm relay contact

►European terminal

►3-pin

►Type of the output load: general use & resistive

Table 1: Connections for voltage-carrying lines:

rear view of the device variants with plugged connections

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

16

1.4 PoE function

TNM4000-TP36FF4X16G24P industrial switches support Power over Ethernet (PoE)

in accordance with 802.3af/at/bt. They allow the connection and remote supply of, for

example, IP telephones (Voice over IP), webcams, sensors, printer servers and

WLAN access points via 10/100/1000BASE-T. With PoE, these terminal devices are

powered by the twisted-pair cable.

TNM4000-TP36FF4X16G24P industrial switches have 8 802.3af/at/bt

PoE/PoE+/PoE++ 10/100/1000BaseT Ports, 12 802.3af/at PoE/PoE+

10/100/1000BaseT Ports, 4 802.3af/at PoE/PoE+ 100/1000BaseT COMBO Ports.

The current is supplied on wire pairs transmitting the signal; the individual ports are

not electrically insulated from each other.

The following conditions are met in accordance with IEEE 802.3af/at/bt:

Endpoint PSE

Alternative A

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

17

1.5 Alarm relay contact

Each TNM4000-TP36FF4X16G24P device is equipped with 1 alarm relay contact.

The alarm relay contact is a potential-free relay contact.

The potential-free relay contact reports through a break in contact:

The failure of at least one supply voltage.

The device is not operational.

When the device is normally working, the normally-open contact is closed and the

normally-closed contact is open. When alarm occurs, the normally-open contact is

open and the normally-closed contact is closed.

Note: You can use the alarm relay contact functions when the voltage supply is

connected. If there is redundant voltage supply, but this is turned off, there is a

contact interruption at the corresponding alarm relay contact.

Figure 3: relay contact

Item

Name

Function

1

Normally Close Contact

Open when the device is working normally.

Closed when alarm occurs.

2

Double-throw Contact

Two-way Contact.

3

Normally Open Contact

Closed when the device is working normally.

Open when alarm occurs.

Table 2: Description of Relay

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

18

2Assembly and start-up

The devices have been developed for practical application in a harsh industrial

environment.

On delivery, the device is ready for operation.

The following procedure has been proven to be successful for the assembly of the

device:

Unpacking and checking

Installing the SFP transceivers (optional)

Connecting the power unit connections for supply voltage and alarm relay

contact

Grounding

Installing the device

Startup procedure

Connecting the data lines

2.1 Installing the device

2.1.1 Unpacking and checking

Check whether the package includes all items named in chapter “Scope of

delivery” on page 36.

Check the individual parts for transport damage.

2.1.2 Installing the SFP transceivers (optional)

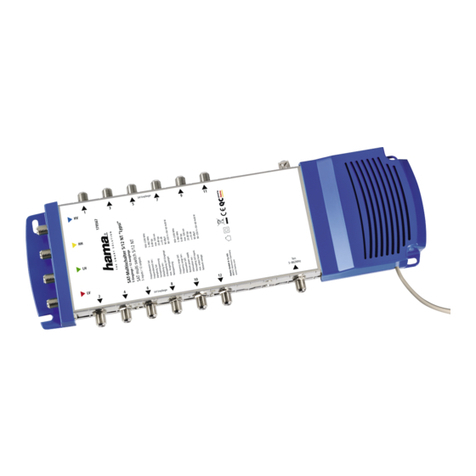

Figure 4: Fast Ethernet / Gigabit Ethernet Fiberoptic SFP Transceiver

Before attaching an SFP transceiver, first remove the protective cap over the

socket.

Push the SFP transceiver with the lock closed into the socket until you hear it

latch in.

Note: Only use MRD SFP transceivers (see page 37 “Accessories”).

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

19

2.1.3 Connecting the power unit connections for supply

voltage and alarm relay contact

Connecting the voltage supply terminals

WARNING

ELECTRIC SHOCK

Only connect a supply voltage as described in the data plate of your device. Never

insert sharp objects (small screwdrivers, wires, etc.) into the connection terminals

for the supply voltage, and do not touch the terminals!

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Note: Relevant for North America:

The torque for tightening the supply voltage terminal block on the device is 4.5 lb

in (0.51 Nm).

Figure 5: Power supply unit , dual DC voltage Connection

1 - supply voltage

2 - relay contact

Connection

Description

+, pin 1

Plus terminal of the supply voltage

-, pin 2

Minus terminal of the supply voltage

, pin 3

Protective conductor

-, pin 4

Minus terminal of the supply voltage

+, pin 5

Plus terminal of the supply voltage

Table 3: Pin assignment of terminal block for voltage supply

For every supply voltage to be connected, perform the following steps:

Ensure the required conditions for connecting the supply voltage are

observed (see page 4 “Supply voltage”).

Installation MRD TNM4000

Release 02 12/2020

Industrial Switch >TNM4000

20

WARNING

ELECTRIC SHOCK

Only start connecting the supply voltage if all the above mentioned requirements

are fulfilled.

(see page 4 “Supply voltage”)

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Remove the power connector from the device.

Connect the protective conductor to the protective conductor terminal.

Connect the lines for the supply voltage to the terminals + and −.

Mount the terminal block on the device using screws.

Connecting the alarm relay contact

WARNING

ELECTRIC SHOCK

Never insert sharp objects (small screwdrivers, wires, etc.) into the connection

terminals for the signal lines, and do not touch the terminals!

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Note: Relevant for North America:

The tightening torque for fixing the signal contact terminal block to the device is

4.5 lb in (0.51 Nm).

For every alarm relay contact to be connected, make sure the following

requirements are met:

The lines to be connected are voltage-free.

The connected voltage is limited by a current limitation device or a fuse.

Observe the electrical threshold values for relay contact (see on page 34

“General technical data”).

For every alarm relay contact to be connected, perform the following steps:

Connect the relay contact lines with the terminal block connections. Mount

the terminal block on the device using screws.

Table of contents

Popular Switch manuals by other brands

HRT

HRT VS-2A user manual

Rose electronics

Rose electronics UltraMatrix AV quick start guide

Sony

Sony PC-3000 operating instructions

Spirax Sarco

Spirax Sarco LCS3050 Installation and maintenance instructions

Renkforce

Renkforce 2621177 operating instructions

Extron electronics

Extron electronics XTP T USW 103 4K user guide