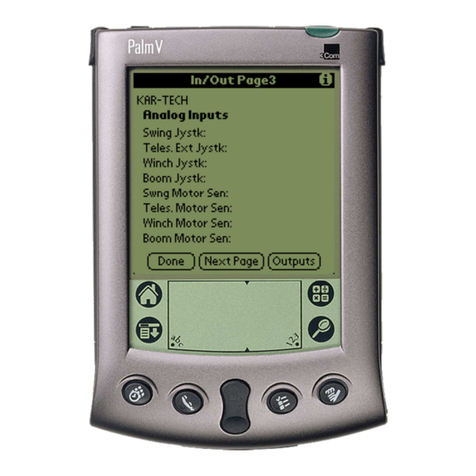

CAN RANGER III INSTALLATION

3

Note to installer: To ensure the safety of this system the

ENGINE STOP must functions properly. After installation

and calibration, use transmitter to start the engine then

move each valve lever on the crane individually away from

the center to ensure that engine stops for each forward

and reverse position. Next, press E-stop switch to ensure

that engine stops running.

Installation video is available at:

http://youtu.be/eLeEO1vsB6E

CONTROL MODULE

1. Loosen the speed knobs on the load sensor module to

accommodate the bracket and slide the control module on.

Tighten the knobs securely (FIG. 1 & 2)

ACTUATOR ASSEMBLY

1. Remove the access panels both above and below the arm

holding the load sensor and control module

2. Install or remove Drain plugs per instruction in Appendix A.

3. Mount the actuators to the bracket using the hardware

provided

4. Mount the actuator assembly to the turret just above the valve

bank using the two holes available and hardware provided

(FIG. 3a)

5. Fabricate the linkages used to connect the actuators to the

valve control arms from the provided hardware:

FIG. 1 FIG. 2