SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR EDGER. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL HEED

ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER: Your edger was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. If you violate any of these rules, you may cause serious injury to yourself or

others.

1. TRAINING AND PREPARATION

•Read the operator’s manual carefully. Be

thoroughly familiar with the controls and proper

use of the equipment. Know how to disengage the

blade control and stop the unit quickly.

•Never allow children to operate equipment. Never

allow adults to operate equipment without proper

instruction.

•Keep the area of operation clear (at least 50 feet)

of all persons, especially small children and pets.

•Use the edger only as manufacture intended and

as described in the operator’s manual.

•Do not operate edger after it has been dropped or

damaged.

•Return product to nearest authorized service

facility for examination and repair. Do not operate

product with damaged or excessively worn cutting

blade.

•Dress properly-always wear safety glasses or

goggles. Always wear safety footwear, and pants

or slacks that cover your legs to reduce the risk of

injury that may be caused by flying debris. Do not

wear loose clothing or jewelry that can be caught

in moving parts. Use of gloves and substantial

footwear is recommended when working outdoors.

Do not operate edger when barefoot or wearing

sandals or open-toed shoes. Wear boots,

preferably with steel-toe caps.

•Objects struck by the blade can cause severe

injuries to persons. The work area should always

be carefully examined and cleared of all stones,

sticks, wires, bones and other foreign

•objects, prior to edging.

•Never attempt to make any adjustments, other

than depth of cut, while engine is running.

•The use of accessory attachments not

recommended by the manufacturer may cause

hazard and will void warranty.

•Never operate the edger without proper guards,

plates or other safety protective devices in place.

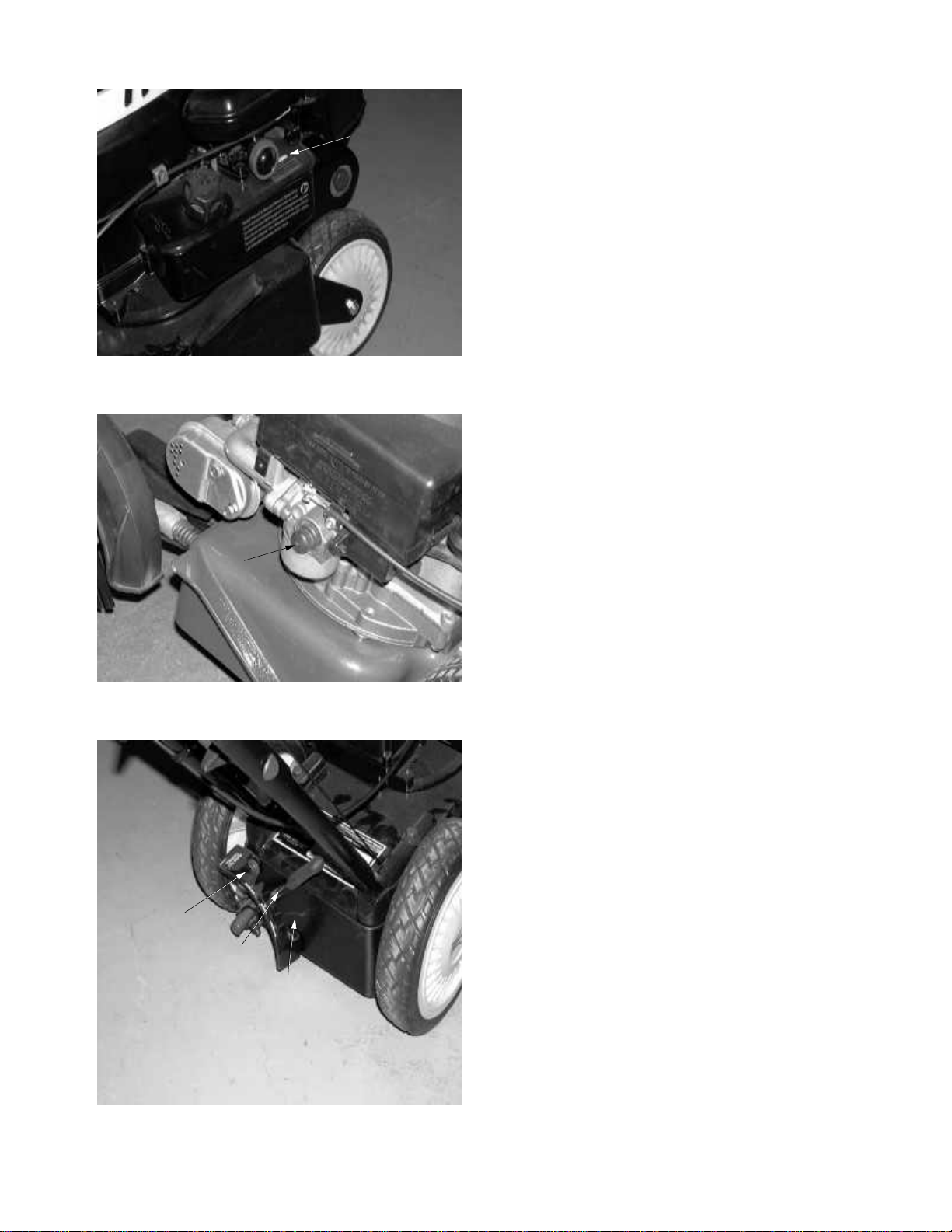

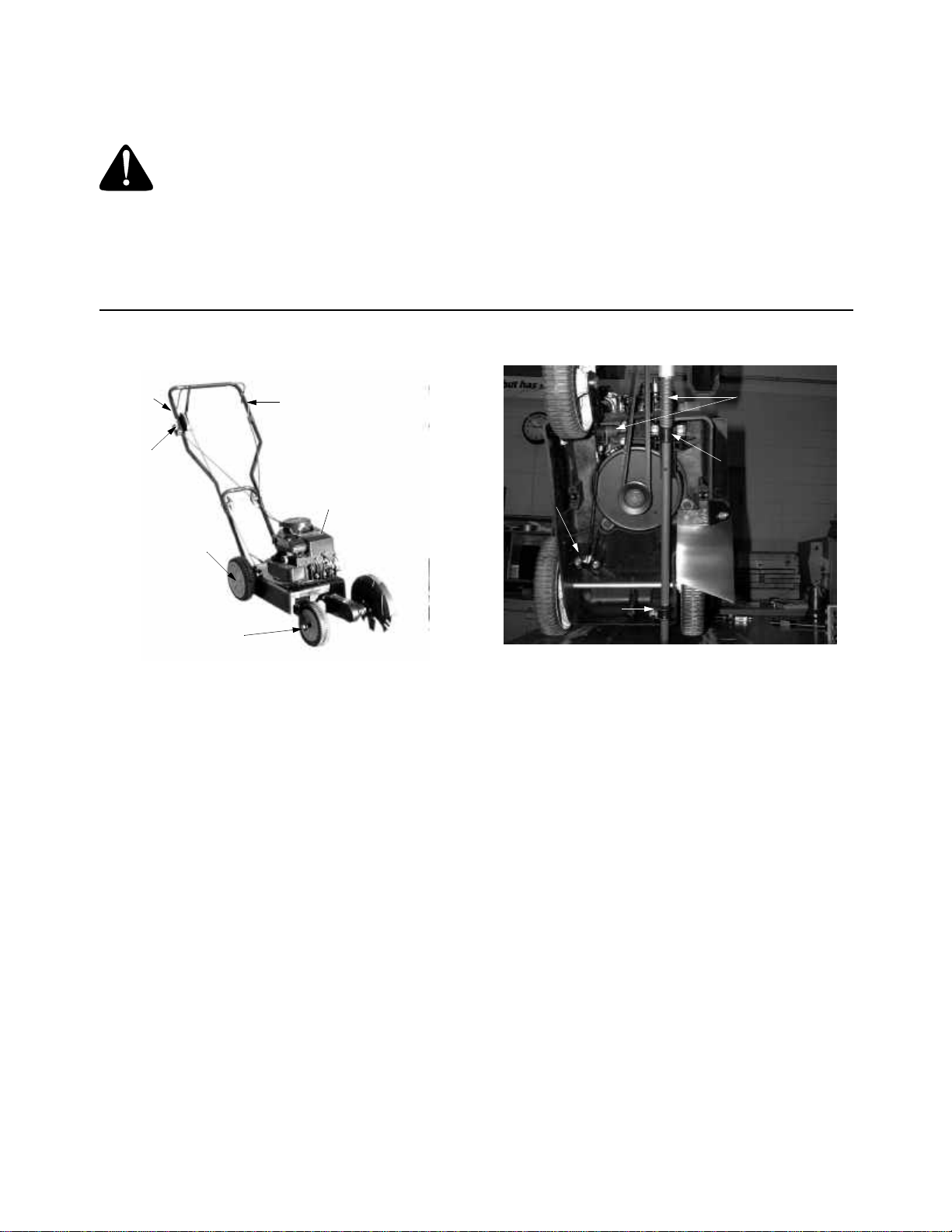

•Turn engine off and disconnect spark plug wire:

•When not in use.

•Before servicing, cleaning and the like.

•Before changing accessories.

•Handle fuel with care; it is highly flammable

•Extinguish all smoking materials and other

possible sources of ignition.

•Use a fuel container acceptable for the purpose.

•Never add fuel to a running or hot engine.

•Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

•Replace gasoline cap securely.

•If fuel is spilled, move product and fuel container

from area and do not create a source of ignition.

Wipe up spilled fuel.

2. OPERATION

•Make sure all nuts, bolts, and screws are kept

tightly in place, especially the blade and all guards.

•Start the engine carefully. Make certain the blade

is disengaged before attempting to start. Keep

hands, feet, clothing, and the like well away from

cutting blade and moving parts.

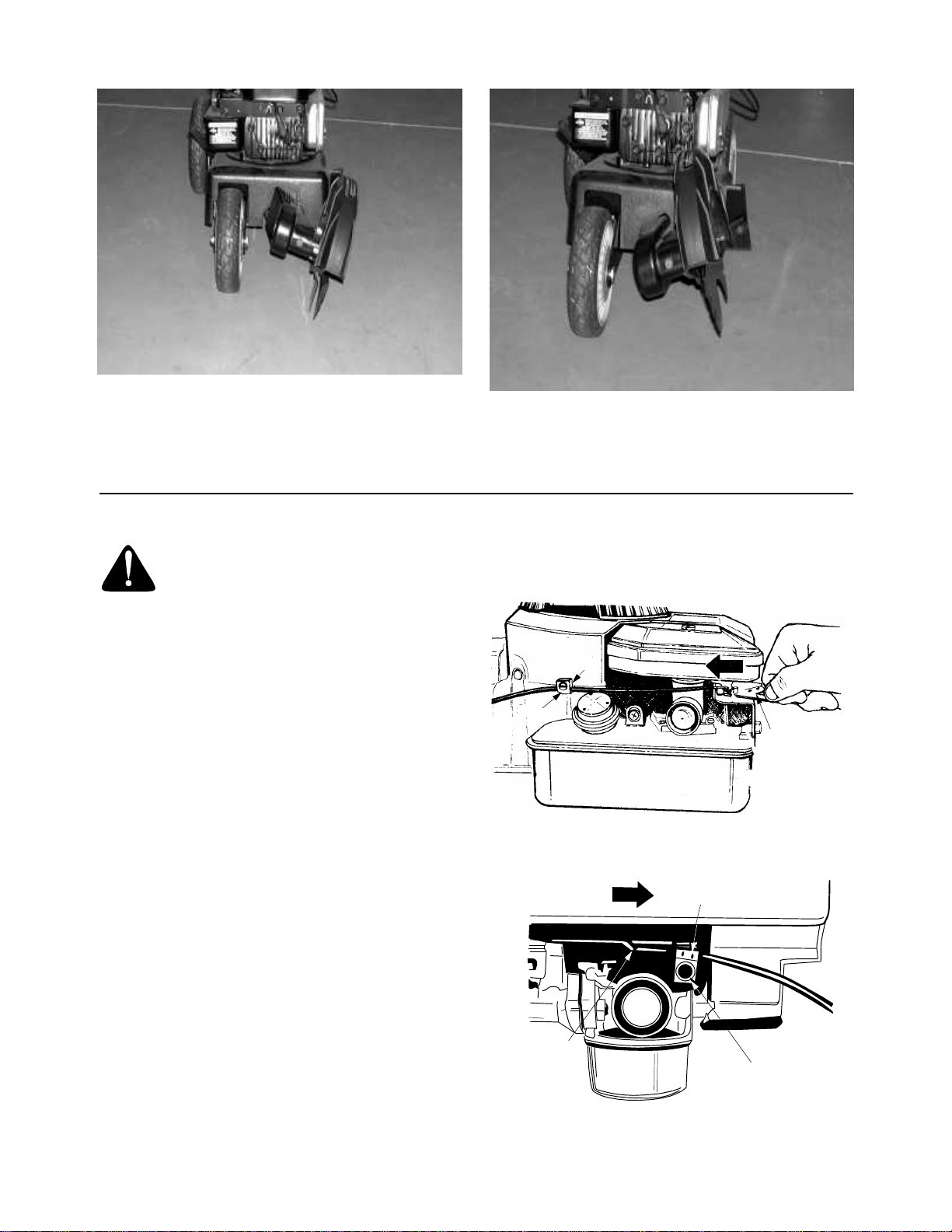

DANGER: ROTATING CUTTING BLADE

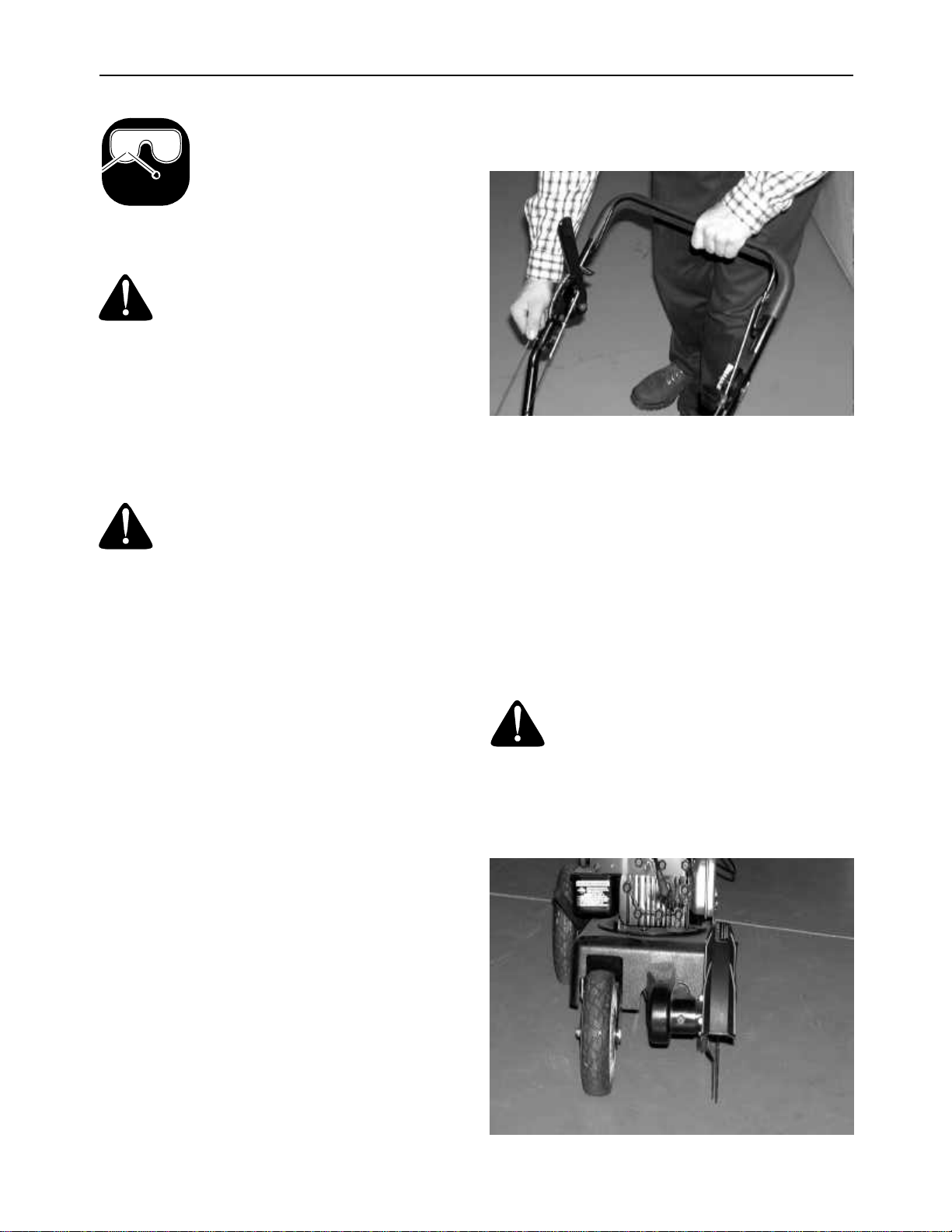

•Keep both hands on handles when blade is

rotating.

•Keep feet away from cutting area.