Preparing for Use

is further secured by a lock device

which fits at the end opposite to the

angle clamp. The lock device fits over

the end of the cover, and is secured in

position by a slotted screw. After the

screw is tightened, it can be filled with

wax to detect any unauthorized per-

son tampering with the battery.

Depending on the Luminator battery

used, the cap lamp is designed to

operate at full brilliance for a minimum

of an 8-10 hour shift, with reserve

energy if needed. At the end of each

shift the battery is recharged in a sin-

gle- or multiple-station charging unit.

The Luminator Power Cell (13 AH) is

designed to operate at cycle routines

of 8-10 hours discharge/16-14 hour

recharge 5 days/week (max). If the

routines are increased, the Luminator

Power Cell Plus (16 AH) is recom-

mended. Battery charging connection

is made through the headpiece. Each

battery has a transparent case with

molded-in electrolyte level indicators

below the filling ports.

Remote Power Connections

(only available with plastic cover)

The Remote Power Connection allows

the Cap Lamp to be used as a power

source for an external remote device

while still operating as a light source.

MSHA regulation permits this configu-

ration as long as the external remote

device current requirement does not

exceed 275 milliamps.

If using the Remote with the ML-3

Cap Lamp, the Luminator Power Cell

Plus 16 AH battery is recommended,

due to higher battery demands.

However, the Luminator Power Cell 13

AH has been approved.

PREPARING THE ML-3 CAP LAMP

FOR FIRST TIME USE

Battery Charging

Every battery must be charged before

it is used for the first time.

1. Allow the battery to remain on

charge for 24 hours.

2. Top off each cell with distilled water

if necessary (see Filling Battery).

Never fill over top of fill line.

Note

Batteries which do not perform satis-

factorily, should be removed from

service and cycled - charged 16

hours, discharged 8 hours. Repeat

several times until battery responds. If

battery does not respond after three

or four cycles, it should be replaced.

3. After weekly shifts, the battery

should be placed on the charger

following the instructions included

with the charger, and left to charge

the remainder of the weekend.

4. If cap lamp needs cleaning, use a

mild detergent and wipe. Do not

submerge in water.

Storage of Batteries

All stored batteries with acid should

be boost charged for 24 hours every 3

months, and immediately before being

placed into regular service.

Recommended storage temperatures

32˚F to 80˚F.

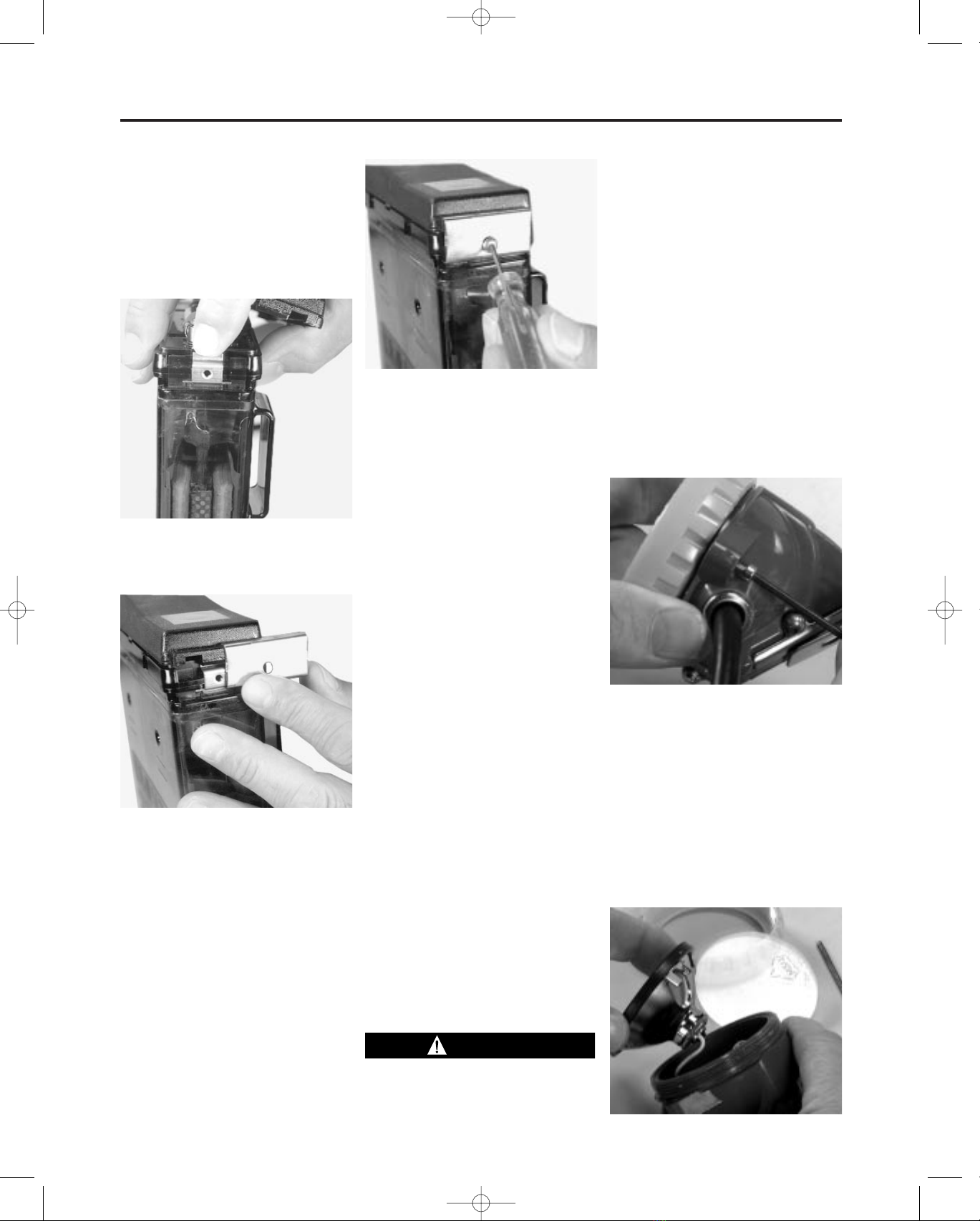

Filling Battery

The electrolyte level should be main-

tained between the two lines below

the filling and venting hole i.e. slightly

above the top of the battery plate.

Normally topping up should not be

necessary more often than once every

4-6 weeks, and should always be car-

ried out when the battery is fully

charged. Only distilled or deionized

water should be used in topping off.

The electrolyte level of all batteries

should be checked once each

week, and after battery is charged.

Water only when battery is fully

charged. If the battery is over-

topped, there is a possibility that

electrolyte may leak out under cer-

tain conditions.

1. Fill the plastic bottle of the MSA

Filling Device (P/N 69422 or

469773) with distilled water only,

and place it at a convenient loca-

tion close to the batteries to be

watered.

2. Insert the nozzle or needle of the

Filling Tube into the small hole pro-

vided in the battery window.

Depending on the style of filling

device, squeeze the bottle or the

bottle handle.

3. Fill until the electrolyte level is

centered between the two scribed

lines below the cell window. The

battery may have to be tilted back

slightly to allow the water to flow.

4. Repeat this procedure in adjacent

battery cell.

The Electrolyte is corrosive and can

cause burns. Take proper precau-

tions to avoid skin and eye contact.

Contact MSA for battery Materials

Safety Data Sheet (MSDS). Phone

1-800-MSA-2222.

USING THE REMOTE POWER

CONNECTION

Note

If using the Remote Power Connec-

tions with the ML-3 Cap Lamp, the

Luminator Power Cell Plus 16 AH bat-

tery is recommended, due to higher

battery demands. However, the

Luminator Power Cell 13 AH has been

approved.

1. To access the battery power for

an external remote device, remove

the connector cover located on

the top of the battery. Keep the

cover for later use.

2. Slide the remote power device’s

connector onto the connector on

top of the battery until it stops.

3TAL 997 (L) Rev. 0 - 100113469