Contents

1. Safety and operation instructions....................................................................................................................................

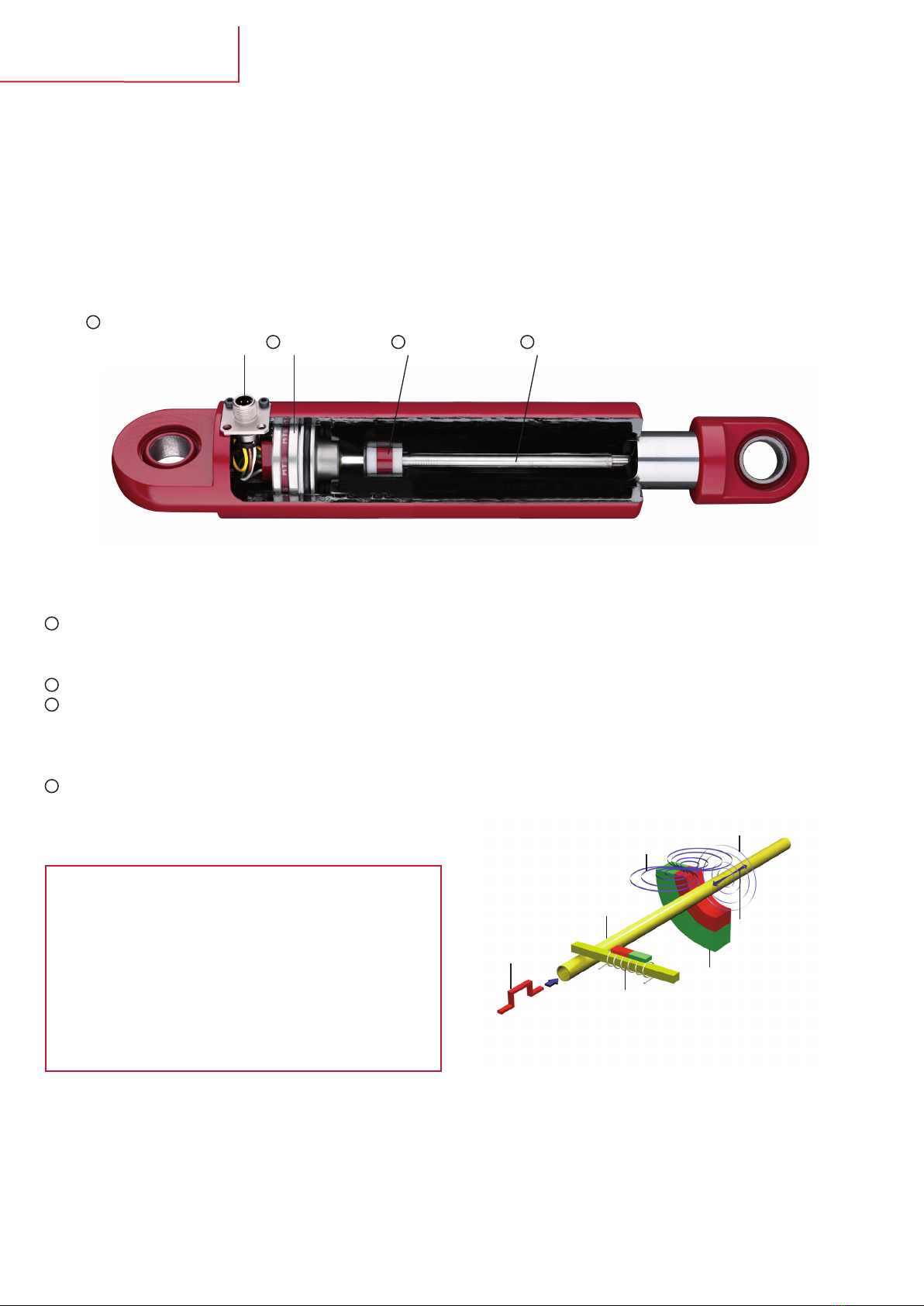

2. Product description and technology.................................................................................................................................

3. Space requirements - conditions, design

3.1 Dimensions, tolerances...................................................................................................................................................

3.2 Chamfered edge for insertion..........................................................................................................................................

3.3 Pistion rod bore and depth..............................................................................................................................................

3.4 CAD-data, download........................................................................................................................................................

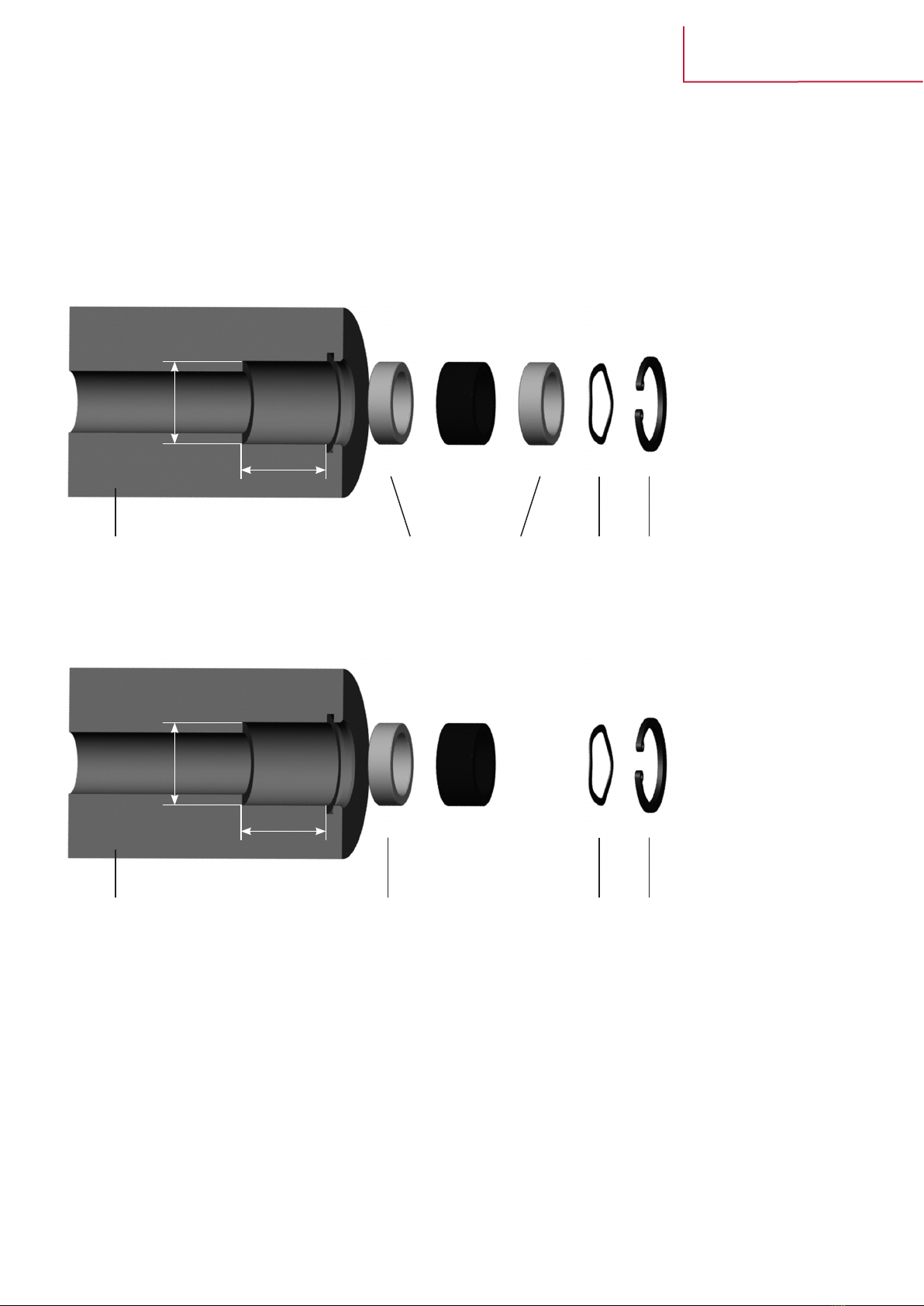

3.5 Installing the magnet.......................................................................................................................................................

3.5.1 Magnet with 2 distant washers...................................................................................................................

3.5.2 Magnet with 1 distant washer.....................................................................................................................

3.5.3 Installing the magnet..................................................................................................................................

3.6 Safety screw to DIN 913..................................................................................................................................................

3.7 Supporting long sensor pipes, sagging...........................................................................................................................

4. Mounting

4.1 Positionining of O- and backup rings..................................................................................................................................

4.2 Load-bearings geometries of sensor housing.................................................................................................................

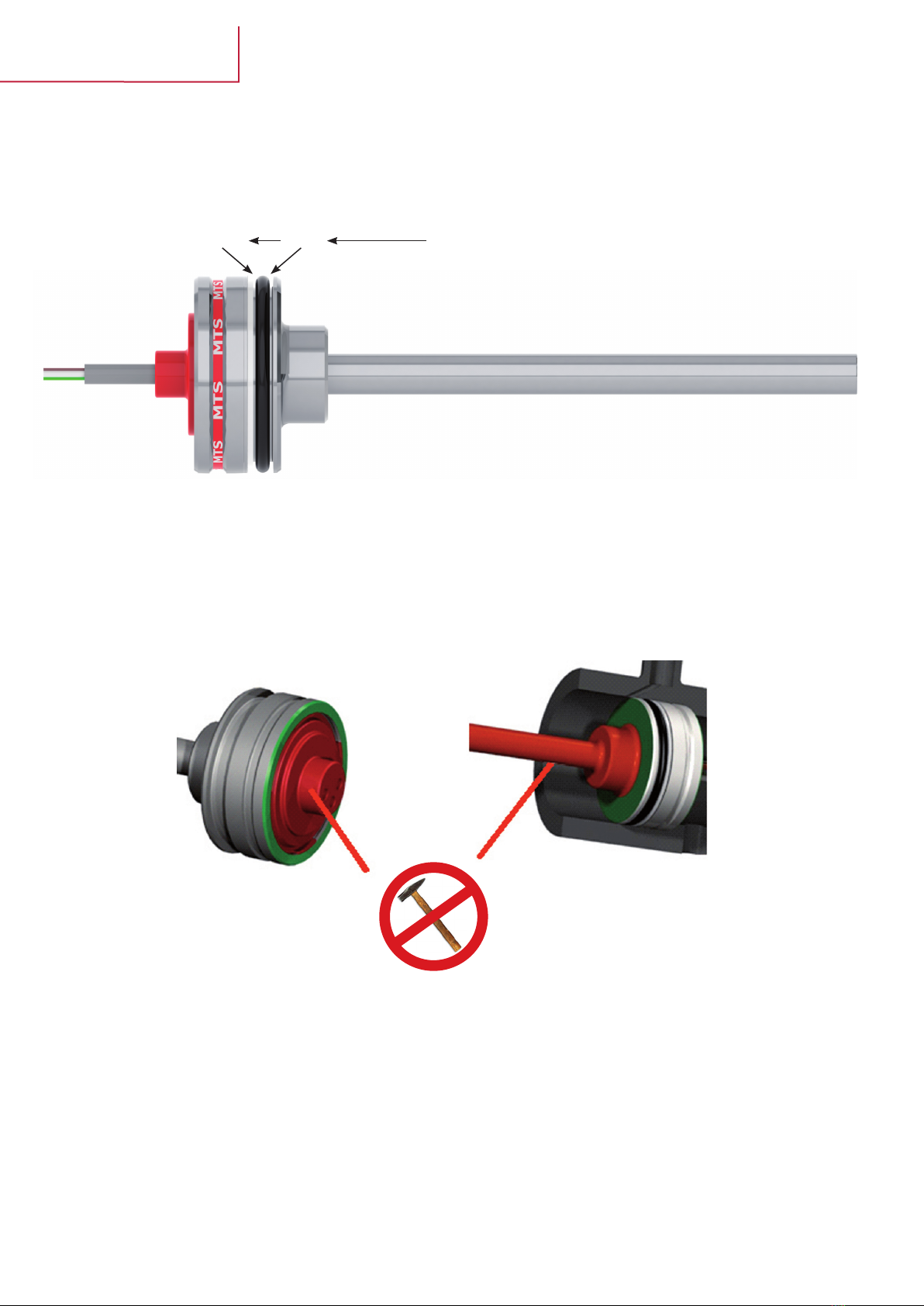

4.3 Mounting in the cylinder..................................................................................................................................................

4.4 Handling connection cables during mounting..................................................................................................................

4.5 Mounting sensors using a Temposonics®M12 connector system..................................................................................

4.6 Mounting in the cylinder..................................................................................................................................................

4.7 Mounting sensors with cable or single conductor connection.........................................................................................

4.7.1 Mounting sensors with cable connection and cable gland...........................................................................

4.7.2 Mounting sensors with single conductor and third-party connector...........................................................

5. Cylinder handling after sensor installation

5.1 Washing and drying cylinders with installed sensors......................................................................................................

5.1.1 Sensors with Temposonics®M12 connector system..................................................................................

5.1.2 Sensors with connecting cable...................................................................................................................

5.1.3 Sensors with third-party connectors..........................................................................................................

5.2 Painting of cylinders............................................................................................................................................................

5.2.1 Electrostatic painting..................................................................................................................................

5.2.2 Cylinders with integrated sensors and Temposonics®M12 connector system...........................................

5.2.3 Cylinders with integrated sensors and connecting cables or third-party connectors..................................

6. Transport, intermediate storage

6.1 Mounting/dismounting cylinders on mobile hydraulics machines...................................................................................

6.2 Electrical and electrostatic effects...................................................................................................................................

6.3 Electrostatic effects.........................................................................................................................................................

7. Drawings

7.1 Dimensions of Temposonics®MH sensor

- with M12 connector system..............................................................................................................................

- with single wires...............................................................................................................................................

- with cable..........................................................................................................................................................

- with cable (till 03.2011).....................................................................................................................................

7.2 Dimensions of Temposonics®MS sensor

- with M12 connector system..............................................................................................................................

- with single wires...............................................................................................................................................

- with cable..........................................................................................................................................................

7.3 Dimensions of Temposonics®MT sensor

- with M12 connector system..............................................................................................................................

- with single wires...............................................................................................................................................

- with cable..........................................................................................................................................................

7.4 Dimensions of sensor magnets (position transducer) ....................................................................................................

7.5 Mounting sensors using Temposonics®M12 connector system (flange)........................................................................

7.6 Dimensions of turned parts made of M12 round material................................................................................................

3

4

5

6

6

6

7

7

7

8

8

9

10

10

11

13

14

14

16

16

16

17

17

17

17

18

18

19

19

20

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34