HYDRO-GUARD® Remote Pressure Monitoring System

Installation and Operating Instructions

4

operatIon and system monItorInG

the client administrator (end user)

identied on the order form. The

email will contain a web link that will

direct the client administrator to the

Device registration web page. The

Registration web page will allow

the client administrator to enter a

password; select how the system

shall send event notications (i.e.,

SMS-text messaging, email – both,

or none); and time zone settings.

NOTE: The Hydro-Guard

Monitoring System registration

email invitation will be sent from

NOREPLY@MIWT.NET. In the event

the customer does not receive

Getting Started

The Device will begin logging data

once the sensor cable is plugged

into the Remote Terminal Unit (RTU);

however pressure readings may take

up to 24 hours to be transmitted to

the website. The Device will reveal

system pressures with no additional

inputs. Up to four (4) customizable

values can be entered into the web

based control panel (Warning High,

Warning Low, Critical High, and

Critical Low).

Upon entering the client’s order,a

Mueller Customer Service Specialist

will send an administrative email to

an invitation email, please check

spam folders for the receipt.

Some servers will block the

message as spam until unblocked

by the client. Suggestion: To

ensure the email is received

please email Mueller Co. at

NOREPLY@MIWT.NET upon the

placement of your order.

Once registered, users may log into

the Mueller secure web page via the

address: miwt.net. Once logged into

the system, registered users can

customize their management prole

by selecting the “Edit Prole” tab on

the top navigation bar.

into the RTU and the pressure

sensor is exposed to line pressure.

The rst reading may take up to

24 hours to be transmitted to the

website. The Device will reveal

system pressures with no additional

inputs. In order to customize

pressure level notications, the

following four (4) values may be

set on the measurements screen:

Warning High, Warning Low, Critical

High, and Critical Low. Entering the

above mentioned inputs into the

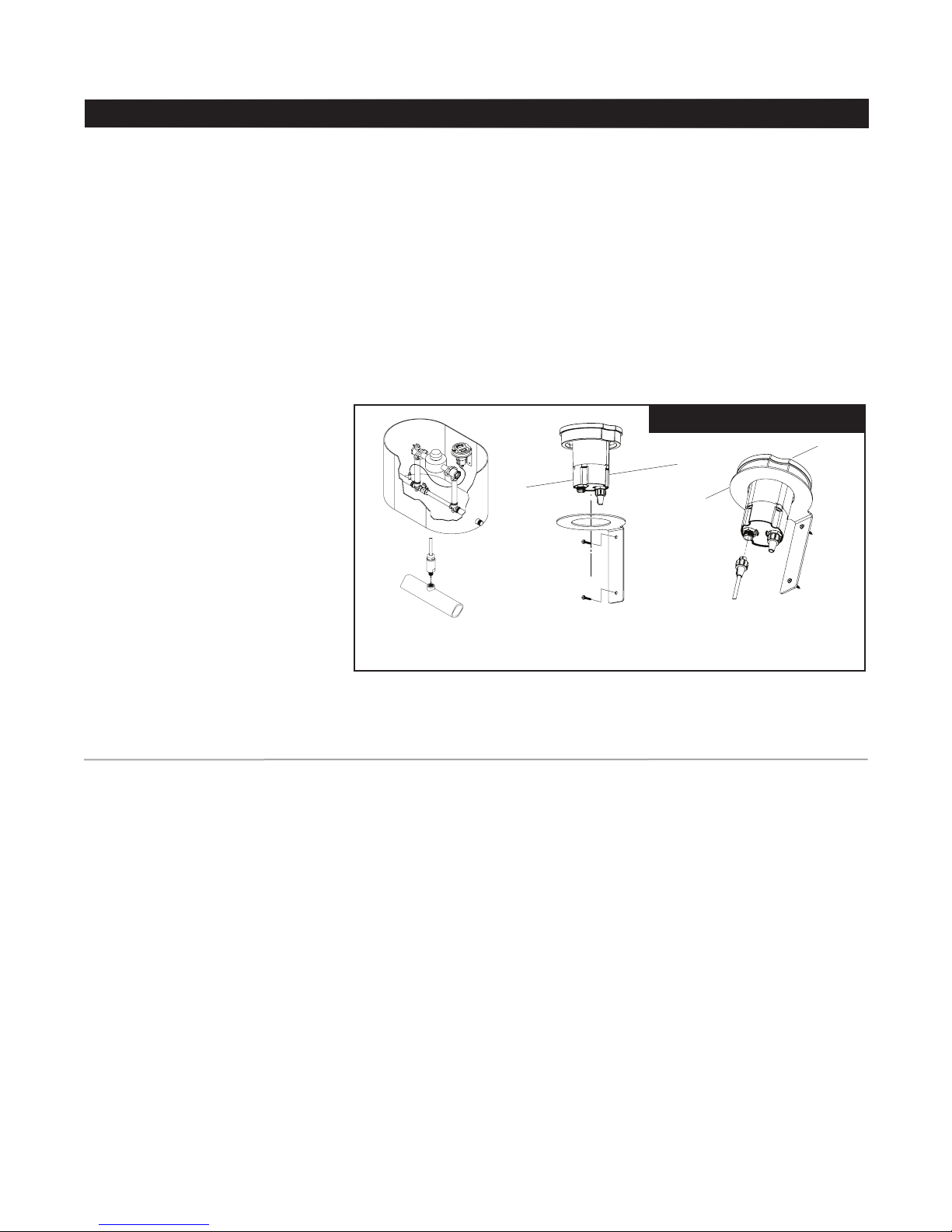

Installation in a Meter Box, Vault,

or other Structure

1. Remove the Device from its

packaging and inspect for possible

damage during shipping.

2. Apply sealant or joint tape to

pressure sensor and thread into

available ¼” NPT port.

NOTE: Avoid use of excessive

sealant. Avoid contact with sensor

transducer tip.

3. Install supplied mounting bracket

onto setter or to side wall of meter

vault no more than 6 inches

below grade to ensure the cellular

communication signal is capable of

transmitting and receiving data.

4. Be sure sensor tip is exposed to

line pressure prior to connecting

the sensor cable to the RTU.

Connect the sensor cable to the

RTU connection port located on

the bottom side of the RTU. The

pressure monitor will begin operating

once the sensor cable is plugged

system is described in the “Getting

Started” below.

NOTES: For best communication

performance RTU must be

installed vertically with the ange

facing up.

Composite lids must be utilized in

vaults or boxes to ensure cellular

communication, unless a suitably

sized hole is cut into a cast iron

lid that will allow the composite

lid to be mounted in the vault

cover.

A. Apply joint-sealant and

thread pressure sensor into 1/4”

NPT port. Turn on the water.

B. Install mounting

bracket to wall of meter

box/vault.

C. Plug sensor cable into

Black connector on RTU

and hand tighten connector.