INDEX

REFERENCE GUIDE .......................................................................................................................... 1

GENERAL ............................................................................................................................................ 2

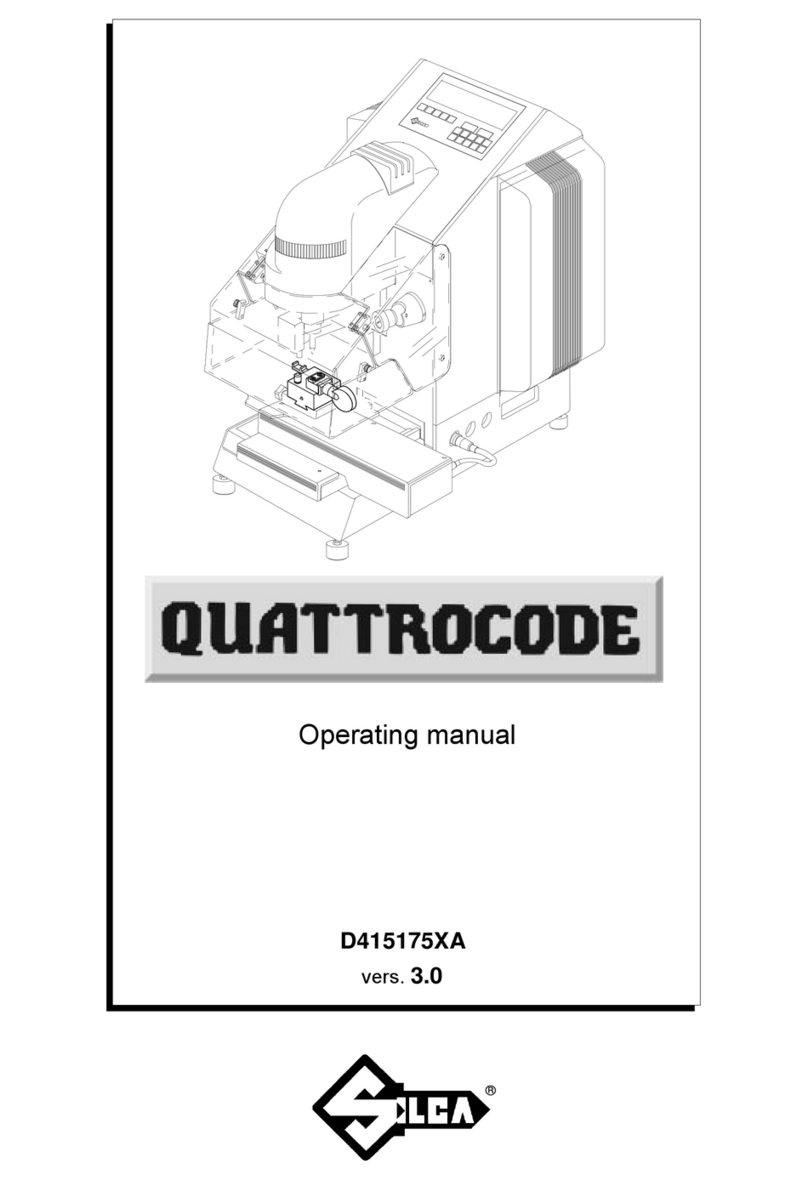

1 MACHINE DESCRIPTION ..........................................................................................................4

1.1 MAIN CHARACTERISTICS ..........................................................................................................4

1.2 SAFETY ...................................................................................................................................5

1.3 MAIN WORKING PARTS .............................................................................................................6

1.4 TECHNICAL DATA ....................................................................................................................8

1.5 ACCESSORIES PROVIDED .........................................................................................................9

2 TRANSPORT ............................................................................................................................10

2.1 PACKING ...............................................................................................................................10

2.2 UNPACKING ...........................................................................................................................11

2.3 MACHINE HANDLING ...............................................................................................................11

3 MACHINE INSTALLATION AND PREPARATION ..................................................................12

3.1 CHECKING FOR DAMAGE ........................................................................................................12

3.2 ENVIRONMENTAL CONDITIONS ................................................................................................12

3.3 POSITIONING AND INSTALLATION .............................................................................................12

3.4 DESCRIPTION OF WORK STATION ............................................................................................13

3.5 GRAPHICS .............................................................................................................................13

4 “SET UP” AND USE OF THE MACHINE .................................................................................14

4.1 USE OF THE CLAMP ...............................................................................................................14

4.2 FITTING THE CLAMP TO THE MACHINE .....................................................................................16

4.3 CUTTER ................................................................................................................................16

4.4 CHANGING THE CUTTER .........................................................................................................16

5 OPERATING GUIDE .................................................................................................................17

5.1 ON-BOARD KEYPAD AND FUNCTIONS ......................................................................................17

5.2 PRELIMINARY OPERATIONS ....................................................................................................18

5.3 COPY BY DATA CARD ............................................................................................................19

5.3.1 FAVOURITE DATA CARDS ................................................................................................. 24

5.3.2 ACCESSORY FUNCTIONS FOR “COPY BY DATA CARD” ........................................ 25

5.4 SPECIAL CASES ................................................................................................................31

5.4.1 CUTS NOT ALLOWED ....................................................................................................... 31

5.4.2 LIMITED ACCESS TO DATA (PROTECTED SYSTEMS) ........................................................... 32

5.5 PC QUEUE FUNCTION ........................................................................................................33

5.6 CODEMAKER CARD MANAGEMENT ...................................................................................... 36

5.7 GAUGING ...........................................................................................................................40

5.7.1 CALIBRATE STANDARD JAWS ...................................................................................... 41

5.7.2 CALIBRATE CUTTERS ................................................................................................... 43

5.7.3 CALIBRATE ADAPTERS ................................................................................................. 43

5.8 MAINTENANCE ..................................................................................................................44

5.8.1 MOTOR TESTS ............................................................................................................ 44

5.8.2 DIGITAL INLETS TEST ................................................................................................ 44

5.8.3 DIGITAL OUTLETS TESTS .......................................................................................... 45

5.8.4 KEYPAD TEST ............................................................................................................. 45

5.8.5 DISPLAY TEST ............................................................................................................ 45

5.8.6 SERIAL PORT .............................................................................................................. 45

5.8.7 MACHINE ZERO POINTS ............................................................................................ 46

5.8.8 PHOTOCELLS AND SENSORS REGULATION .......................................................... 49

5.9 OPTIONS ............................................................................................................................52

5.10 ENABLING ..........................................................................................................................55

5.11 MESSAGES ............................................................................................................................56

5.11.1 ATTENTION MESSAGES .................................................................................................... 56

5.11.2 ERROR MESSAGES .......................................................................................................... 58

5.11.3 ALARM MESSAGES .......................................................................................................... 59

5.11.4 CODEMAKER MESSAGES .............................................................................................. 60