© 2001, MSA Rose Page9

User Instructions nLynxHoist P/N 10016732, Rev. B

! CAUTION

Read this User Instruction completely and inspect the device before and after

each use. Read and heed all labels on the device. Failure to observe

instructions may result in serious or fatal injury. Keep this User Instruction in

a safe place, readily accessible to all who may need to use the hoist. Require

anyone intending to use the hoist to read this User Instruction carefully and

completely before using it. Periodically read all labels and this User

Instruction to reinforce knowledge.

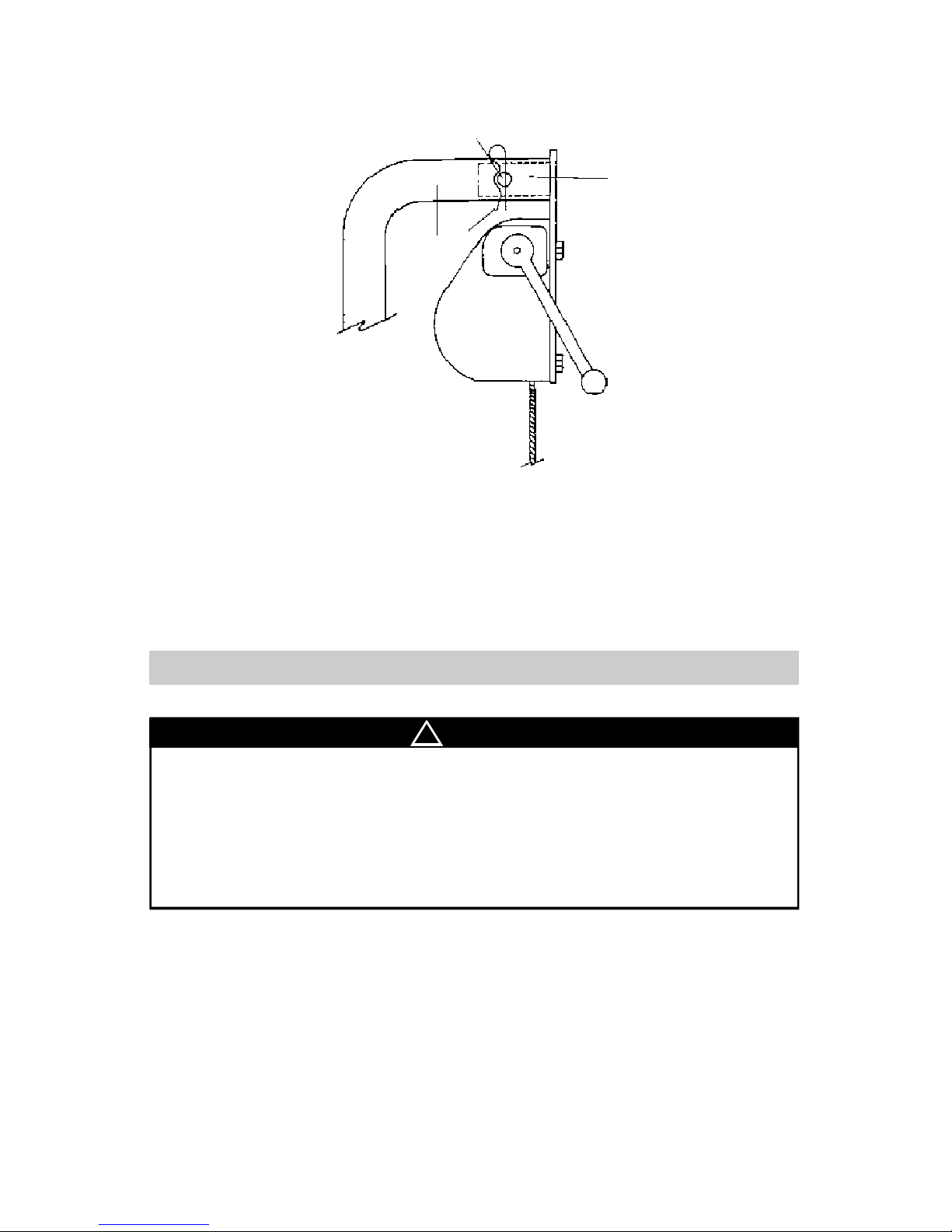

3.3 OPERATION OFTHE HOIST

! CAUTIONS

nNever leave a load hanging from the hoist while the hoist is unattended.

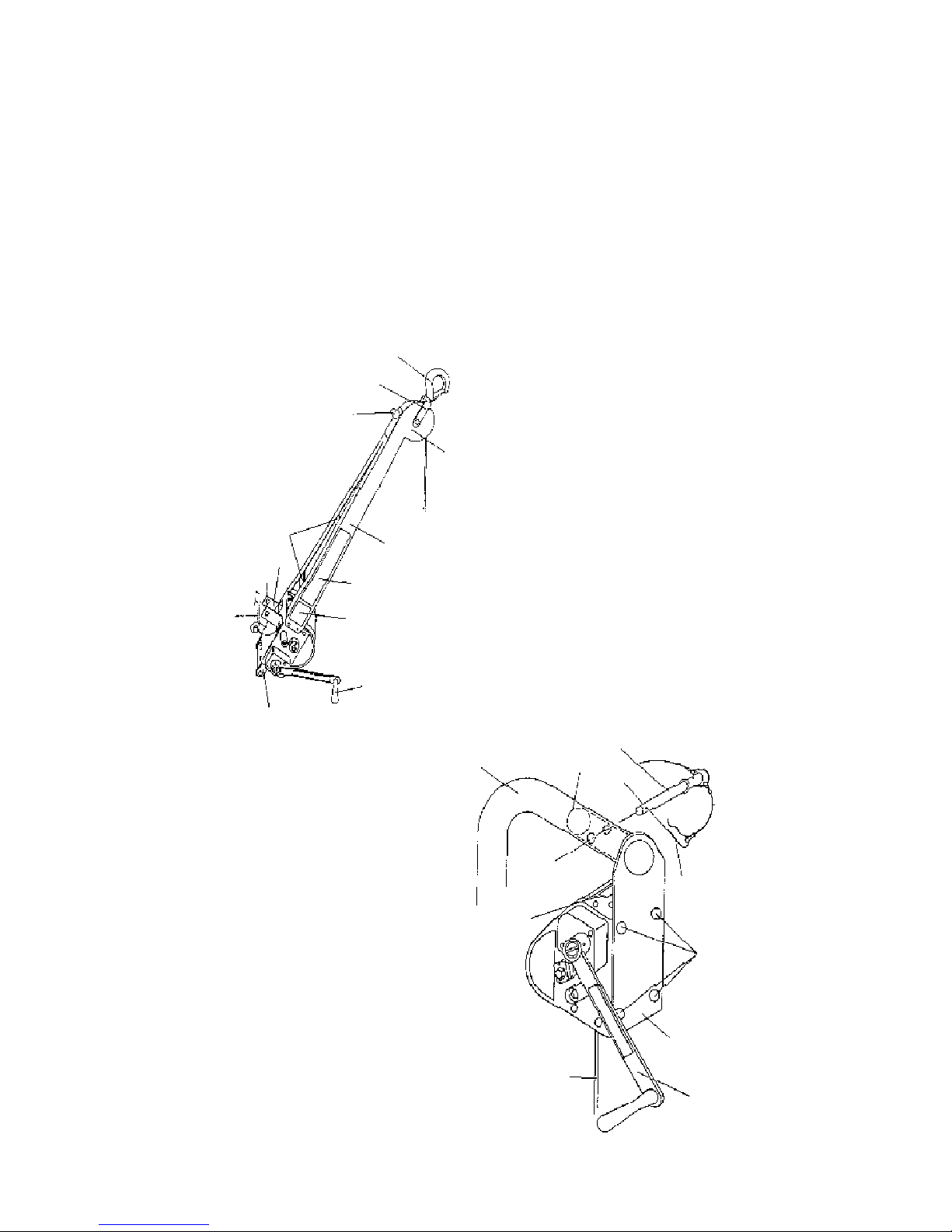

nAlways be sure the line is pulling straight out from the hoist drum – never

at an angle.

nNever exceed the maximum rated loads listed on the hoist specification

label.

nNever alter the mechanics of the hoist except to retrofit the air drive adapter

kit in accordance with these instructions.

nNever use two or more hoists to raise or lower a heavier load. Load shifting

may place the entire load on one hoist, causing sequesntial failure of both

units.

nAlways apply loads evenly. Do not jerk or bounce loads as this dynamic

loading may generate forces in excess of the maximum working load.

nEach time a load is lifted, first test the hoist by lifting the load a few inches.

nAlways keep hands away from pinch points around load-bearing lines,

pulleys and drums during operation.

nAlways ensure level winding when extracting or retracting line by guiding

the line. Use a gloved hand when guiding the line to avoid cuts and wire

slivers. Continually inspect for level winding during operation.

nIt is critical that the hoist operator remain a safe distance away from any

fall hazard or load which could cause injury in the event of a loss of

balance on the part of the operator, or in the event of a load fall. When

operating the hoist in a fall hazard area, the operator must wear appropri-

ate fall protection equipment connected to an independent anchorage.

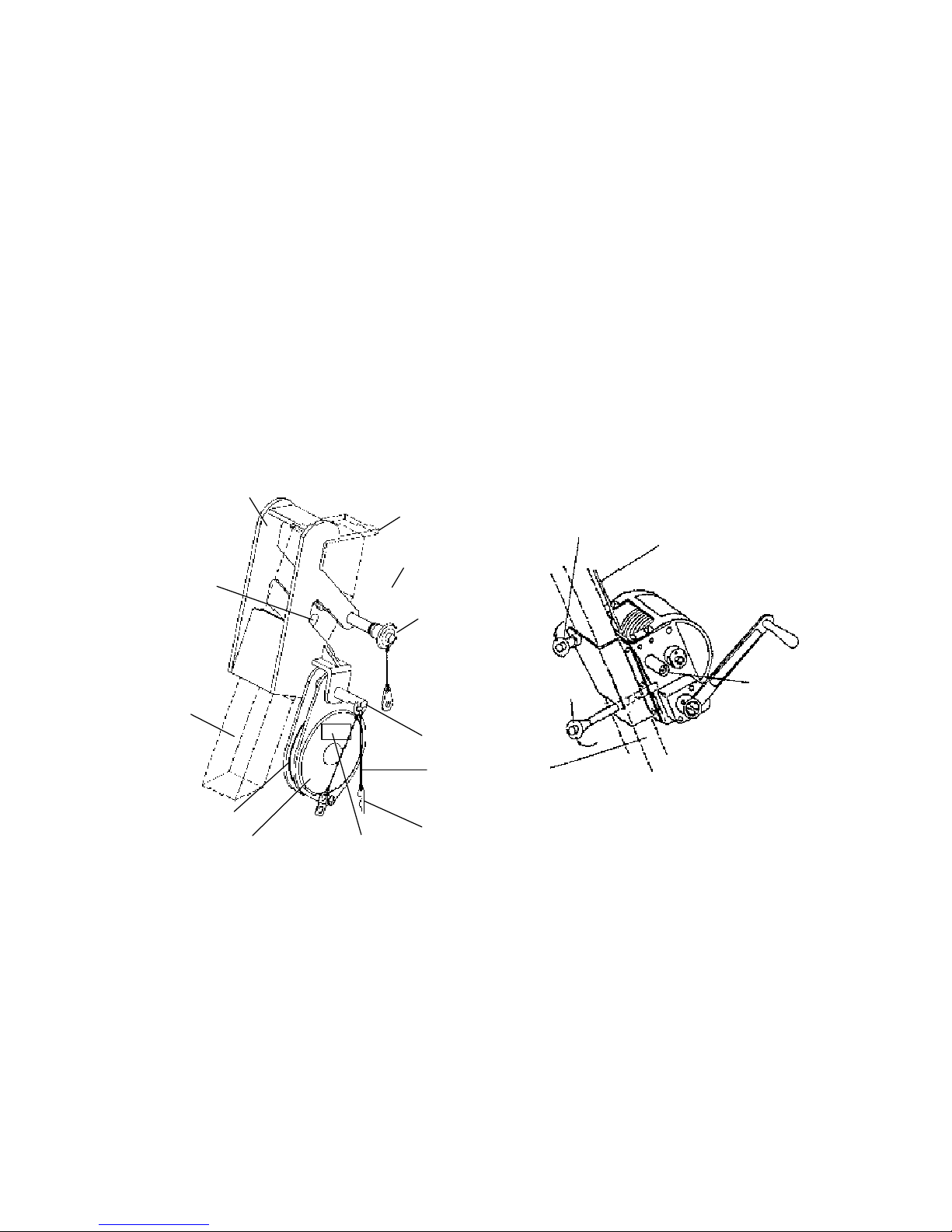

nAll labels must be visible and the operator should never come between the

hoist housing and line. The hoist operator must always operate the hoist

with the housing and crank between him or herself and the load.

nNever install the hoist where any member of the work crew must be

stationed in line with a tensioned hoist line. Should the line fail, stored

energy may cause recoil of the line with sufficient force to cause serious or

fatal injury.