www.multispanindia.com

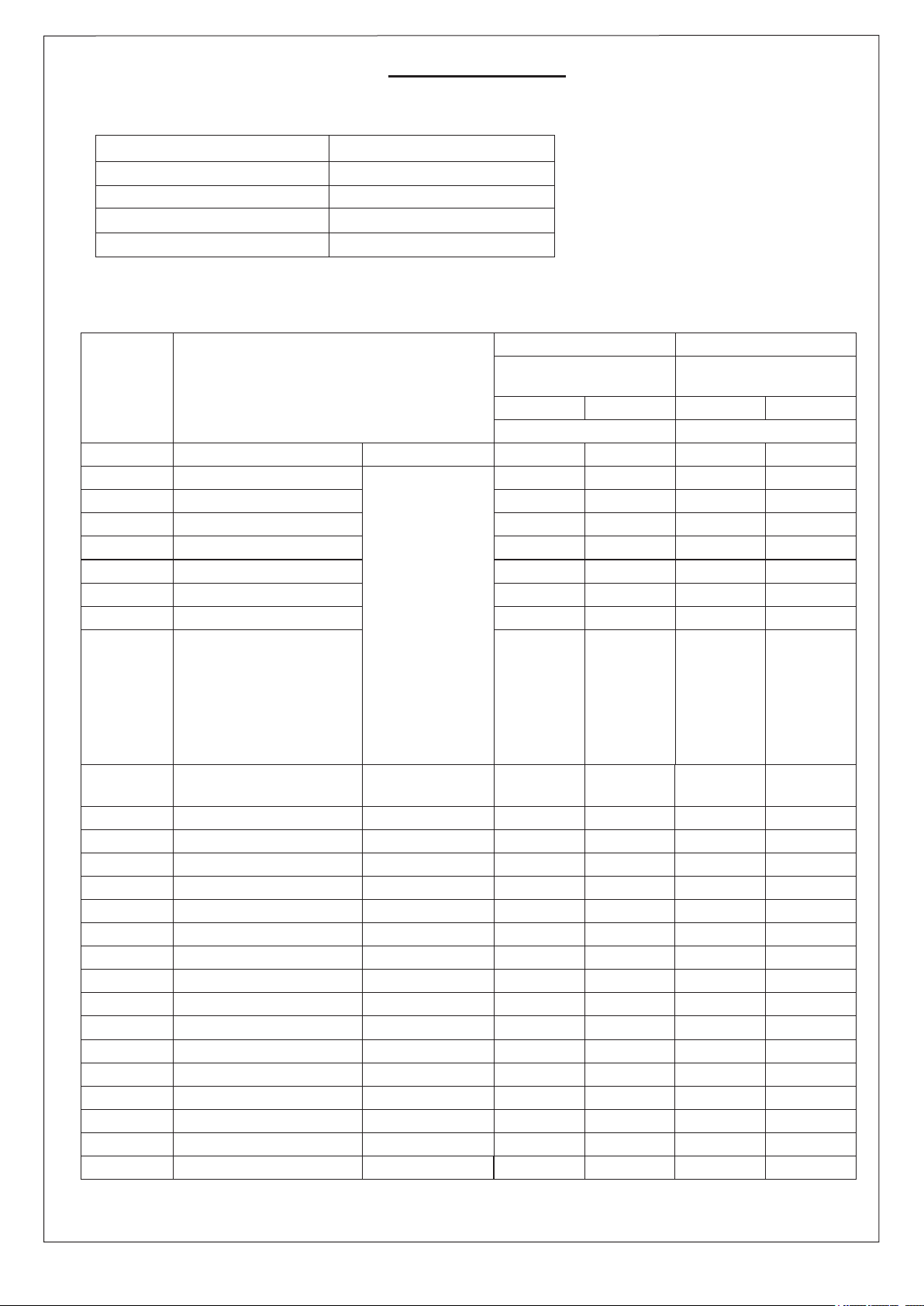

Main Menu: To change set value & hystersis based on relay mode & grouping

In Group No 1, If 1st channel, have a set point as a high alarm, 1 relay.

In Group No 2 If 2nd channel, have a set point as a low alarm, 1 relay.

For, 3rd, 4th channel have a set point as high & low alarm, 2 relay.

For Example:

Page-3

(Repeat the same procedure for all 4 channels).

Scan time. (Second)

Press + key.

Presskey.

Use or key to Skip or Unskip Channel.

SET

5

J-TY

UNS

SCN

CH 1

CH 1

J-TY

Ch 4

1

S 1P

S 1P

/

/

To change the Input Type, Press or Key.

( J, K , PT-100,PT.1,0-10V DC, 0-20mA DC & 4-20mA DC ).

(Repeat the same procedure for all 4 channels).

h

UNS

Ch 4

1

h

h

h

Press key to save & exit.

Input Selection

MENU-1

Note :- Values can be changed

by pressing or keys.

SET

Presskey.

SET

Presskey.

SET

Presskey.

SET

Presskey.

SET

ENT

MSU-1244U-M1

SET

SET

SET

2) Press & Key to change the parameter setting.

5) Press + Key to set OFFSET.

6) Press & hold key to enter in scroll & hold mode.

3) Press + Key to enter in parameter menu

4) Press + Key to enter in group menu for relay

(Input selection, skip-unskip selection)

mode selection.

1) Press key to enter in set value menu.

SET

SET

Key Operation

Note :- Values can be changed

by pressing or keys.

7) Press key for 3 Sec to Change continuous

scrolling or manual scrolling.