13 14

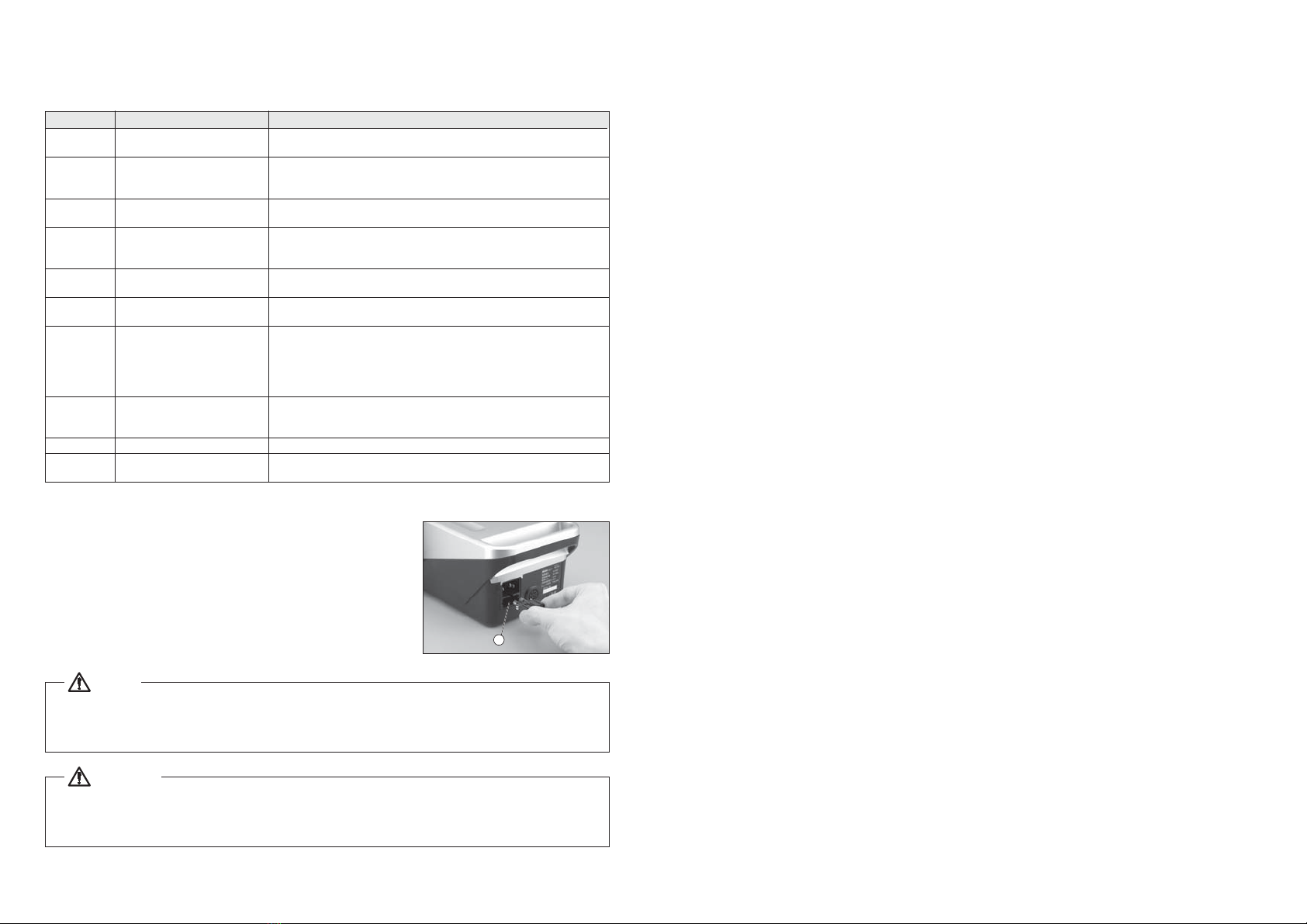

Trouble Cause/Check Remedy

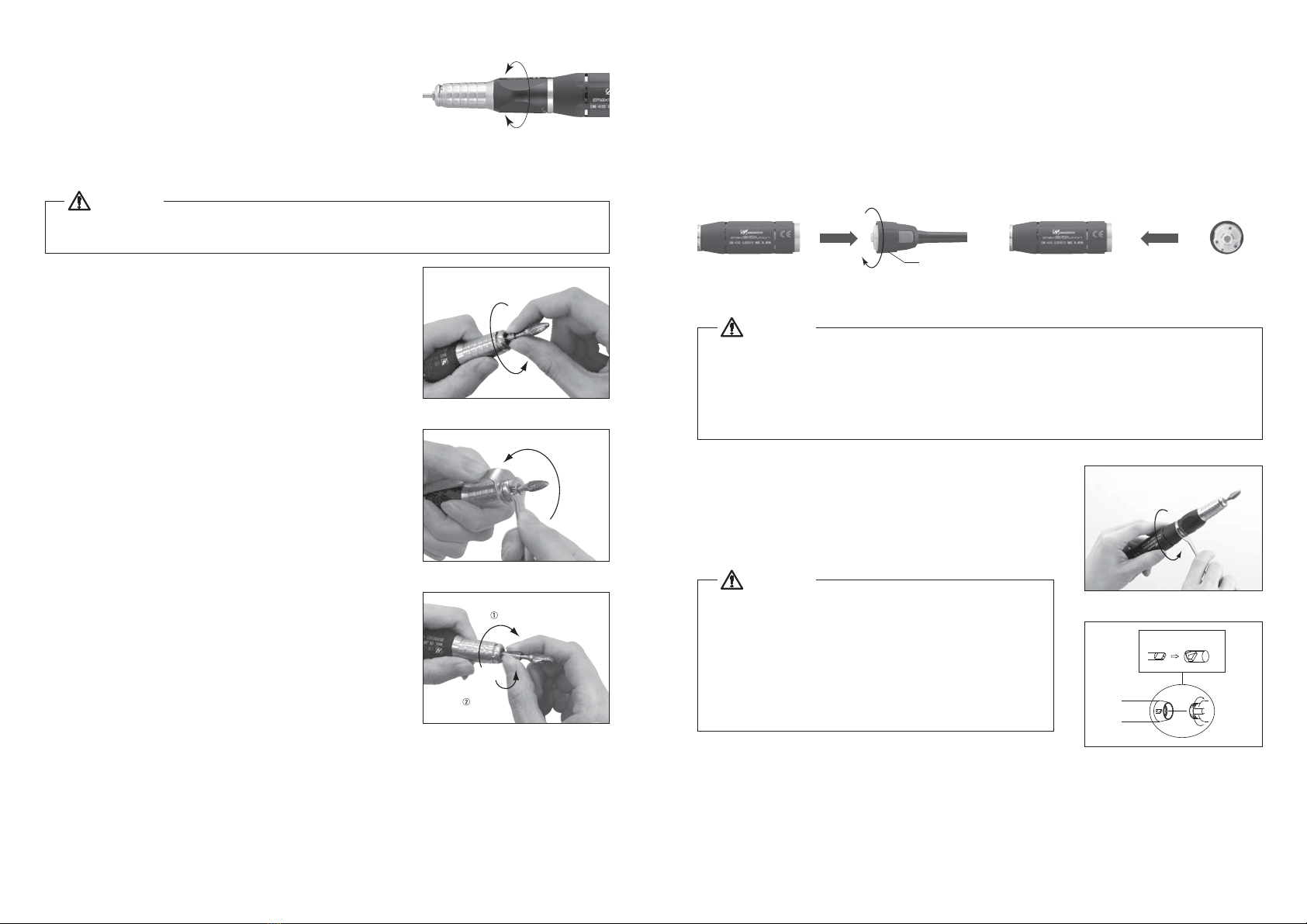

The Attachment does not turn

with the chuck closed

Attachment gets hot during

use

Vibration or Noise during use

High Runout

Bur slips out

Bearings Contaminated or Seized. Send for Service.

Bearings Contaminated. Same as Above.

Same as Above. Same as Above.

Contaminants in chuck or spindle. Clean the chuck and spindle ID.

Chuck is worn. Replace the chuck.

Bearings worn. Send for Service.

Chuck is Loose. Adjust the Chuck.

Bur is bent or damaged. Replace the bur.

Attachment

Trouble Cause/Check Remedy

Speed Display does not light

The power plug is disconnected. Insert the power plug correctly.

Power Switch is faulty.

The connection of the foot control cord plug is loose.

Foot Pedal dose not

work.

Error code E0 appears.

Ask for repair.

The fuse is blown.

Replace it with a specified fuse. If the reason the fuse has

blown is unknown, ask for an inspection.

The motor and handpiece do not run

Maintenance mode (4) “Pd”: Check to

see if the foot control operates normally.

Connect the foot control cord plug correctly.

If the foot control dose not operates normally, ask for

repair of the foot control or replace it with a new one.

Turn on the power again. If the same error code appears, ask for repair of the unit.

Turn on the power again. If it operates normally, the error display is temporarily due

to overload,which is not a problem.

Error code E1 appears.

If it operates normally after replacing the motor and the motor

cord, the motor and/or the motor cord may be shorted. Ask for

repair of the motor and/or the motor cord. If the same error code

still appears after replacing, ask for repair of the unit.

If you have two or more units, replace

the motor and check the operation.

The motor cord is disconnected. Connect the motor cord correctly.

If you have two or more units, replace the

motor and the motor cord and check the

operation.

Error code E2 appears.

The motor cord is disconnected. Connect the motor cord correctly.

If any problem is found during a check, the motor cord

may be severed or the sensor in the motor may be faulty.

Ask for repair.

If it operates normally, there is no problem. Check the operating

environment, storage location, etc., for high temperature. If the

same error code appears frequently, ask for repair of the unit.

Maintenance mode (3) “HL”: Confirm

whether you work by a motor signal

check normally.

Error code E3 appears.

Error code E4 appears.

After stopping to cool it down place for

about 10 minutes, check the operation

again.

If it operates normally, there is no problem. If the same

error code appears, ask for repair of the unit.

Lock the chuck. If any problem is found during a check, the motor cord

may be severed or the sensor in the motor may be faulty. Ask for repair.

Error code E5 appears.

Error code E6 appears.

Error code E8 appears.

Error code E9 appears.

Error code EF appears.

The rotation speed does not

rise.

Turn on the power again, and repeat

starting and stopping several times.

The chuck is open.

If any problem is found during a check, the motor cord

may be severed or the sensor in the motor may be faulty.

Ask for repair.

Maintenance mode (3) “HL”: Confirm

whether you work by a motor signal

check normally.

If the rotation is abnormal, ask for repair of the motor and

handpiece.

Check turning a tip with a finger lightly

and turning around it lightly.

Error indication is a temporary thing by the overload if I

work normally. There is not it abnormally.

Turn on the power again.

If it operates normally after replacing the motor cord, the motor

and/or the motor cord may be shorted. Ask for repair of the

motor and/or the motor cord. If the same error code still appears

after replacing the motor cord, ask for repair of the unit.

If it operates normally after replacing the motor cord, the motor

and/or the motor cord may be shorted. Ask for repair of the

motor and/or the motor cord. If the same error code still appears

after replacing the motor cord, ask for repair of the unit.

If it does not operate normally, change the Foot Pedal for

new or ask for repair.

Set the maximum rotation speed with the Speed Control

Knob.

If you have two or more units, replace the

motor cord and check the operation.

If you have two or more units, replace the

motor cord and check the operation.

Maintenance Mode (4) “Pd”: Check

whether Foot Pedal operates normally

by Foot Pedal Chuck.

The maximum rotation speed for operation by foot

pedal should be set with the Speed Control Knob.

STroubleshooting

When trouble is found, please check the following prior to consulting your dealer.

Control Unit and Motor

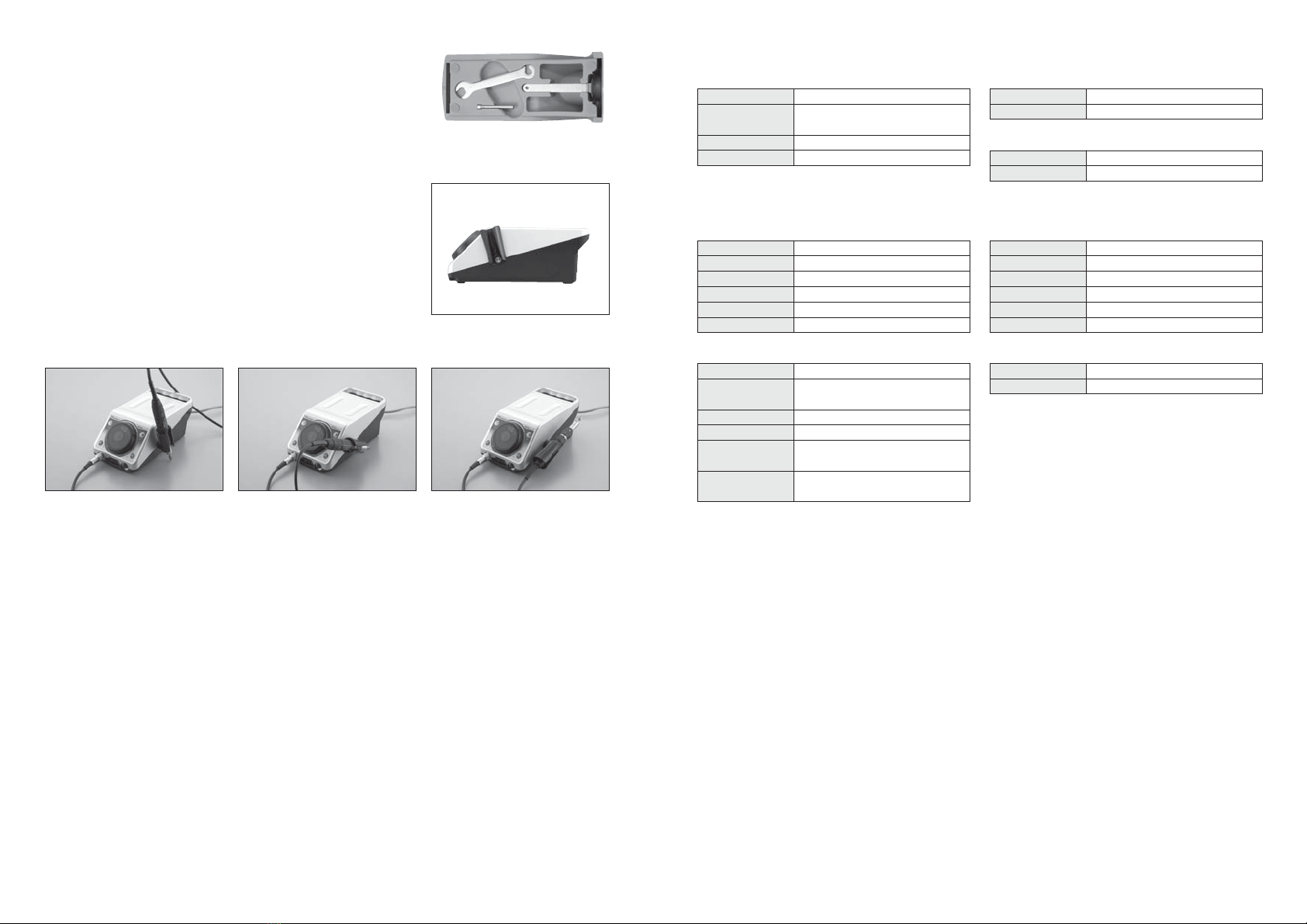

Product Model No.

Model No. Specification

SOptional Motors and Handpieces

Ring Type Attachment

IR-310

Torque Type Motor

ENK-250T

Standard Type Motor

ENK-410S

Lever Type Attachment

IH-300

Straight Type Attachment

IG-400

Simple lever turning for bur exchange. Designed to make it light

weight and fit to pen-grip type holding. ø2.35mm, ø3.0mm or

ø3.175mm (1/8")

High precision NK Micron Collet Chuck system. Strong tool

retention strength and highly precision metal removal are

achieved.

Torque Type Attachment

HG-200 Chuck Diameter ø6.0mm or ø6.35mm (1/4")

BMH-300

MFC-300S

MFC-300M

90˚Angle Attachment IC-300

90˚Angle attachment with ø3.0mm or ø3.175mm (1/8") Collet Chuck.

When using it with Rubber Pad or Felt buff in lower speed, please use

RG-01 Reducer together.

45˚Angle Attachment KC-300

Reciprocating Type Compact

Grinder LUSTER LS-100

Reciprocating Type Compact Grinder

(Built in motor) LUSTER NLS-110

The grinding surface can be set at any between 0 and 360˚.

Stroke range:0-6mm adjustable by allen wrench.

Fine Belt Sander

KBS-101

8mm Belt (Grits #120, #240, #400 )

6mm Belt (Grits #120, #240, #400 )

4mm Belt (Grits #120, #240, #400 )

1/4 Reduction Gear

RG-01

May be Connected between Motor and Attachment for 4 time

the Regular Power

Extension Joint

CN-01

Joint used by Connection between Attachment and Motor to

Extend the Length

MINI-LUSTER

ML-8

Stroke range of 0.8mm, Reciprocating Stroke (variable):Approx0-9,000 times/min.

Suitable for polishing narrow grooves, details, etc. Stroke range of 0.8mm.

1,000-40,000min-1 Brushless Motor. Excellent combination of high

speed, light weight, small diameter, high torque and FWD/REV

rotation.

1,000-25,000min-1 Brushless Motor. Higher power and higher

torque than Standard motor ENK-410S.

Ring type chucking system makes it easier to change tools.

This unique slim body makes it ideal for cutting and grinding the

bottom surface of deep ribs or holes Chuck diameter ø3.0mm

or ø3.175mm (1/8") Optional ø2.35mm

90˚MINI ANGLE TYPE Attachment for Chamfering Deep Hole,

Bur Only ø1.6mm