DLW500ESA4 WELDER/GENERATOR • OPERATION MANUAL — REV. # 0 (01/13/23) — PAGE 7

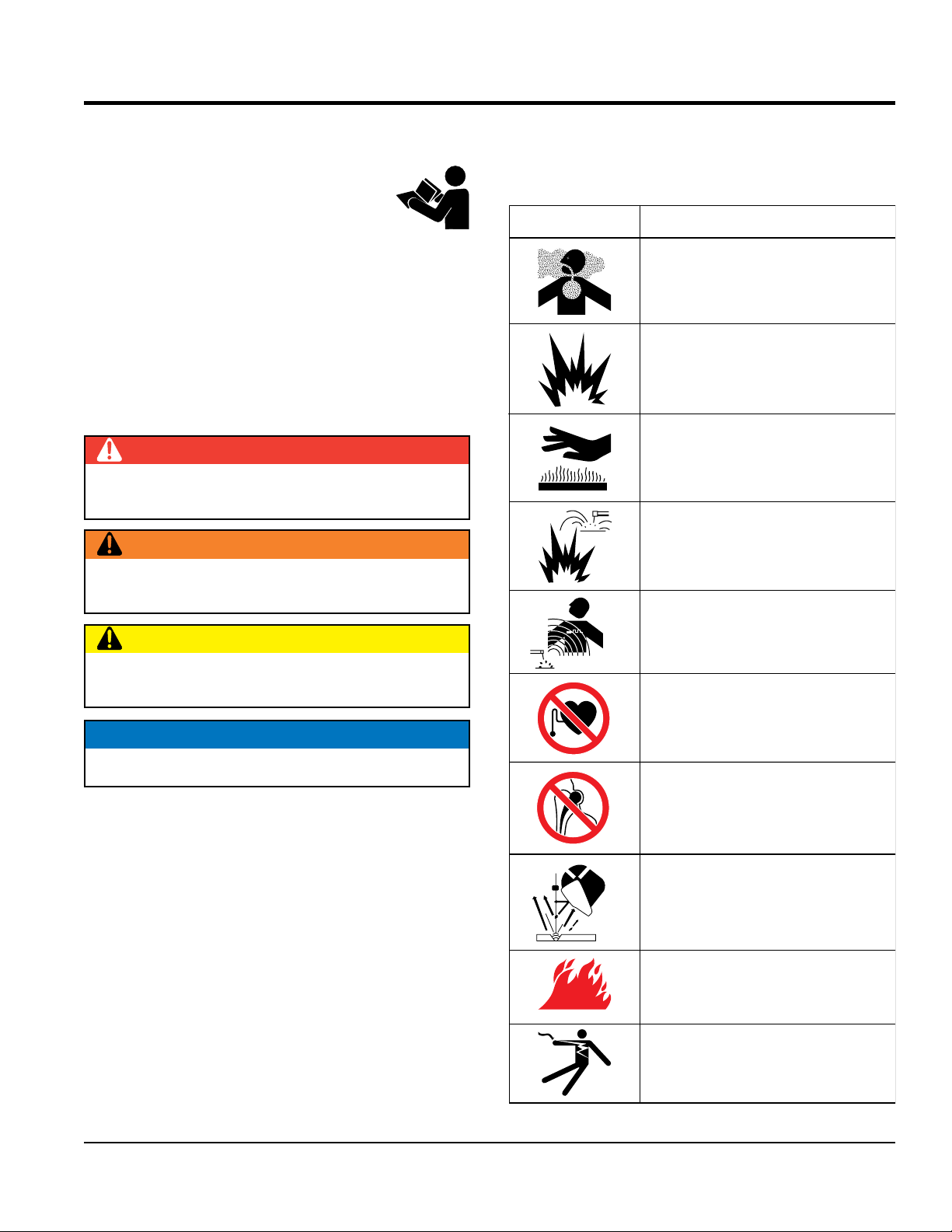

SAFETY INFORMATION

DANGER

NEVER install or operate the welder-

generator in an explosive atmosphere or

near combustible materials. An explosion

or fire could result causing severe bodily

harm or even death.

Flying sparks can cause injury. Wear a face

shield to protect eyes and face.

Remove all flammables within 35 ft (10.7 m)

of welding arc. If this is not possible, tightly

cover them with approved covers.

Do not weld where flying sparks can strike flammable

material.

Hot metal from air arc cutting and gouging

can cause fire or explosion. DO NOT cut or

gouge near flammables.

Welding on closed containers, like tanks, drums or

pipes, can cause them to blow up. DO NOT weld on

closed containers unless they are properly prepared

according to AWS F4.1 (see Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping from American Welding Society

Standards). Check and be sure area is safe before doing

any welding.

Protect yourself and others from flying sparks and hot metal.

Wear oil-free protective garments like leather gloves,

heavy shirt, cuffless trousers, high shoes and a cap.

Be alert that welding sparks and hot materials from

welding can go through small cracks and openings to

adjacent areas.

Be aware that welding on a ceiling, floor, bulkhead or

partition can cause fire on hidden side.

Connect welding cable to the work as close to welding

area as practical to prevent welding current from traveling

long, possibly unknown paths and causing electric shock,

sparks and fire hazards.

DO NOT use welder-generator to thaw frozen pipes.

Remove stick electrode from holder or cut off welding

wire at contact tip when not in use.

DO NOT touch output terminals during operation.

Contact with output terminals during operation can cause

electrocution, electrical shock or burn.

Remove any combustibles, such as a butane lighter or

matches, from your person before doing any welding.

After completion of work, inspect area to ensure it is free

of sparks, glowing embers and flames.

Follow requirements in OSHA 1910.252 (a) (2) (iv) and

NFPA 51B for hot work and have a fire watcher and

extinguisher nearby.

WARNING

Keep your head out of the fumes. Use enough ventilation

or exhaust at the arc, or both, to keep the fumes and

gases from your breathing zone and the general area.

In a large room or outdoors, natural ventilation may be

adequate if you keep your head out of the fumes.

DO NOT

get too close to the arc. Use corrective lenses

if necessary to stay a reasonable distance away from

the arc.

Use natural drafts or fans to keep the fumes away from

your face.

Welding wire can cause injury. Do not press

gun trigger until instructed to do so. Do

not point gun toward any part of the body,

other people or any metal when threading

welding wire.

Have only qualified people remove doors, panels,

covers or guards for maintenance and troubleshooting

if necessary.

Reinstall doors, panels, covers or guards when servicing

is finished and before starting engine.

NEVER disconnect any

emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.