2 INSTALLATION INSTRUCTIONS

CAPABILITIES

The Atomic LS EFI system is designed to fit OE intake manifolds, as well as some aftermarket intakes.

The Atomic EFI is a self-tuning fuel system that continuously adjusts after the basic configuration is

complete. There is no laptop programming. Based on the engine descriptors you input, the Atomic

will automatically create a base fuel map to get the engine running. Once running, the self learning

system will optimize those maps resulting in the best performance possible. If you change altitude,

outside temperature, or other factors the Atomic will adjust accordingly, on the fly. This ensures that

your engine will produce excellent driveability at all times, even if you drive from the sunny coast to

the cold mountains.

The Atomic LS fuel injection system is capable of running the fuel and ignition system of most LS engines.

The system incorporates OE style connectors to use with the factory sensors on the engine. The only

external sensor required to add is the supplied Wide-Band Oxygen sensor.

There are four main components of the Atomic LS system; the driver’s side and passenger side integrated

fuel rails, the Power Module and the Handheld Monitor. The ECU of the system is divided onto the fuel

rail assemblies and communicate to each other, as well as the Power Module, through MSD’s proprietary

CAN-Bus technology.

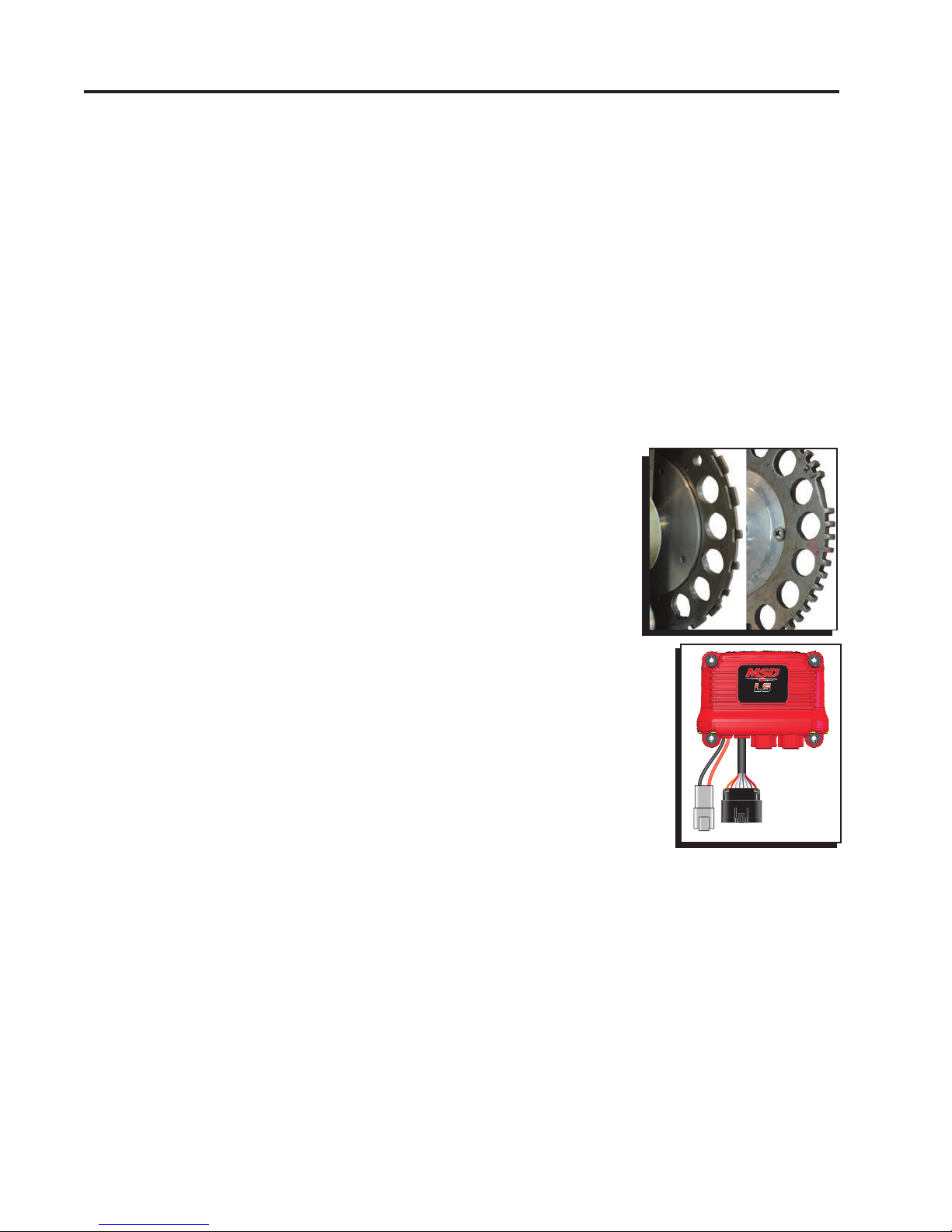

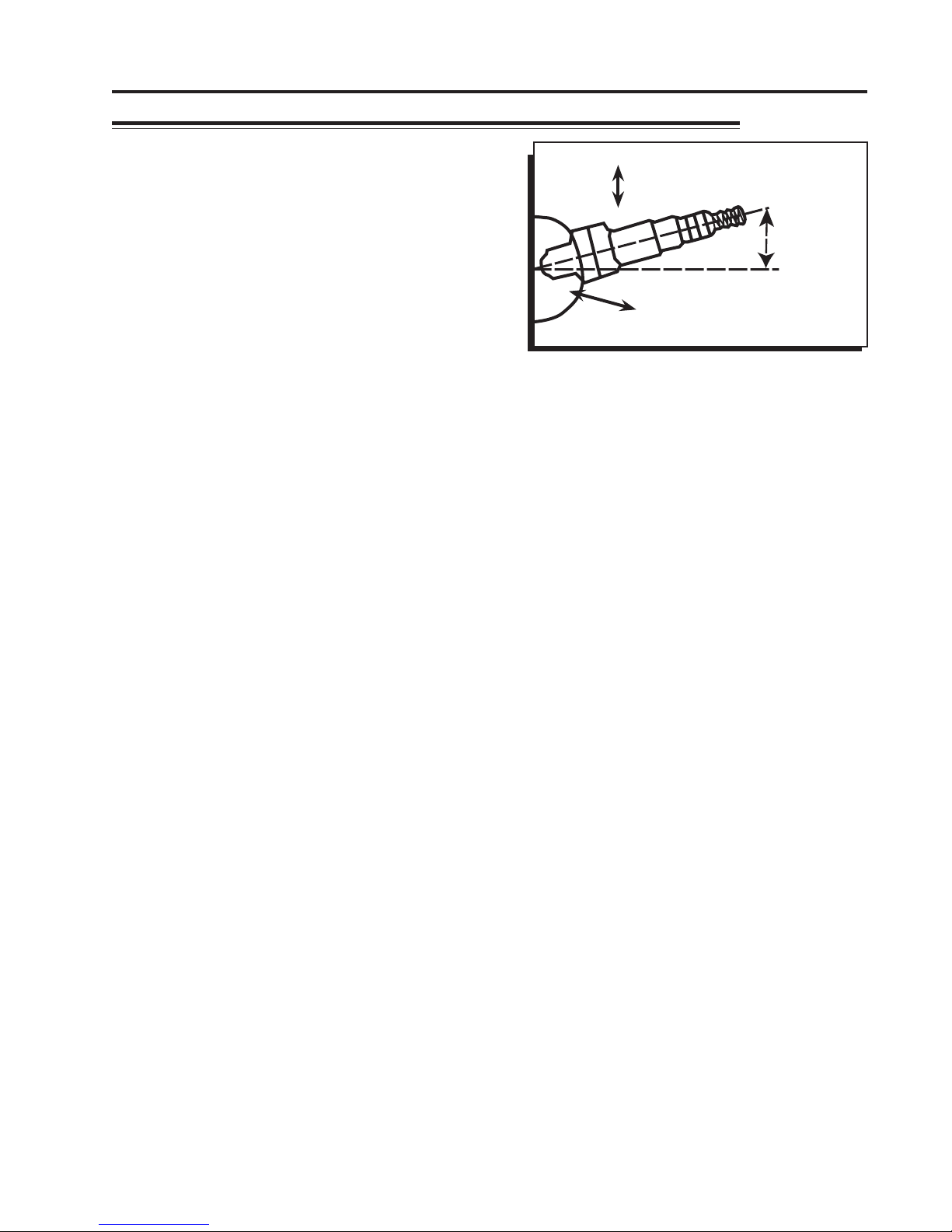

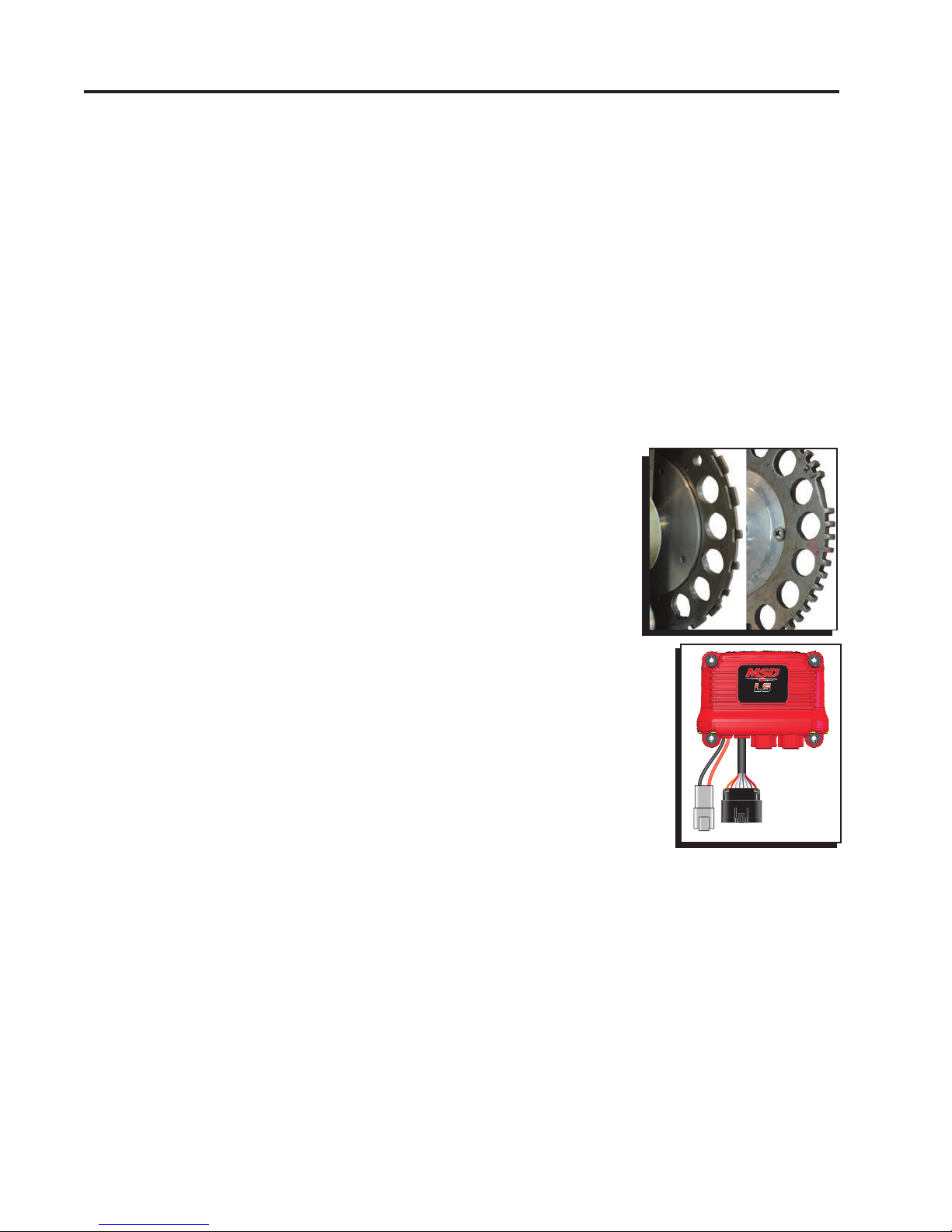

Crankshaft Trigger Wheel ID: It is important to know what crankshaft

trigger wheel your engine is fit with. There are two; early engines used a

24-tooth wheel and later model engines use a 58-tooth wheel. These can

be identified by removing the crank sensor (located behind the starter)

and looking inside the engine (see photo at the right).

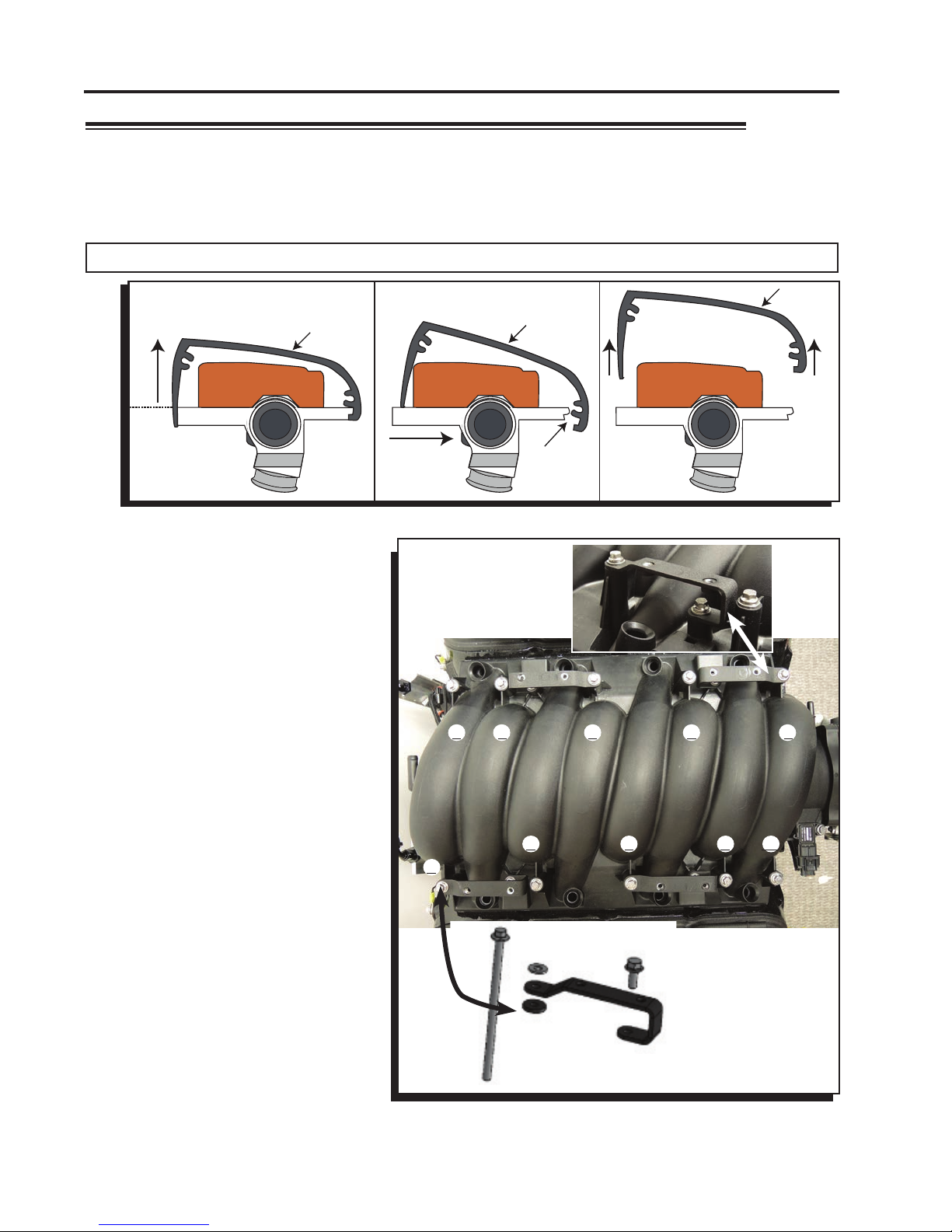

Fuel/ECU Rails: The unique fuel rails of the Atomic LS EFI system also

incorporate the ECU of the system. The two banks receive power from the

Power Module and communicate to the system through MSD’s CAN-Bus

network. To install the rails to the intake manifold, the covers will need to be

removed (which is outlined in the instructions).

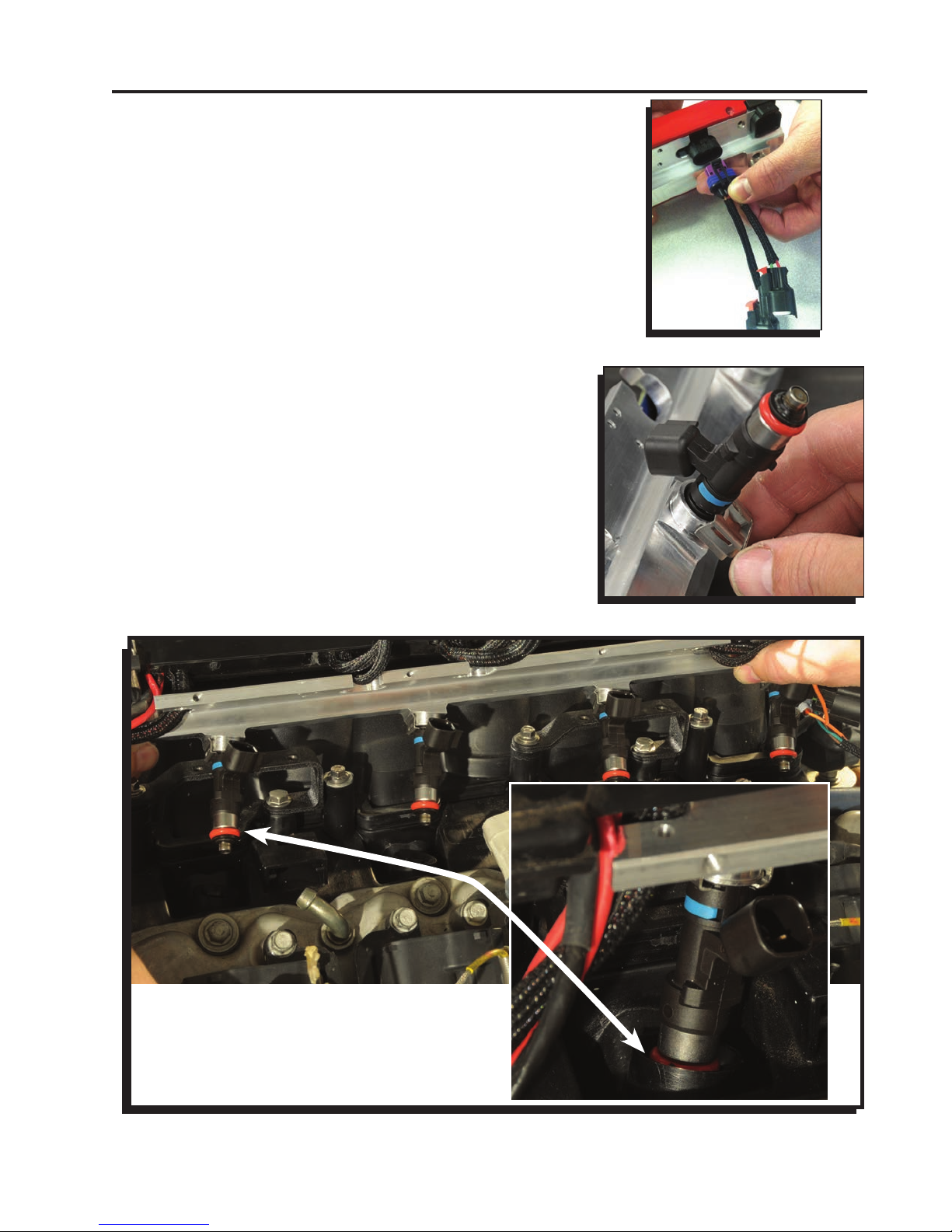

Each bank has OEM connectors that plug into the injectors, coils and specific

sensors of the engine. Each bank has a ground wire that must be connected to the

block. The fuel line inlets of the rail accept -6 AN and -8 AN fittings and internally

are equivalent to a -8 line (-6 AN fittings are supplied.)

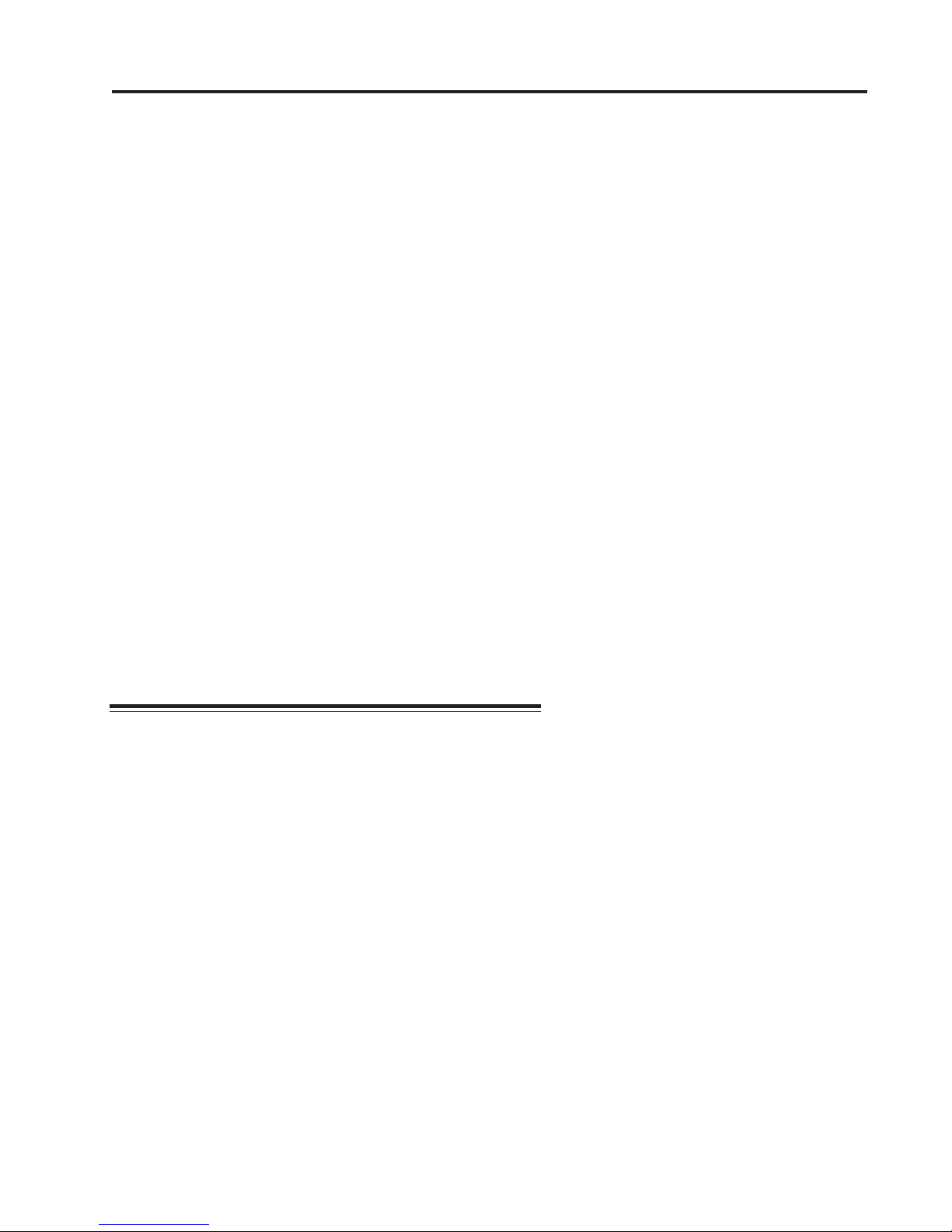

Power Module: The Power Module of the Atomic LS is the communication hub of

the system and provides the high current fuel pump circuit and other input/outputs

for optional features. The unit has two ports for the MSD CAN system as well as

a wiring harness. There are connections for the WB02, the Handheld Monitor as

well as power and communication to the integrated fuel rails.

Programming: The Atomic EFI is a self-tuning fuel system that continuously adjusts after the basic

configuration is complete. There is no laptop programming. Based on the engine descriptors you input, the

Atomic will automatically create a base fuel map to get the engine running. Once running, the self- learning

system will continuously adjust those maps to obtain the desired air/fuel ratio. This feature ensures that

your engine will have the right fuel mixture at all times, no matter where you are driving.

Intake Manifolds: The Atomic LS EFI system is designed to fit most OE intake manifolds, as well as some

aftermarket intakes. There are different mounting brackets available for several of the key intake manifolds.

MSD offers two Installation Kits that are supplied with different injector connects and fuel rail brackets for

manifolds such as the LS1 or truck. They are described in the ‘Not Included’ list of parts above.

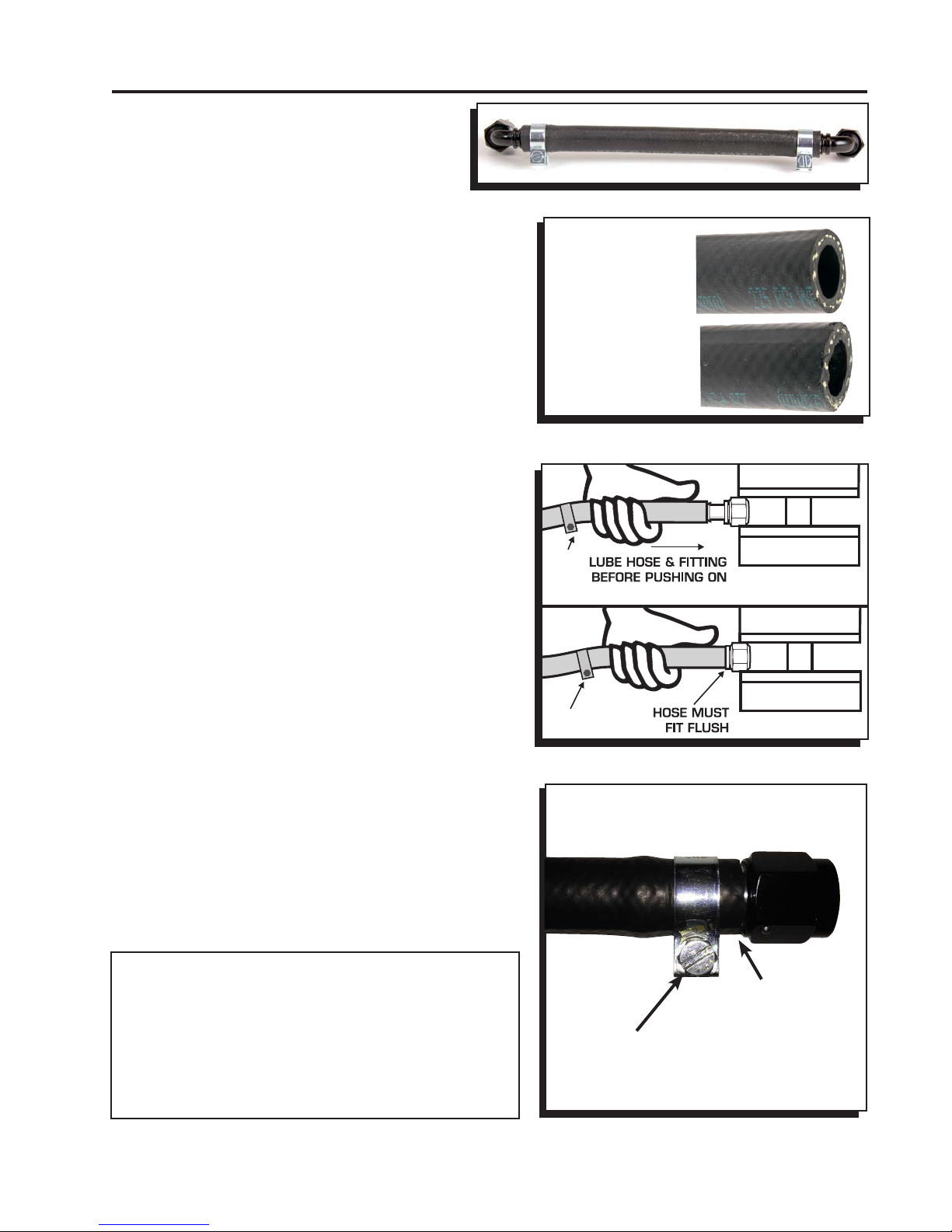

Fuel System: The Atomic LS system can be used with return or returnless EFI system. Review the Fuel

System Information section starting on page 3 for detailed information.

®

LS

CONTROLLER

24x 58x

POWER MODULE