2

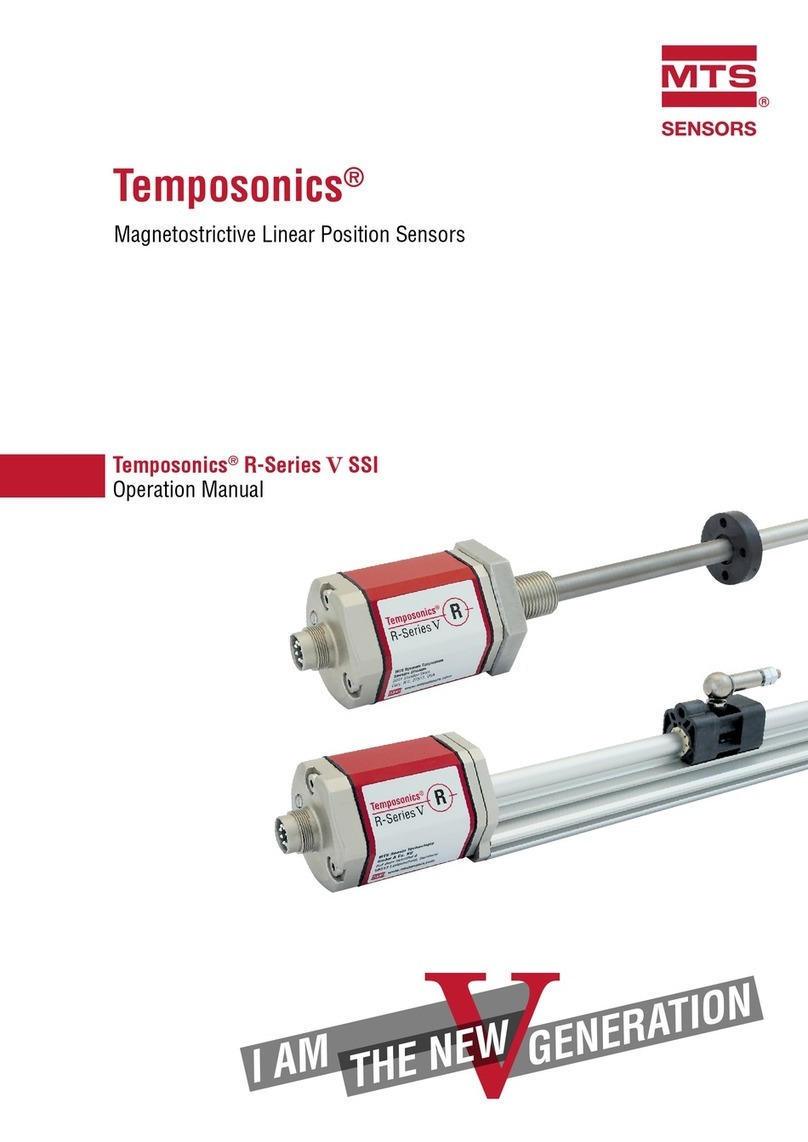

Temposonics® R-Series SSI

Operation Manual

Temposonics® R-Series SSI

Operation Manual

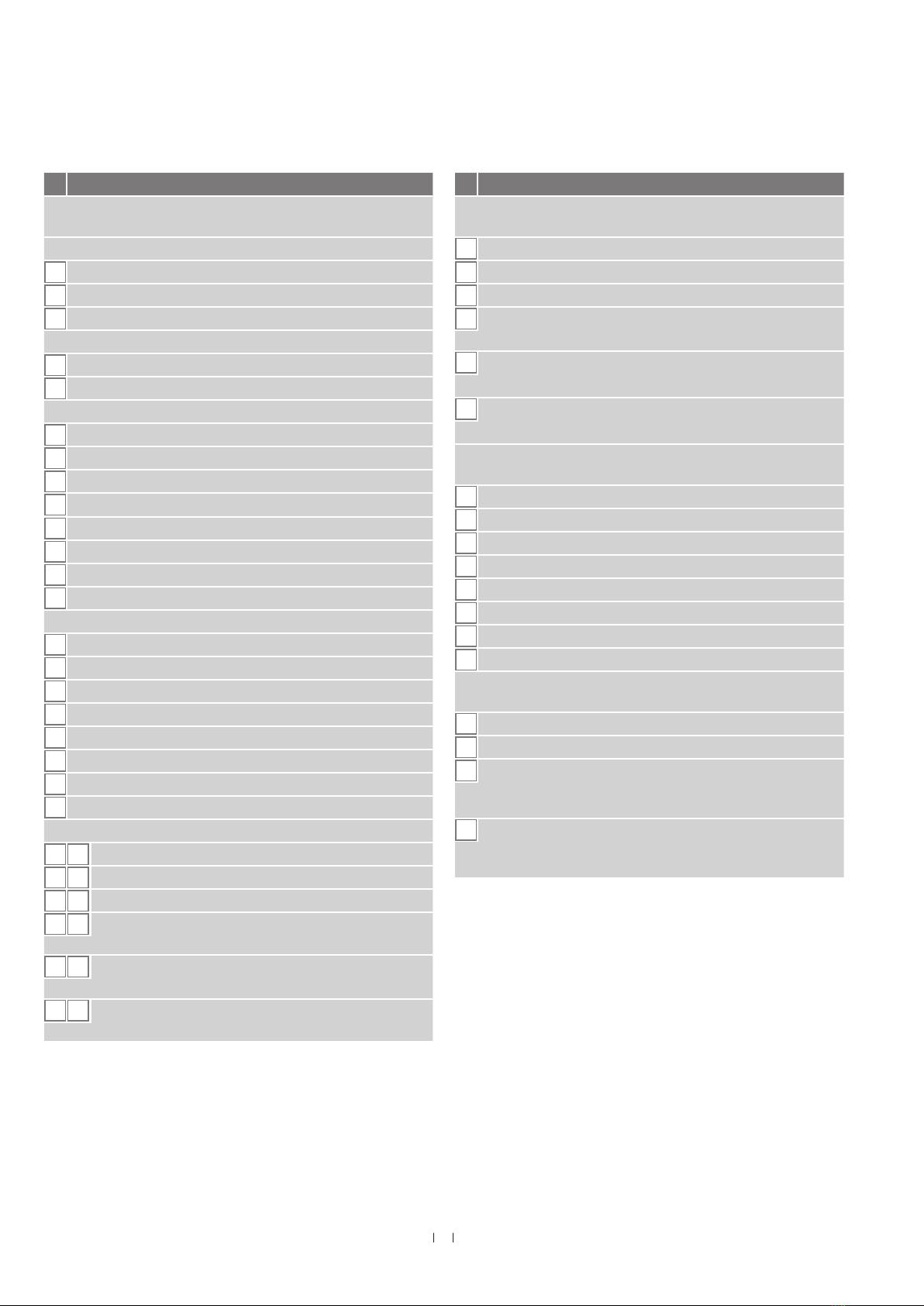

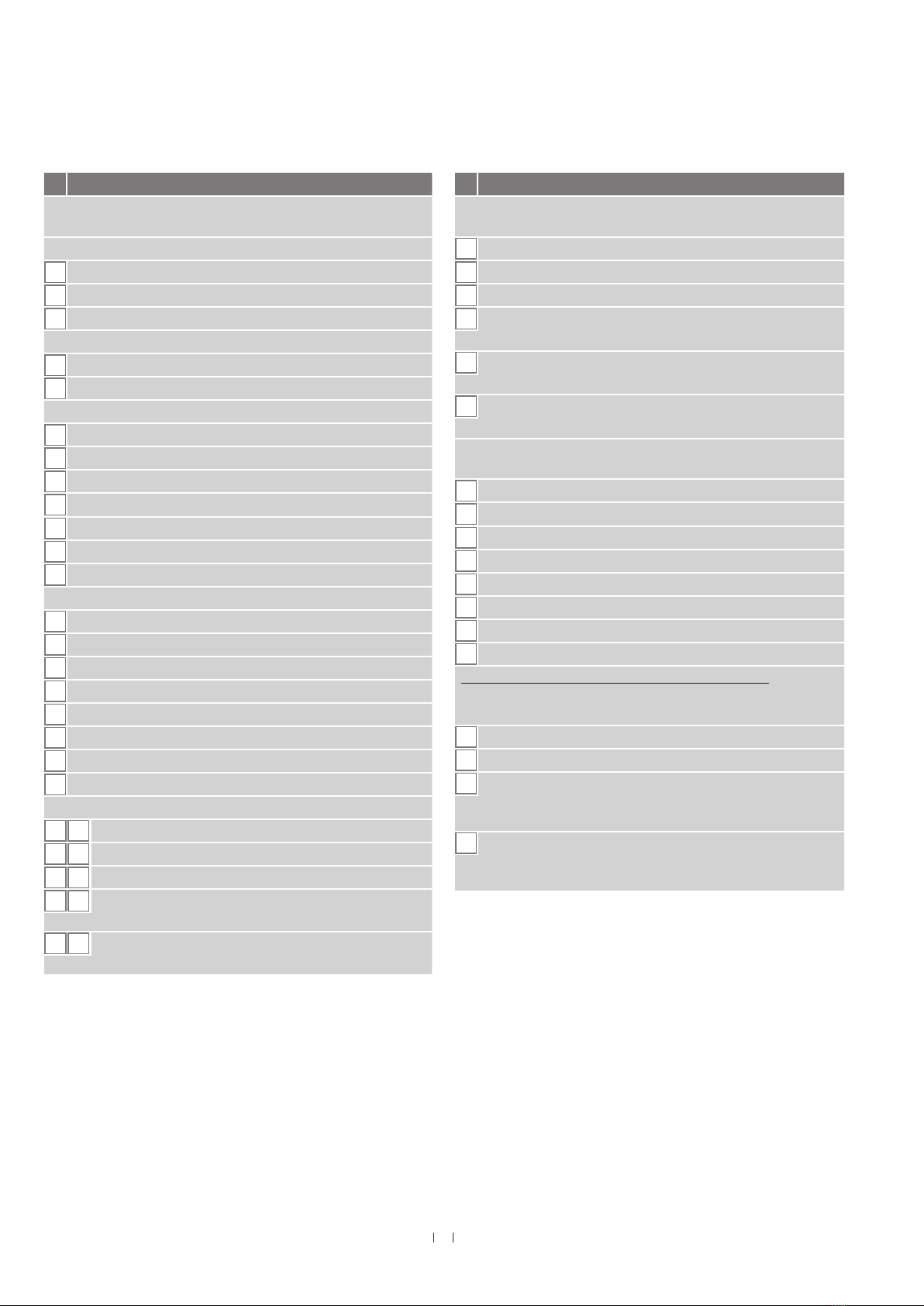

Table of contents

1. Introduction.......................................................................................................................................................3

1.1 Purpose and use of this manual....................................................................................................................................................................3

1.2 Used symbols and warnings .........................................................................................................................................................................3

2. Safety instructions...............................................................................................................................................3

2.1 Intended use..................................................................................................................................................................................................3

2.2 Forseeable misuse.........................................................................................................................................................................................3

2.3 Installation, commissioning and operation....................................................................................................................................................4

2.4 Safety instructions for use in explosion-hazardous areas .............................................................................................................................4

2.5 Warranty........................................................................................................................................................................................................4

2.6 Return ...........................................................................................................................................................................................................4

3. Identification......................................................................................................................................................5

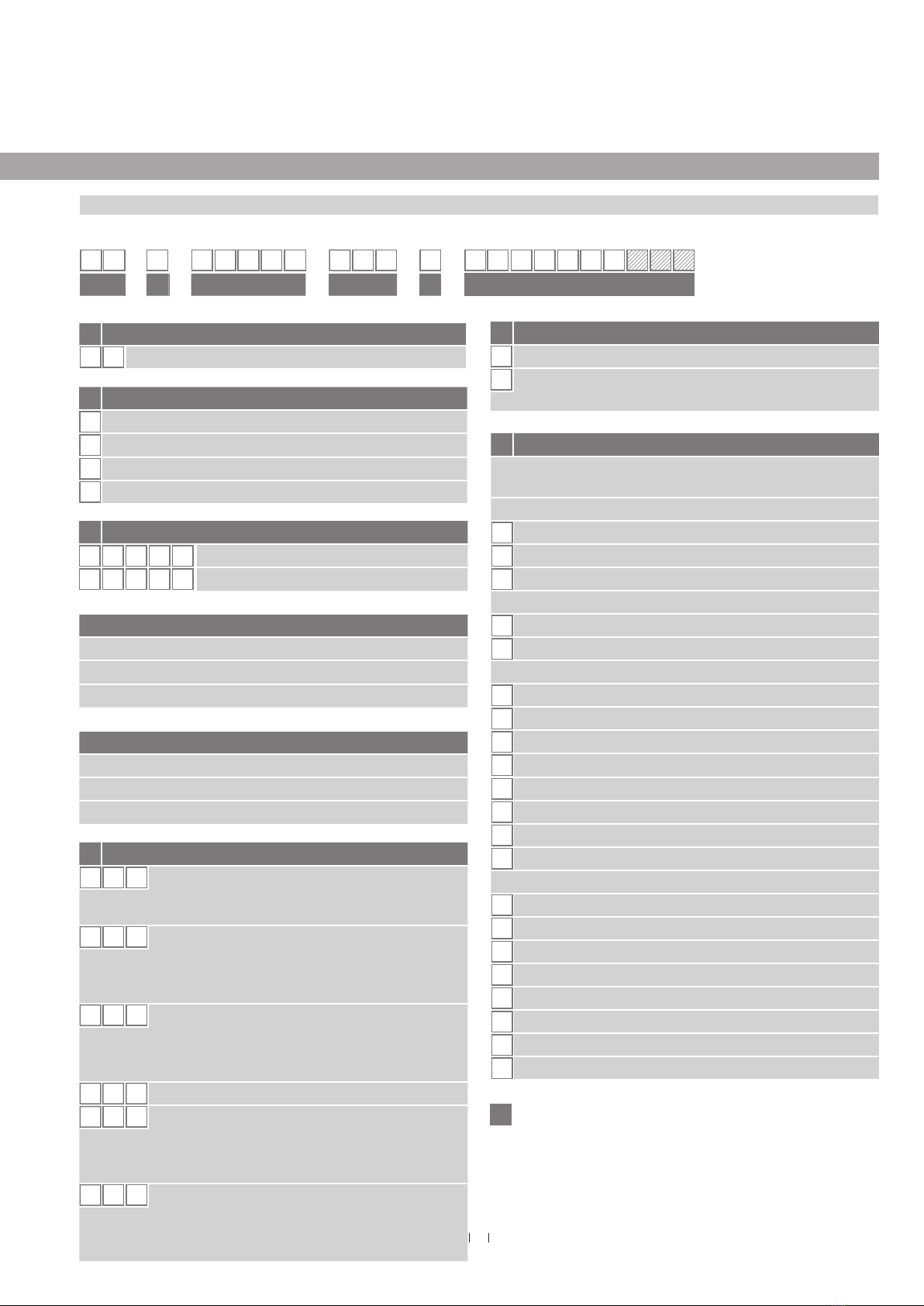

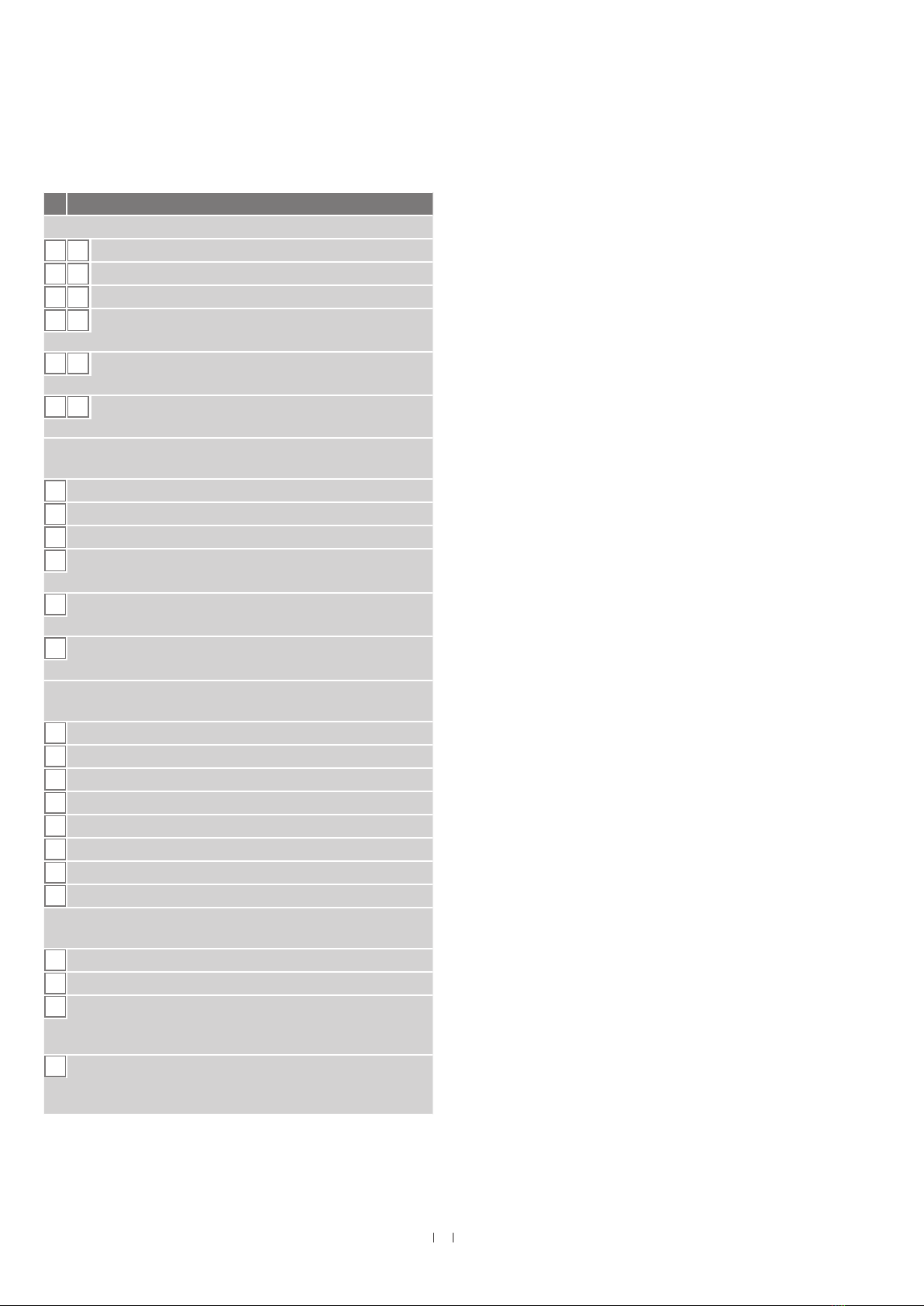

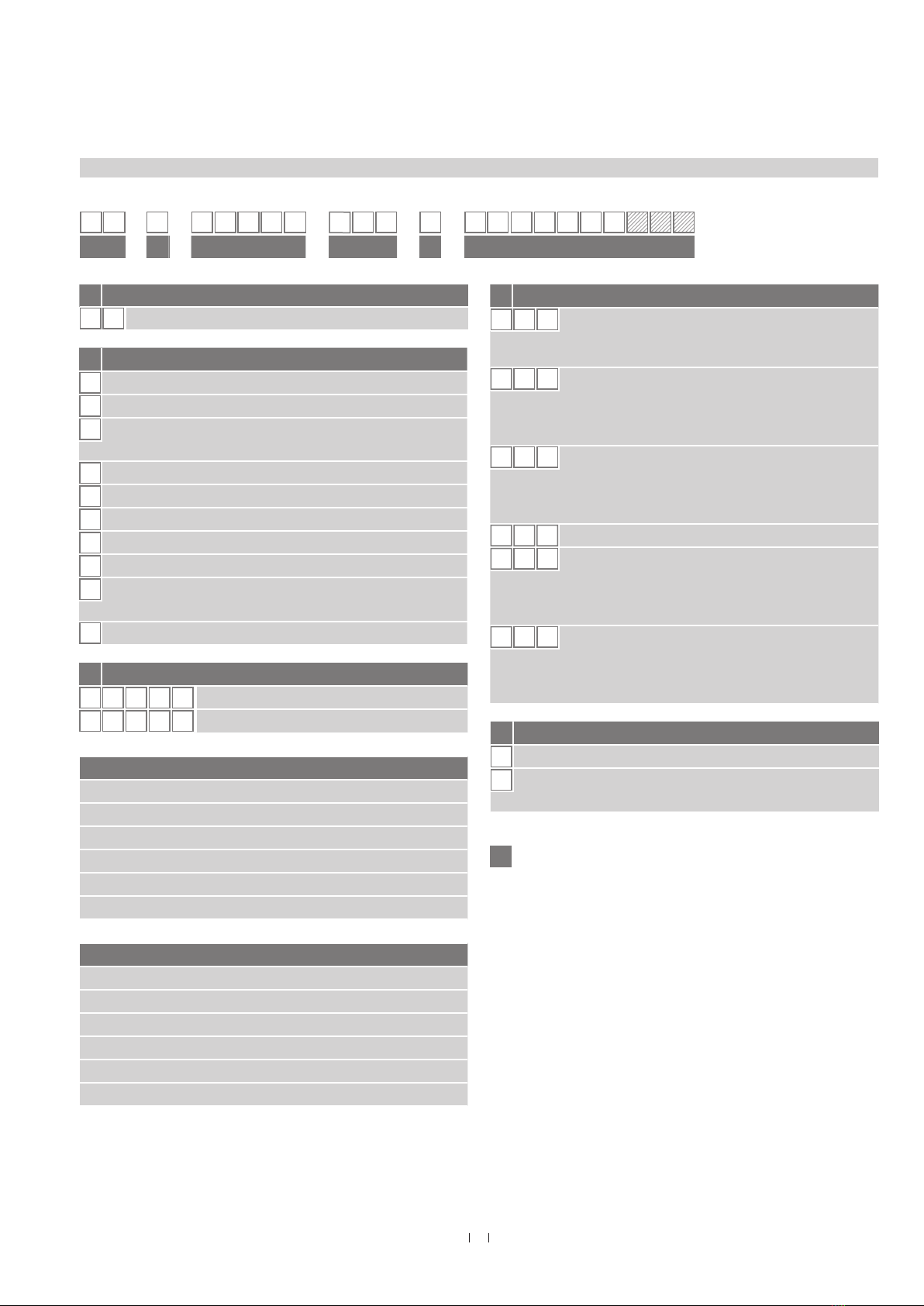

3.1 Order code of Temposonics®RP...................................................................................................................................................................5

3.2 Order code of Temposonics®RH................................................................................................................................................................... 7

3.3 Order code of Temposonics®RD4................................................................................................................................................................. 9

3.4 Order code of Temposonics®RT4 ............................................................................................................................................................... 11

3.5 Order code of Temposonics® RF .................................................................................................................................................................13

3.6 Nameplate ...................................................................................................................................................................................................15

3.7 Approvals ....................................................................................................................................................................................................15

3.8 Scope of delivery......................................................................................................................................................................................... 15

4. Product description and commissioning ................................................................................................................... 16

4.1 Functionality and system design .................................................................................................................................................................16

4.2 Styles and installation of Temposonics® RP ................................................................................................................................................17

4.3 Styles and installation of Temposonics® RH ................................................................................................................................................18

4.4 Styles and installation of Temposonics® RD4 ..............................................................................................................................................21

4.4.1 Installation of RD4 with threaded flange ..........................................................................................................................................24

4.4.2 Installation of RD4 with pressure fit flange ........................................................................................................................................ 25

4.4.3 Installation of RD4’s sensor electronics housing ...............................................................................................................................26

4.5 Styles and installation of Temposonics® RT4...............................................................................................................................................27

4.5.1 Installation of RT4 with threaded flange.............................................................................................................................................29

4.5.2 Installation of RT4’s sensor electronics housing................................................................................................................................30

4.6 Styles and installation of Temposonics® RF.................................................................................................................................................31

4.7 Magnet installation......................................................................................................................................................................................33

4.8 Replacement of sensor................................................................................................................................................................................37

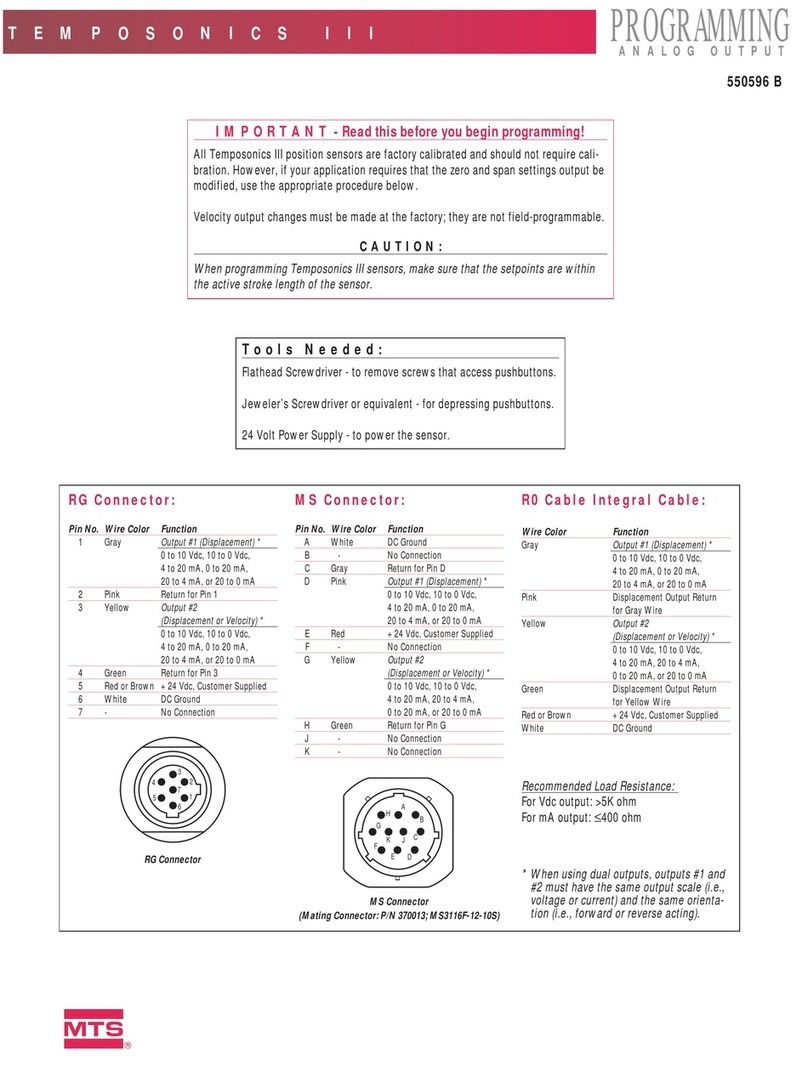

4.9 Electrical connections..................................................................................................................................................................................38

4.10 Frequently ordered accessories.................................................................................................................................................................39

5. Operation........................................................................................................................................................ 42

5.1 Getting started.............................................................................................................................................................................................42

5.2 Programming and configuration .................................................................................................................................................................42

6. Maintenance and troubleshooting .......................................................................................................................... 46

6.1 Error conditions, troubleshooting................................................................................................................................................................46

6.2 Maintenance................................................................................................................................................................................................46

6.3 Repair..........................................................................................................................................................................................................46

6.4 List of spare parts .......................................................................................................................................................................................46

6.5 Transport and storage .................................................................................................................................................................................46

7. Removal from service / dismantling........................................................................................................................ 46

8. Technical data.................................................................................................................................................. 47

8.1 Technical data of Temposonics®RP ............................................................................................................................................................47

8.2 Technical data of Temposonics® RH ............................................................................................................................................................49

8.3 Technical data of Temposonics® RD4 ..........................................................................................................................................................51

8.4 Technical data of Temposonics® RT4........................................................................................................................................................... 53

8.5 Technical data of Temposonics® RF............................................................................................................................................................. 55

9. Appendix ........................................................................................................................................................ 57