4 Description of psp Family

Rectifiers

4.1 Basic Information

Psp family switching-mode power supply

rectifiers stand out because of their compact

design, high control accuracy, low ripple, low

weight, and a high efficiency.

In contrast to other electronic rectifiers, such

as thyristor rectifiers, the ripple of psp family

power supplies is constant. Thus, psp family

rectifiers generate high quality direct currents.

As the operating frequency of the switching

mode power supply rectifiers is higher than

20 kHz the wound components, such as main

transformer and smoothing filter, as well as

the capacitors can be designed much smaller

while generating the same output power.

Another outstanding characteristic is the

improved dynamic response of the output

values which allow set point value deviations

at the DC voltage output to be adjusted within

milliseconds. These specific control

properties render the output variables very

stable.

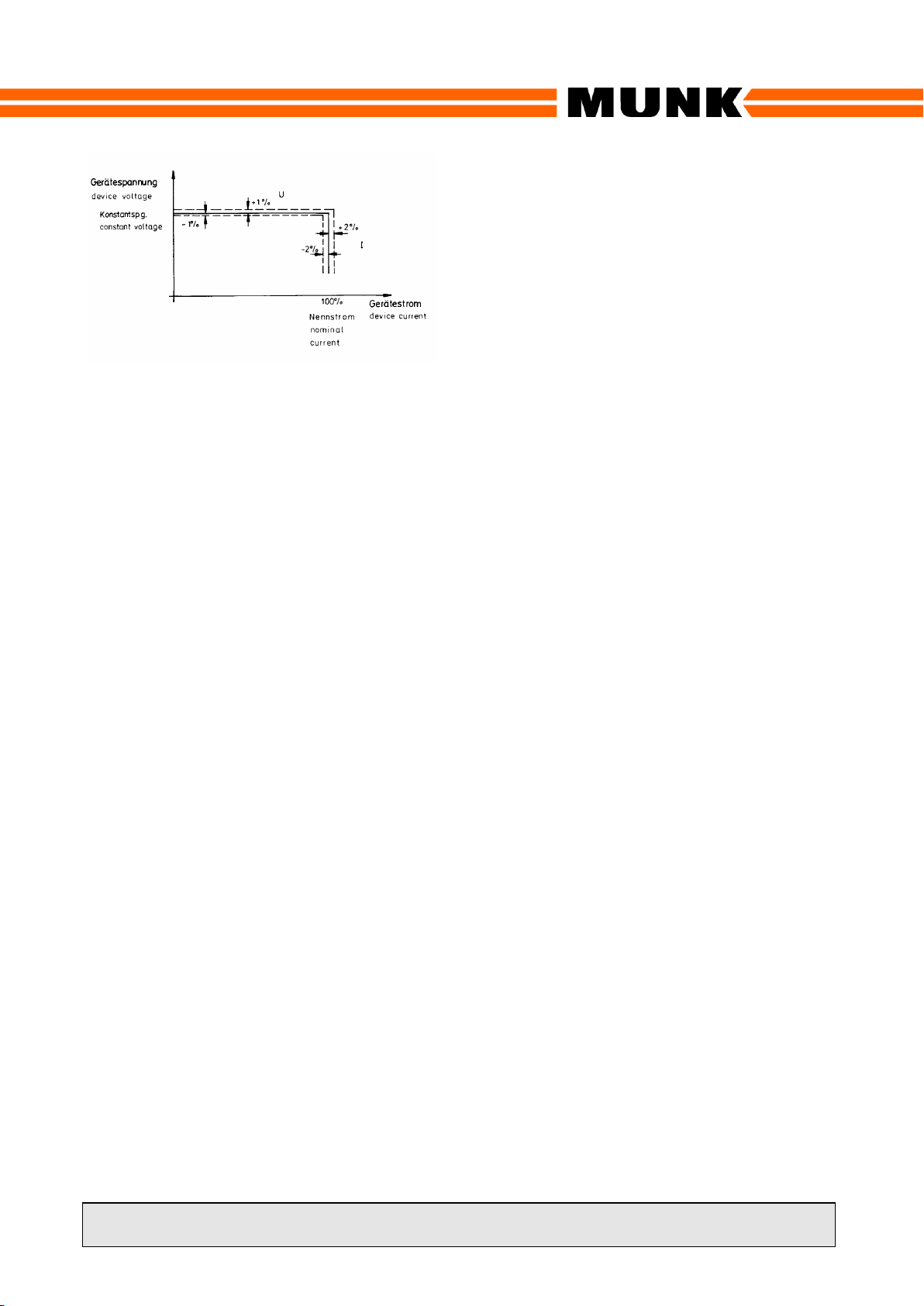

The control accuracy of the internal closed-

loop control amounts to just 1% referring to

the nominal voltage or current. The current

and voltage ripple values of the DC output

are below 1 –3% of the nominal values

across the entire control range, if not

indicated otherwise in the technical

specification.

The power section is installed in an enclosure

made from insulating material, thus

preventing direct access to live components.

Psp family rectifiers are DC power supplies

designed on the basis of switching-mode

power supply technology. The internal control

electronics facilitate very short adjustment

times in case of sudden load variations.

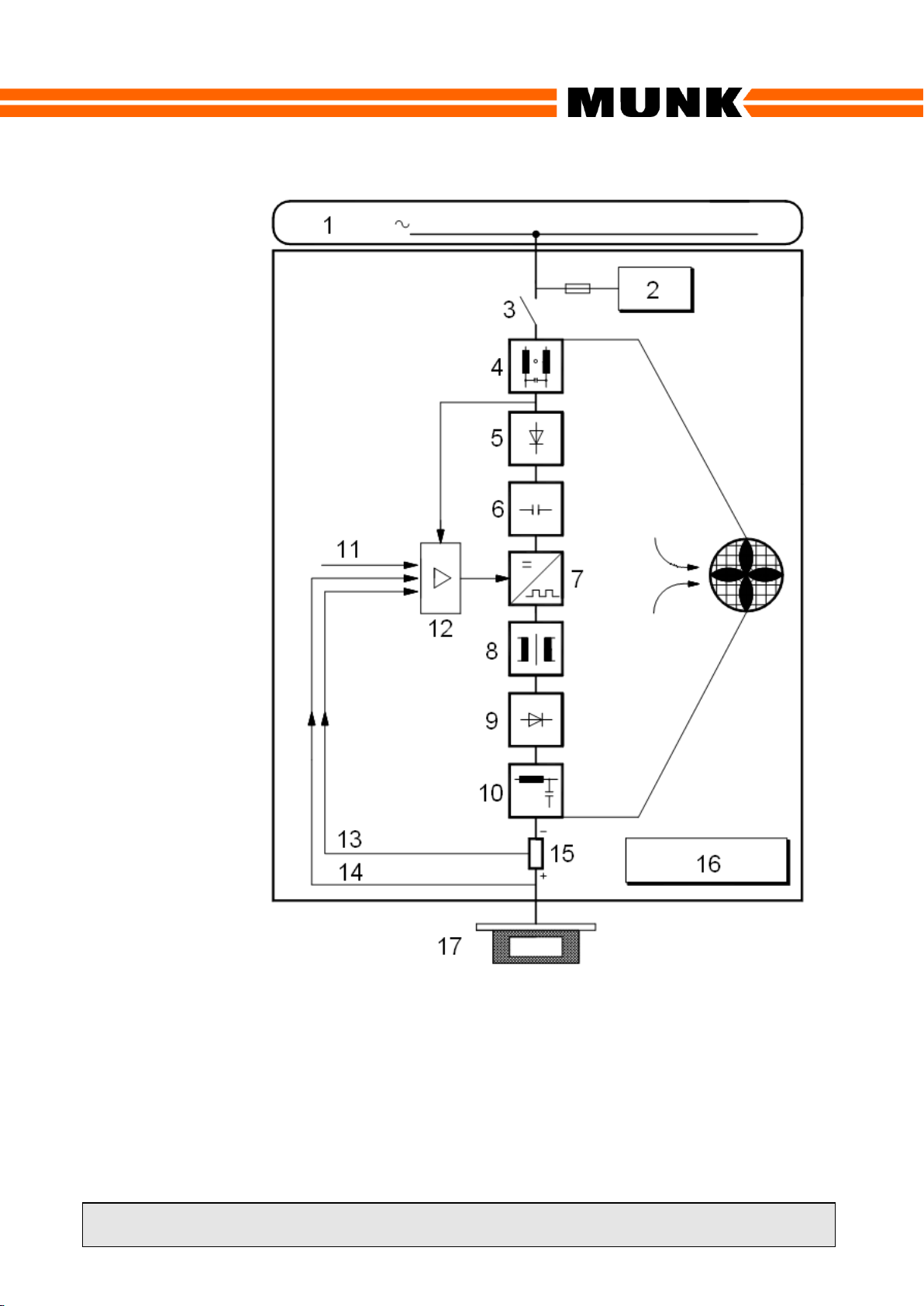

4.2 Switching Mode Power Supply

Technology

Switching-mode power supply technology

rectifies the mains voltage and supplies it to a

DC link consisting of capacitors and

connected to a high frequency inverter, which

converts the DC link voltage into an AC

voltage of a higher frequency. This AC

voltage is transferred to the transformer

primary circuit, which adjusts the voltage and

implements electrical isolation. The

secondary voltage of the transformer is

rectified and transferred via an output filter to

the rectifier output.

4.3 High Current Circuit

The high-current circuit includes the

transformer secondary circuit, a high-current

rectifier and a smoothing filter.

The high-current rectifier consists of rapid-

high-current diodes. The received DC voltage

is transferred via the smoothing filter to the

rectifier output. The smoothing filter filters the

superimposed high-frequency AC voltage of

the high-current rectifier. This allows a low-

ripple DC voltage to be applied to the rectifier

output.

4.4 Closed-Loop Control

Psp family rectifiers, are equipped with

current and voltage controllers. Owing to the

internal connection the controller limiting the

output variable is always the active one.

Therefore, you can only preset current and

voltage set point values or adjust them using

the potentiometers.

The rectifier operates according to a

controlled voltage/current characteristic to

DIN 41773.