GENERAL

Read the entire contents of this manual

before beginning installation. Multiaqua

assumes no responsibility for equipment

installed contradictory to any code

requirement or installation instructions.

The components of this fan coil have

been inspected at the factory and readied

for shipment. Upon receiving the

shipment a visual inspection of the

packaging must be performed.

If any damage to the packaging is

discovered, an inspection of the

components must be performed and

noted on the delivery documents. If

component damage is found a damage

claim must be filed by the receiving party

against the delivery party immediately.

This product is designed and

manufactured to permit installation in

accordance with national codes. It is the

installer’s responsibility to install the

product in accordance with national

codes and/or prevailing local codes and

regulations.

Care must be taken to ensure the

structural integrity of the supporting

members, clearances and provisions for

servicing, power supply, coil connections

and/or condensate removal. Before the

installation ensure the structural strength

of the supporting members is sufficient.

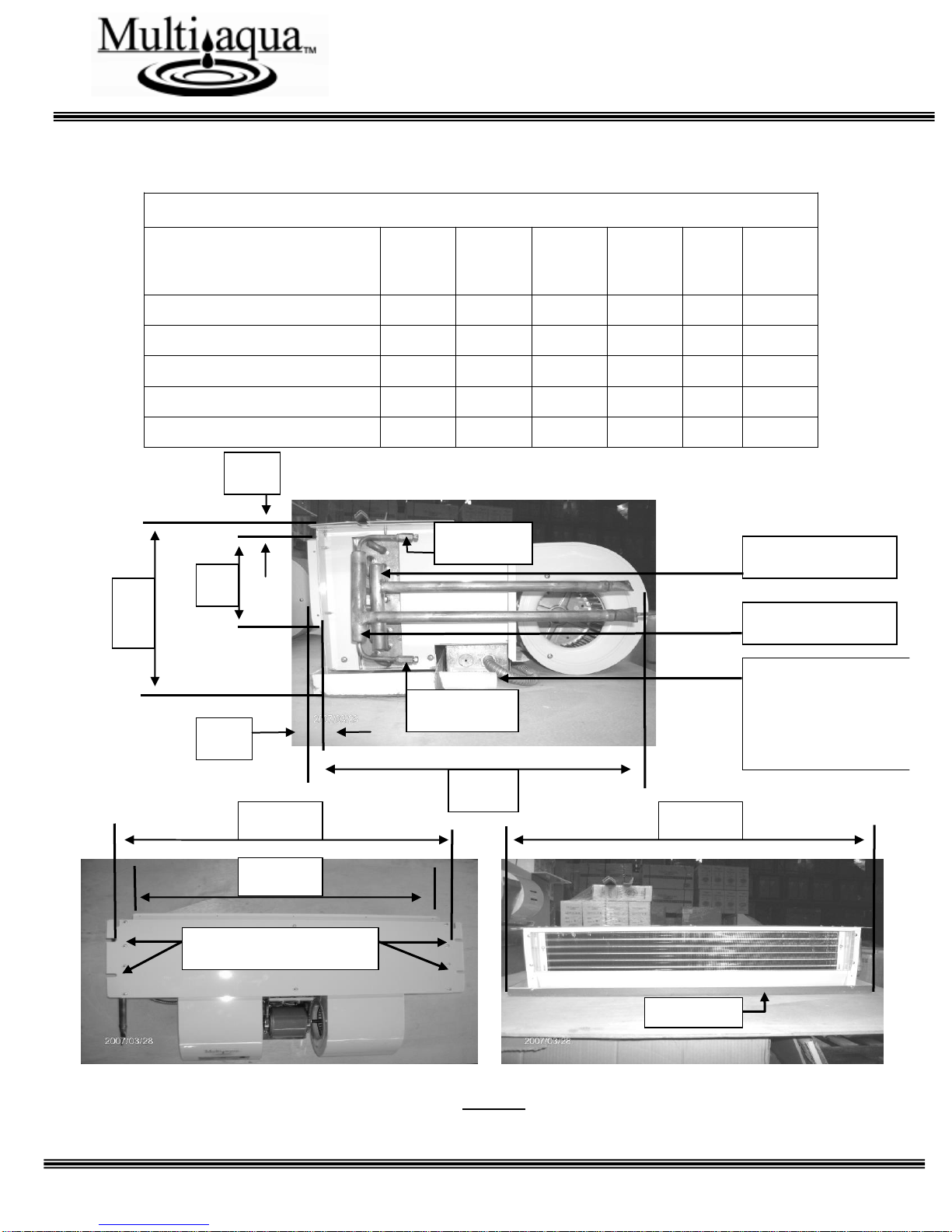

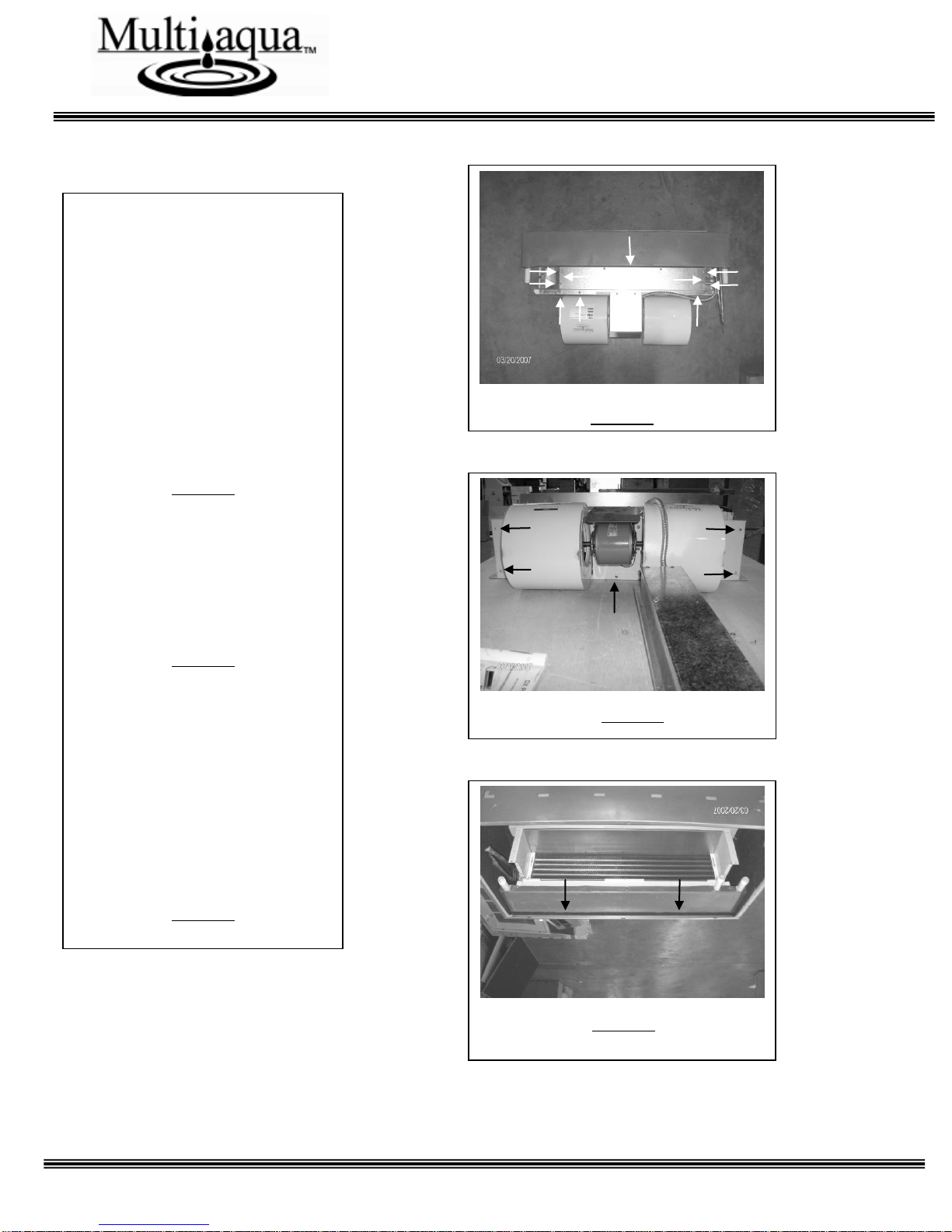

See Figure 1 for hanging weights of the

fan coils.

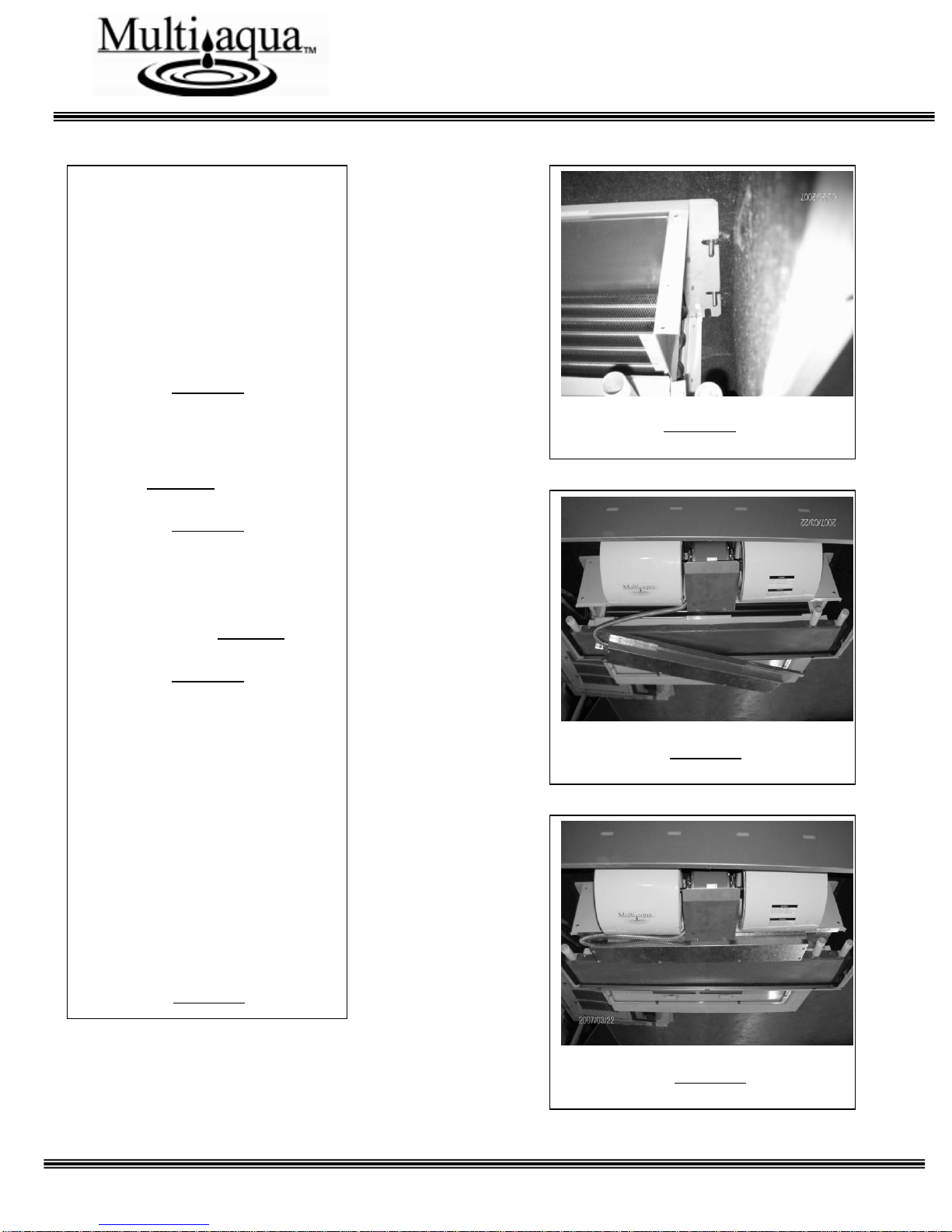

This unit is designed to be installed in an

horizontal configuration only, and into an

enclosure assembly. The enclosure assembly

can be ordered separately or field fabricated

by the installing contractor. See Figure 2

for enclosure part numbers, dimensions and

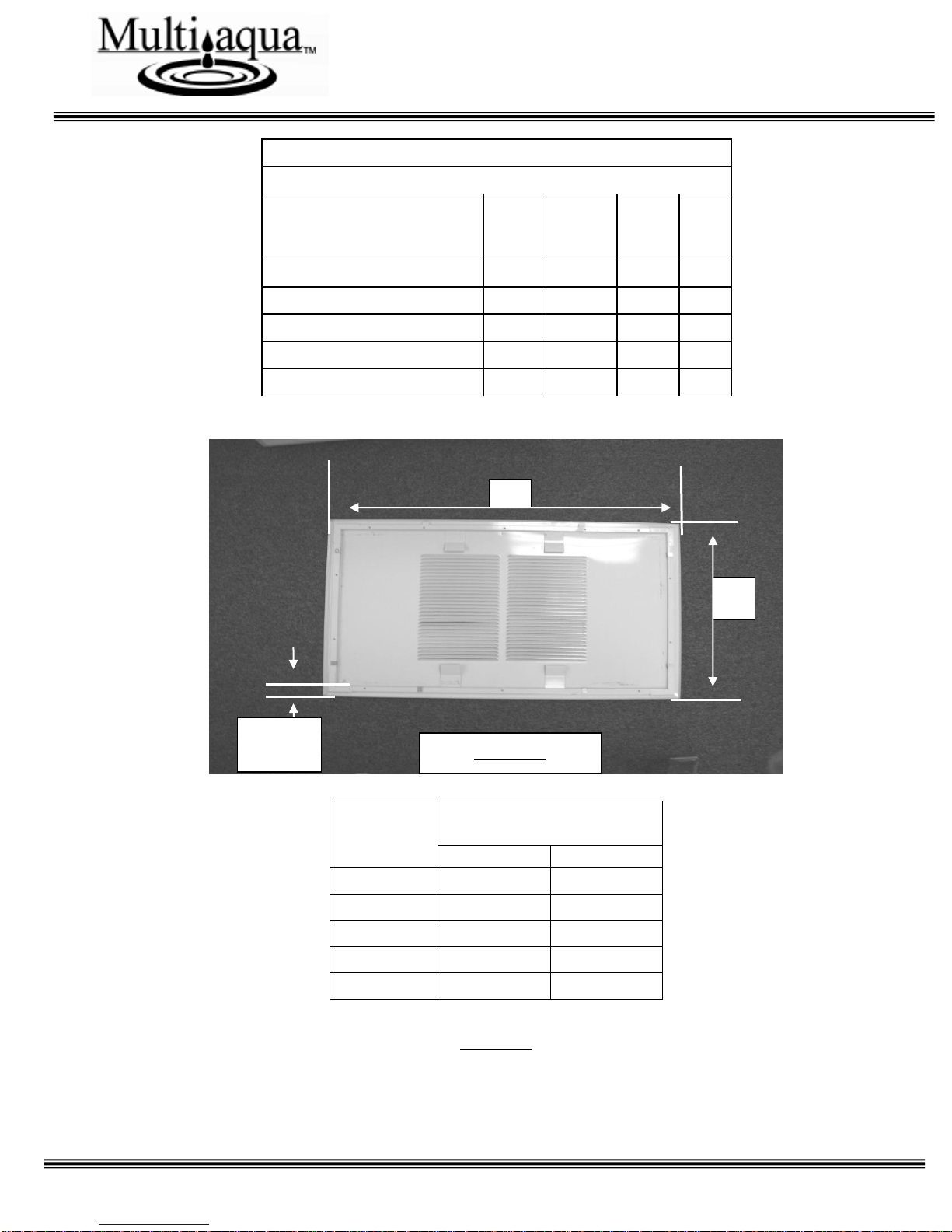

weights. See Figure 3 for fan coil only

dimensions.

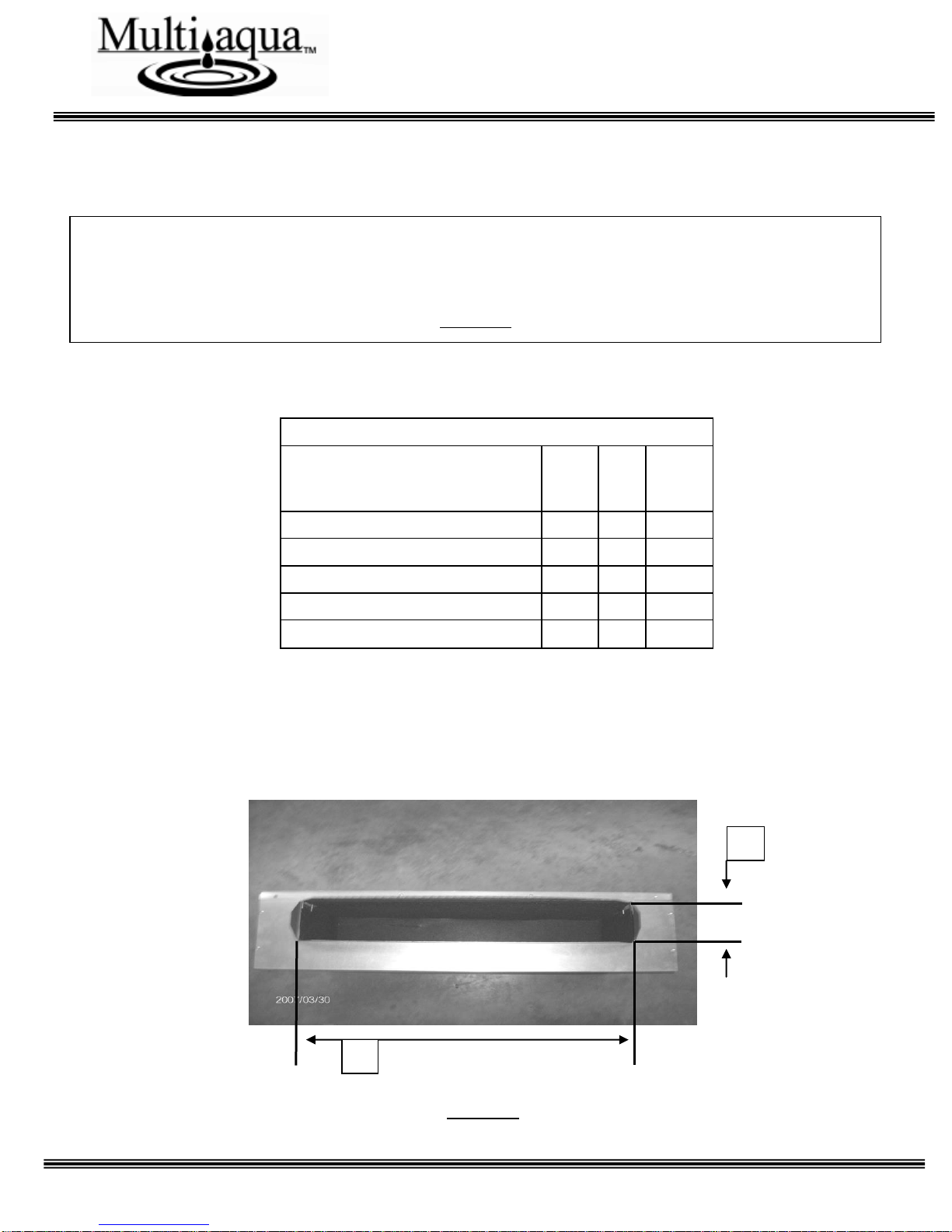

The coil hand of connection is field

reversible to left or right hand connection.

See Figures 4-6 for converting the coil hand

of connection.