WTE5C/WTE5HP SERIES WATER TRAILERS — SERVICE BULLETIN WT20180925 — 10/01/18 — PAGE 4

SAFETY

PROCEDURE

Axle Removal

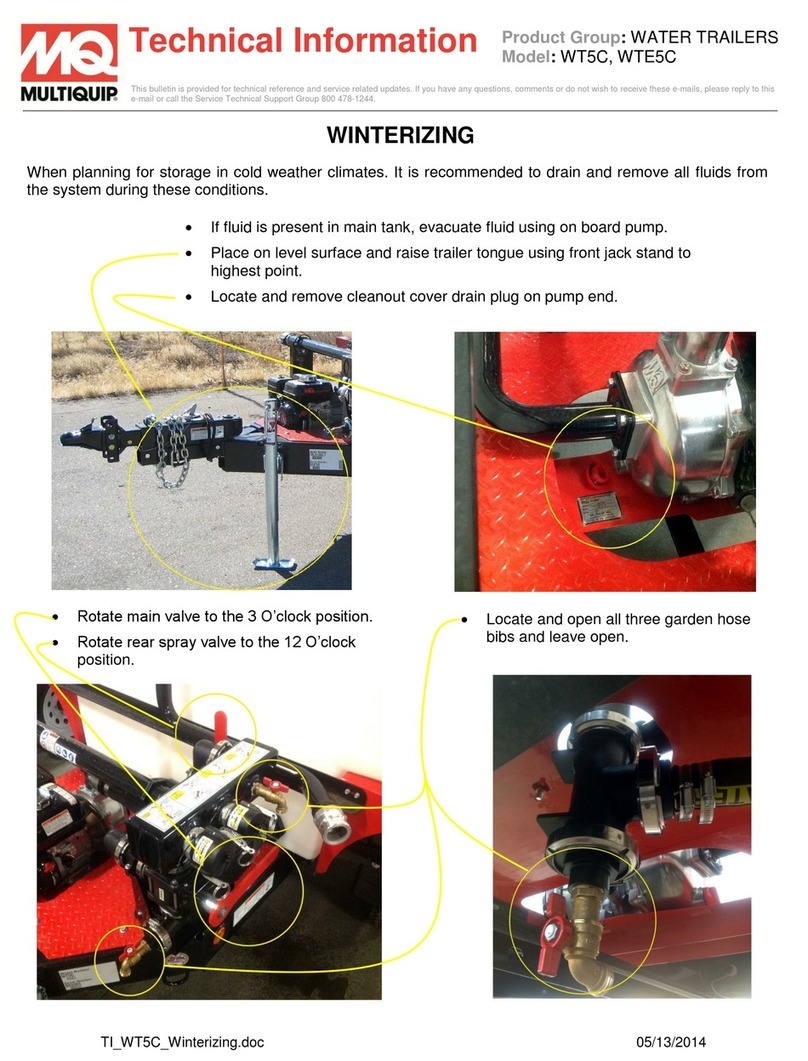

1. Place water trailer on firm and level ground (Figure 2). DO

NOT place trailer on soft or uneven ground. Soft or uneven

ground will not allow for secure placement of hydraulic jack

or jack stands.

Figure 2. Trailer Placement

2. Position a hydraulic jack behind the tire, using the frame

(only) as a lift or contact point.The use of a wood block

is acceptable to extend the height of the hydraulic jack.

NOTICE

Only qualified personnel with proper training should

perform this installation. Follow all shop safety rules

when performing this installation.

NOTICE

The following step-by-step procedures are provided to

assist in the removal and replacement of the tandem

electric axle assemblies used on the Multiquip Water

Trailer models: WTE5C and WTE5HP. Both axle

assemblies will be replaced.

NOTICE

Secure trailer in accordance with Job Hazard

Analysis (JHA) 20140618-002, Securing Trailer for

Maintenance/Repairs.

3. Raise the trailer until the tire is no longer contacting

the ground. The tire should be able to freely rotate

while maintaining a minimum clearance between the

ground and tire.

Figure 3. Jacking The Trailer

4. Next, place jack stands underneath the trailer frame.

5. Remove the tires (4) - break the wheel lug nuts (5) loose

with a ratchet (or breaker bar) and socket.

Figure 4. Removing The Tire

6. Save the lug nuts they will be used later.

7. Locate the wiring harnesses along the right and left

side of the trailer rails beneath the trailer frame.

NOTICE

DO NOT attempt to raise the trailer by jacking on

the axles or the suspension. This will cause damage

to the axles or suspension. ALWAYS place the jack

underneath the frame to prevent bending or deformation

of the axles or suspension.

WOOD BLOCK

HYD. JACK

FRAME