© Ernst Nagel GmbH 2S Trimmer Service Manual en.doc Rev.1.0. 20.07.2011

3

Contents

TITLE PAGE

CONTENTS....................................................................................................................................................... 3

1. SAFETY..................................................................................................................................................... 5

2. GENERAL.................................................................................................................................................. 6

2.1 BASIC INFORMATION ................................................................................................................................... 6

2.1.1 Basic Information............................................................................................................................... 6

2.1.1 Type of machine and TAG ................................................................................................................ 7

2.2 GETTING TO KNOW THE STR....................................................................................................................... 8

2.2.1 Main components overview............................................................................................................... 8

2.2.2 Components overview Inside............................................................................................................ 9

2.2.2 Components overview Inside.......................................................................................................... 10

2.2.3 Components overview Interlock breaker & Safety block for knife beam......................................... 13

2.2.4 Components overview I-CAN plug & Mode Selection plug............................................................. 14

2.2.5 Rollers and Belts ............................................................................................................................. 15

2.2.6 Interface signals explanation........................................................................................................... 18

3. GLOBAL FUNCTIONALITY DESCRIPTION.......................................................................................... 19

3.1 BYPASS MODE .......................................................................................................................................... 20

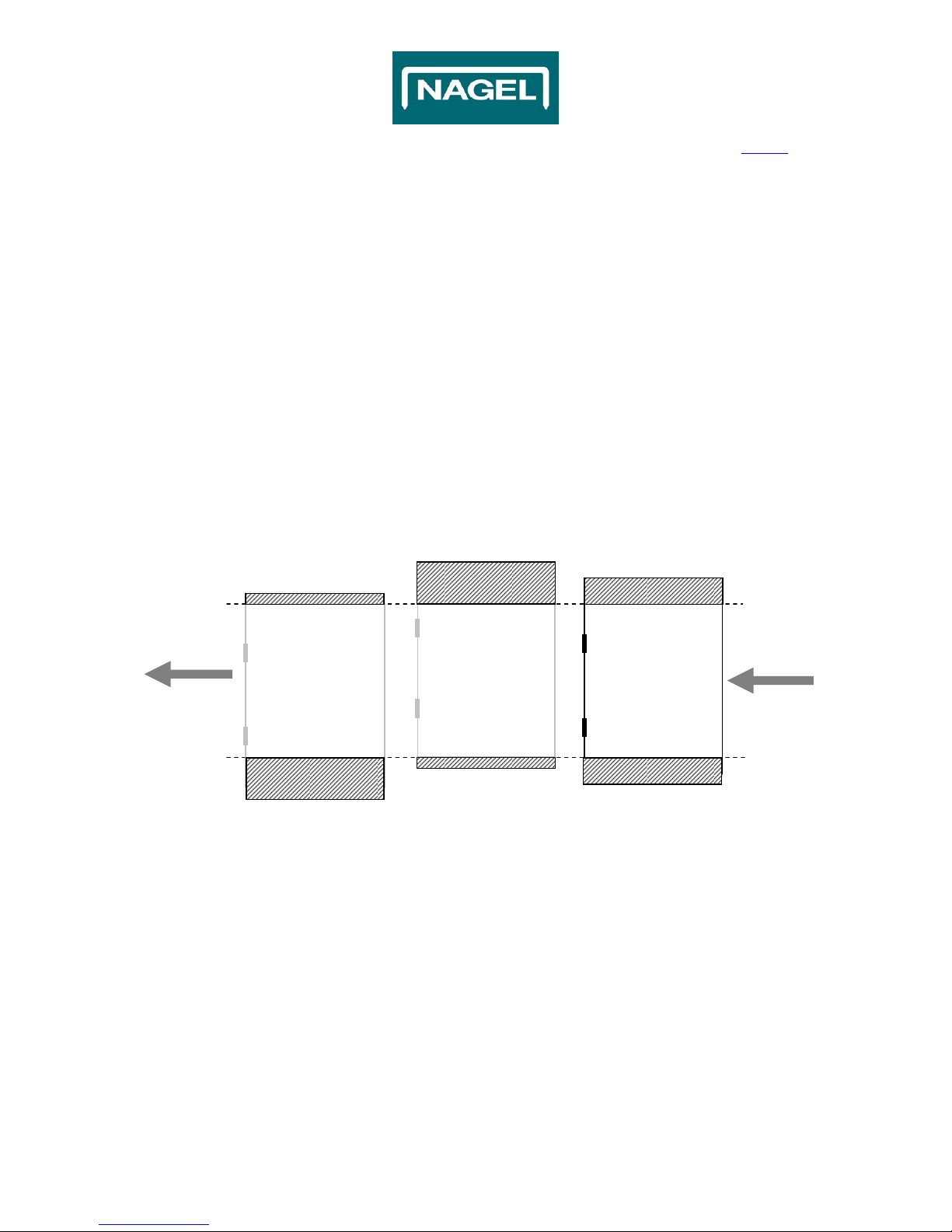

3.2 TRIMMING MODE ....................................................................................................................................... 24

4. COVERS.................................................................................................................................................. 29

4.1 FRONT COVER ......................................................................................................................................... 29

4.2 REAR COVER ........................................................................................................................................... 30

4.3 UPPER INFEED COVER.............................................................................................................................. 31

4.4 LOWER INFEED COVER ............................................................................................................................. 32

4.5 UPPER OUTFEED COVER .......................................................................................................................... 33

4.6 LOWER OUTFEED COVER.......................................................................................................................... 34

4.7 BASE PLATE COVER ................................................................................................................................. 35

4.8 USER INTERFACE COVER .......................................................................................................................... 36

5. TROUBLESHOOTING............................................................................................................................. 37

5.1 SERVICE PROGRAM MODE......................................................................................................................... 37

5.1.1 Software Version............................................................................................................................. 38

5.1.2 Diagnostics...................................................................................................................................... 39

5.1.3 Motors.............................................................................................................................................. 40

5.1.4 Solenoids......................................................................................................................................... 41

5.1.5 Sensors and Switches..................................................................................................................... 42

5.1.6 Voltmeters ....................................................................................................................................... 43

5.1.7 Non Volatile Memory (NVM)............................................................................................................ 44

5.1.8 Dead cycle....................................................................................................................................... 45

5.1.9 Calibration ....................................................................................................................................... 46

5.2 FAULT CODE DESCRIPTIONS ..................................................................................................................... 47

5.3 FAULT CODE SOLUTIONS .......................................................................................................................... 49

6. DEFAULT / BASIC ADJUSTMENTS...................................................................................................... 80

6.1 REPLACING KNIVES .................................................................................................................................. 80

6.1.1 Preparation...................................................................................................................................... 80

6.1.2 Removal Upper Knife...................................................................................................................... 81

6.1.3 Removal Lower Knife...................................................................................................................... 82

6.1.4 Placement Lower Knife ................................................................................................................... 83

6.1.5 Placement Upper Knife ................................................................................................................... 84

6.1.6 Adjustment Upper Knife .................................................................................................................. 85

6.1.7 Adjustment Lower Knife .................................................................................................................. 86