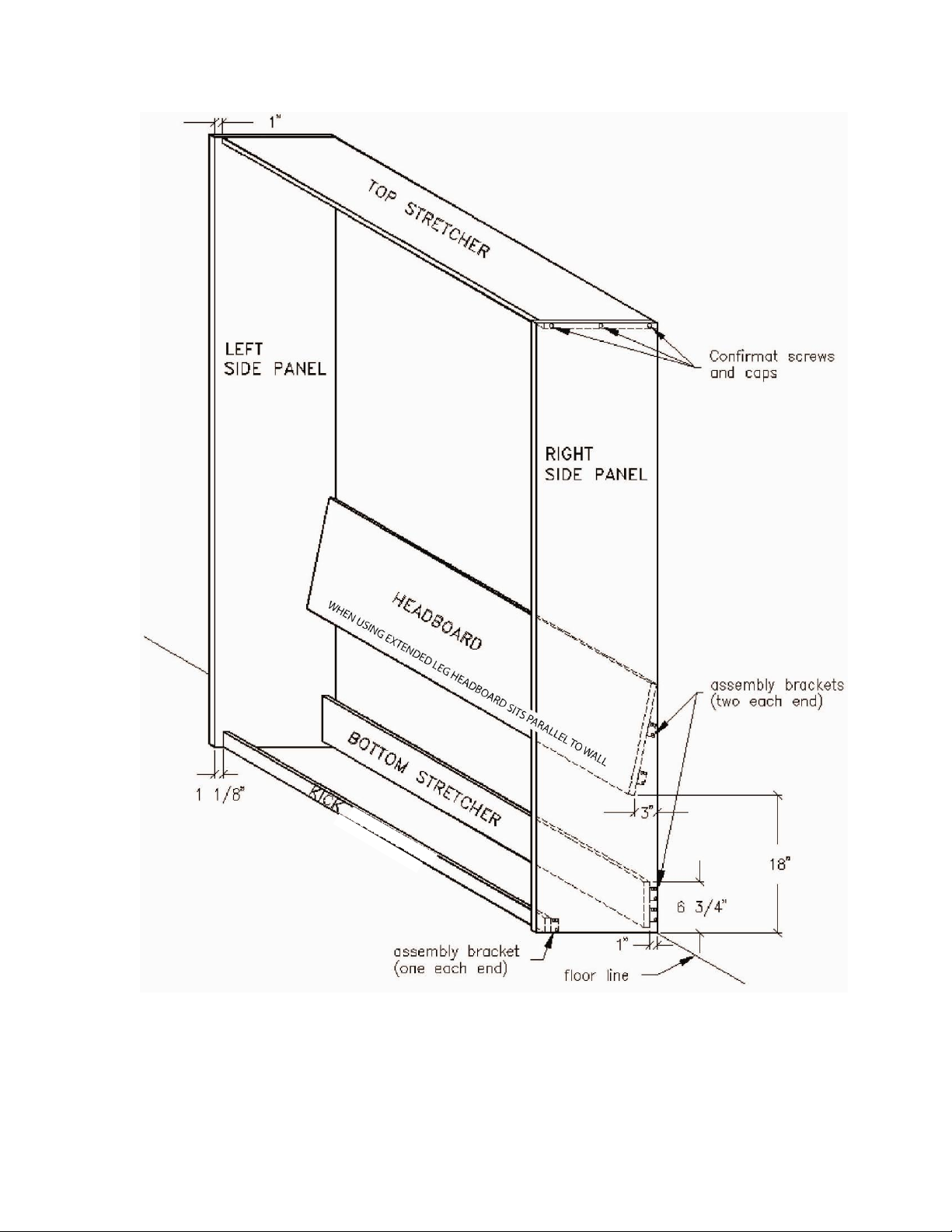

Bed Cabinet Assembly Instructions

1. Cut panels exactly as specified in the Cut List

located on page page 5(reg leg), page 20

(extended leg) and page 21(Long Leg) of these

instructions. As you cut each piece, identify it using

a pencil, as indicated in Figure 1. Label the Bed

Panels (not shown in Figure 1) BED PANEL. You

will use these names throughout the instructions to

reference the particular items.

2. Clean and/or sand pieces. Tape the following

edges that will be exposed after construction:

TOP STRETCHER & SIDE PANELS –front

edges

HEADBOARD –both long edges

BOTTOM STRETCHER –top edge

KICK –both long edges (to prevent bowing)

FACE PANELS –all four sides

Helpful Hint: The simplest method is to use pre-

glued, iron-on tape appropriate for the construction

material you are using.

3. Make a small mark on the inside of each Side

Panel, 3″ from the back and 18″ from the bottom.

From this mark measure up and back 147/8″ to the

back edge of the Side Panels. Make another mark

and pencil a line to indicate the back of the

Headboard Position.

4. Attach 1″ x 1″ x 1¾″ assembly brackets to the

Headboard, Bottom Stretcher and Kick as per

Figure 1. Note that you must set the top brackets

of the Headboard low enough so they do not

protrude beyond the back of the cabinet. If you will

be notching out Side Panels to accommodate a

baseboard, attach the Bottom Stretcher. Brackets

to the front side of the notches.

5. Accurately mark the Lift Mechanism mounting

holes on the inside of each Side Panel. See

Figure 2 for the layout of these holes. When

drilling the holes, first drill a 1/16″ hole with a 5/16″

bit. Countersink (5/8″ diameter) each hole on the

outside of the panels, just deep enough for the

head of the 5/16″ x 1¼″ flathead slot machine screw

to sit flush with the surface. (You can sand and

paint the machine screws’ heads to match your

Cabinet finish.)

6. Align the back edges of the Top Stretcher and the

Side Panels and clamp with 72″ bar clamps. Using

a 3/16″ (5mm) bit, drill three Confirmat screw holes

per side to a depth of 2″. Keep the outer holes 1″

away from the front and back edges of the Top

Stretcher. Center the third hole between them. Un-

clamp and re-drill the Side Panel (shank) holes

using a 9/32″ (7mm) drill bit. Do not countersink

these holes. See Figure 3.

7. Prior to assembling the Bed Cabinet, you may

wish to apply your choice of finish to the individual

pieces.

8. You can now begin assembling the Bed Cabinet –

if possible, do this in the room where you will

install the Bed Cabinet. Refer to Figure 1 for

positioning and dimensions. Prop up one Side

Panel and the Top Stretcher on their back edges

and attach with Confirmat screws. Attach other

Side Panel. Press-fit the Confirmat caps.

Helpful Hint

Before you begin, you may wish to visit our website at

www.murphybeds.com to view the Quick Time

Video showing the assembly of an Elite Aluminum

Frame. Please note that your Supreme Steel Frame

does not require the adhesive tape on the frame and

stiffeners, and the Supreme Steel stiffeners are

attached side to side.

Please Note:

Be sure to use the section of the Bed Frame Cut List

that corresponds to the size of the bed that you are

constructing.

Do not glue the Bed Cabinet together.