CT-2

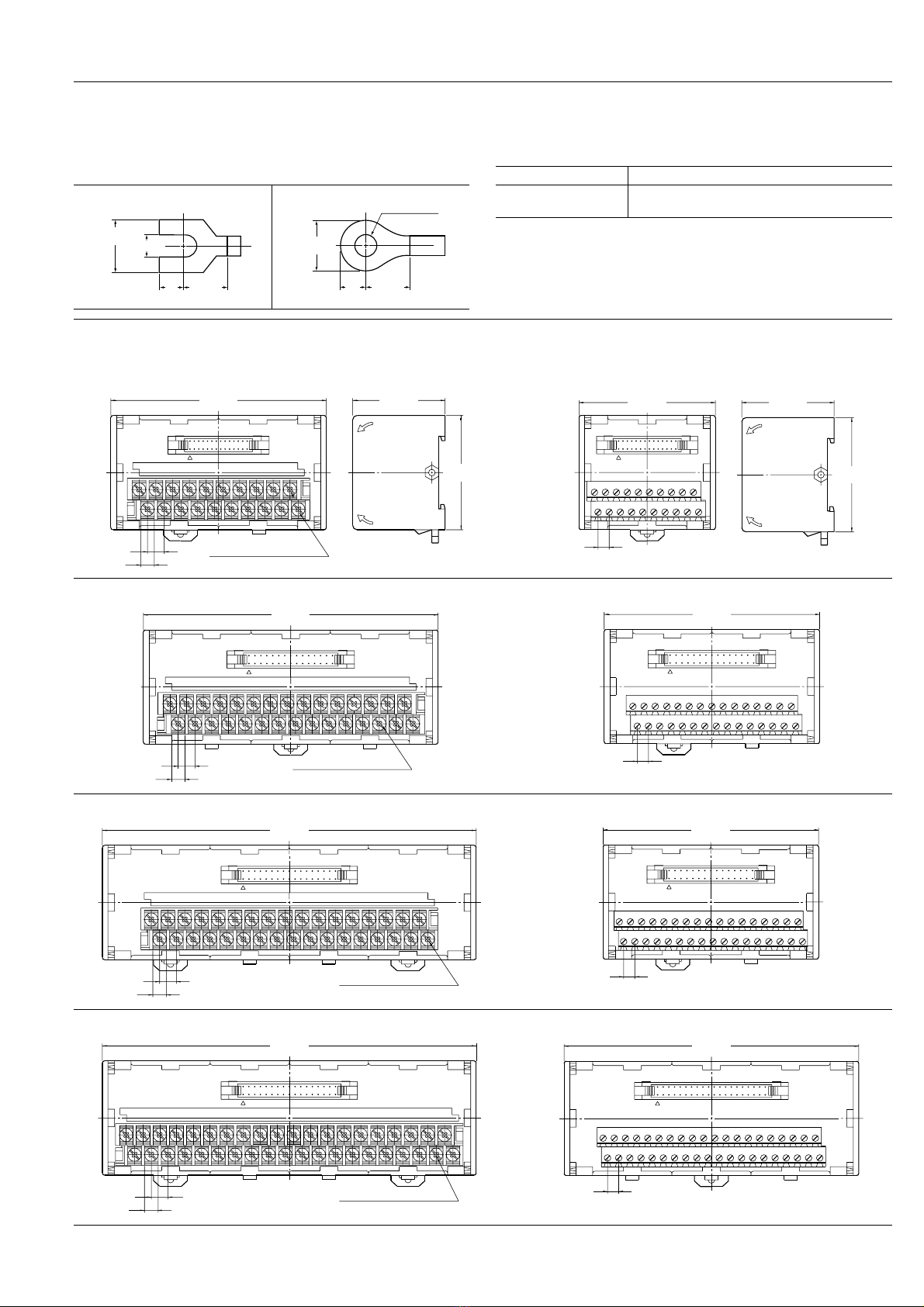

SCHEMATIC (Top View)

20 poles

30 poles

34 poles

40 poles

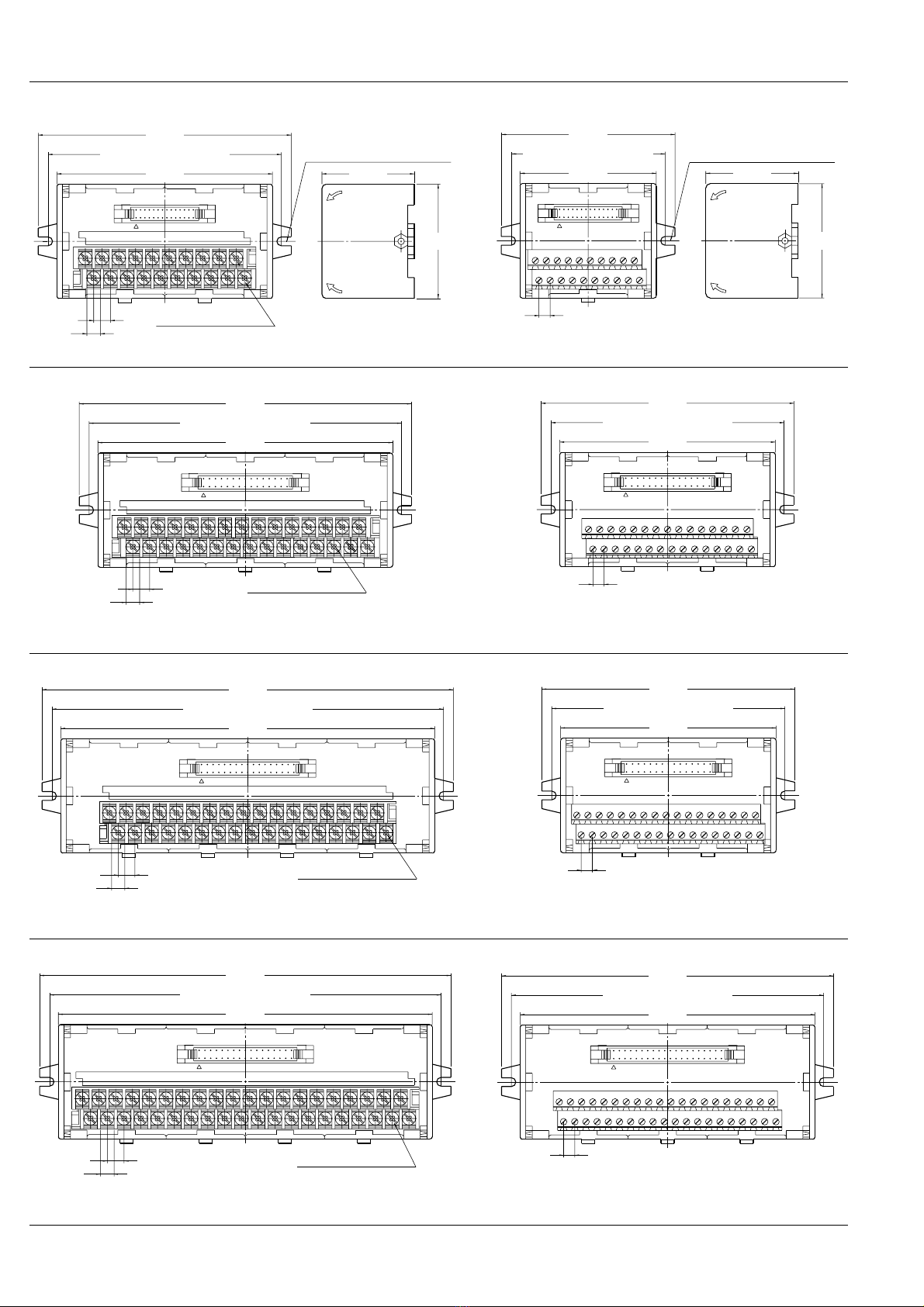

A

A

1Connector No.

Terminal No.

(from left on the lower stage)

2345678910

12345678910

B

B

1Connector No.

Terminal No.

(from left on the upper stage)

2345678910

12345678910

A

A

1 2 3 4 5 6 7 8 9 101112131415

1 2 3 4 5 6 7 8 9 101112131415

B

B

1 2 3 4 5 6 7 8 9 101112131415

1 2 3 4 5 6 7 8 9 101112131415

Connector No.

Terminal No.

(from left on the lower stage)

Connector No.

Terminal No.

(from left on the upper stage)

A

A

1 2 3 4 5 6 7 8 9 1011121314151617

1 2 3 4 5 6 7 8 9 1011121314151617

B

B

1 2 3 4 5 6 7 8 9 1011121314151617

1 2 3 4 5 6 7 8 9 1011121314151617

Connector No.

Terminal No.

(from left on the lower stage)

Connector No.

Terminal No.

(from left on the upper stage)

A

A

1 2 3 4 5 6 7 8 9 1011121314151617181920

1 2 3 4 5 6 7 8 9 1011121314151617181920

B

B

1 2 3 4 5 6 7 8 9 1011121314151617181920

1 2 3 4 5 6 7 8 9 1011121314151617181920

Connector No.

Terminal No.

(from left on the lower stage)

Connector No.

Terminal No.

(from left on the upper stage)

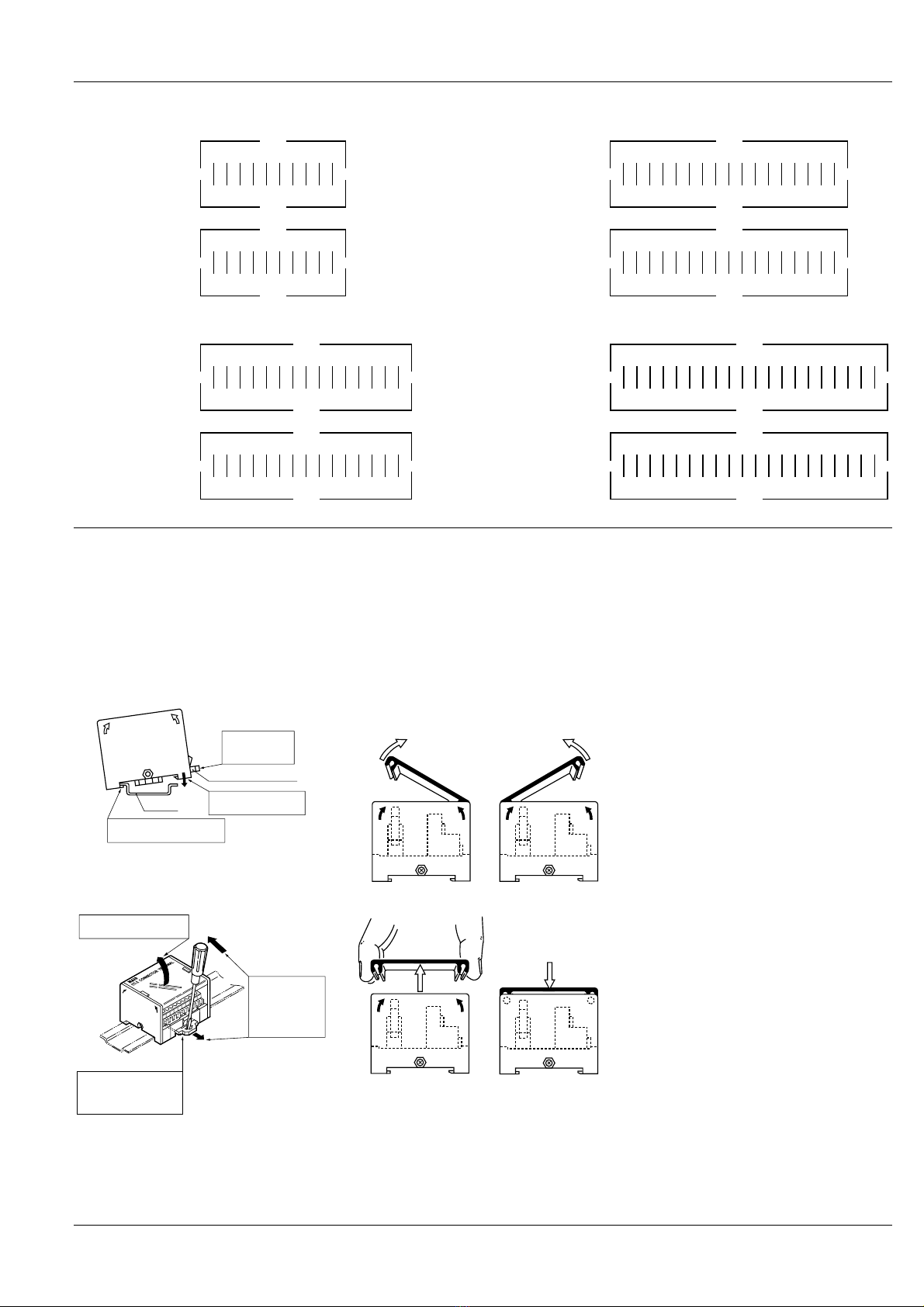

CAUTIONS FOR USE

1. Installation

1) Perform mounting hole cutout accord-

ing to the panel cutout drawings.

2) When installing the unit on a DIN rail,

use the DIN rail locking lever on the side

of the unit. Installation is accomplished by

simply fitting the unit onto the rail and

pressing gently.

3) To remove the unit from the DIN rail,

use a flat head screwdriver to pull out the

DIN rail locking lever.

4) Be careful not to drop or shock the unit.

Excessive shock such as dropping may

cause damage or malfunction.

2. Removal of cover

1) Insertions and withdraws of connector

can be done by lifting the cover like

1

.

2) Wiring to the terminal can be done by

lifting the cover like

2

.

3) Removal of the cover can be done by

lifting it like

3

.

4) In case of resetting the cover, please

push the cover like

4

.

3. Wiring and circuit configuration

1) Make all connections according to the

schematic.

2) When wiring power lines or power ca-

bles, twisted pair treatment (standed wire

treatment) should be done in order to im-

prove noise resistance.

3) In order to improve noise resistance,

class 3 grounding of the control panel is

recommended.

4) Turn off the power before connecting/

disconnecting connector cables.

4. Operating environment

1) Use the product at ambient operating

temperature between 0

°

C and 55

°

C 32

°

F

and 131

°

F.

2) The main unit is made of resin; there-

fore, do not use it in areas where it may

come in contact with (or be exposed to)

organic solvents such as benzine, thinner,

and alcohol or strong alkaline substances

such as ammonia and caustic soda.

3) Do not use the product in areas where

it may be exposed to flammable gases,

corrosive gases, excessive dust, or mois-

ture, or areas where it may be subjected

to strong vibration or shock.

5. Transporting and storage

1) If the product is subjected to extreme

vibration while being transported, the re-

lays may become detached, the lead may

become bent, and the unit may become

damaged. Handle the inner and outer

boxes with care.

2) If the product is stored in an extremely

adverse environment, visible defects and

deterioration of performance characteris-

tics may result. We recommend the fol-

lowing storage conditions.

•Temperature: 5 to 30

°

C 41 to 86

°

F

•Humidity: Max. 60% R.H.

•Environment: No hazardous sub-

stances such as sulfurous acid gases

and little dust.

DIN rail locking lever

DIN rail

1

2

3

First push in

the DIN rail

locking lever.

Hook the holders on the

unit over the DIN rail.

Press the unit onto

the DIN rail.

1

2

3

Insert the tip of the

flat head screwdriver

into the slot in the

DIN rail locking lever.

Move the

screwdriver in

the direction

of the arrows,

and pull out

the lever.

Remove the unit from

the DIN rail.

12

34

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.