Technical manual

SMCI33 V2.0

Overview

Issue: V 2.0 - 2009-07-01 5

SMCI33 functions

The stepper driver SMCI33 contains the following functions:

•Microstep 1/1 – 1/64 Final output stage (0.014° step resolution)

•Closed-Loop current control (sinusoidal commutation via the encoder)

•Powerful DSP microprocessor for flexible I/O

•Rotation monitoring for optional encoder

•RS485 or USB interface for parameterisation and control

•Network capability of up to 32 motors

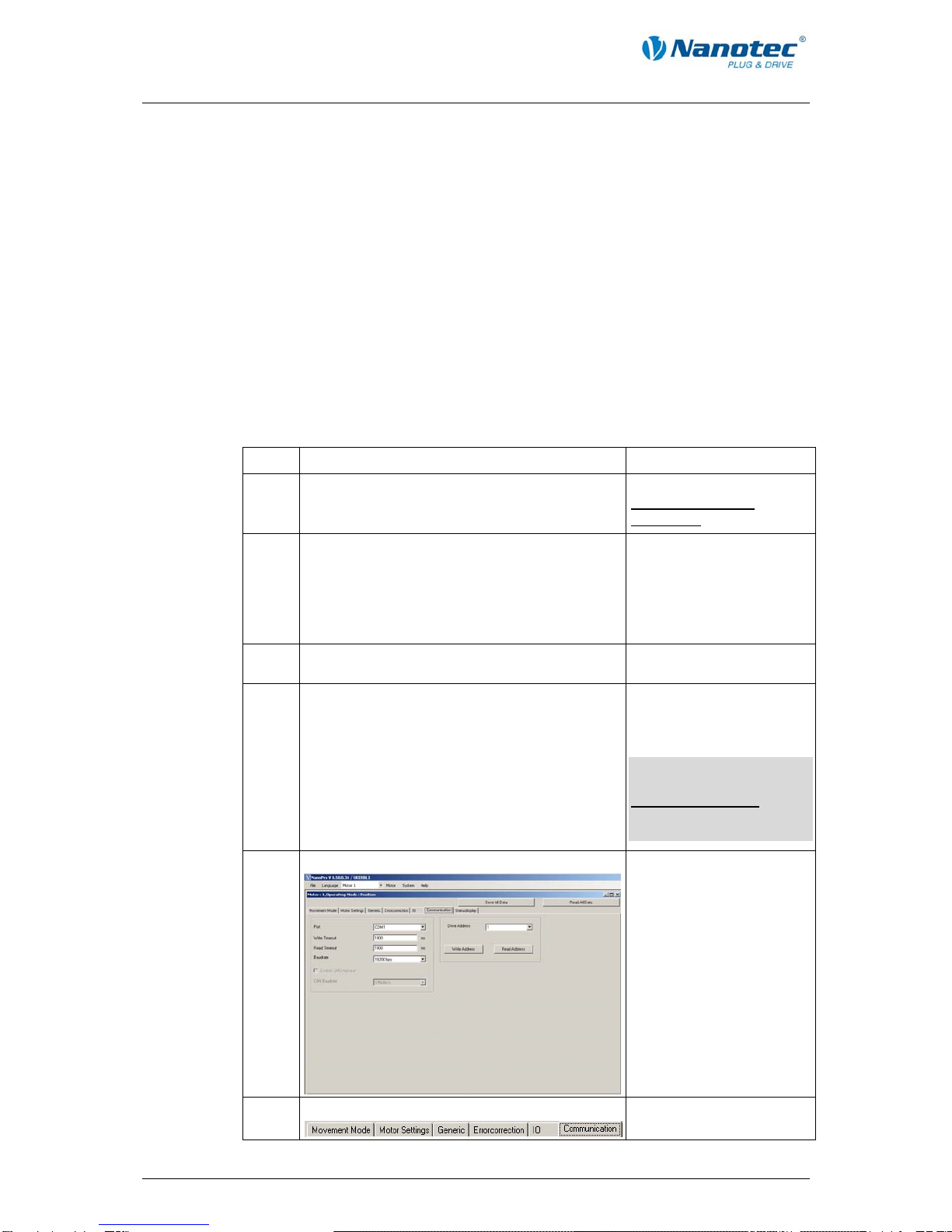

•Easy programming with the Windows software NANOPRO

Operating modes

The following operating modes can be selected:

•Positioning

•Speed

•Flag positioning

•Clock direction

•Analogue or joystick operation (±10 V)

•Analogue positioning mode

•Torque mode

Function overview

The operating behaviour of the motor can be set and optimised according to individual

requirements by setting the motor-related parameters such as phase current

(selectable in 1% increments), step resolution (from 1.8° - 0.014°), as well as the

adaptive microstep (automatic adaption of step width). Machine-related parameters

can be set using the NANOPRO software and significantly reduce commissioning

time:

•Distance in steps, degrees or mm

•Speed in Hertz, rpm or mm/s

•Feed constant in mm/revolution

•Gear reduction with reverse clearance

Three adjustable reference modes (external and internal) enable automatic machine

settings, whereby external reference switches may be inapplicable if there is a shift <

360° possibly due to the index signal of the internal encoder.

Even if stepper motors do not lose steps during normal operation, the integrated

speed control provides additional security in all operating modes, e.g. against motor

stalling or other external sources of error. The monitoring function detects a stalled

motor or step loss after half a step at the most (for 1.8° stepper motors).

Automatic error correction is possible after the drive profile is ended or during the

drive.