Quick reference guide only. Avoid accidents. Read and strictly

follow complete manual on back and at www.naild.it

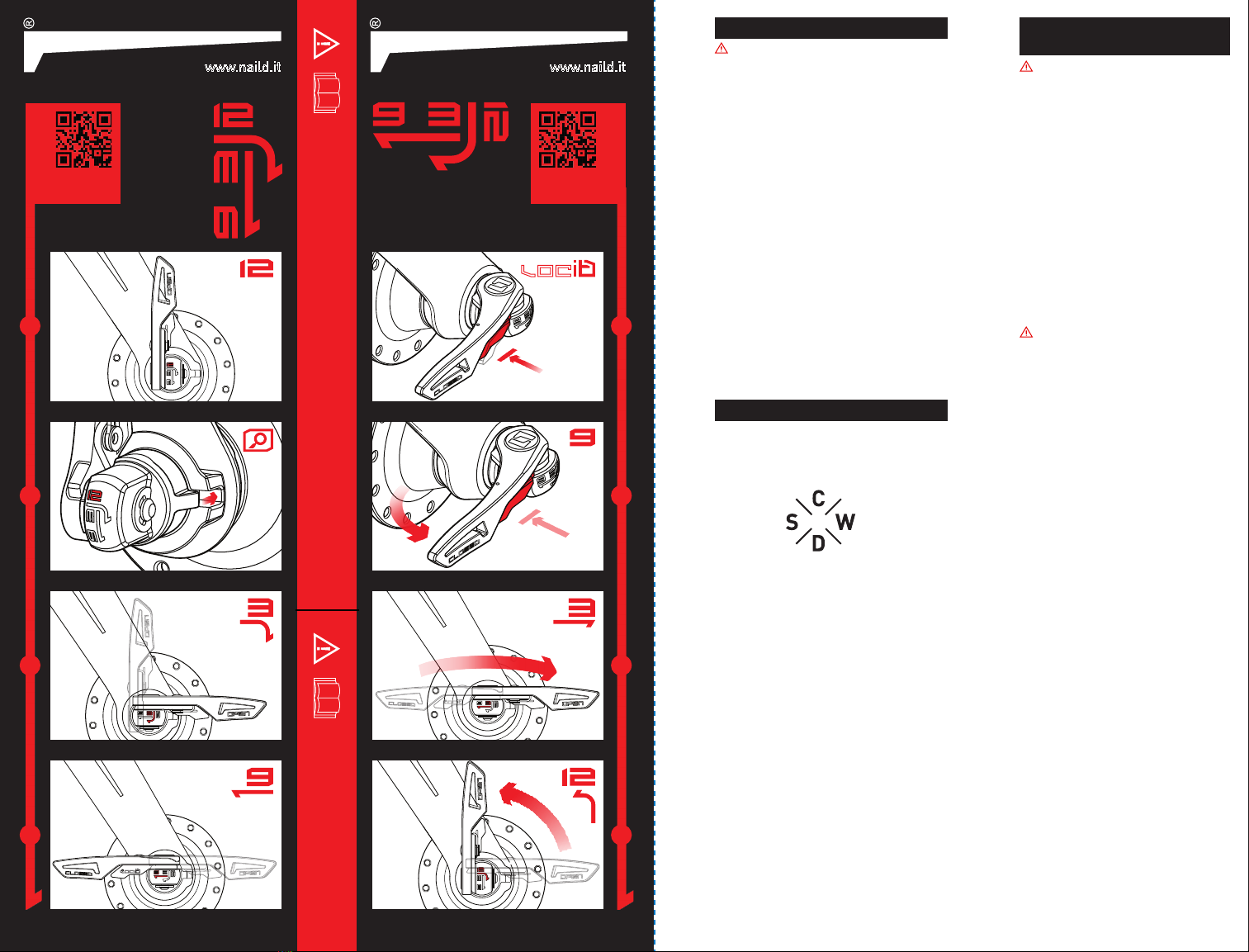

QUICK GUIDE to be

removed by user only

INSTALL

AXLE

QUICK GUIDE

www.naild.it

1

2

3

4

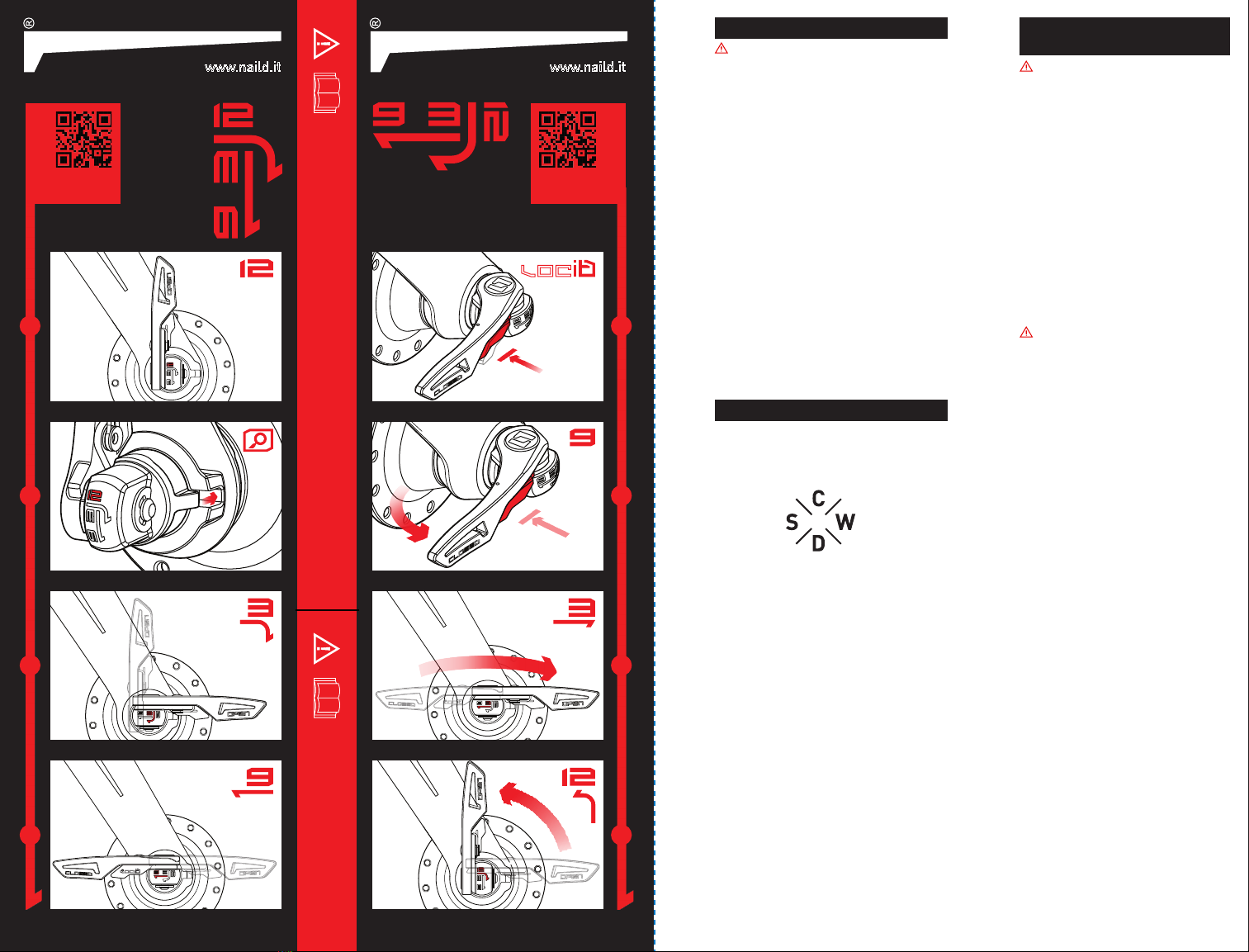

REMOVE

AXLE

QUICK GUIDE

www.naild.it

1

2

3

4

WARNING: BEFORE USING THIS PRODUCT,

READ, UNDERSTAND AND FOLLOW THE

WARNINGS AND INSTRUCTIONS PROVIDED

IN THIS MANUAL. IMPROPER INSTALLATION

CAN RESULT IN SEVERE PERSONAL INJURY

OR DEATH.

If you have any questions, contact the place of

purchase, or a bicycle dealer. A dealer’s manual

for professional and experienced bicycle

mechanics is available on our website (www.

naild.it).

Never use tools to operate the 12-3-9® system

as damage may occur. Hand pressure is all that

is needed.

Do not disassemble or alter this product.

Products are not guaranteed against natural

wear or deterioration from normal use and

aging. See www.naild.it for warranty terms

and conditions.

For maximum performance timely and

appropriate service is mandatory. If unclear

whether the product is in need of service or

repair, contact the place of purchase or a

bicycle dealer.

GENERAL NOTICE GENERAL SAFETY

GUIDELINES

WARNING: BEFORE USING THIS

PRODUCT, READ, UNDERSTAND

AND FOLLOW THE WARNINGS AND

INSTRUCTIONS PROVIDED IN THIS MANUAL.

IMPROPER INSTALLATION CAN RESULT IN

SEVERE PERSONAL INJURY OR DEATH.

The 12-3-9® system requires specific

features that are integral to the frame

and fork for proper use of the system.

Never use the 12-3-9® system on non-

compatible frames and forks. For a list of

compatible frames and forks please visit

www.naild.it

The 12-3-9® system is not compatible with

some hub designs. Do not attempt to use

the 12-3-9® system with non-compatible

hubs. For a list of compatible hubs please

visit www.naild.it.

EVERY TIME YOU RIDE

WARNING: Clamping forces should be

checked before every ride and any time the

wheel is removed and reinstalled. Before

attempting to install the 12-3-9® system

always inspect all surfaces to make sure

they are clean and free from debris and

other matter that would prevent full

engagement.

The 12-3-9® system has been carefully

engineered to be easy and intuitive to set

up and use. Once set up properly and

maintained according to the instructions

in this manual the 12-3-9® system is

very stable and should require very little

adjustment. However, the following safety

guidelines should always be observed to

ensure your 12-3-9® equipped bike is safe

and read to ride.

Always check your 12-3-9® system before

riding to make sure that the wheels are

correctly installed on the bicycle frame.

See www.naild.it for warranty terms and

conditions. Make sure that the 12-3-9®

system levers are in the CLOSED position

with the Locit® trigger fully engaged and

the CLOSED inscription on the end of the

lever visible.

Lift up the bicycle so that the wheel is off

the ground, and give the top of the tire a

few sharp downward blows as shown in the

diagram. The wheel should not be loose or

come off. Also check for side-to-side play

and make sure the disc rotors are properly

aligned and not rubbing. If the rotor is

rubbing then open the 12-3-9® system

and make sure that everything is clean and

properly adjusted and try again.

A misaligned rotor can cause the brakes

to fail resulting in severe personal injury

or death. If you are unsure how to properly

align your brake rotors take the bike to a

dealer or qualified bicycle mechanic.

These checks do not guarantee that the

quick release lever has received adequate

tightening torque. If you are uncertain as to

whether the 12-3-9® system is tightened

correctly, repeat the INSTALL AXLE AND

ADJUSTMENT section of this guide.

The Naild 12-3-9® system employs the

Quadrant Code System to provide a quick visual

reference to the appropriate use, warranty

period, durability and recommended service

intervals. Please refer to the markings on your

product in reference to the Quadrants shown

herein.

Category of Use (C)- the type of riding the

product was intended for on a scale of 1 through

9 with 1 being light recreational use and 9 being

downhill or freeride use.

Warranty Period (W)- warranty period in

months.

Durability Index (D)- level of expected

durability where a higher number indicates a

greater margin of strength and durability within

a given usage category.

Service Interval (S)- recommended service

interval in hours, e.g., 20 would indicate that

the product should be serviced every 20 hours

of riding time.

Regularly clean and inspect your 12-3-9®

system for wear or damage. For example,

lubricating the inside of the Axle Assembly

with a high quality, waterproof grease will help

ensure top performance and extend the life of

the parts. If you are unsure how to clean and

inspect your 12-3-9® system take it to your

place of purchase or a qualified bicycle dealer.

The 12-3-9® system carries a 36 months

warranty on parts and assembly. See www.

naild.it for warranty terms and conditions. A

few things to note will help extend the life of

the system and ensure years of trouble-free

riding. Never force the system to open or close.

Never use anything other hand pressure to

operate the system, no tools are ever required.

Depressing the Locit® trigger until it has fully

disengaged from the lever will prolong it’s life.

QUADRANT CODE SYSTEM