LS-04006N page 2 of 4

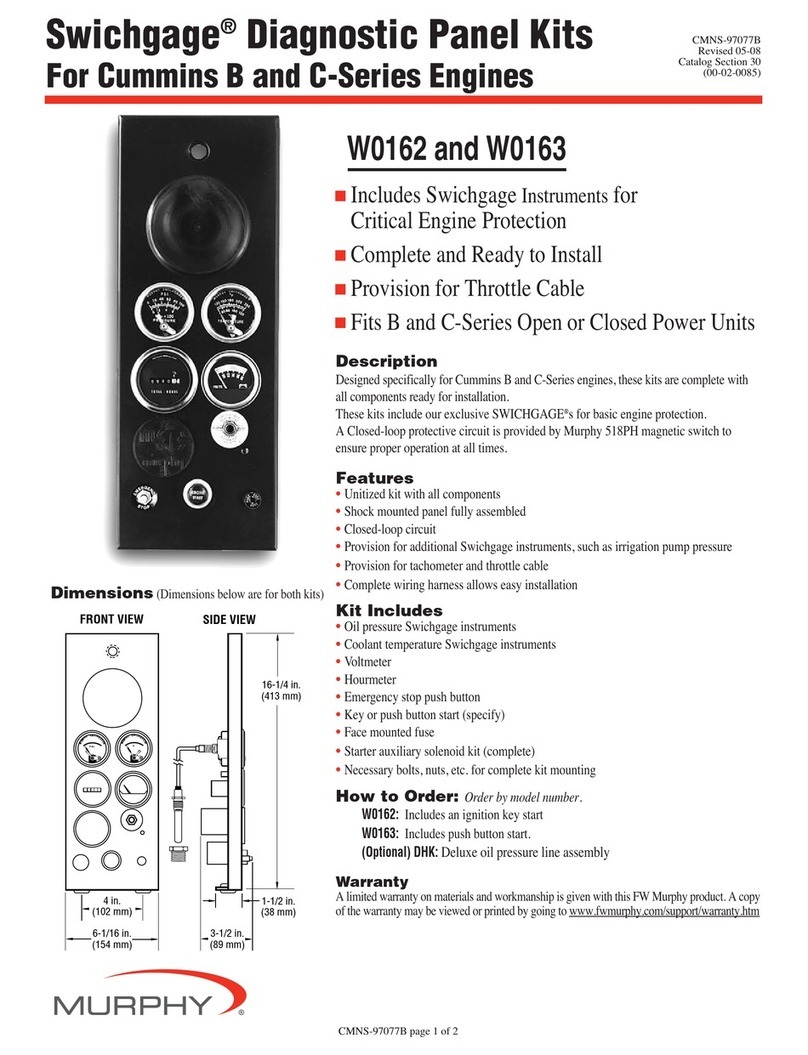

Direct Installation into the Wall of the

Pressure Vessel

1. Determine that the float travel is not

obstructed by the coupling in the

vessel wall, internal baffles, etc.

Do NOT use more than one

float shaft extension P/N

15000478.

2. BE SURE that the float and

extension are tight.

3. Before installing the level

switch, use of a pipe thread

sealant is recommended. Screw

the unit directly into the threaded

connection in the wall of the pressure

vessel.

4. For LS200 and L1100 be sure that the electrical connection is

positioned at the bottom.

5. For LS200N the 1/8” NPT pneumatic connection should be on top

(the 3/8” NPT vent connection should be on the bottom) for

service on a “Trip on Rising” application. The LS200N can be

rotated 180° for service on a “Trip on Falling” application.

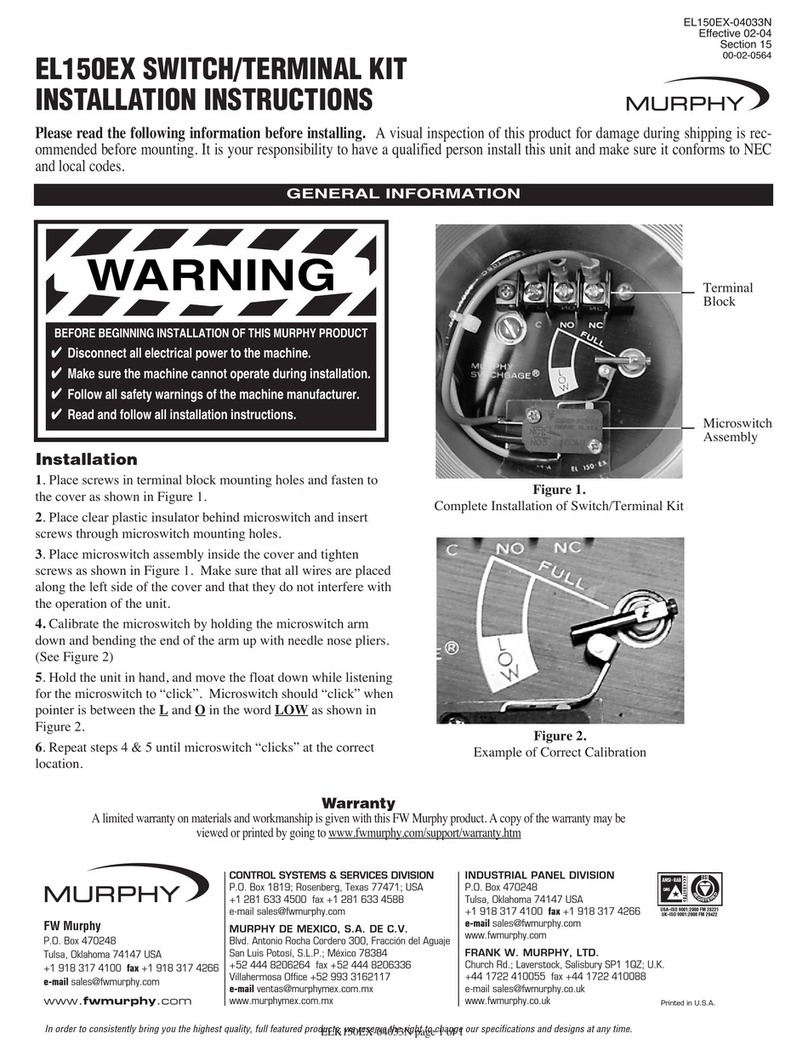

6. Make the electrical wiring connections according to

appropriate wiring diagrams for the alarm or shutdown

system to be used. The electrical connection is 1/2”-14 NPT.

7. BE SURE all electrical connections are insulated and the

cover is fully installed before reconnecting electrical power.

8. BE SURE all pressure connections are tight before

pressurizing the system.

Installation with a Weld Collar

1. The weld collar, P/N 15050375, must be welded into the wall

of the pressure vessel according to

code standards and good

welding practices.

2. Follow above instructions

for installation directly

into the wall of the

pressure vessel.

3. NOTE: Weld collar

15050375 can be used

ONLY with model LS200.

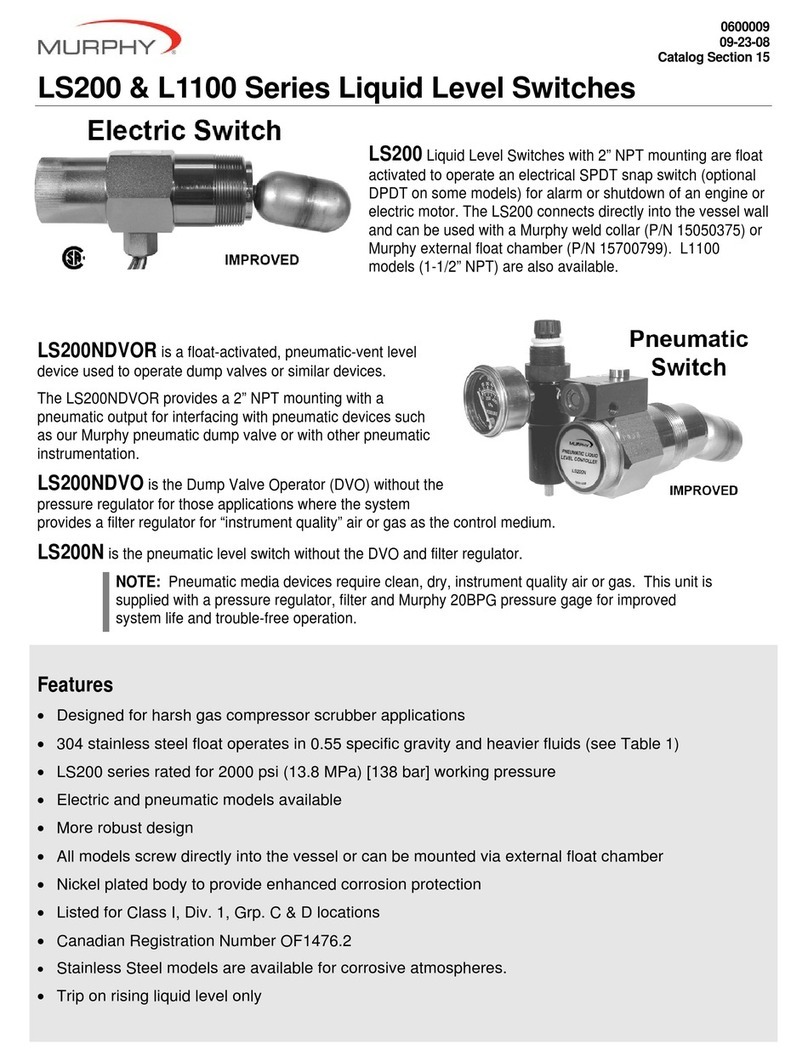

Installation Using

External

Float Chamber 15051098

1. Install the float chamber 15051098 on the outside wall of the

pressure vessel using 1” NPT piping or use the mounting

surface with a bracket. Position the 2” NPT threaded

connection at the height where you want the level switch to

operate. The 2” NPT threaded connection must be positioned

away from the tank wall.

2. A tee and bleed valve are typically installed at the bottom of the lower 1

inch pipe riser to allow draining of the float chamber for servicing or

replacement.

NOTE: A typical installation with Blocking and

Bleed valves is shown at right.

3. Install the LS200 or

LS200N/NDVO/NDVOR

in the 2” NPT connection of

the float chamber.

BE SURE float travel

is not restricted and that

the float is tight onto

the float shaft.

4. To complete installation and

wiring, follow the instructions for

mounting directly into wall of

the vessel and for wiring.

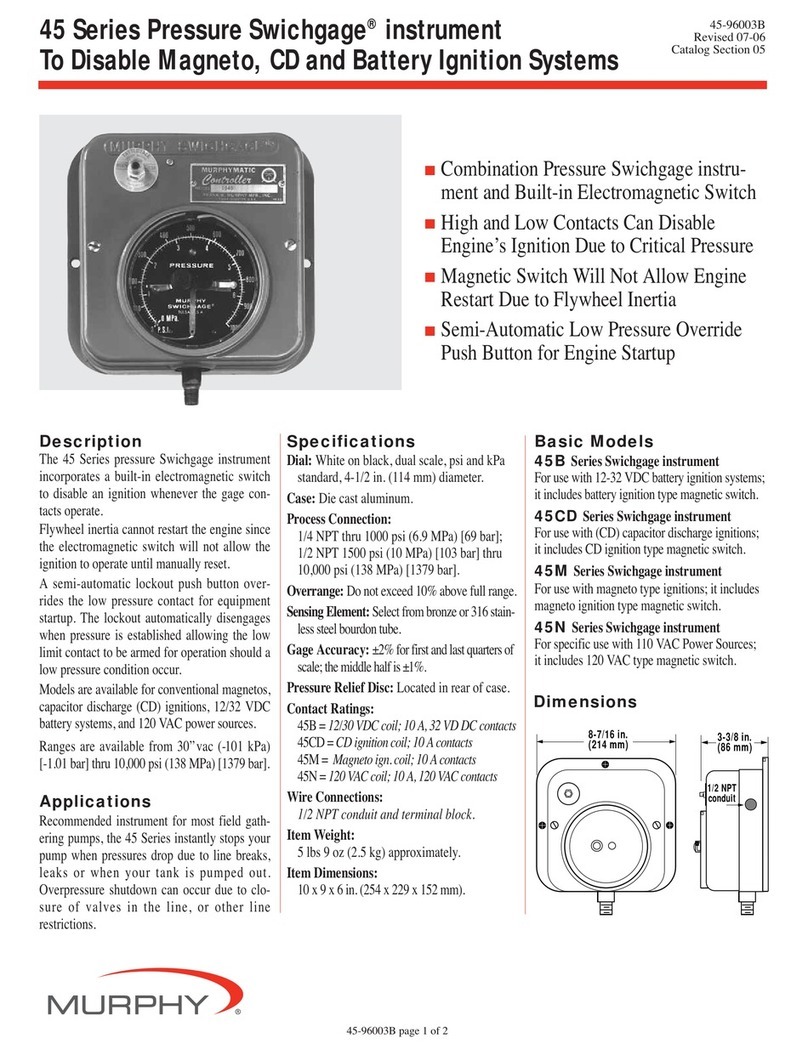

Pneumatic Models

1. All pneumatic models

operate on the vent

principle.

The pneumatic signal

source must be clean and

dry“Instrument

Quality”air or natural

gas.

The input pneumatic signal

must be regulated between 30

and 70 psi (207-483 kPa) [2 -4.83

bar].

If produced gas is used as the signal source,

it should be taken after gas passes through the final scrubber.

A suitable filter must be positioned before the LS200NDVO to prevent

liquids and/or particulates from entering the dump valve operator.

NOTE: Check filter periodically for wear and tear and elements

that hamper the flow of the pneumatic signal.

2. All pressure connections must be tight and maintained tight so as

not to leak air/gas.

3. Valve seat adjustment can be made if air/gas begins to leak. Care

should be taken when adjusting as only slight movement is necessary

to stop the leakage; excessive force will bind the seating mechanism.

See the instruction below for adjustment.

PRESSURE VESSEL INSTALLATION: LS200, LS200N and L1100