23

Safety Precautions

English

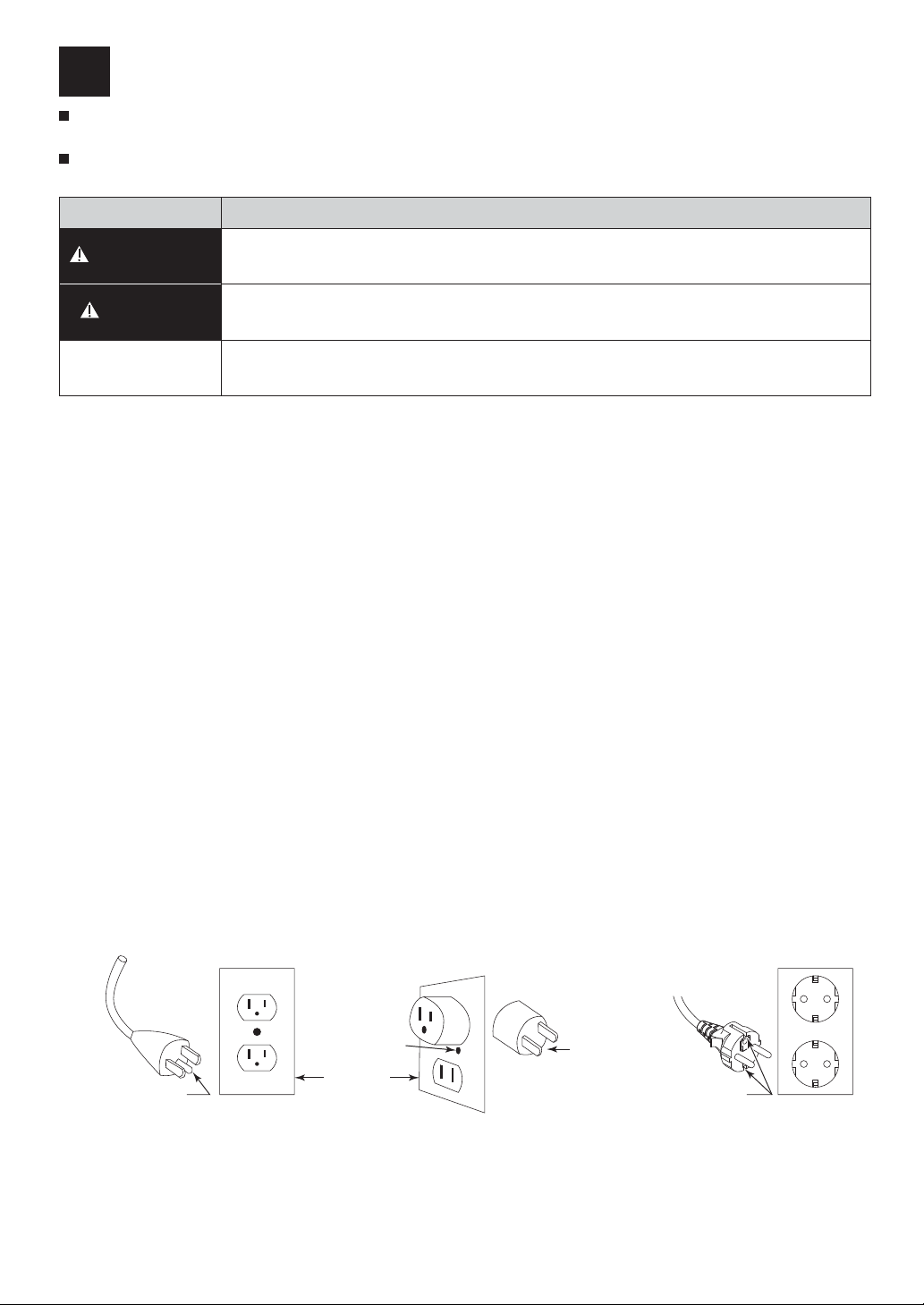

Ampere Rating Volts Total length of cord

120V

240V 7.5m (25ft.)

15m (50ft.) 15m (50ft.)

30m (100ft.) 30m (100ft.)

60m (200ft.) 45m (150ft.)

90m (300ft.)

More Than Not More

Than

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

Use the table above for your correct voltage.

WARNING

ƔFor safety reasons, always wear protective gloves and goggles when using this product.

ƔDo not drop or impact the product. Strong impacts may result in deformation or damage.

ƔDo not modify or disassemble this product in any way that is not described in the instruction manual. This can

have a significant impact on performance and safety. If the controller is disassembled, you may receive an

electric shock due to the high voltage section inside. In the event of malfunction or repair, please contact the

place of purchase for repair.

ƔBe sure to ground the grounding wire of the power cord before use. Failure to do so may result in a malfunction,

fire or electric shock.

ƔDo not use this product in an unventilated room where there is a risk of explosion or near flammable materials. If

the tool is in contact with flammable materials for a long periods of time in an oscillating state, it may ignite.

ƔUse the controller at room temperature in the range of 10 - 40°C (75 - 104ºF), with no condensation.

Condensation may cause a short circuit or an electric shock.

ƔAvoid installing the controller in the vicinity of high temperature, high humidity, condensation, corrosive or

explosive gases, flammable gases, salt damage, and direct sunlight. Failure to do so may result in a malfunction,

fire or electric shock.

ƔThe bottom of the controller also serves as a heat sink. Install it so that the space between it and the work desk

is not blocked. A temperature increase can occur inside the controller, causing failure.

ƔIf there is any dust or damage to the threaded part of the blade holder, handpiece, or blade mountings, normal

oscillation will not be possible. It can also cause the handpiece to heat up. In addition,the handpiece maygenerate

heat,so be sure to remove any dust before use.

ƔMake sure the blade is securely installed. If it is not secured firmly, it will cause a loss of power and heat in the

handpiece.

ƔDo not touch the blade or horn during ultrasonic vibration or immediately after the output stops. The blade and

horn parts may become hot and may cause injury or burns.

ƔIf oil or other contaminants get into the handpiece, it may cause a malfunction. Do not lubricate the handpiece.

ƔDamaged main power cord must be replaced with new cord as they may cause fires or electric shock due to a

short circuit. Please contact us or your local distributor for details.

ƔWhen shipped, the handpiece comes with a blade attached. Remove the cap to avoid touching the blade and

causing injury.

ƔIf the blade is over-tightened or cracked, turning the ON / OFF key to "ON" may cause the blade to break off and

fall out oftheholder.