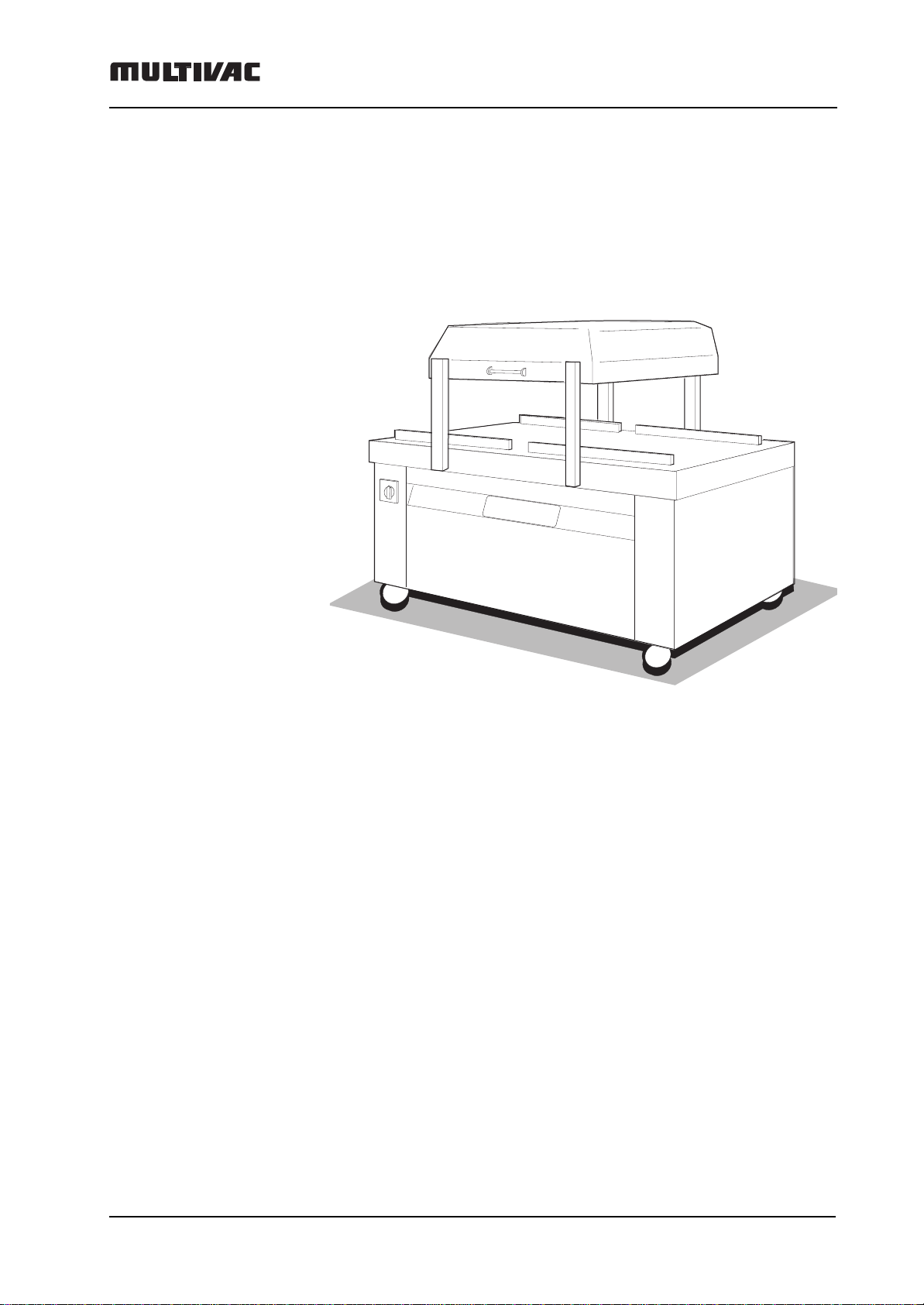

Elements of the machine

Betriebsanleitung 07.06.2005 4/43

ba_c500_50s2GB06IVZ.fm ega

Contents

Instruction manual C 500 ..................................................... 1

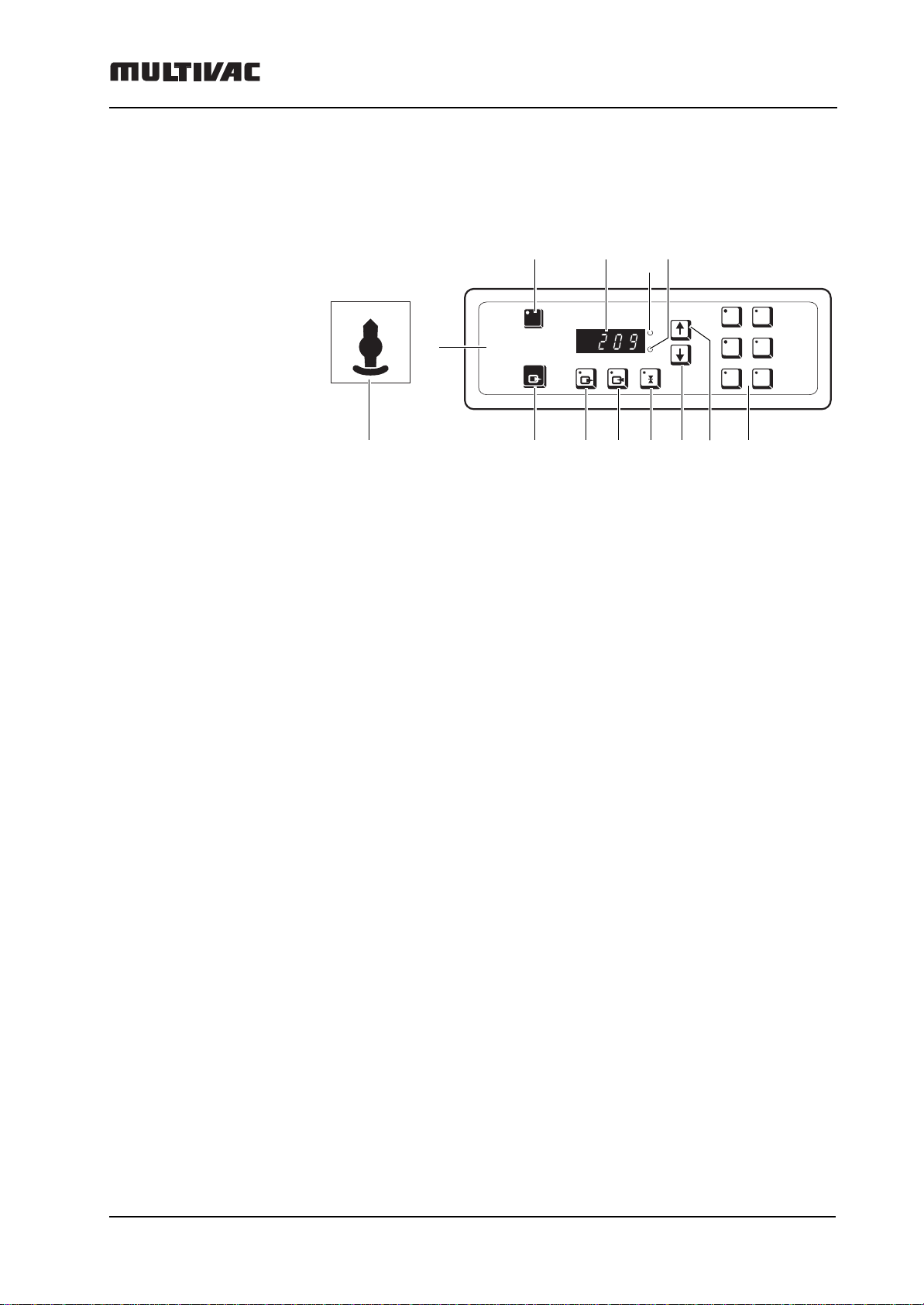

Control panel ......................................................................... 2

Elements of the machine ...................................................... 3

Manufacturer, service address, user information .............. 5

Use ......................................................................................... 6

Safety ..................................................................................... 7

Electromagnetic Compatibility (EMC) ............................................ 8

Operation with inert gas .................................................................. 8

Transport, Set-up, Putting into operation ........................... 9

External vacuum connection (Option) ......................................... 11

Cooling water connection (optional) ............................................ 12

Pressurised air connection ........................................................... 14

Inert gas connection ...................................................................... 15

Operation ............................................................................. 16

Packing – First steps ..................................................................... 16

Start up ............................................................................................ 16

Recommended Settings ................................................................... 17

Check pouch .................................................................................... 22

Displaying values, changing values ............................................ 24

Pressure indicator ............................................................................ 24

Displaying or changing the post-evacuation time ............................ 25

Displaying or changing the sealing time .......................................... 26

Displaying or changing separation time ........................................... 27

Displaying or changing the inert gas value ...................................... 28

Calling up or saving a program .................................................... 29

Care and maintenance ........................................................ 31

Cleaning .......................................................................................... 32

Disinfection - Corrosion protection ............................................. 33

Care products ................................................................................. 34

Replacing the cover seal ............................................................... 35

Trouble-shooting ................................................................ 36

Technical data ..................................................................... 39

Special equipment .............................................................. 40

MHP-evacuation time ..................................................................... 40

Working area sound pressure level .................................. 42

Assembly instructions, repair kit, sealing equipment ..... 43