TAH-97029N page 3 of 4

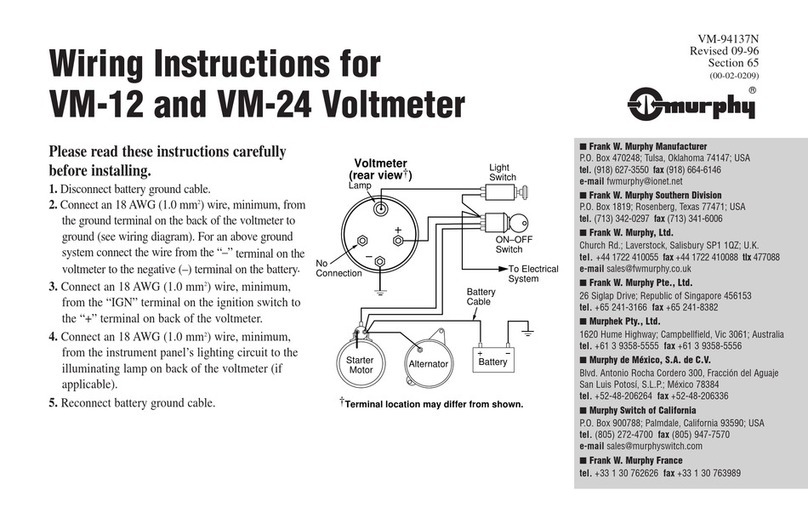

ATA and ATHA Series Models Typical Wiring

Connecting or Replacing Light Bulb

1.

Twist the “light assembly” socket one-eight turn counterclockwise and remove the

“light assembly”. See Fig. 4 at right.

2.

To replace the bulb, pull the bulb from the socket and replace with an 00-00-4617

(for 12V), 00-00-4618 (for 24V) bulb or equivalent size as marked on the bulb.

3.

Connect the lamp blade connector to (+) positive side of instrument lighting circuit.

Connecting to Alternator (see Fig. 4)

1.

Connect a wire from “SIG” terminal to an AC phase terminal (sometimes

marked “STA” or “R”) on your alternator. If your alternator does not have an AC

phase terminal, solder the “SIG” wire to one of the negative or positive rectifier

diodes of the alternator.

2.

After soldering, securely tape the wire to an alternator lead or wiring harness to

dampen vibration on diode terminal.

NOTE: On some alternators it may be necessary to remove the rear housing to

solder the wire to the diode.

Connecting to Power (see Fig. 4)

Important: These units are for 12 VDC only.

1.

Connect a wire from “BAT” to a 12 VDC circuit activated by the ignition switch.

2.

Connect a wire from “GND” to negative voltage source (electrical ground).

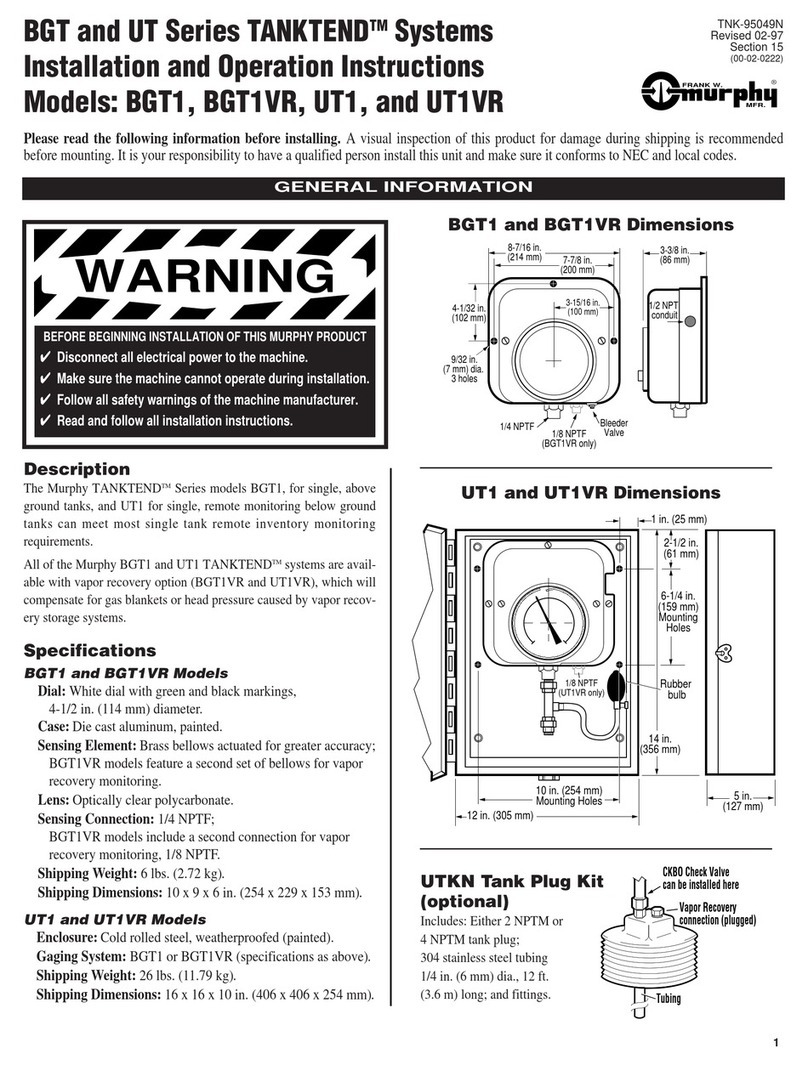

Connecting ATVC12/24 Convertor (see Fig. 5)

For 24 VDC applications, a ATVC12/24 convertor must be used.

1.

Insert the ATVC12/24 convertor as shown.

2.

Secure the ATVC12/24 convertor with a nut on the “BAT” and “GND”stud ter-

minals of the Tachometer.

3.

Notice that the stud terminal on the ATVC12/24 convertor becomes the “BAT”

stud for connecting to 24 VDC. Proceed with the connection as shown.

4.

Replace the 12 V bulb with the 24 V bulb supplied with the converter assembly.

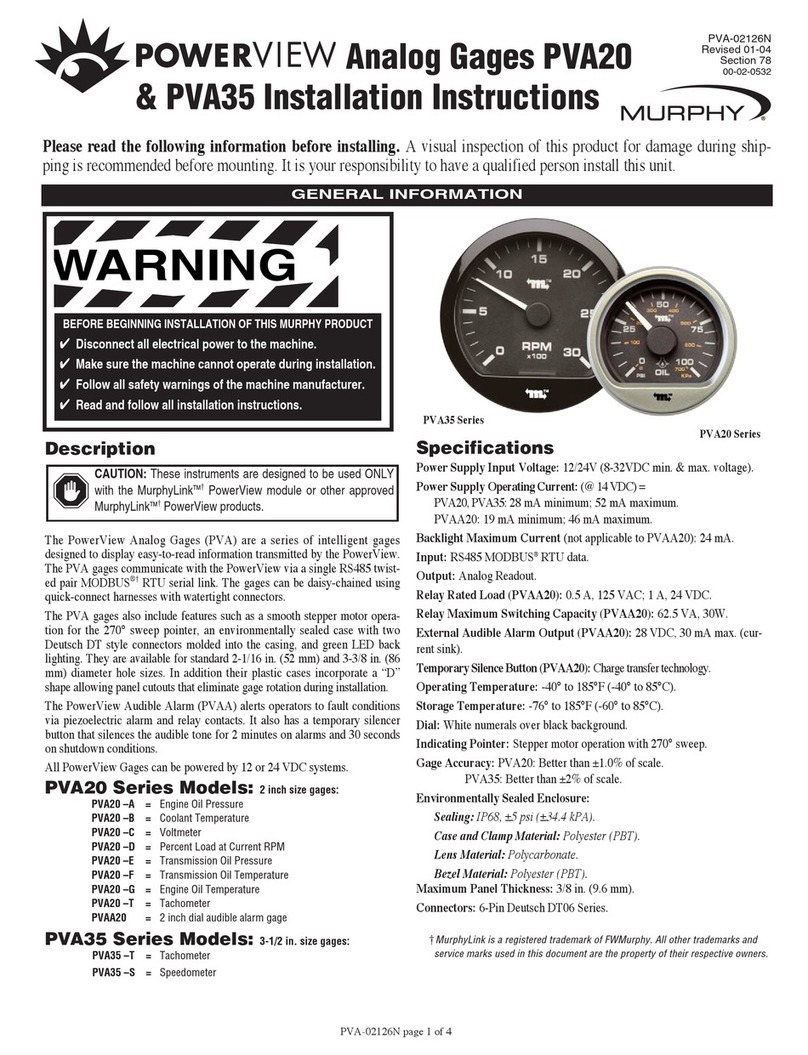

ATS and ATHS Series Models Calibration Instructions

Calibration

The ATS and ATHS Series models have been designed to function with flywheels

having anywhere from 70 to 225 teeth. This wide range is divided into 6 switched

positions acting as a “coarse adjustment” as follows:

Switch Position Range of Flywheel Teeth

170 - 80 teeth

281 - 100 teeth

3101 - 130 teeth

4131 - 160 teeth

5161 - 190 teeth

6191 - 225 teeth

1.

If the number of teeth on the flywheel is known, set the calibration “course

adjustment switch”, (see Fig. 6, at right), using a fine blade slotted head screw-

driver to the applicable position per chart above.

2.

If the number of teeth on the flywheel is not known, set up a calibrated “shop

tach” to monitor the engine’s true RPM. Start the engine and after an appropriate

warm-up period increase to normal running RPM as read on the shop tach. If the

course switch was not set in step 1, set it now to the position that causes the

Murphy tach to read closest to true RPM.

*

*

Some engines incorporate a governor that limits full throttle RPM to pre-set

level equal to the engine’s recommended maximum running speed. If your

engine has such a governor, and if the governed full throttle RPM is known (it

should be clearly stated on the engine’s certification documentation), use of a

calibrated shop tach is not necessary. Simply run the engine up to governed

maximum running RPM and calibrate the Murphy tach to the rated RPM as

specified in the engine’s certification documentation.

WARNING:

Make sure that the engine has a properly functioning

and certified governor before attempting this alternate procedure.

Fine Adjustment

The “fine adjustment” of calibration is accomplished by varying the calibration

Trimpot located behind the “fine adjustment” access hole on the rear of the case,

(see Fig. 6, below). Proceed with calibration as follows:

1.

To adjust the trimpot for the exact true RPM, punch through the label and insert

a 5/64 in. (2 mm) hex-end plastic electronic turning tool (or allen wrench)

through the access hole and into the fine adjustment calibration.

2.

Rotate the trimpot clockwise or counterclockwise as necessary.

3.

Once calibration at the engine’s normal running RPM has been set, the tach will

simultaneously be calibrated at all other engine speeds.

CAUTION:

Disconnect the battery/power source and determine voltage and polarity of the application before wiring

the unit. Use the appropriate wire size. It is recommended using 16 AWG (1.5 mm2) or larger stranded, insulated wire and

insulated crimp-on (solderless) ring-type wire terminals. Allow a few inches of excess wire to make adjustments.