FlexMEAs

4

3Setting Up and Connecting the MPA

3.1 General Setup Recommendations

In the following, you find general recommendations for the installation.

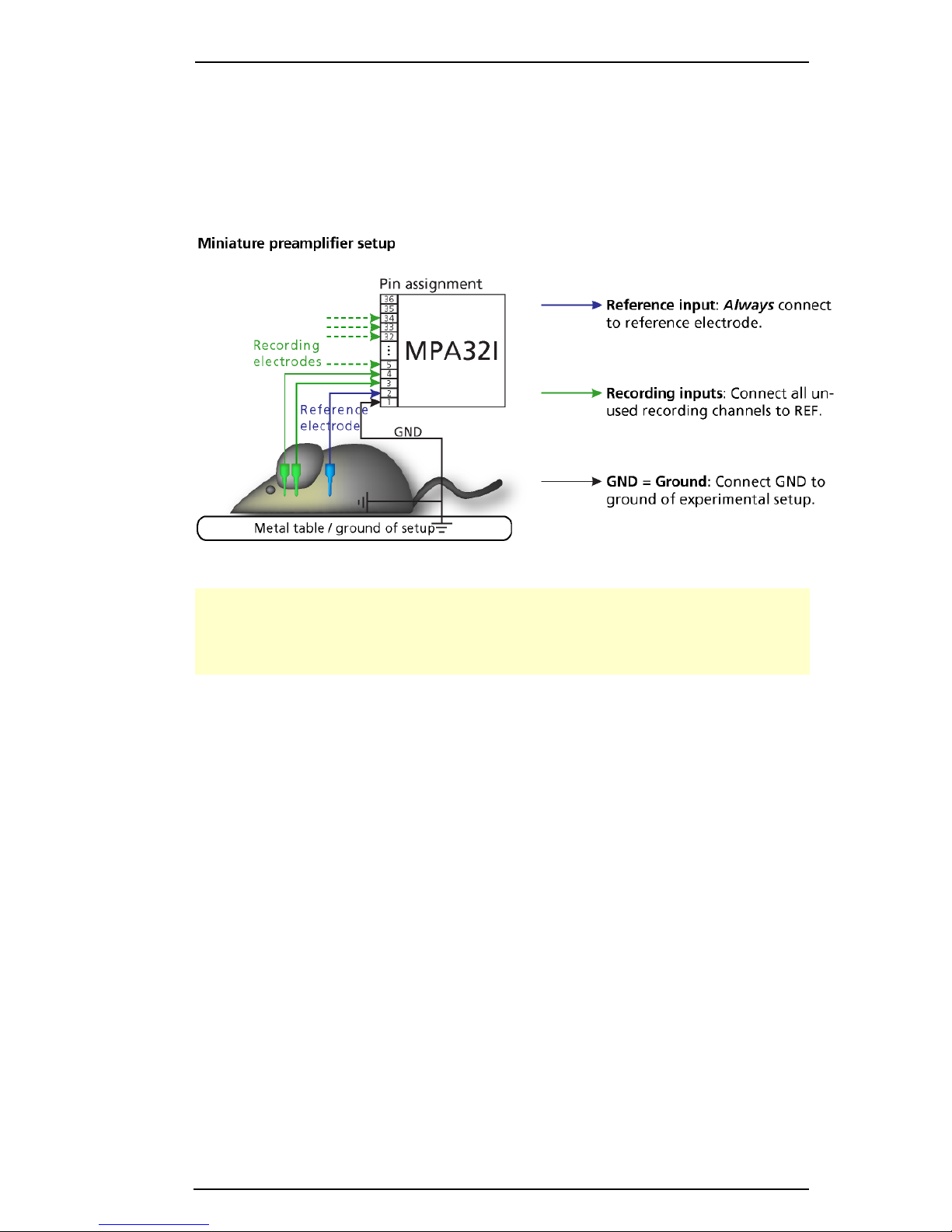

Important: It is important that the complete setup refers to a single common ground. The

reference input has always to be connected. It is recommended to use a reference electrode.

However, if you are not using a reference electrode, connect the reference input to ground

(GND). Otherwise, noise picked up by the reference input will be subtracted from the recording

signals. This will either lead to signal loss or to a very high noise level.

1. Ground the animal with a ground electrode of large surface area, for example, a liquid gel

adhesive electrode,that is connected to the ground of the setup, for example, a large metal

table or a Faraday cage, to avoid pickup of noise from the environment. The ground electrode

is best positioned in an electrically inactive region (not near muscle, nor heart), for example, at the

belly.

2. Connect the GND input or the metal case of the miniature preamplifier to the common

ground of the setup. (The GND input is internally connected to the metal case.)

3. Connect the reference electrode to the reference input of the miniature preamplifier.

Generally, a reference electrode is inserted into non-active tissue of the experimental model.

The reference electrode should be identical to the recording electrode so that both electrodes see

the same background noise. This is necessary because despite the grounding, the animal’s body

often has not exactly a potential of zero, due to the electrode impedance, for example. The

background noise is then subtracted from the recording signal, increasing the signal to noise ratio.

Please note that this may not work if the complete setup is not properly grounded.

4. (Optional) If two reference electrodes are used, connect the second electrode to the free

reference input. Otherwise, leave it free. It is generally not necessary to use a second reference

electrode. It can be used to enlarge the surface area of the reference, though.

5. Connect the recording electrodes to the recording channels of the miniature preamplifier.

You can either use single electrodes or multitrodes with the miniature preamplifier. MCS provides

adapters for standard probes.