ELWA®Modbus Interface Operation Manual, 171018

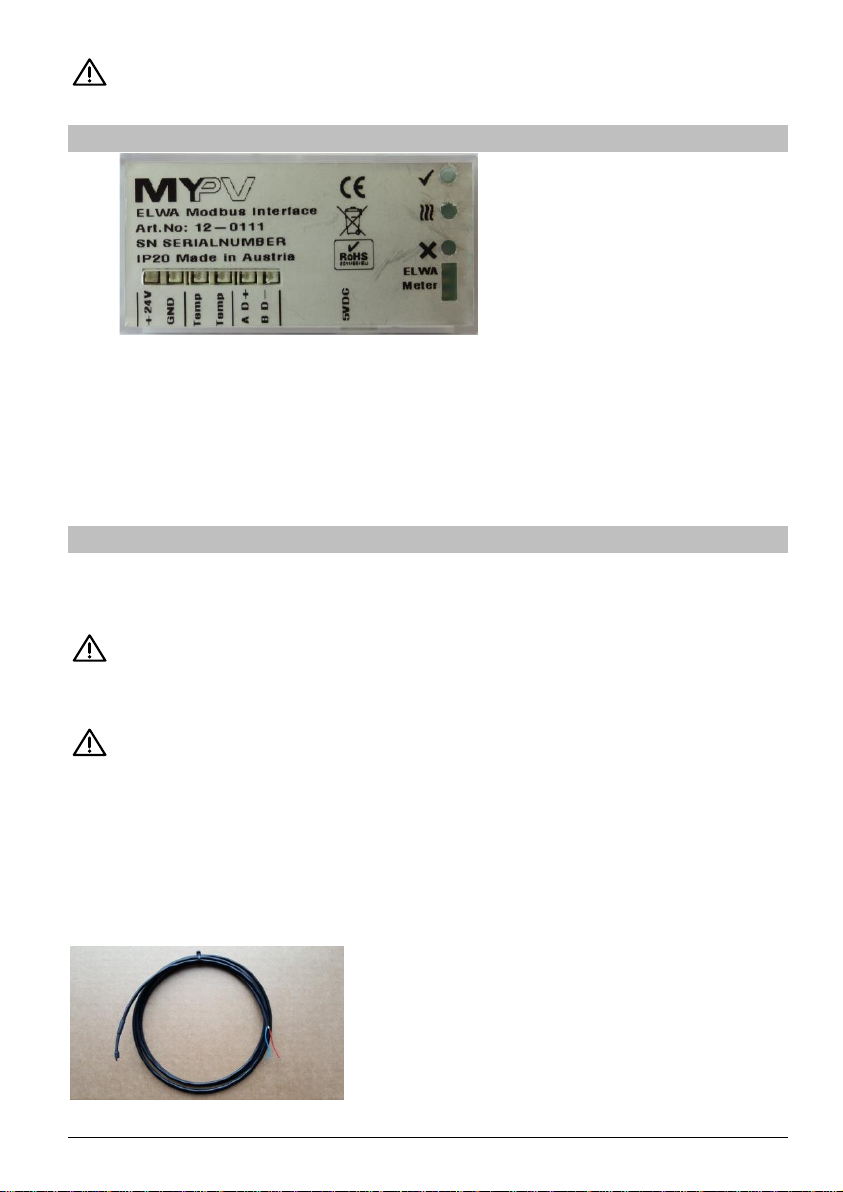

If the sensor (see figure) indicates a value >80 °C the pins may not be connected correctly or

there might be a sensor break. A negative value can be an indication of a short circuit.

Terminating resistor in the bus system

Bus systems are high-resistive. For this reason, a terminating resistor (120 Ohm) must be set,

ideally at the most remote location of the bus master. The resistance is included in the package.

6. Modbus register description

Modbus RTU Standard, Comm parameters 9600/8/N/1, All registers unsigned int (16 bit)

Register Address mode Content

1000 R Operating Day Counter

1001 R/W Operation mode (see Table 1), write 1 skips 10 minutes startup delay

1002 R DC Breaker status, 0: open, 1: closed

1003 R DC Relay status, 0:open, 1: closed

1004 R/W AC Relay status, 0: open, 1: closed, write to register starts/stops ELWA AC relay

1005 R Temperature in 1/10°C

1006 R Current Water Temp Day minimum in 1/10°C

1007 R Current Water Temp Day maximum in 1/10°C

1008 R DC Temp Setting in 1/10°C

1009 R/W AC Temp Setting In 1 / 10°C

1010 R Internal Temperature of Electronics in °C

1011 R DC Isolation value

1012 R DC Voltage 0.1V

1013 R DC Current mA

1014 R DC Power in W

1015 R Current Day DC Energy in Wh

1016 R Total DC Energy kwh

1017 R Current Day AC Energy in Wh

1018 R Internal clock (minutes from noon)

1019 R Minutes since current day wakeup

1020 R/W AC boost mode, AC switch on time in minutes from noon

0 ELWA internal temperature controlled

1-1440 ELWA internal time controlled in minutes from noon

>1440 ELWA internal control off, controlled via ELWA Modbus Interface