Circulating Fluid Temperature Controller

Thermo-chiller Dual ChannelRefrigerated Thermo-chiller for Lasers HRL Series

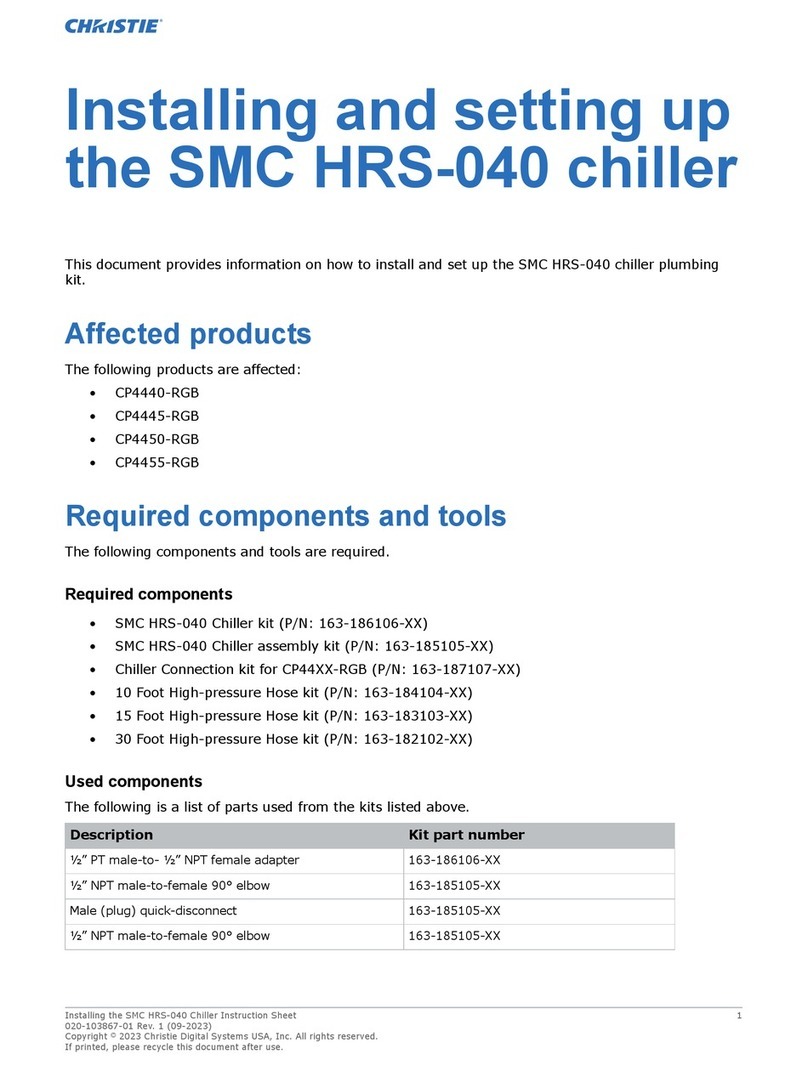

How to Order

Specifications

HRL A 20

Pipe thread type

Nil Rc

FG (with Rc-G conversion fitting)

NNPT (with Rc-NPT conversion fitting)

Power supply

20 3-phase 200 VAC (50 Hz)

3-phase 200 to 230 VAC (60 Hz)

Cooling method

AAir-cooled refrigeration

Cooling capacity

CH1 CH2

100 9 kW 1 kW

200 19 kW 1 kW

300 26 kW 1 kW

Model HRL100-A -20 HRL200-A -20 HRL300-A -20

CH1 CH2 CH1 CH2 CH1 CH2

Cooling method Air-cooled refrigeration

Refrigerant R410A (HFC)

Refrigerant charge [kg] 1.4 2.2 3.0

Control method PID control

Ambient temperature [°C] 2 to 45

Circulating fluid system

Circulating fluid CH1: Tap water/CH2: Tap water, Deionized water∗1

Set temperature range [°C] CH1: 15 to 25/CH2: 20 to 40

Cooling capacity∗2[kW] 9 1∗819 1∗826 1∗8

Heating capacity∗3[kW] 1.5 1 4.5 1 6.5 1

Temperature stability∗4[°C] CH1: ±0.1/CH2: ±0.5

Pump

capacity

Rated flow (Outlet)

[L/min] 45 (0.43 MPa)10 (0.45 MPa)45 (0.45 MPa)10 (0.45 MPa)125 (0.45 MPa) 10 (0.45 MPa)

Maximum flow rate

[L/min] 120 16 130 16 180 16

Maximum pump head

[m] 50 49 55 49 68 49

Settable pressure range∗5[MPa] 0.10 to 0.50 0.10 to 0.49 0.10 to 0.55 0.10 to 0.49 0.10 to 0.68 0.10 to 0.49

Minimum operating flow rate∗

6

[L/min] 202252402

Tank capacity [L] 427427607

Bypass circuit (With valve) Installed

Electric conductivity setting range

[μS/cm]

— 0.5 to 45.0 — 0.5 to 45.0 — 0.5 to 45.0

Particle filter nominal filtrationrating (Accessory)

[μm] 5

Circulating fluid outlet,

circulating fluid return port

CH1: Rc1 (Symbol F: G1, Symbol N: NPT1)

CH2: Rc1/2 (Symbol F: G1/2, Symbol N: NPT1/2)

Tank drain port CH1: Rc3/4 (Symbol F: G3/4, Symbol N: NPT3/4) CH2: Rc1/2 (Symbol F: G1/2, Symbol N: NPT1/2)

Fluid contact material

(Metal/Resin)

CH1: Stainless steel, Copper (Heat exchanger brazing), Brass, Bronze, Fluororesin, PP, PBT, POM, PU, PC, PVC, EPDM, NBR

CH2: Stainless steel, Alumina ceramic, Carbon, Fluororesin, PP, PBT, POM, PU, PVC, PPS, AS, PS, EPDM, NBR, Ion replacement resin

Electrical system

Power supply 3-phase 200 VAC (50 Hz), 3-phase 200 to 230 VAC (60 Hz)

Allowable voltage range ±10% (No continuous voltage fluctuation)

Earth leakage

breaker

Rated current [A] 30 40 50

Sensitivity current

[mA] 30

Rated operating current∗4[A] 17 32 41

Rated power consumption∗4

[kW(kVA)]

5.4 (5.9) 10.5 (11.0) 13.1 (14.2)

Noise level (Front 1 m/Height 1 m)∗4

[dB(A)] 75 75 71

Accessories Operation Manual (for installation/operation) 2 pcs. (English 1 pc./Japanese 1 pc.), Particle filter set for CH1,

Particle filter set for CH2, Anchor bolt fixing brackets 2 pcs. (including 6 M8 bolts)∗7

Weight (dry state) [kg] Approx. 222 Approx. 251 Approx. 315

∗1 Use fluid in condition below as the circulating fluid.

Tap water: Standard of The Japan Refrigeration And Air Conditioning Industry Association (JRA GL-02-1994)

Deionized water: Electric conductivity 1 μS/cm or higher (Electric resistivity 1 MΩ·cm or lower)

∗2 Ambient temperature: 32°C, Circulating fluid: Tap water, Circulating fluid temperature: CH1 20°C/CH2 25°C, Circulating fluid flow rate: Rated

flow, Power supply: 200 VAC

∗3 Ambient temperature: 32°C, Circulating fluid: Tap water, Circulating fluid flow rate: Rated flow, Power supply: 200 VAC

∗4 Ambient temperature: 32°C, Circulating fluid: Tap water, Circulating fluid temperature: CH1 20°C/CH2 25°C, Load: Same as the cooling ca-

pacity, Circulating fluid flow rate: Rated flow, Power supply: 200 VAC, Piping length: Shortest

∗5

With the pressure control mode by inverter. If the pressure control mode is not necessary, use the flow control function or the pump output setting function.

∗6 Fluid flow rate to maintain the cooling capacity. If the actual flow rate is lower than this, adjust the bypass valve.

∗7 The anchor bolt fixing brackets (including 6 M8 bolts) are used for fixing to wooden skids when packaging the thermo-chiller. No anchor bolt is included.

∗8 Max. 1.5 kW. When 1.5 kW is applied, the cooling capacity of CH1 decreases by 0.5 kW.

100

9