Narada Power Source CO., LTD TT Series Battery Operation Manual

Contents

Chap

Chap

Chap

Annex 1...........................................................................................................................................20

Security Instructions .........................................................................................................................3

ter One Product Introduction.................................................................................................4

1.Features..................................................................................................................................4

2. Main Applications.................................................................................................................4

3. Types and Dimensions ..........................................................................................................4

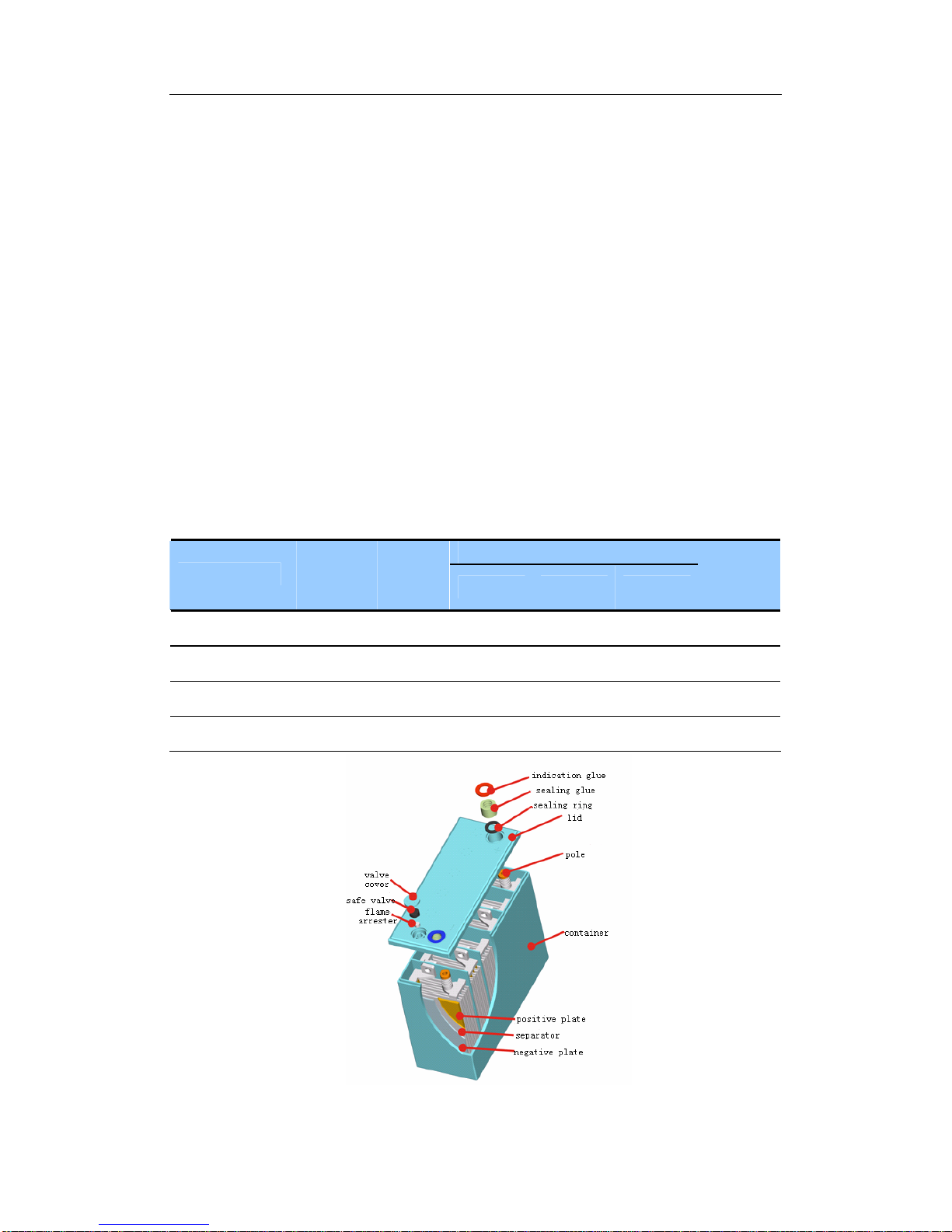

4 Structure of battery.................................................................................................................4

5. Dimension and sketch map...................................................................................................6

6. Terminal sketch.....................................................................................................................6

7. Working Principal .................................................................................................................4

ter Two Technical Characteristics..........................................................................................7

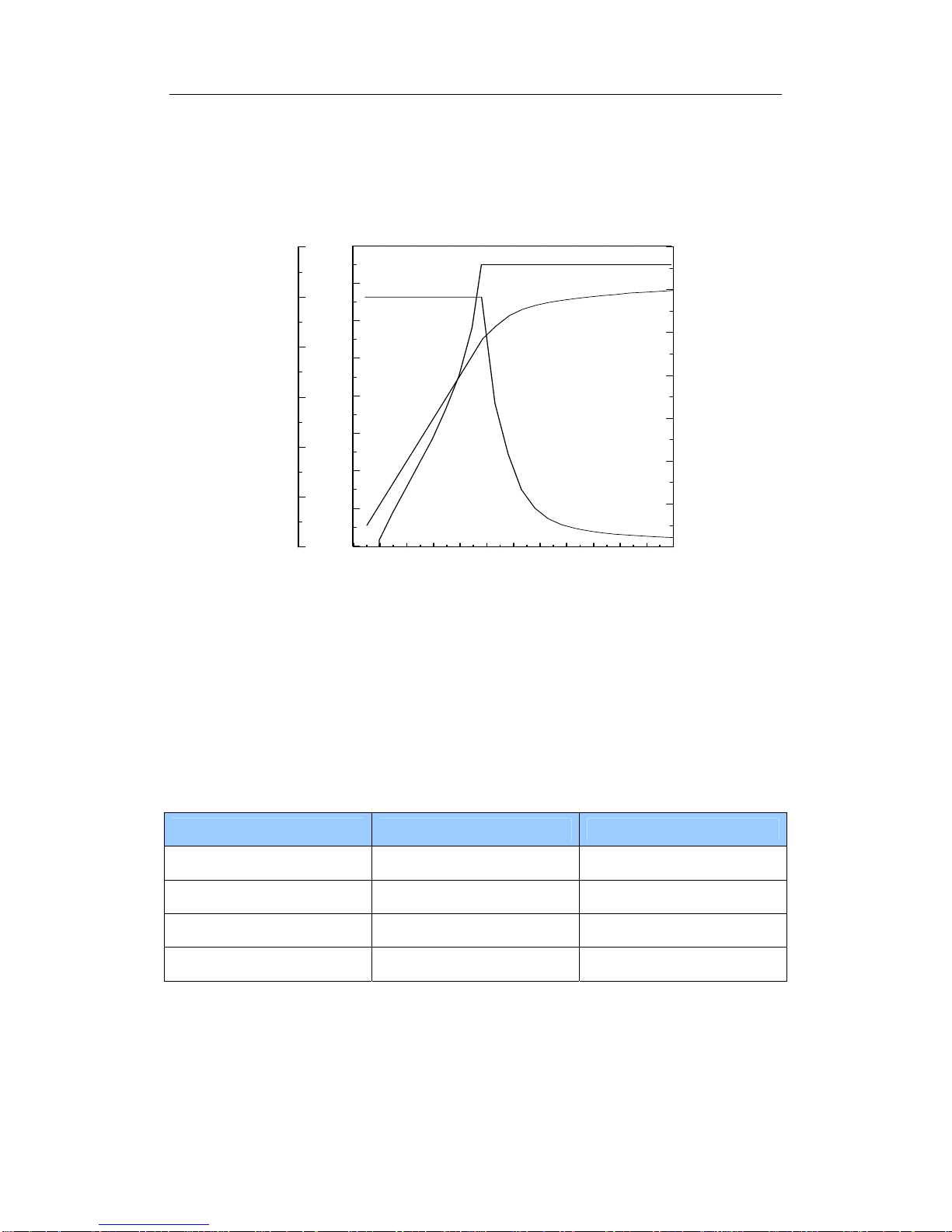

1. Charge Characteristics Curve................................................................................................7

3. Internal resistance and short circuit current ..........................................................................7

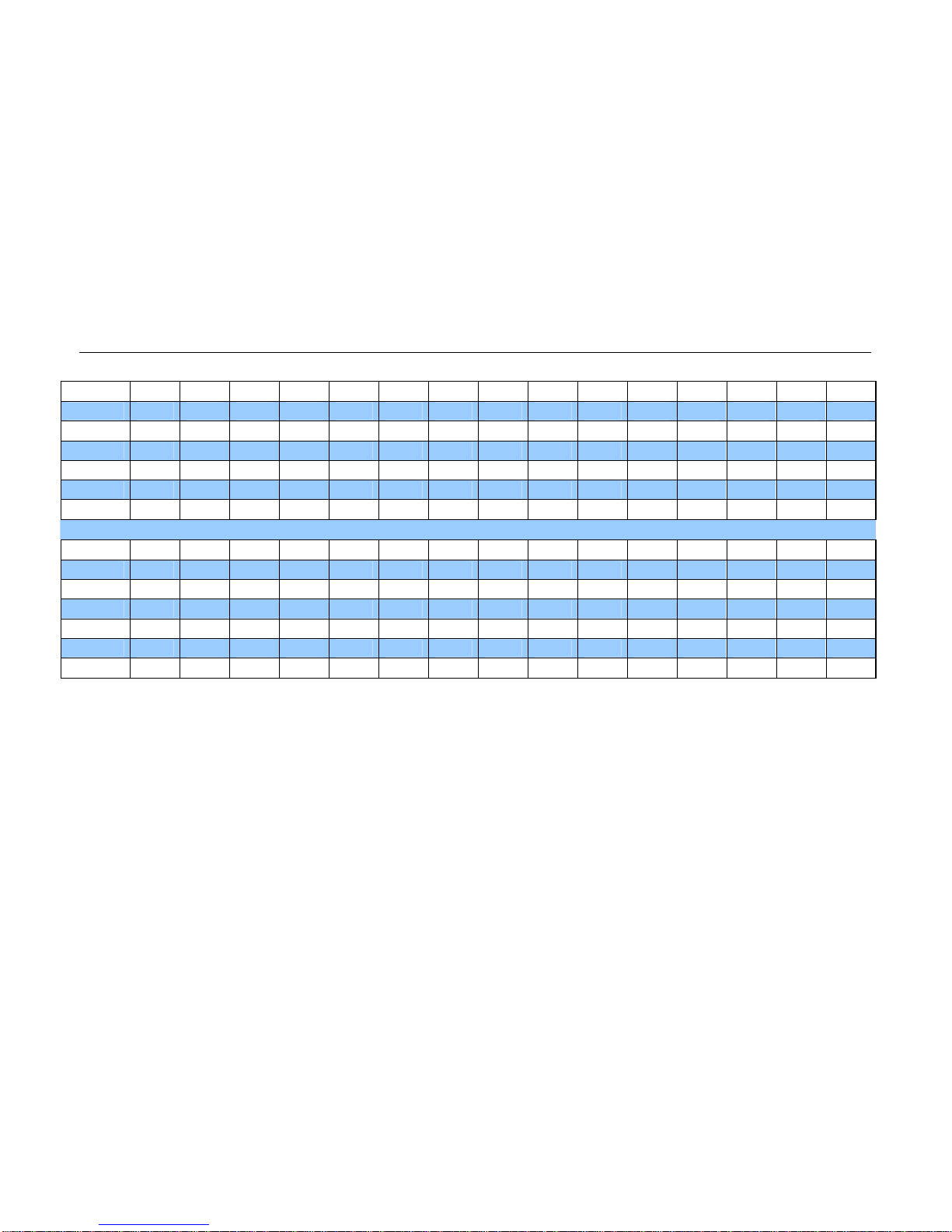

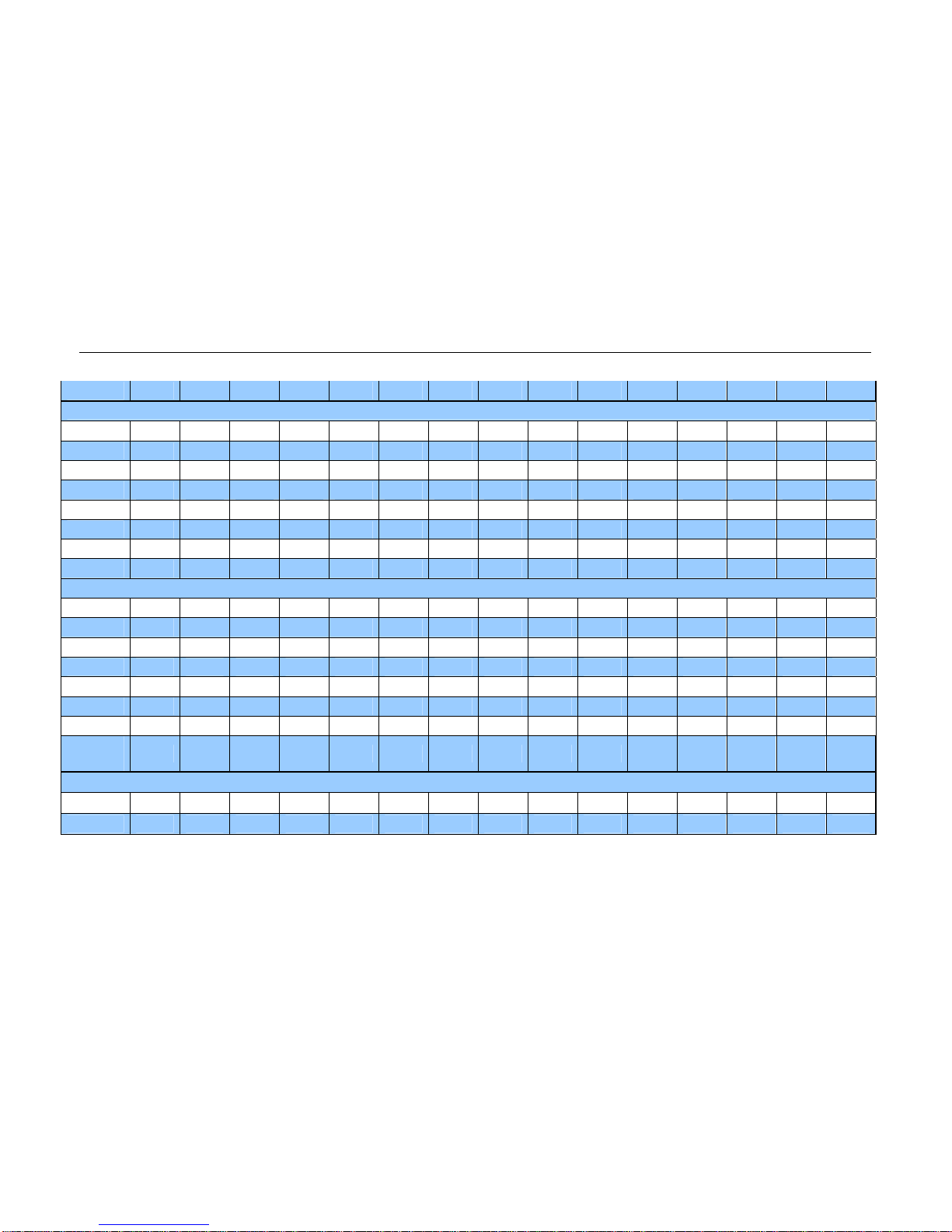

4. Discharge Data with Constant Current & Constant Power...................................................8

ter Three Operation and Maintenance .................................................................................12

1. Operation Condition............................................................................................................12

2. Capacity ..............................................................................................................................12

3. Temperature ........................................................................................................................13

4. Charge and discharge requirements ....................................................................................15

5. Storage ................................................................................................................................16

6. Maintenance........................................................................................................................17

After-sales Service..........................................................................................................................19

2