5

Zeta Rev HE FC

High efciency, air-condensed free cooling water

chiller unit, with scroll compressors and plate heat

exchanger.

PRODUCT DESCRIPTION

BODY

The structure of the unit is made of galvanized sheet-iron

coated with polyester powder in RAL 5017/7035 at 180°C,

which makes it highly resistant to weather conditions.

The structure is a load-bearing frame, with removable

panelling lined with sound absorbing expanded polyure-

thane matting.

All screws and bolts are stainless steel.

COMPRESSORS

The compressors are hermetic orbiting spiral scroll com-

pressors connected in tandem, tted with oil level sight

glass, oil equalization line, crankcase heater and electron-

ic protection.

The compressors, enclosed in a soundproof compartment

and separated from the air ow, can be accessed through

special panelling that allows maintenance operations to be

carried out even with units running.

CONDENSING COIL

The source-side exchanger is made with aluminium micro-

channel coil.

The microchannel coils are made using specic aluminium

alloys for the tubes and for the ns. This allows the effects

of galvanic corrosion to be drastically reduced to always

ensure protection of the tubes that conne the refriger-

ant. The entire coil is also subjected to SilFLUX coating

processes (or equivalent) or has zinc added to further in-

crease its corrosion resistance.

The use of microchannel coils compared to convention-

al copper/aluminium coils reduces the total weight of the

unit by about 10% and gives a reduction in refrigerant

charge of at least 30%.

Refer to chapters "Installation advice" and "Description of

accessories" for assessment of any options or treatments

based on the place of installation.

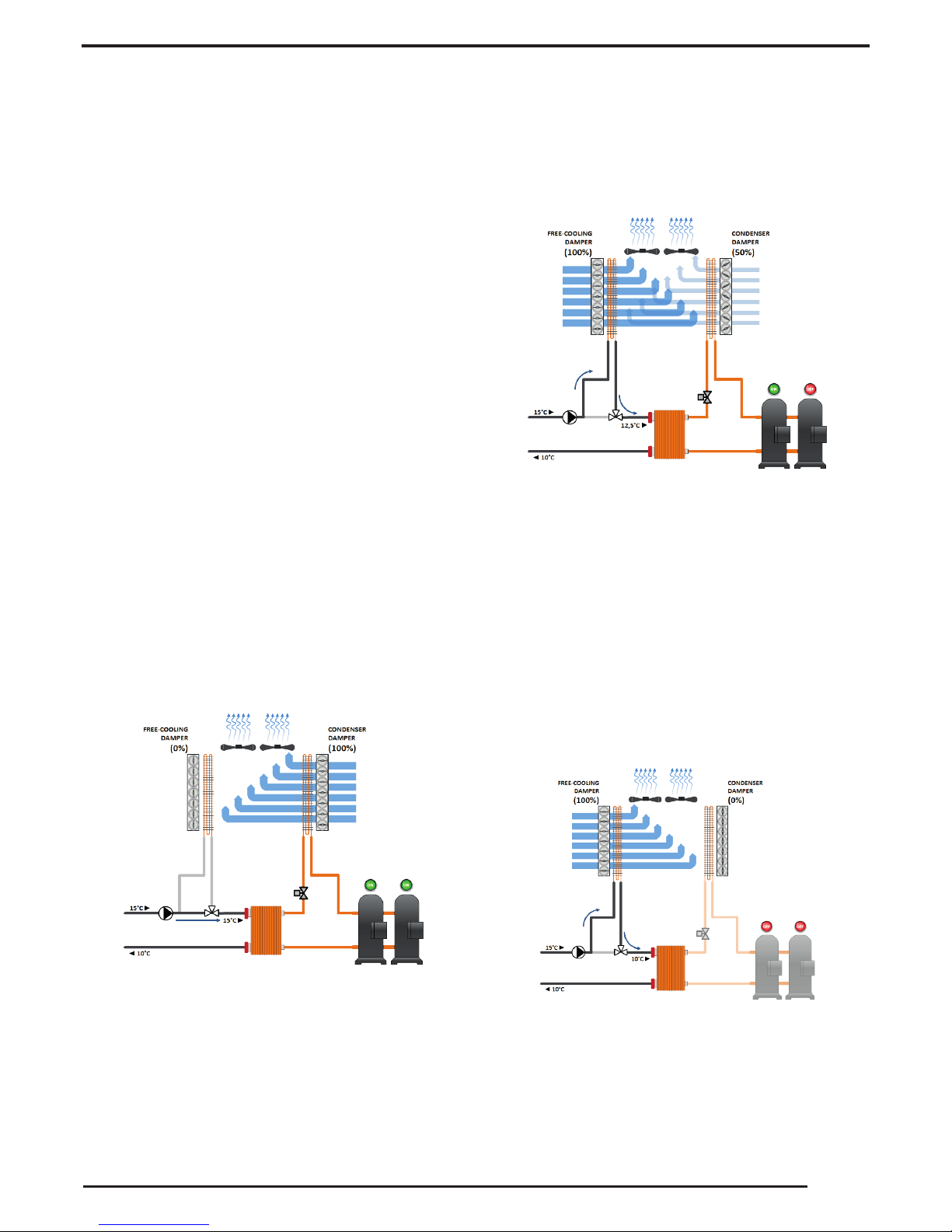

In front of the condensing coil, there is a damper dedicat-

ed to controlling the air ow rate at the exchanger, com-

plete with modulating servo control. Damper management

is done by the controller following the logics of the patent-

ed free cooling system (patent n° IT1855070):

• in chiller mode, the damper is fully open, so allowing

the maximum air ow rate, and condensation control is

carried out by adjusting the speed of the fans

• in mixed mode (chiller + free cooling) the fans operate

at full speed and condensation control is done by mod-

ulating the opening of the damper

• in free cooling mode, the damper is fully closed, so en-

suring the full ow rate at the free cooling coil alone.

FREE COOLING COIL

The free cooling exchanger consists of a row coil with cop-

per tubes and aluminium ns.

Refer to chapters "Installation advice" and "Description of

accessories" for assessment of any options or treatments

based on the place of installation.

This exchanger is put in series with the user-side heat

exchanger by means of a 3-way valve. When the unit is

not working in free cooling mode, the valve allows the

coil to be bypassed to prevent unnecessary hydraulic head

losses.

For /NG version units, the free cooling coil is connected to

a decoupling exchanger situated in series with the evapo-

rator. The coil is supplied by a dedicated circulation pump

that will be switched on only with free cooling active.

The free cooling coil is positioned on the opposite side of

the machine to the condensing coil so that it can be man-

aged completely independently.

In front of the coil, there is a damper dedicated to con-

trolling the air ow rate at the exchanger, complete with

point servo control. Damper management is done by the

controller following the logics of the patented free cooling

system (patent n° IT1855070):

• in chiller mode, the 3-way valve is closed (for the /NG

version, the circulation pump is off), the damper is fully

closed, so ensuring the full air ow rate at the condens-

ing coil alone

• in mixed mode (chiller + free cooling), the 3-way valve

is open (for the /NG version, the circulation pump is

on), the fans work at full speed and the damper is fully

open, so allowing the maximum air ow rate at the free

cooling coil

• in free cooling mode, the damper is fully open and con-

trol of the capacity given by the free cooling coil is done

by the controller of the unit by modulating the speed of

the fans

FANS

The fans are axial fans, directly coupled to a three-phase

6-pole electric motor, with integrated thermal overload

protection (klixon) and IP 54 protection rating.

The fan includes the shroud, designed to optimize its ef-

ciency and reduce noise emission to a minimum, and the

safety guard.

The fans are controlled as standard by a phase cutting

speed adjuster managed by the controller.